Operator's manual (PDF) - McElroy Manufacturing, Inc.

Operator's manual (PDF) - McElroy Manufacturing, Inc.

Operator's manual (PDF) - McElroy Manufacturing, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Equipment SafetySafety AlertsThis hazard alert sign appears in this <strong>manual</strong>.When you see this sign, carefully read what it says.YOUR SAFETY IS AT STAKE.You will see the hazard alert sign with these words:DANGER, WARNING, and CAUTION.WR00051-11-30-92Indicates an imminently hazardoussituation which, if not avoided, willresult in death or serious injury.Indicates a potentially hazardoussituation which, if not avoided, couldresult in death or serious injury.Indicates a hazardous situation which,if not avoided, may result in minor ormoderate injury.In this <strong>manual</strong> you should look for two other words:NOTICE and IMPORTANT.NOTICE: can keep you from doing something thatmight damage the machine or someone’s property.It may also be used to alert against unsafe practices.IMPORTANT: can help you do a better job or makeyour job easier in some way.TX00030-12-1-92Read and UnderstandDo not operate this equipment until you have carefullyread, and understand the "Safety" and "Operation"sections of this <strong>manual</strong>, and all other equipment<strong>manual</strong>s that will be used with it.Your safety and the safety of others depends uponcare and judgment in the operation of this equipment.Follow all applicable federal, state, local, and industryspecific regulations.<strong>McElroy</strong> <strong>Manufacturing</strong>, <strong>Inc</strong>. cannot anticipate everypossible circumstance that might involve a potentialhazard. The warnings in this <strong>manual</strong> and on themachine are therefore not all inclusive. You mustsatisfy yourself that a procedure, tool, work method,or operating technique is safe for you and others.You should also ensure that the machine will not bedamaged or made unsafe by the method of operationor maintenance you choose.TX00031-12-8-92WR00052-12-1-921 – 1

Equipment SafetyGeneral SafetySafety is important. Report anything unusual that younotice during set up or operation.LISTEN for thumps, bumps, rattles, squeals, air leaks,or unusual sounds.SMELL odors like burning insulation, hot metal,burning rubber, hot oil, or natural gas.FEEL any changes in the way the equipment operates.SEE problems with wiring and cables, hydraulicconnections, or other equipment.REPORT anything you see, feel, smell, or hear that isdifferent from what you expect, or that you think maybe unsafe.TX00114-4-22-93THINK1 STSAfe1ST-12-22-92Wear Safety EquipmentWear a hard hat, safety shoes, safety glasses, andother applicable personal protective equipment.Remove jewelry and rings, and do not wearloose-fitting clothing or long hair that couldcatch on controls or moving machinery.WR00053-12-2-92TX00032-4-7-93Equipment is Not Explosion ProofDataLogger TM equipment is notexplosion proof. Operation ofequipment in a hazardous environmentwill result in explosion and death.Do not operate this equipment in a hazardousenvironment.WR00034-11-30-92TX01395-6-12-971 – 2

Equipment SafetyUnits With HydraulicsAlthough the hydraulic pressures in this machine arelow compared to some hydraulically operatedequipment, it is important to remember that a suddenhydraulic oil leak can cause serious injury, or even befatal if the pressure is high enough.Escaping fluid under pressure canpenetrate the skin causing seriousinjury. Keep hands and body awayfrom pinholes which eject fluid underpressure. Use a piece of cardboard orpaper to search for leaks. If any fluid isinjected into the skin, it must beimmediately removed by a doctorfamiliar with this type of injury.WR00078-4-8-93NOTICE: wear safety glasses, and keep face clear ofarea when bleeding air from hydraulic system to avoidspraying oil into eyes.TX00110-8-23-95Fusion Machine ProceduresFamiliarize yourself with the fusion machine you willbe working with by reading the Manufacturer’s<strong>manual</strong>s for the machine. Read the Safety Informationto avoid potentially dangerous situations.Follow the pipe manufacturer’sprocedures for fusing the pipe beingused.WR00079-2-7-96Failure to adhere to proper machine and fusionprocedures can result in injury and bad fusion joints.TX01396-6-12-97Heater Is HotThe heater is hot and will burn clothingand skin. Keep the heater in itsinsulated heater stand or blanket whennot in use, and use care when heatingthe pipe.WR00030-2-10-93NOTICE: Use only a clean non-synthetic cloth such asa cotton cloth to clean the heater plates.TX00104-8-12-941 – 3

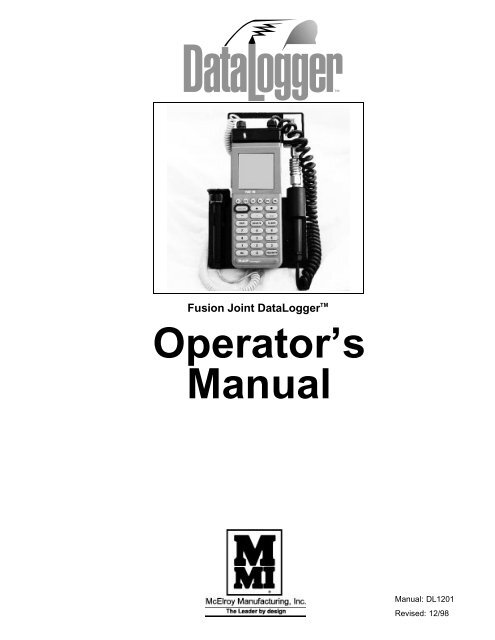

OverviewComputerThe DataLogger TM is a MS-DOS computer with a 16line by 21 character display screen. The unit is sealedto resist moisture and dust. There is a numerickeyboard with large key buttons for operating thesystem and entering joint data. The combination oflead-through operator prompts on the screen andsimple keyboard data entry make for easy operatortraining and use.The computing unit is programmed to operate in fivelanguages: English, French, German, Italian, andSpanish. The language is selected by the operator.PH01163-6-9-97TX01339-4-28-97Battery OperationThe computing unit is battery operated and willtypiically operate continuously for 8 hours withoutrecharging. The batteries are charged while in theunit. It can be operated and charged simultaneously orcan be charged when not being used to log fusiondata.PH01164-6-9-97TX01340-4-28-97Temperature ProbeThe temperature probe uses non-contact infra-redtechnology. The probe is attached to a coiled cord.The probe is fastened to the DataLogger TM unit whennot in use.PH01165-6-9-97TX01341-4-28-97Pressure TransducerThe pressure transducer is attached to the unit by acoiled cord. The transducer is fitted with a quickdisconnect for connecting to the fusion machine. Thefusion machine must be fitted with an adapter forconnecting the transducer. Power for the transducer issupplied by the computing unit. The transducer isstored on the DataLogger TM unit for transportationbetween machines.PH01166-6-9-97TX01342-4-28-972 – 1

OverviewFusion Data Storage and DisplayThe computing unit will capture and store data on thefusion process. The number of joints that can bestored is determined by the number of data pointsrecorded for each joint. Joints with more pressurevariations consume more storage space than jointswith consistent pressure readings. The fusion recordcan be displayed on the screen in the form of a graphshowing a pressure profile of the cylinder pressure vs.time. The fusion record can be downloaded to aPersonal Computer for storage or further analysisPH01173-6-9-97TX01343-4-28-97Printer OptionAn optional portable printer is available for printing thefusion data. The printer is a portable, rechargeable,battery operated unit which attaches to the computingunit with an electrical cable. The fusion report isprinted on 2-1/4" wide paper and includes themachine, job, and operator identification informationalong with the graph of the pressure profile vs. time.PH01167-6-9-97TX01344-4-28-97Limit Exposure to SunNOTICE: Do not leave the DataLogger TM exposed tothe sun for long periods of time. The airtight casingcan accumulate sufficient heat to cause a malfunction.CD00373-6-12-97TX01391-6-4-972 – 2

InstallationConnecting To A Fusion MachineNOTICE: The fusion machine must have a hydraulicquick disconnect for connecting the DataLoggerTMpressure transducer. If the machine does not haveone, contact your distributor for the proper adapter orretrofit kit.NOTICE: make sure the fusion machine hydraulicpump is turned off and the pressure is at 0 psi beforeconnecting the DataLogger TM to the fusion machine.PH01168-6-9-97TX01336-4-28-97No.28, No.412 and No.618 FusionMachinesLoosen the thumb screw on the back of the unit.Place the slotted swivel adapter on the back of theunit over the top rectangular bar around the hydraulicmanifold. Position the unit on the bar and lightlytighten the thumbscrew.Remove the pressure transducer from the holder onthe unit by pulling down on the knurled collar on thequick disconnect. Connect the pressure transducerquick disconnect to the fusion machine quickdisconnect.PH01174-6-9-97TX01337-4-28-97Mc28 Pit Bull TM , No.824, No.1236,No.1648 & No.2063Fusion MachinesThe Mc28 Pit Bull TM and all MegaMc ® machinesexcept the No.1236 require an adapter to mount theDataLogger TM on the bar surrounding the <strong>manual</strong>hydraulic controls. Install the adapter in a convenientplace on the bar. Tighten the adapter. Loosen thethumbscrew on the back of the DataLogger TM unit andplace the unit on the bar (1236) or on the bar adapter.Lightly tighten the thumbscrew.Remove the pressure transducer from the holder onthe unit by pulling down on the knurled collar on thequick disconnect. Connect the pressure transducerquick disconnect to the fusion machine quickdisconnect.PH01169-6-9-97PH01170-6-9-97TX01338-6-12-973 – 1

InstallationSidewinder TM Fusion MachineAttach DataLogger TM to mounting bracket on top ofSidewinder TM and tighten thumbscrew.Remove the pressure transducer from the holder onthe unit by pulling down on the knurled collar on thequick disconnect. Connect the pressure transducerquick disconnect to the fusion machine quickdisconnect.PH01143-4-21-97TX01392-6-9-973 – 2

Keyboard CommandsOn and OffTo turn the unit on, press the blue ON/OFF key.To turn the unit off, press the blue 2nd key once andthen press the ON/OFF key.NOTICE: The unit cannot be turned off while it isplugged into the battery charger.Notice: The unit will remember the screen you were inwhen you turn the unit off. It will come back to thatscreen when you turn it back on.TX01345-4-29-97F1 F2 F3 F4 F5 F6ON/OFF_ . 2ndEXIT DELETE CLEAR7 8 9CD00372-4-30-97Function KeysThere are six function keys across the top of thekeyboard, F1 through F6.F1 Turns the diagnostic screen on and off.F2 Selects pressure units.F3 Starts the datalogging and used in pressuretransducer calibration.F4 Selects date format.F5 Used to reset stopwatch and to select decimalpoint format.F6 Turns the screen backlight on and off.F1 F2 F3 F4 F5 F6ON/OFF_ . 2ndEXIT DELETE CLEAR7 8 9CD00372-4-30-97TX01346-4-29-97Arrow KeysThere are two arrow keys, an up arrow, and a downarrow. These keys are used for scrolling throughvarious menu selections, for entering alphabet letters,and for scrolling across the pressure graph.When you see the reverse video on the screen (blackbackground with green text) use the arrow keys toscroll through the selections in reverse video.When prompted to enter alphabet characters use thearrow keys to scroll through the alphabet. The UParrow scrolls forward in the alphabet and the DOWNarrow scrolls backward.When you are viewing the pressure graph use thearrow keys to scroll across the graph so that you canview the entire graph.F1 F2 F3 F4 F5 F6ON/OFF_ . 2ndEXIT DELETE CLEAR7 8 9CD00372-4-30-97TX01347-4-29-974 – 1

Keyboard CommandsDelete KeyThe Delete key is used like a backspace key whenyou want to erase characters which you have enteredfrom the keyboard.F1 F2 F3 F4 F5 F6ON/OFF_ . 2ndEXIT DELETE CLEARCD00372-4-30-977 8 94 5 6TX01348-4-29-971 2 3Clear KeyThe Clear key is used to backup from screen toscreen. Each time you press the Clear key you willback up one screen in the operating sequence.F1 F2 F3 F4 F5 F6ON/OFF_ . 2ndEXIT DELETE CLEARCD00372-4-30-977 8 94 5 6TX01349-4-29-97– KeyThe – key is used to enter a white space inalpha-numeric entry screens.F1 F2 F3 F4 F5 F6ON/OFF_ . 2ndCD00372-4-30-97EXIT DELETE CLEAR7 8 9TX01350-4-29-974 5 6Exit KeyA prompt appears when the Exit key may be used toexit the present function being used. When enteringletters, pressing Exit advances to the next position.ON/OFF_ . 2ndEXIT DELETE CLEARCD00372-4-30-977 8 94 5 6TX01351-4-29-974 – 21 2 3

Keyboard CommandsYes/Enter KeyThe Yes/Enter key is used to accept the data listed oneach screen and to move on to the next screen.7 8 94 5 61 2 3NO 0 YES/ENTRTX01352-4-29-97No KeyThe No key skips an entry and advances a screen ormoves back a screen, depending on the prompt.7 8 94 5 61 2 3NO 0 YES/ENTRTX01353-4-29-97Number and Decimal KeysThe number and decimal keys are used to enternumeric information when prompted._ . 2ndEXIT DELETE CLEAR7 8 94 5 61 2 3TX01354-4-29-974 – 3

OperationLogging a Fusion JointTurn the unit on by pressing ON/OFF. In a few secondsthe display screen will appear. If this is the start of thejob, press CLEAR until you see screen 000. The screensare numbered in the upper left corner.Use the following function keys to select data units:Press F2 to select a pressure unit (PSI, BAR, or Kg/cm2).Press F3 to select temperature unit (F or C)Press F4 to select date format (month/day/year orday/month/year)Press F5 to select decimal point (. or ,)Select the appropriate language using the numeric keypad.From the Main Menu screen, check the date and time. Ifeither is incorrect, select the System Menu by pressing 3and select SET CLOCK from the menu. Follow theinstructions on the screen to set the date and time. PressENTER to return to the Main Menu.From the Main Menu select LOG DATA.Follow the instructions on the screen to enter the machineand job setup data.PH01180B-6-10-97TX01367-5-19-97Unlisted MachinesA list of machines are programmed into theDataLogger TM for selection. If your machine is not onthe list, you may enter the name of the machine. Toenter a machine, scroll to UNLISTED from the SelectMachine menu and press enter. Enter the machinedescription or name using numeric keys or arrow keys.This is an optional field. If you do not wish to enter aname, press - and YES/ENTR to enter a blank for themachine name.TX01368-5-19-97Piston AreaPiston area is required to determine recommendedgauge pressures. Machines listed in the DataLogger TMSelect Machine menu have piston area values assignedto them. If an unlisted machine is selected, the pistonarea must be entered to calculate gauge pressure.However, pressure calculation is not mandatory. Leavingthe piston area and the piston area unit entries blank,skips all the prompts for interfacial pressure entries.To enter piston area, type in the piston area value indesired units, then select the units in the next screen.TX01369-5-19-97PH01181-6-10-97PH01182-6-10-975 – 1

OperationCalculate Recommended GaugePressuresA total of six interfacial pressures can be entered; twoheat pressures, two soak pressures and two fusepressures. To skip a pressure, simply pressYES/ENTR. An interfacial pressure that is skipped willnot be displayed or printed out. Entering zero (0)pressure is not the same as skipping a pressure. Zero(0) pressure is a valid entry, and the resultingrecommended pressure is the sum of the calculatedpressure, which is 0, and the drag pressure enteredlater on.PH01183-6-10-97TX01370-5-19-97Measuring DragUse the fusion machine controls to measure dragusing the following procedure.Move the carriage so that the inner jaws areapproximately 3" apart.Shift the carriage control valve to the middle (neutral)position.Select the heating mode, and adjust the middlepressure reducing valve to its lowest pressure byturning the valve counterclockwise.Shift the carriage control valve to the left.Gradually increase the pressure by turning the valveclockwise. <strong>Inc</strong>rease the pressure until the carriagemoves.Quickly reduce the heating pressure valve clockwiseuntil the carriage is just barely moving.Record this drag pressure.To read the drag pressure you can use either thepressure gauge on the fusion machine or the pressuredisplay on the screen. After measuring drag, enter thedrag pressure using the DataLogger TM keyboard. If youdo not enter a drag pressure value, the defaultpressure of 30psi will be used.The DataLogger TM records actual hydraulic cylinderpressure. When you are analyzing the pressure profilerecorded by the DataLogger TM you must subtract thedrag pressure from the recorded pressure to get theactual fusion pressure.PH01184-6-10-97TX01371-5-19-975 – 2

OperationMeasuring the Heater TemperatureUsing The DataLogger TM ProbeFollow the instructions on the screen to measure theheater plate surface temperature. Remove thetemperature probe from the storage location on theDataLogger TM and place the metal tip flat on thesurface of the heater plate. Read the heater platetemperature on the screen. Press ENTER to recordthe measured heater temperature while still holdingthe probe on the heater plate.NOTICE: Make sure the probe is not at an angle whenmeasuring the temperature. <strong>Inc</strong>orrect probe placementwill result in measurement errors.NOTICE: Keep the lens on the temperature probeclean. If the lens is dirty, it will give an inaccuratereading.When finished measuring the heater temperature,return the probe to the holder on the DataLogger TM .Press the probe onto the plastic strip firmly to securethe probe.PH01171-6-9-97TX01372-5-19-97Using an External Source ForMeasuring Heater TemperatureWhen using an external probe for measuring heatertemperature, key in the measured value instead ofusing the datalogger TM probe.PH01185-6-10-97TX01373-5-19-975 – 3

OperationRecording the Fusion PressuresThe proper time to begin recording the fusion pressureis just after placing the heater into the fusion machine.Install the heater in the machine and then press F3 tobegin recording the pressure. When recording thepressure, simply operate the fusion machine in thenormal manner. There is no special technique requiredto use the DataLogger TM .The logging screen shows the elapsed time since theF3 key was pressed and also shows a stopwatchtimer. The stopwatch can be used for timing during thefusing process. Press F5 to reset and restart thestopwatch.The recording should be stopped as soon as therecommended cool time is finished. Press the EXITkey to stop recording before doing any other machineoperation. Stopping the recording will prevent filling upthe joint storage memory with unneeded data.Follow the screen instructions to view the graph, printthe graph, or log another joint.PH01186-6-10-97TX01374-5-19-97GraphsThere are two plots associated with each joint report,a front end plot and a summary plot. The front endplot shows the actual start time to the last significantchange in pressure. This feature zooms into the partof the pressure profile where pressure fluctuates themost. Typically, this includes the pressure changes atthe beginning of heat, soak and the beginning of thecool cycle.The summary plot shows the entire cycle, from thestart of data logging until the end of data logging,either canceled by the operator, timed out, or ran outof memory.For plots of 5 minutes or less, the time scale is shownin seconds. For long plots, the time scale changes tominutes.NOTICE: To prolong the battery charge, turn off theunit if there will be some time until you want to log thenext joint. Remember that you will not lose yourmachine and job setup and will not have to re-enterthe data because the unit will return to the samescreen where it was turned off.PH01173-6-9-97PH01187-6-10-97TX01375-5-19-975 – 4

OperationPrinting Joint ReportsAn optional portable printer, EXTECH Instruments MiniSerial Printer, lla42, is available to print joint reports.You may print the report at the end of each joint oruse the Report Menu.Connect the printer to the DataLogger TM with the cableprovided with the printer. Connect the 15-pin cableconnector to the connector on the bottom of theDataLogger TM and connect the 25-pin connector to theprinter.NOTICE: Use the cable provided. Use of other cablesmay cause damage to the unit or the printer.Make sure the printer batteries are charged and thatthe printer has enough paper to print all the reportsyou will be printing.Turn the printer on with the switch on the right side ofthe printer.Any number of available reports can be printed fromthe Report Menu. Use the arrow keys to select therange of reports you want to print. Note that thereports are listed by date and time. If you only want toprint one report select the same report on both the’From’ and ’To’ selections. Start the printing process.If you have problems operating the printer, refer to theprinter <strong>manual</strong> provided with the printer.PH01172-6-9-97TX01376-5-19-975 – 5

OperationTransferring Joint Datato a Personal Computer<strong>Inc</strong>luded in the DataLogger TM package is a CompanionProgram for Microsoft Windows 3.1. This programallows you to download reports from theDataLogger TM , display the joint data, display andanalyze the pressure profile, and print the displayedscreens at the resolution of your printer in theMicrosoft Windows 3.1 environment.The program WDATACOM.EXE and its associatedfiles are provided on a 3-1/2” diskette labeled“DataLogger TM Companion for MS-Windows 3.1.”Follow these steps to install the program:1) Start Microsoft Windows.2) Insert Disk in Drive A or B.3) From Program Manager, select File menu andchoose RUN.4) Type A:\SETUP (or B:\SETUP) and press Enter.You MUST use the path C:\WDATACOM. The setupprogram will automatically install the program on yourhard disk. After the installation, a new program groupwill be created for you. To run the companionprogram, double click on the icon labeledDataLogger TM Companion.Choose a language in which you want to operate in byclicking the corresponding language button. After that,you will be informed that there is no data to display.You may exit the program at this point, or download anew report from a DataLogger TM .PH01188-6-10-97TX01378-5-19-975 – 6

OperationDownloading a Report FileFollow these steps to download a report file from theDataLogger TM :1. Locate the special communication cable (15-pin to25-pin), and plug the 25-pin end labeled "IBM" to thePC’s serial port. If your PC has a 9-pin serial portconnector you will have to also use the 25-pin to 9-pinadapter cable provided. The "PC9000" end goes to theDatalogger’s 15-pin socket.NOTICE: Use the cables provided. Use of othercables may cause damage to the unit or the printer.2. Use the CLEAR key on the DataLogger TM to get tothe MAIN MENU. Press 2 to select the Report Menu.3. Press 4 to select Upload Reports.4. Press YES/ENTR. The DataLogger TM is now readyto send the report to the personal computer as soonas the Windows Companion program is started on thepersonal computer.5. Start the Companion program on the personalcomputer. From the File menu, select Download.Once the file transfer is started, both the DataLogger TMand PC screens will be updated with the file transferstatus. At the end of the transfer, the Companionprogram will prompt you to enter a description for thereport. After that, you may view or print the report andgraphs.PH01189-6-10-97TX01379-5-19-975 – 7

OperationTypical PlotThe pipe is brought together against the heater. Heatmode is selected on the manifold and pressure dropsrapidly to zero for the soaking period. The carriagecontrol is then shifted to neutral.When the soaking time is complete, the carriage isshifted to remove the heater and the pipe is broughtback together under fusion pressure.PH01161-6-12-97PH01160-6-12-97Interruption Before Data Loggingis CompleteThe right side of the plot shows a tappering off ofpressure. This could indicate that power was lost or ajaw was opened before Datalogging was complete.5 – 8

OperationPH01162-6-12-97Pressure Drop Too SlowPressure not dropping to zero in a timely mannnercould indicate that the carriage was shifted to neutralbefore heat mode was selected on the manifold.5 – 9

Maintenance and TroubleshootingRecharging BatteriesComputerTo recharge the unit select the DAP plug-in chargermarked "DataLogger Computer" and plug the cord intothe connector on the bottom of the DataLogger TM . Plugthe charger into an electrical outlet with the correctvoltage for the charger you are using. The unit willcome on when the charger is connected and youcannot turn it off with the ON/OFF key. It may take afew seconds for the batteries to charge to a levelsufficient to turn the unit on.When you disconnect the charger you may have towait 10 seconds before turning the unit off with theON/OFF key. The internal charging circuit will retainvoltage for about 10 seconds.PrinterTo recharge the printer select the EXTECH plug-incharger marked "Printer" and plug the cord into theconnector on the side of the printer. Plug the chargerinto an electrical outlet with the correct voltage for thecharger you are using.NOTICE: Use only the battery charger provided.Other chargers with the incorrect voltage, current, orpolarity will result in damage to the unit.Battery LifeThe batteries can be recharged many times. If you findthat they are not lasting for the normal period (at least8 hours) after having been recharged, it is time tochange them. In order to avoid problems, we stronglysuggest that you replace the batteries once a year.To maintain battery efficiency at optimum levels, wesuggest that you periodically leave the unit on until thebatteries are fully discharged. You can do this byleaving the unit on continuously until the unitautomatically shuts off due to low battery charge.Backup BatteryThe backup battery requires no special care orpreventive maintenance. The backup battery allowsyou to keep programs and data in the unit memory fortwo years without power from the main batteries.If you have to store the unit for a period longer thansix months, download all the data and remove themain batteries.PH01164-6-9-97PH01179-6-9-97TX01380-6-4-976 – 2

Maintenance and TroubleshootingReplacing Batteries in UnitIt is preferable to replace the batteries in a clean, dryarea. Make sure that neither water nor dust enter theunit.NOTICE: Always shut off the DataLogger TM beforereplacing the batteries. Your data will be retained bythe backup battery.To change the batteries follow the steps below:1. Turn the power off.2. Unlock the drawer by turning the screw located onthe right side of the unit 1/4 turn to the left(counterclockwise).3. Slowly pull the drawer out of the unit case. Ablocking system will keep it in place when totallypulled out (about 3 inches).4. Remove the three batteries and replace them withnew ones. Insert the flat end (-) first. Be careful of thebattery polarity. Follow the indicators found at thebottom of the drawer. You must use only Ni-Cdrechargeable batteries, the exact size Sub-C.5. To close the drawer, slowly push it back into thecase. Lock the drawer by turning the screw on theright side of the case 1/4 turn to the right (clockwise).6. Press the ON/OFF key to turn on the unit.PH01175-6-9-97PH01176-6-9-97TX01381-5-20-97Replacing Batteries in PrinterTurn the printer off.Remove the access panel on the bottom of the printer.Replace the battery pack.PH01178-6-9-97TX01393-6-9-976 – 3

Maintenance and TroubleshootingUnit Does Not RespondThere is a reset plug labeled (RESET DC900)furnished with the unit. If the unit does not respond topressing any keys (appears to be ’locked up’) insertthe reset plug in the 15-pin connector on the bottom ofthe unit for about 1 second and then remove it. Theunit will perform a reset and after a few seconds willbecome ready at the start of the program.Performing a reset will return the password, pressuretransducer calibration, and temperature probe offset totheir default values. You will have to recalibrate thetransducer and input the temperature probe offset.NOTICE: Performing a reset will abort datalogging anddata will be lost for the joint currently in progress. Usethis method only in case of an apparent " lock up" ofthe unit.PH01177-6-9-97TX01383-5-20-97Diagnostic Test ScreenThe diagnostic test screen can be accessed any timeexcept when displaying the DRAG measurementscreen 160, or TEMPERATURE measurement screen170, or when the unit is logging joint data, screen 200or 202. This screen is accessed by pressing the F1function key. The displayed information is useful indiagnosing problems that may arise in the computingunit, temperature probe, or pressure probe.Displayed information is:Transducer pressure reading in psi, bars and Kg/cm 2 .(Final) = actual pressure transducer output voltageminus offset voltage. (Input minus offset).(Offset) = The initial 0 psi offset of the pressuretransducer.(Input) = the actual voltage output of the pressuretransducer.[ Raw temperature, filtered temperature 0 F ] : adjustedfinal temperature, 0 F- 0 C = The actual temperatureprobe reading.The initialization character string (MICROFLEXPC9000) [Program version number]If you have problems with the unit this information willbe useful in diagnosing the trouble when you contactyour distributor for assistance.PH01190-6-11-97TX01384-5-20-976 – 4

Maintenance and TroubleshootingReprogramming UnitThis section gives step by step instructions on loadingnew software and setting up a DataLogger.1. Turn on the DataLogger. (If the battery is low, youwill need to plug in the AC adapter for the unit tocome on).2. Use the reset plug (labeled RESET DC900) toreset the DataLogger.This is done by plugging the reset plug into the 15-pinsocket of the DataLogger momentarily and thenunplugging it.3. At the sound of the first beep after reset, press immediately.This will bring up the "COM" program of theDataLogger. You may watch the power-up screenclosely so that you can get your hand ready to press when the RAM disk byte count approaches 640K.NOTICE: Once in a while the DataLogger might turnoff its screen when the setup is lost. Simply press the key to bring back the screen. Also make surethat the AC adapter is plugged in at all times until thesoftware downloading is completed.4. The second line on the DataLogger should read"COM1:38400 BAUDS". If not, press to set thebaud rate, and press to set the port to COM1. Inall the menu screens, you need to press to getback to the top screen that says "LOGON->" on thesecond line.5. Now go to your PC. Insert the DataLoggerProgram Diskette into floppy drive A (or B) of your PCand go to a DOS prompt. At the DOS prompt,type A: (or B:) to log on to your PC’s floppy drive.6. At the A:\> prompt, change directory to\DATALOG on your PC using the command: cd datalogThe last line on your screen should look likeA:\DATALOG>7. Type "..\COM" on your PC:A:\DATALOG>..\COMThis starts the communication program between thePC and the DataLogger.Notice the display on the PC is similar to that on theDataLogger.8. Make sure that the PC screen reads"COM1:38400 BAUDS" on the second line if you areusing COM1, or "COM2:38400 BAUDS" if you areusing COM2.Setting up the COM port and baud rate is similar tothe procedure described above (4).9. Locate the special communication cable (15-pin to25-pin), and plug the 25-pin end labeled "IBM" to thePC’s serial port. The "PC9000" end goes to theDataLogger’s 15-pin socket. Also use the 25 pin to 9pin adapter cable if the PC has a 9 pin connection.10. Press on the PC keyboard to activate"Master mode" on the PC. This automatically puts theDataLogger in the slave mode.11. Press to send files to the DataLogger. Typein *.* for "FILE TO SEND" and press . For"DESTINATION", press .NOTICE: When a file is transferring, the PC screenwill not update until a file is completely transmitted.The file DATALOG.EXE takes about 3 to 4 minutes totransfer. The entire file transfer should take about 5minutes. If you suspect that a problem has occurred,you may press to quit. The program will thenprompt you to press to confirm.The COM program may lock up especially if you try tomulti-task it under Windows. To avoid unnecessarylock ups, run the COM program in a full DOS screenunder Windows.12. If the files transferred successfully, the PC willreturn to the file utility screen, where "1" is SEND.Press to end. In the top screen where ’1’ isMODEM/DIAL, press to exit.13. The DataLogger screen should read "C>CTTYCOM1". Disconnect the communication cable fromthe DataLogger. Use the RESET plug to reset theDataLogger, as described above (2). The DataLoggershould be up and running after the power-up sequence.6 – 5TX01385-5-20-97

Maintenance and TroubleshootingNo Maintenance Inside CaseNOTICE: There are no parts inside the DataLogger TMthat can be repaired by the user. Do not try to openthe case. Any attempt to open the case can affect theweatherproofing and can damage the unit.PH01111-6-12-97TX01390-6-4-976 – 6