REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

13/6 <strong>PLASTICS</strong><br />

<strong>REGISTER</strong> <strong>OVERVIEW</strong><br />

<strong>PLASTICS</strong><br />

The range covered in the following pages<br />

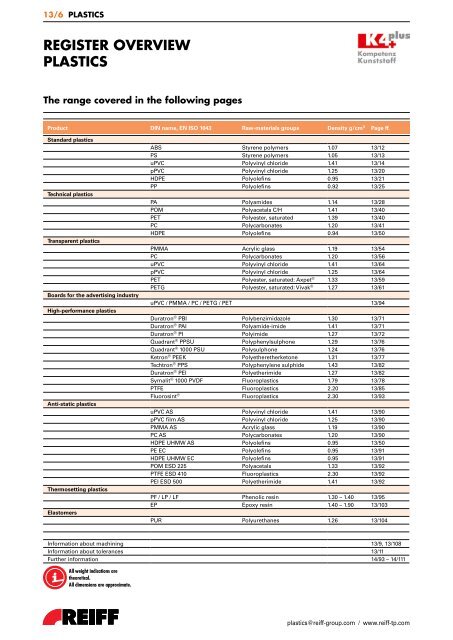

Product DIN name, EN ISO 1043 Raw-materials groups Density g/cm 3 Page ff.<br />

Standard plastics<br />

Technical plastics<br />

Transparent plastics<br />

Boards for the advertising industry<br />

High-performance plastics<br />

Anti-static plastics<br />

Thermosetting plastics<br />

Elastomers<br />

ABS Styrene polymers 1.07 13/12<br />

PS Styrene polymers 1.05 13/13<br />

uPVC Polyvinyl chloride 1.41 13/14<br />

pPVC Polyvinyl chloride 1.25 13/20<br />

HDPE Polyolefins 0.95 13/21<br />

PP Polyolefins 0.92 13/25<br />

PA Polyamides 1.14 13/28<br />

POM Polyacetals C/H 1.41 13/40<br />

PET Polyester, saturated 1.39 13/40<br />

PC Polycarbonates 1.20 13/41<br />

HDPE Polyolefins 0.94 13/50<br />

PMMA Acrylic glass 1.19 13/54<br />

PC Polycarbonates 1.20 13/56<br />

uPVC Polyvinyl chloride 1.41 13/64<br />

pPVC Polyvinyl chloride 1.25 13/64<br />

PET Polyester, saturated: Axpet ® 1.33 13/59<br />

PETG Polyester, saturated: Vivak ® 1.27 13/61<br />

uPVC / PMMA / PC / PETG / PET 13/94<br />

Duratron ® PBI Polybenzimidazole 1.30 13/71<br />

Duratron ® PAI Polyamide-imide 1.41 13/71<br />

Duratron ® PI Polyimide 1.27 13/72<br />

Quadrant ® PPSU Polyphenylsulphone 1.29 13/76<br />

Quadrant ® 1000 PSU Polysulphone 1.24 13/76<br />

Ketron ® PEEK Polyetheretherketone 1.31 13/77<br />

Techtron ® PPS Polyphenylene sulphide 1.43 13/82<br />

Duratron ® PEI Polyetherimide 1.27 13/82<br />

Symalit ® 1000 PVDF Fluoroplastics 1.79 13/78<br />

PTFE Fluoroplastics 2.20 13/85<br />

Fluorosint ® Fluoroplastics 2.30 13/93<br />

uPVC AS Polyvinyl chloride 1.41 13/90<br />

pPVC film AS Polyvinyl chloride 1.25 13/90<br />

PMMA AS Acrylic glass 1.19 13/90<br />

PC AS Polycarbonates 1.20 13/90<br />

HDPE UHMW AS Polyolefins 0.95 13/50<br />

PE EC Polyolefins 0.95 13/91<br />

HDPE UHMW EC Polyolefins 0.95 13/91<br />

POM ESD 225 Polyacetals 1.33 13/92<br />

PTFE ESD 410 Fluoroplastics 2.30 13/92<br />

PEI ESD 500 Polyetherimide 1.41 13/92<br />

PF / LP / LF Phenolic resin 1.30 – 1.40 13/95<br />

EP Epoxy resin 1.40 – 1.90 13/103<br />

PUR Polyurethanes 1.26 13/104<br />

Information about machining 13/9, 13/108<br />

Information about tolerances 13/11<br />

Further information 14/93 – 14/111<br />

All weight indications are<br />

theoretical.<br />

All dimensions are approximate.<br />

plastics@reiff-group.com / www.reiff-tp.com

MACHINING SERVICE – BLANKS<br />

Workshop machining centre<br />

We machine all types of plastic precisely<br />

and accurately in a modern workshop<br />

centre.<br />

We perform the following operations on<br />

semi-finished products:<br />

• Drilling<br />

• Sawing<br />

• Milling<br />

• Planing<br />

• Turning<br />

Please submit your samples or drawings<br />

to us.<br />

Our staff will be pleased to offer comprehensive<br />

advice on all the available options.<br />

Just call!<br />

You need blanks made from thermoplastics, thermosetting plastics or elastomers? Then you have two options:<br />

1.<br />

You order the semi-finished product from us…<br />

and take care of your own machining...<br />

... which means you are stuck with managing the machining/<br />

materials and the waste!<br />

Depending on your precise circumstances, you will have to<br />

calculate, store, manage, factor in, pay interest on, separate, sort,<br />

label or dispose of this waste!<br />

Result: additional costs<br />

... and environmentally questionable<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

2.<br />

<strong>PLASTICS</strong> 13/7<br />

You order blanks from us and we supply them in the exact<br />

dimensions you need!<br />

Our waste...<br />

... stays with us, is correctly sorted and then forwarded<br />

for recycling straight away.<br />

Result: your benefit = profit<br />

... and environmentally sound

13/8 <strong>PLASTICS</strong><br />

SELECTION GUIDE FOR SEMI-FINISHED PRODUCTS<br />

Round rods – Hollow bars<br />

You manufacture turned parts?<br />

Then you have two options.<br />

Manufacturing hollow bars or round rods<br />

from plastic semi-finished products?<br />

Advantages of hollow bars:<br />

Semi-finished<br />

product<br />

The advantages to you of purchasing a hollow bar rather than<br />

a round rod are as follows:<br />

1. Disposal costs reduced<br />

2. Hourly machine rates made more efficient<br />

3. Dimensional stability<br />

4. Fewer stresses<br />

In addition, hollow bars offer better dimensional stability than<br />

round rods and are associated with fewer stresses when finished<br />

products are being manufactured with bores.<br />

An extract from our range of hollow bars<br />

Finished<br />

product<br />

Avoid remainders<br />

Lower costs<br />

Chippings<br />

Disposal<br />

costs<br />

By using hollow bars instead of round rods in manufacturing your<br />

finished products, you can save:<br />

1. Money thanks to efficient machine utilisation<br />

2. Disposal costs for the chippings created<br />

The planning of how to use hollow bars is up to you.<br />

But their availability: that's up to us!<br />

Ask us about hollow bars.<br />

PA 6 E natural PA 6 cast natural POM C natural PET natural<br />

D. A / i / mm kg/m D. A / i / mm kg/m D. A / i / mm kg/m D. A / i / mm kg/m<br />

20 x 10 0.314 50 x 20 2.200 20 x 10 0.388 25 x 15 0.515<br />

25 x 12 0.488 60 x 30 2.770 25 x 12 0.605 30 x 20 0.640<br />

30 x 15 0.675 70 x 30 4.010 28 x 12 0.785 36 x 20 1.160<br />

32 x 15 0.835 80 x 40 4.820 30 x 15 0.850 40 x 20 1.510<br />

32 x 20 0.740 80 x 60 3.100 32 x 15 1.040 45 x 30 1.470<br />

32 x 25 0.497 90 x 40 6.600 36 x 17 1.290 50 x 30 2.020<br />

36 x 17 1.040 90 x 70 3.830 36 x 25 0.930 50 x 40 1.270<br />

36 x 25 0.755 100 x 40 8.550 40 x 20 1.520 60 x 40 2.660<br />

40 x 25 1.040 100 x 80 4.510 40 x 30 0.990 65 x 50 2.410<br />

40 x 30 0.800 110 x 50 9.630 45 x 25 1.780 70 x 30 4.890<br />

45 x 30 1.200 110 x 90 4.860 50 x 20 2.570 70 x 40 4.150<br />

50 x 25 2.070 120 x 60 10.980 55 x 35 2.360 80 x 60 3.720<br />

All prices indicated in this<br />

catalogue are subject to<br />

federal VAT.<br />

plastics@reiff-group.com / www.reiff-tp.com

PERMISSIBLE TOLERANCES<br />

FOR PLASTIC SEMI-FINISHED PRODUCTS<br />

Permissible tolerances for plastic semi-finished products<br />

DIN name Round rods Boards, pressed Panels, extruded Tubes, cast<br />

Flat bars Films, calendered or extruded<br />

PA DIN EN 15860 DIN EN ISO 11833 DIN EN ISO 11833 DIN 16982<br />

PE HD DIN EN 15860 DIN 16972 DIN EN ISO 14632 –<br />

POM DIN EN 15860 DIN EN ISO 11833 DIN EN ISO 11833 DIN 16978<br />

PVDF / PPE / PEEK / PET, etc. DIN EN 15860 DIN EN ISO 11833 DIN EN ISO 11833 DIN EN 15860<br />

PP DIN EN 15860 DIN EN ISO 11833 DIN EN ISO 15013 –<br />

PVC DIN EN 15860 DIN EN ISO 11833 DIN EN ISO 11833 –<br />

We deliver non-toleranced dimensions according to the following standards:<br />

Item DIN standards<br />

Turned and milled parts DIN ISO 2768 medium<br />

< 400 mm ><br />

DIN ISO 2768 coarse<br />

Films/boards DIN EN ISO 14632<br />

DIN EN ISO 11833<br />

DIN EN ISO 15013<br />

DIN 16972<br />

DIN EN 15860<br />

Moulded components –<br />

PTFE semi-finished products<br />

Films up to 3 mm According to the GKV guideline<br />

Boards: 4 + 5 mm +/–10 %<br />

Boards: 6 mm and above According to the GKV guideline<br />

Tubes/round rods and hoses According to the GKV guideline<br />

Tubes DIN EN 15860<br />

Round rods DIN EN 15860<br />

Blanks DIN ISO 2768 coarse<br />

Punched parts DIN ISO 2768 coarse<br />

Parts cut with water jets DIN ISO 2768 coarse<br />

The tolerances only apply to measurements taken at room temperature.<br />

All data is intended as a guide.<br />

Please observe the tolerances for other plastic semi-finished products with separate DIN standards accordingly.<br />

Please contact us for closer tolerances.<br />

DIN standards can be purchased from:<br />

Beuth Verlag GmbH, Burggrafenstraße 6, 10787 Berlin, Germany, Tel.: +49 (0)30/2601-0, Fax: +49 (0)30/2601-1260<br />

All weight indications are<br />

theoretical.<br />

All dimensions are approximate.<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/9

13/10 <strong>PLASTICS</strong><br />

ABS<br />

ABS copolymers<br />

Item No.<br />

Thickness<br />

mm<br />

Length<br />

mm<br />

Width<br />

mm<br />

Weight/unit<br />

kg €/kg<br />

176960 2 2000 1000 4.240 9.75<br />

176970 3 2000 1000 6.420 9.75<br />

176980 4 2000 1000 8.560 9.75<br />

176990 5 2000 1000 10.700 9.75<br />

177000 6 2000 1000 12.840 9.75<br />

427580 8 2000 1000 17.120 9.75<br />

Technical information:<br />

In Chapter 14 "Technical Knowledge" starting<br />

on page 93 we inform you in detail.<br />

ABS (acrylonitrile-butadiene-styrene<br />

copolymers)<br />

ABS types are rigid and impact-resistant<br />

even at low temperatures, thanks to<br />

butadiene rubber. They are very hard, whilst<br />

also offering good scratch and chemical<br />

resistance. ABS is less ageing and weatherresistant<br />

than other types.<br />

- Good mechanical strength<br />

- Good impact strength<br />

- Good further processing characteristics<br />

- Good dielectric properties<br />

- Good hardness and dimensional stability<br />

- Low moisture absorption<br />

- Combustible (adjustments can be made<br />

to make it non-flammable)<br />

- Physiologically safe<br />

Comment:<br />

ABS is not suitable for mechanical sliding<br />

functions.<br />

Grades: modifications available on request,<br />

not transparent due to rubber component,<br />

rather, opaque white.<br />

Use: technical parts subject to impact stress<br />

including housings and covering parts, also<br />

for low temperatures<br />

Processing: hot forming, bonding, welding,<br />

machining, printing<br />

Density: 1.07 g/cm 3<br />

Service temperature:<br />

- 45 °C to + 85 °C, some up to 100°<br />

Colour: white<br />

plastics@reiff-group.com / www.reiff-tp.com

PS<br />

Polystyrene<br />

Standard polystyrene is a hard and<br />

dimensionally stable, yet brittle<br />

thermoplastic that is one of the most<br />

inexpensive plastics available. In its<br />

injection-moulded form, it is used in the<br />

manufacture of mass-produced articles and<br />

disposable parts.<br />

In technical applications, PS (unloaded)<br />

is used primarily in the field of electrical<br />

engineering, thanks to its good dielectric<br />

properties.<br />

- Low mechanical strength<br />

- Low impact strength<br />

- Good further processing characteristics<br />

- Very good dielectric properties<br />

- Good hardness and dimensional stability<br />

- Very low moisture absorption<br />

- Combustible<br />

Item No.<br />

Thickness<br />

mm<br />

Prices on request.<br />

Length<br />

mm<br />

Comment:<br />

PS without UV stabilisers must not be<br />

exposed to the elements. PS is not suitable<br />

for sliding functions.<br />

Grades:<br />

- Transparent (glass clear) types<br />

- Impact-resistant types mostly with<br />

copolymers such as butadiene rubber<br />

SB - SAN<br />

- Mostly glass clear, coloured boards<br />

available on request<br />

- Certain grades are physiologically safe<br />

Application: advertising sector, electrical<br />

industry, housing construction<br />

Processing: hot forming, bonding, welding,<br />

machining, printing<br />

Density: 1.05 g/cm3 Service temperature:<br />

-30 °C to +70 °C<br />

Colour: white<br />

Width<br />

mm<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/11<br />

Weight/unit<br />

kg €/kg<br />

404940 2 2000 1200 5.180 5.52<br />

181320 3 2000 1200 7.760 5.52<br />

181330 4 2000 1200 10.840 5.52<br />

404950 5 2000 1200 12.600 5.52

13/12 <strong>PLASTICS</strong><br />

uPVC (UNPLASTICISED POLYVINYL CHLORIDE)<br />

uPVC FOAM BOARDS<br />

uPVC (unplasticised polyvinyl chloride) uPVC foam boards<br />

(unplasticised polyvinyl chloride)<br />

Density:<br />

1.41 g/cm 3<br />

Service temperature:<br />

+/–0° to +60 °C<br />

Special types, –20° to +80 °C<br />

uPVC offers standard impact resistance, is stabilised against<br />

environmental influences and has a high chemical resistance to<br />

acids and alkalis.<br />

• Simple processing possible<br />

• Outstanding electrical insulating properties<br />

• Good hardness, dimensional stability and rigidity<br />

• Low moisture absorption<br />

• Combustible but self-extinguishing (low flammability according<br />

to DIN 4102 B 1 – guaranteed for standard grade boards up to<br />

4 mm)<br />

• Low tendency towards stress cracking thanks to good chemical<br />

resistance<br />

Comment:<br />

Standard uPVC types do not meet the requirements of the<br />

German Foodstuffs Act.<br />

Grades:<br />

Extruded and pressed design, special design with improved<br />

impact-resistance grade – even at negative temperatures down to<br />

–20 °C<br />

Application:<br />

Machine tools, chemical equipment and laboratory construction,<br />

electrical industry, advertising sector and building industry<br />

Semi-finished product for turned and milled parts subject to little<br />

stress<br />

Processing:<br />

Hot forming, bonding, welding, machining, printing<br />

Dimensions:<br />

Boards: Extruded thicknesses of 1 – 50 mm<br />

Pressed thicknesses of 10 – 100 mm/<br />

2000 x 1000 mm/3000 x 1500 mm<br />

Round rods: 5 – 300 mm<br />

Differentiating characteristics<br />

Material density:<br />

0.70 g/cm 3<br />

Service temperature:<br />

+/–0° to +60 °C<br />

uPVC foam boards are a composite material made from solid outer<br />

layers specially stabilised for outdoor use and a foamed uPVC core<br />

material. The average density is only around 0.70 g/cm 3 , although<br />

a high level of rigidity is still achieved.<br />

The outer layers, made from solid, unplasticised PVC, create an<br />

outstanding surface finish, which means the material is perfect<br />

for use in advertising, displays and the construction of exhibition<br />

stands, etc.<br />

It goes without saying that sound and heat insulation are ensured.<br />

• Boards possess low flammability characteristics<br />

• Low thermal conductivity<br />

• Oscillation and vibration-damping<br />

• Easy to process<br />

Comment:<br />

Advantages over solid boards<br />

1 m 2 uPVC foam board of 8 mm weighs approx. 5.6 kg<br />

1 m 2 uPVC solid board of 8 mm weighs approx. 11.4 kg<br />

Grades:<br />

Boards are available with an anti-static coating<br />

White is the standard colour/other colours on request<br />

Application:<br />

Electrical engineering = switch cabinets<br />

Advertising sector = signs/displays/perimeter advertising, etc.<br />

Processing:<br />

Excellent machining properties<br />

Sticking properties: good, contact or solvent adhesives,<br />

2-component adhesives<br />

Surface finishes such as printing, painting, coating and flocking<br />

possible<br />

Dimensions:<br />

Board thickness 2 – 30 mm<br />

Dim. 2000 x 1000/3000 x 1000/2440 x 1220/<br />

3050 x 1220/3050 x 1500 mm<br />

Available depending on design and thickness<br />

Name according to DIN ISO 1043 uPVC uPVC<br />

Increased impact resistance<br />

Material name PVC CAW PVC MZ<br />

Impact strength Standard impact resistance Increased impact resistance<br />

Notch toughness 4 kJ/m2 10 kJ/m2<br />

Lower service temperature limit +/–0 °C –20 °C<br />

Stabilisation for outdoor exposure High, adequate for many applications Very good<br />

Colour fastness in outdoor use<br />

(shades of white and light grey)<br />

Low level of colour change<br />

to be expected over time<br />

Very good colour fastness<br />

Deep-drawing properties Sufficiently good ability to be drawn Good ability to be drawn<br />

Low flammability<br />

according to DIN 4102 B1<br />

Yes<br />

(for wall thicknesses up to 4 mm –<br />

PA-III 2.732)<br />

No,<br />

but self-extinguishing<br />

Chemical resistance DIN 8061 supplement sheet 1 DIN 8061 supplement sheet 1<br />

plastics@reiff-group.com / www.reiff-tp.com

uPVC<br />

pPVC<br />

Material characteristics for uPVC (unplasticised polyvinyl chloride)<br />

pPVC (plasticised polyvinyl chloride)<br />

Material density: 1.22 g/cm 3<br />

Service temperature: –35 °C standard resistance to cold,<br />

up to +60 °C<br />

pPVC boards, transparent, particularly for use as replacement<br />

swing-door leaves, rolling or folding gates, or strip doors.<br />

Board strips for vertical blinds with round extruded edges.<br />

• For sound and heat insulation<br />

• Fire behaviour according to DIN 53 382, i.e. does not continue<br />

to burn or smoulder<br />

• High cold crack resistance<br />

• Transparency > 80 %<br />

• Stabilised against ageing and UV<br />

• High wear resistance<br />

Filter and light-protection material also characterised by:<br />

• Reliable absorption of damaging rays<br />

• Protection against flying sparks<br />

• Non-flammable<br />

• DIN tested safety (GS) UV 4 or 7<br />

Comment:<br />

Special grades – particularly for cold-store areas,<br />

with excellent flexibility even at negative temperatures:<br />

–45 °C extremely resistant to cold, up to +60 °C (on request)<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/13<br />

Name according to DIN ISO 1043 uPVC uPVC<br />

Increased impact resistance<br />

Material name Norm Unit PVC CAW PVC MZ<br />

Density DIN 54379 g/cm 3 1.42 1.42<br />

Flexural modulus of elasticity DIN 53457 N/mm 2 3000 2800<br />

Yield stress DIN 53455 N/mm 2 58 52<br />

Elongation at tear DIN 53455 % 15 20<br />

Impact strength DIN 53453 kJ/m 2 NB NB<br />

Notch toughness DIN 53453 kJ/m 2 4 10<br />

Ball indentation hardness H 358/30 DIN 53456 N/mm 2 130 110<br />

Shore hardness D DIN 53505 – 82 77<br />

Vicat softening temperature B/50 DIN 53460 K (°C) 351 (78) 348 (75)<br />

Av. linear coefficient of thermal expansion DIN 53752 K–1 0.8 ·10 –4 1.0 ·10 –4<br />

Thermal conductivity* DIN 52612 W/mK 0.159 0.159<br />

Dielectric strength** method K20/P50 DIN 53481 kV/mm 39 34<br />

Volume resistivity, annular electrode DIN 53482 Ohm · cm > 10 15 > 10 15<br />

Surface resistivity, electrode A DIN 53482 Ohm 10 15 10 14<br />

Tracking resistance method KC DIN 53480 V > 600 > 600<br />

Permittivity<br />

at 300 – 1000 Hz DIN 53483 – 3.2 3.3<br />

at 3 · 105 Hz DIN 53483 – 3.0 3.1<br />

Dielectric power factor<br />

at 300 Hz DIN 53483 – 0.03 0.03<br />

at 1000 Hz DIN 53483 – 0.02 0.02<br />

at 3 · 10 5 Hz DIN 53483 – 0.02 0.03<br />

** Measured on test specimens 10 mm thick<br />

** Measured on test specimens 1 mm thick<br />

The data given is a guide and may vary according to the processing<br />

method used and the way in which the test specimen was produced.<br />

If there is no indication to the contrary, these are average<br />

values of measurements taken on extruded boards 4 mm thick.<br />

The data cannot be transferred to finished products as is.<br />

The processor and/or user must check that our materials are suitable<br />

for the specific purpose in question.<br />

Moulding material name (DIN 7748, version of 9/85)<br />

PVC CAW: FM DIN 7748-PVC-U, ED, 078-04-33<br />

PVC MZ: FM DIN 7748-PVC-U, EDLP, 076-08-28<br />

Grades:<br />

pPVC boards natural, transparent<br />

Fabric-reinforced boards, as well as filter and light-protection<br />

strips including fastening material and installation available on<br />

request<br />

Application:<br />

Transparent grade, e.g. for flexible door leaves of any type.<br />

Filter protection with sun protection factor (strip goods)<br />

Tech. grade, colour natural, e.g. for machine bases, as impact<br />

protection for linings, as well as seals and punched parts<br />

Processing:<br />

Can be cut/punched/stuck to one another using solvent adhesives<br />

Dimensions:<br />

Board thickness 2 - 3 - 4 - 5 - 7 - 10 mm – 1000 mm standard width<br />

Special widths up to 2200 mm possible (on request)<br />

Roll lengths of 20 m/or blanks<br />

pPVC board strips, transparent, with round extruded edges<br />

200 x 2 mm/300 x 3 mm/400 x 4 mm/roll length of 50 m or blanks

13/14 <strong>PLASTICS</strong><br />

UPVC BOARDS<br />

Extruded<br />

Item No.<br />

grey<br />

Item No.<br />

light grey<br />

Also, page through online!<br />

www.reiff-tp.com<br />

Item No.<br />

red<br />

Item No.<br />

black<br />

Thickness/mm Tolerance/mm<br />

10 – 20 mm + 2 mm<br />

21 – 45 mm + 3 mm<br />

46 – 75 mm + 4 mm<br />

76 – 100 mm + 6 mm<br />

101 – 120 mm + 7 mm<br />

Thickness<br />

mm<br />

Length<br />

mm<br />

Width<br />

mm<br />

Weight/unit<br />

kg<br />

Density: 1.41 g/cm 3<br />

Service temperature: +/-0 °C to +60 °C<br />

Largely UV-<br />

stabilised<br />

Special types: -20 °C to +80 °C<br />

UV-stabilised<br />

Colour: grey, light grey,<br />

red, black<br />

404960 181890 569110 1 2000 1000 2.900 4.31 4.31 5.74<br />

955140 10030838 10028088 1.5 2000 1000 4.300 4.31 4.31 5.74<br />

181410 181900 181550 405080 2 2000 1000 5.800 4.31 4.31 5.73 5.74<br />

181420 181910 181560 405190 3 2000 1000 8.600 4.31 4.31 5.73 5.74<br />

404970 405440 181570 181830 4 2000 1000 11.500 4.31 4.31 5.73 5.74<br />

181440 405450 181580 181840 5 2000 1000 14.400 4.31 4.31 5.73 5.74<br />

181450 405460 181590 405420 6 2000 1000 17.300 4.31 4.31 5.73 5.74<br />

181460 405470 181600 181850 8 2000 1000 23.000 4.31 4.31 5.73 5.74<br />

181470 405480 181610 10034671 10 2000 1000 28.800 4.31 4.31 5.73 5.74<br />

181480 405490 405430 12 2000 1000 34.600 4.31 4.31 5.74<br />

181490 405500 4132910 181870 15 2000 1000 43.200 4.31 4.31 5.73 5.74<br />

181500 405770 926150 181880 20 2000 1000 57.600 4.31 4.31 5.73 5.74<br />

181510 10018750 470030 25 2000 1000 72.000 4.31 5.73 5.74<br />

181520 689080 569090 30 2000 1000 86.400 4.31 4.31 5.74<br />

410890 4575190 10018752 35 2000 1000 101.000 4.31 4.31 5.73<br />

181530 10023607 40 2000 1000 115.200 4.31 4.31<br />

Pressed<br />

Item No.<br />

grey<br />

Thickness<br />

mm<br />

Length<br />

mm<br />

Width<br />

mm<br />

€/kg<br />

grey<br />

€/kg<br />

light<br />

grey<br />

€/kg<br />

red<br />

€/kg<br />

black<br />

Density: 1.41 g/cm 3<br />

Service temperature: +/-0 °C to +60 °C<br />

Largely UV-<br />

stabilised<br />

Special types: -20 °C to +80 °C<br />

UV-stabilised<br />

Colour: Grey<br />

Weight/unit<br />

kg<br />

569130 60 2000 1000 170.400 14.81<br />

489900 70 1000 1000 99.400 14.81<br />

427670 80 1000 1000 113.600 14.81<br />

489920 100 1000 1000 142.000 14.81<br />

€/kg<br />

grey<br />

plastics@reiff-group.com / www.reiff-tp.com

UPVC ROUND RODS<br />

Extruded<br />

Density: 1.41 g/cm 3<br />

Service temperature: +/-0 °C to +60 °C<br />

Largely UV-stabilised<br />

Special types: -20 °C to +80 °C<br />

UV-stabilised<br />

Colour: red, grey, black<br />

Item No.<br />

red<br />

Minimum<br />

order<br />

€ 40.–<br />

Item No.<br />

grey<br />

Item No.<br />

black<br />

Length<br />

mm<br />

Diameter<br />

mm<br />

Weight/m<br />

kg<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/15<br />

182020 2000 6 0.040 6.05<br />

182030 10004050 2000 8 0.070 6.05 6.30<br />

182040 10003815 2000 10 0.120 6.05 6.30<br />

182050 1060030 2000 12 0.160 6.05 6.30<br />

182060 927700 2000 15 0.270 6.05 6.30<br />

182070 871650 2000 18 0.380 6.05 6.30<br />

182560 182080 490530 2000 20 0.470 6.30 6.05 6.30<br />

182570 182100 871660 2000 25 0.730 6.30 6.05 6.30<br />

182580 182120 454430 2000 30 1.050 6.30 6.05 6.30<br />

182590 182130 4478390 2000 35 1.390 6.30 6.05 6.30<br />

182600 182140 627790 2000 40 1.860 6.30 6.05 6.30<br />

182610 182150 4041600 2000 45 2.360 6.30 6.05 6.30<br />

182620 182160 627800 2000 50 2.920 6.30 6.05 6.30<br />

182630 182170 10015547 2000 55 3.520 6.30 6.05 6.30<br />

182640 182180 627810 2000 60 4.190 6.30 6.05 6.30<br />

410970 182190 2000 65 4.920 6.30 6.05<br />

182650 182200 4342080 2000 70 5.690 6.30 6.05 6.30<br />

182660 182210 4317760 2000 80 7.400 6.30 6.05 6.30<br />

182670 182220 1060040 2000 90 9.370 6.30 6.05 6.30<br />

182680 182230 728100 2000 100 11.560 6.30 6.05 6.30<br />

182690 182240 10022980 2000 110 13.950 6.30 6.05 6.30<br />

182700 182250 4625420 2000 120 16.640 6.30 6.05 6.30<br />

182270 2000 130 19.560 6.05<br />

10012913 2000 140 22.170 6.05<br />

182720 182280 1000 150 25.970 6.30 6.05<br />

410920 1000 160 29.560 6.05<br />

182730 182290 1000 180 36.640 6.30 6.05<br />

182740 182300 1000 200 46.710 6.30 6.05<br />

10022615 1000 225 58.900 6.05<br />

490520 1000 250 72.370 6.05<br />

€/kg<br />

red<br />

€/kg<br />

grey<br />

Shop<br />

€/kg<br />

black

13/16 <strong>PLASTICS</strong><br />

UPVC TUBES<br />

Extruded<br />

Item No.<br />

grey<br />

Length<br />

mm<br />

Density: 1.41 g/cm 3<br />

Service temperature: +/-0 °C to +60 °C<br />

Largely UV-stabilised<br />

Special types: -20 °C to +80 °C<br />

UV-stabilised<br />

Colour: Grey<br />

Outer diameter<br />

mm<br />

Wall thickness<br />

mm<br />

4428840 5000 6 1 0.79<br />

4428850 5000 8 1 0.92<br />

873310 5000 10 1.2 1.06<br />

4428860 5000 12 1 1.03<br />

4428870 5000 12 1.4 1.30<br />

4428880 5000 16 1.2 1.30<br />

4428890 5000 16 1.8 1.62<br />

4428900 5000 20 1.5 1.73<br />

4322610 5000 20 2.3 3.06<br />

4428910 5000 25 1.5 2.16<br />

4322620 5000 25 1.9 2.59<br />

4428920 5000 25 2.8 3.89<br />

10020786 5000 32 1.8 3.39<br />

4428940 5000 32 2.4 3.89<br />

4428950 5000 32 3.6 5.18<br />

4428970 5000 40 3.0 5.81<br />

4428980 5000 40 4.5 9.43<br />

10014679 5000 50 1.8 4.64<br />

4322630 5000 50 2.4 5.72<br />

4428990 5000 50 3.7 8.69<br />

4429000 5000 50 5.6 14.59<br />

10019146 5000 63 1.9 6.26<br />

928190 5000 63 3.0 7.34<br />

4429010 5000 63 4.7 13.82<br />

4429020 5000 63 7.0 22.73<br />

998050 5000 75 2.2 8.86<br />

4429030 5000 75 3.6 10.69<br />

4429040 5000 75 5.6 19.50<br />

4429050 5000 75 8.4 36.50<br />

10041999 5000 90 1.8 10.61<br />

10003089 5000 90 2.7 13.93<br />

4429060 5000 90 4.3 15.12<br />

4429070 5000 90 6.7 28.08<br />

4429090 5000 110 1.8 11.77<br />

4429090 5000 110 2.2 11.77<br />

998060 5000 110 5.3 22.36<br />

4429080 5000 110 8.2 37.26<br />

10009439 5000 125 1.8 12.96<br />

10003064 5000 160 1.8 16.31<br />

10024755 5000 160 2.5 23.87<br />

10041784 5000 160 11.9 99.86<br />

10039528 5000 180 1.8 23.44<br />

10040956 5000 200 9.6 117.72<br />

10013347 5000 250 2.0 34.78<br />

4628260 5000 250 4.9 55.84<br />

10017373 5000 315 2.9 62.64<br />

€/m<br />

grey<br />

plastics@reiff-group.com / www.reiff-tp.com

UPVC HOLLOW BARS<br />

Extruded<br />

Density: 1.41 g/cm 3<br />

Service temperature: +/-0 °C to +60 °C<br />

Largely UV-stabilised<br />

Special types: -20 °C to +80 °C<br />

UV-stabilised<br />

Colour: Grey<br />

Item No.<br />

Length<br />

mm<br />

Other colours and designs<br />

on request.<br />

Outer diameter<br />

mm<br />

Inner diameter<br />

mm<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/17<br />

Weight/m<br />

kg €/kg<br />

4425860 2000 15 5 0.250 12.69<br />

4425870 2000 18 5 0.360 12.69<br />

1008310 2000 20 6 0.440 12.69<br />

4425900 2000 22 6 0.570 12.69<br />

4425880 2000 25 8 0.680 12.69<br />

4425920 2000 28 10 0.780 12.69<br />

4425940 2000 30 10 0.960 12.69<br />

4425990 2000 32 12 0.980 12.69<br />

4426000 2000 35 12 1.310 12.69<br />

4426020 2000 40 15 1.660 12.69<br />

4426030 2000 45 20 1.990 12.69<br />

4426050 2000 50 20 2.470 12.69<br />

4426060 2000 55 25 2.900 12.69<br />

4426070 2000 60 30 3.450 12.69<br />

4426080 2000 70 30 4.510 12.69<br />

4426090 2000 80 40 5.860 12.69<br />

4426110 2000 100 50 9.130 12.69<br />

Shop

13/18 <strong>PLASTICS</strong><br />

PPVC<br />

Boards/Films<br />

Item No.<br />

transparent<br />

Minimum<br />

order<br />

€ 40.–<br />

Item No.<br />

natural<br />

Thickness<br />

mm<br />

Property Method Value Unit<br />

Density DIN 53 479 ~ 1.22 g/cm3 Shore hardness<br />

A/15 sec<br />

DIN 53 505 70 –<br />

Cold crack<br />

temperature<br />

DIN 53 372 Below 30 °C<br />

Water absorption DIN 53 472 14<br />

mg<br />

Condition at time<br />

of supply<br />

51 x 51 x 5.5 mm<br />

0.14<br />

%<br />

Tearing strength DIN 53 455 Approx. 200 kg/cm2 Elongation at tear DIN 53 455 Approx. 450 %<br />

Tear growth<br />

resistance<br />

DIN 53 515 > 40 kp/cm<br />

Fire behaviour DIN 53 382 Burns or<br />

smoulders<br />

no further<br />

–<br />

Flammability<br />

According to<br />

US MVSS 302<br />

Non-<br />

flammable<br />

Abrasion DIN 51 954 0.01 mm<br />

Property Method Value Unit<br />

Density DIN 53 479 ~ 1.22 g/cm3 Shore hardness<br />

A/15 sec<br />

DIN 53 505 70 –<br />

Cold crack<br />

temperature<br />

DIN 53 372 Below 30 °C<br />

Water absorption DIN 53 472 14<br />

mg<br />

Condition at time<br />

of supply<br />

51 x 51 x 5.5 mm<br />

0.14<br />

%<br />

Tearing strength DIN 53 455 Approx. 200 kg/cm2 Elongation at tear DIN 53 455 Approx. 450 %<br />

Tear growth<br />

resistance<br />

DIN 53 515 > 40 kp/cm<br />

Fire behaviour DIN 53 382 Burns or<br />

smoulders<br />

no further<br />

–<br />

Flammability<br />

Length<br />

m<br />

According to<br />

US MVSS 302<br />

Non-<br />

flammable<br />

Abrasion DIN 51 954 0.01 mm<br />

–<br />

–<br />

Density: 1.25 g/cm 3<br />

Service temperature: -35 °C to +60 °C<br />

Special types: -45 °C to +60 °C<br />

Colour: Natural, transparent<br />

Width<br />

mm<br />

€/m²<br />

transparent<br />

€/m²<br />

natural<br />

184940 0.50 50 1220 4.50<br />

416180 1 30 1220 8.95<br />

182980 183020 2 20 1000 6.74 6.74<br />

182990 183030 3 20 1000 6.74 6.74<br />

183000 183040 4 20 1000 6.74 6.74<br />

660740 183050 5 20 1000 6.74 6.74<br />

855270 7 20 1000 6.74<br />

855280 10 20 1000 6.74<br />

Strips<br />

Item No.<br />

Red-transp.<br />

Item No.<br />

transparent<br />

Thickness<br />

mm<br />

Length<br />

m<br />

Density: 1.25 g/cm 3<br />

Service temperature: -35 °C to +60 °C<br />

Special types: -45 °C to +60 °C<br />

Colour: Transparent,<br />

red-transparent<br />

Width<br />

mm<br />

€/m €/m<br />

Red-transp. transparent<br />

928340 979850 2 50 200 2.93 2.66<br />

826440 979870 3 50 300 6.50 5.91<br />

993490 979880 4 50 400 11.54 10.49<br />

plastics@reiff-group.com / www.reiff-tp.com

PE HD (POLYETHYLENE HIGH DENSITY)<br />

Characteristic properties of PE HD (polyethylene high density)<br />

The properties of polyethylene are primarily determined by the<br />

chain length (degree of polymerisation).<br />

Compared to standard natural and black polyethylenes,<br />

PE HD 500 (HMW) and PE HD 1000 (UHMW) have a higher<br />

molecular weight (M), which can be established via various<br />

methods. According to Margolies' equation (based on viscometric<br />

measurements), the materials are classified as follows:<br />

Standard PE HD natural or black = approx. 250.000 M<br />

PE HD 500 (HMW) = approx. 500.000 M<br />

PE HD 1000 (UHMW) = approx. 4.4 – 8 million M<br />

PE HD standard natural or black<br />

(polyethylene)<br />

Material density: 0.95 g/cm 3<br />

Service temperature: -50 °C to +70 °C<br />

Without significant mechanical stress and with air as the<br />

surrounding medium, up to +80 °C<br />

PE HD is very tough, even at low temperatures, has a low density<br />

(compared to other materials) and impresses with its high<br />

chemical resistance.<br />

• Very good electrical insulating properties<br />

• Good sliding properties<br />

• Almost no moisture absorption<br />

• Combustible according to DIN 4102 B2<br />

• Physiologically indifferent (compatible with foodstuffs)<br />

• Anti-adhesive properties (so 100 % sticking not possible)<br />

Comment:<br />

PE natural is intended exclusively for indoor use.<br />

PE black is specially UV-stabilised for outdoor use.<br />

Pressed boards have fewer stresses compared to extruded boards,<br />

so priority should be given to them for milled parts.<br />

Grades:<br />

Extruded and pressed design/colour natural/black<br />

Other grades/modifications on request<br />

Application:<br />

Machine tools, chemical equipment and laboratory construction,<br />

electroplating technology, use wherever physiological safety is<br />

required.<br />

Processing:<br />

Hot forming, welding, machining,<br />

Sticking properties: high bonding strength not possible<br />

Printing: surface pre-treatment required<br />

Dimensions:<br />

Boards 0.5 – 50 mm extruded design –<br />

Dim. 2000 x 1000 mm<br />

10 – 200 mm pressed design –<br />

Dim. 2000 x 1000 mm<br />

Other board sizes on request<br />

Round rods: 8 – 500 mm diameter, lengths of 1000/2000 mm<br />

Tolerances: see technical knowledge<br />

Standard tolerances for thermoplastic/thermosetting plastic<br />

materials<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/19<br />

In addition to the general characteristics of standard PE HD,<br />

such as<br />

• Good resistance to stress cracks<br />

• No water absorption<br />

• Compatible with foodstuffs<br />

• Excellent electric and dielectric properties<br />

• Good processability and machinability<br />

• Chemical resistance<br />

as the molecular weight of HMW PE HD types increases, so a<br />

number of the material properties improve. For example:<br />

• Notch toughness<br />

• Resistance to stress cracking<br />

• Tearing strength/elongation at tear<br />

• Rigidity and abrasion also decrease as the molecular weight<br />

increases<br />

PE HD 1000 (UHMW) (polyethylene)<br />

Material density: 0.94 g/cm 3<br />

Service temperature: –200 °C to + 70 °C<br />

An increase of around 10 % is permissible, provided that the parts<br />

are not subject to significant mechanical stress.<br />

PE HD 1000 (UHMW) features high impact strength and notch<br />

toughness even at low temperatures, as well as a high tearing<br />

strength and elongation at tear with optimum long-term behaviour.<br />

This material will not be destroyed by slow or sudden stresses.<br />

• Very low wear, abrasion-resistant<br />

• Good sliding properties, prevents sticking<br />

• Almost no moisture absorption<br />

• Combustible according to DIN 4102 B2<br />

• Physiologically indifferent (compatible with foodstuffs)<br />

• Anti-adhesive properties (so 100 % sticking not possible)<br />

Comment:<br />

PE HD 1000 UHMW natural is not specially stabilised for outdoor<br />

use and, as such, is intended for indoor applications.<br />

PE HD 1000 UHMW black is specially UV-stabilised for outdoor use.<br />

Pressed boards have fewer stresses compared to extruded boards,<br />

so priority should be given to them for milled parts.<br />

Grades:<br />

Extruded/sliced and pressed boards<br />

Colour natural/black/green<br />

Special types modified for parts subject to high stresses on<br />

request<br />

Round rods ram extruded/extruded design<br />

Application:<br />

Machine tools, chemical equipment construction, electroplating<br />

technology, use wherever physiological safety is required and<br />

where sliding properties are necessary along with optimum wear<br />

resistance, e.g. hopper linings<br />

Processing: see PE HD<br />

Dimensions:<br />

Boards: Thicknesses of 1 – 8 mm = extruded or sliced boards<br />

10 – 120 mm = pressed/extruded boards<br />

Storage dimensions 2000 x 1000 mm,<br />

other dim. on request<br />

Round rods: 20 – 350 mm D<br />

Tolerances: see technical knowledge<br />

Standard tolerances for thermoplastic/thermosetting plastic<br />

materials

13/20 <strong>PLASTICS</strong><br />

PE HD<br />

Material characteristics<br />

Name according to DIN ISO 1043 PE black PE natural PE UHM PE UHMW<br />

Material name PE HWU PE HWST PE HMW 500 PE HMG 1000<br />

Technical data Norm Unit<br />

Density ISO 1183 g/cm3 0.95 0.95 0.95 0.94<br />

Yield stress DIN EN ISO 527 MPa 22 21 28 22<br />

Elongation under yield stress DIN EN ISO 527 % 9 9 8 10<br />

Elongation at tear DIN EN ISO 527 % 300 500 300 350<br />

Tensile modulus of elasticity DIN EN ISO 527 MPa 800 800 850 800<br />

Impact strength DIN EN ISO 179 kJ/m2 No breakage No breakage No breakage No breakage<br />

Notch toughness DIN EN ISO 179 kJ/m2 12 13 50 No breakage<br />

Ball indentation hardness DIN EN ISO 2039-1 MPa 40 43 45 40<br />

Shore hardness<br />

Average<br />

ISO 868 D 63 62 66 64<br />

linear coefficient of thermal<br />

expansion<br />

DIN 53752 K –1 1.8 x 10 –4 1.8 x 10 –4 1.5 x 10 –4 1.6 x 10 –4<br />

Thermal conductivity DIN 52612 W/m-K 0.38 0.38 0.38 0.38<br />

Fire behaviour DIN 4102 Standard<br />

flammable<br />

Standard<br />

flammable<br />

Standard<br />

flammable<br />

Standard<br />

flammable<br />

Dielectric strength IEC 243-1 kV/mm 47 50 44 44<br />

Surface resistivity DIN IEC 167 Ohm 10 14 10 14 10 14 10 14<br />

Usable temperature range °C -50 to +80 -50 to +80 -100 to +80 -200 to +80<br />

Chemical resistance Very good in contact with many acids, alkalis and solvents<br />

Physiologically safe<br />

according to BgVV (Federal<br />

Institute of Consumer Health<br />

Protection and Veterinary<br />

Medicine)<br />

Yes Yes Yes<br />

Yes<br />

(natural colour<br />

only)<br />

Processing<br />

Welding Yes Yes Yes Possible<br />

Bonding, GFRP coating Only possible following pre-treatment<br />

Painting, printing Only possible following pre-treatment<br />

Hot forming Good Good Possible Restricted<br />

Properties and applications<br />

Also, page through online!<br />

www.reiff-tp.com<br />

Specially UV- Physiologically<br />

stabilised for out- safe, particularly<br />

door applications, for applications in<br />

good deep- the food industry<br />

drawing properties,<br />

particularly<br />

for use in tank and<br />

equipment construction,<br />

as well<br />

as in the deepdrawing<br />

sector<br />

High molecular<br />

weight, abrasionresistant,<br />

good<br />

sliding properties,<br />

particularly for<br />

applications in<br />

conveying<br />

technology, as<br />

well as machine<br />

tools and plant<br />

engineering<br />

Ultra-high molecular<br />

weight, particularlyabrasionresistant,<br />

good<br />

sliding properties,<br />

particularly for use<br />

in conveying technology,<br />

as well as<br />

in silo and hopper<br />

construction<br />

plastics@reiff-group.com / www.reiff-tp.com

PE BOARDS<br />

Extruded<br />

Density: 0.95 g/cm 3<br />

Service temperature: -50 °C to +80 °C<br />

Colour: natural<br />

for indoor applications<br />

black<br />

UV-stabilised<br />

Item No.<br />

natural<br />

Item No.<br />

black<br />

Thickness<br />

mm<br />

Length<br />

mm<br />

Width<br />

mm<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

Weight/unit<br />

kg<br />

<strong>PLASTICS</strong> 13/21<br />

€/kg<br />

natural<br />

179840 179990 1 2000 1000 1.900 5.59 5.59<br />

10067966 1.5 2000 1000 2.880 5.59<br />

179850 180000 2 2000 1000 3.800 4.95 4.95<br />

179860 180010 3 2000 1000 5.700 4.95 4.95<br />

179870 180020 4 2000 1000 7.600 4.95 4.95<br />

179880 180030 5 2000 1000 9.500 4.95 4.95<br />

179890 180040 6 2000 1000 11.400 4.95 4.95<br />

179900 180050 8 2000 1000 15.300 4.95 4.95<br />

179910 180060 10 2000 1000 19.100 4.95 4.95<br />

179920 180070 12 2000 1000 22.900 4.95 4.95<br />

179930 180080 15 2000 1000 28.700 4.95 4.95<br />

179940 180090 20 2000 1000 38.200 4.95 4.95<br />

179950 574760 25 2000 1000 47.800 4.95 4.95<br />

179960 410720 30 2000 1000 57.300 4.95 4.95<br />

4450900 40 2000 1000 76.000 5.80<br />

4450910 50 2000 1000 95.000 6.45<br />

Pressed<br />

Density: 0.95 g/cm 3<br />

Service temperature: -50 °C to +80 °C<br />

Colour: natural<br />

for indoor applications<br />

black<br />

UV-stabilised<br />

Item No.<br />

natural<br />

Item No.<br />

black<br />

Thickness<br />

mm<br />

Length<br />

mm<br />

Width<br />

mm<br />

Weight/unit<br />

kg<br />

€/kg<br />

natural<br />

4400920 20 2000 1000 38.000 7.48<br />

4400840 4400930 25 2000 1000 47.500 7.48 7.48<br />

4400850 4400940 30 2000 1000 57.000 7.48 7.48<br />

619680 35 2000 1000 65.500 7.48<br />

179970 410730 40 2000 1000 76.000 7.48 7.48<br />

179980 410740 50 2000 1000 95.000 7.48 7.48<br />

4400860 4400950 60 2000 1000 114.000 7.48 7.48<br />

4400870 4400960 70 2000 1000 133.000 7.48 7.48<br />

4400880 4134060 80 2000 1000 152.000 7.48 7.48<br />

€/kg<br />

black<br />

€/kg<br />

black

13/22 <strong>PLASTICS</strong><br />

PE ROUND RODS<br />

Extruded<br />

Item No.<br />

natural<br />

Item No.<br />

black<br />

Other dimensions on request<br />

Length<br />

mm<br />

Density: 0.95 g/cm 3<br />

Service temperature: -50 °C to +80 °C<br />

Colour: natural<br />

for indoor applications<br />

black<br />

UV-stabilised<br />

Diameter<br />

mm<br />

Weight/m<br />

kg<br />

€/kg<br />

natural<br />

180260 10040361 2000 10 0.080 9.45 9.45<br />

4590830 2000 12 0.110 9.45<br />

10033725 2000 15 0.170 9.45<br />

406160 180340 2000 20 0.320 9.45 9.45<br />

180300 4463010 2000 25 0.490 9.45 9.45<br />

406170 427650 2000 30 0.700 8.43 8.43<br />

574740 1120540 2000 35 0.950 8.43 8.43<br />

180320 180360 2000 40 1.200 8.43 8.43<br />

470070 647820 2000 45 1.520 8.43 8.43<br />

410800 410840 2000 50 1.880 8.43 8.43<br />

4395140 2000 55 2.250 8.43<br />

410810 415920 2000 60 2.700 8.43 8.43<br />

10009244 2000 65 3.400 8.43<br />

574750 577790 2000 70 3.850 8.43 8.43<br />

415910 410820 2000 80 4.800 8.43 8.43<br />

574780 410830 2000 90 6.310 8.43 8.43<br />

410790 577800 1000 100 7.500 8.43 8.43<br />

470080 10024125 1000 110 9.080 8.43 8.43<br />

4449190 10008408 1000 120 11.250 8.43 8.43<br />

10012091 1000 125 12.230 8.43<br />

4313530 1000 140 15.290 8.43<br />

4449200 10000741 1000 150 16.880 8.43 8.43<br />

4449210 10017449 1000 200 30.000 8.43 8.43<br />

10014177 1000 225 39.640 8.43<br />

773300 1000 250 48.570 8.43<br />

773290 1000 300 69.700 8.43<br />

€/kg<br />

black<br />

plastics@reiff-group.com / www.reiff-tp.com

PP<br />

PP (polypropylene)<br />

Material density:<br />

0.91 g/cm 3<br />

Service temperature:<br />

+/–0 °C to +80 °C<br />

Without significant mechanical stress and with air as the<br />

surrounding medium, up to +100 °C<br />

More rigid, harder and stronger than PE.<br />

• High chemical resistance<br />

• Very good electrical insulating properties<br />

• Almost no moisture absorption<br />

• Combustible according to DIN 4102 B2<br />

• Physiologically safe (according to BGA/FDA)<br />

• Anti-adhesive properties (so 100 % sticking not possible)<br />

Comment:<br />

PP is not generally designed for outdoor use.<br />

For restrictions in terms of chemical resistance, see the separate<br />

data sheet.<br />

Due to the way they are manufactured, pressed boards are more<br />

neutral in terms of stress and priority should be given to them for<br />

milled parts.<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/23<br />

Material name PP DWU PP DWST PPs<br />

Name according to DIN ISO 1043 PP grey PP natural PP low flammability<br />

Technical data Norm Unit<br />

Density ISO 1183 g/cm3 0.91 0.90 0.95<br />

Yield stress DIN EN ISO 527 MPa 32 30 32<br />

Elongation under yield stress DIN EN ISO 527 % 8 8 8<br />

Elongation at tear DIN EN ISO 527 % 70 70 70<br />

Tensile modulus of elasticity DIN EN ISO 527 MPa 1400 1400 1300<br />

Impact strength DIN EN ISO 179 kJ/m2 No breakage No breakage No breakage<br />

Notch toughness DIN EN ISO 179 kJ/m2 6 6 7<br />

Ball indentation hardness DIN EN ISO 2039-1 MPa 70 70 70<br />

Shore hardness<br />

Average<br />

ISO 868 D 72 72 72<br />

linear coefficient of thermal<br />

expansion<br />

DIN 53752 K –1 1.6 x 10 –4 1.6 x 10 –4 1.6 x 10 –4<br />

Thermal conductivity DIN 52612 W/m-K 0.22 0.22 0.22<br />

Fire behaviour DIN 4102 Standard<br />

flammable<br />

Grades:<br />

Extruded/pressed design, colour natural/pebble grey<br />

Other PP grades on request<br />

Application:<br />

Machine tools, chemical equipment and laboratory construction,<br />

electroplating technology, use wherever physiological safety is<br />

required<br />

Processing:<br />

Hot forming, welding, machining,<br />

Sticking properties: high bonding strength not possible<br />

Printing: surface pre-treatment required<br />

Good cutting properties<br />

Dimensions:<br />

Boards 0.5 – 40 mm extruded design –<br />

Dim. 2000 x 1000 mm<br />

10 – 200 mm pressed design –<br />

Dim. 2000 x 1000 mm<br />

Other board sizes on request<br />

Round rods: 8 – 500 mm diameter, lengths of 1000/2000 mm<br />

Tolerances:<br />

See technical knowledge<br />

Standard tolerances for thermoplastic/thermosetting plastic<br />

materials<br />

Weight indications are theoretical.<br />

Standard<br />

flammable<br />

Standard<br />

flammable<br />

Dielectric strength IEC 243-1 kV/mm 52 58 22<br />

Surface resistivity DIN IEC 167 Ohm 1014 1014 1014 Usable temperature range °C 0 to +100 0 to +100 0 to +100<br />

Chemical resistance<br />

Physiologically safe<br />

Very good in contact with many acids, alkalis and solvents<br />

according to BgVV (Federal<br />

Institute of Consumer Health<br />

Protection and Veterinary<br />

Medicine)<br />

Processing<br />

Yes Yes No<br />

Welding Yes Yes Yes<br />

Bonding, GFRP coating Possible with laminated boards<br />

Painting, printing Only possible following pre-treatment<br />

Hot forming<br />

Properties and applications<br />

Good Good Good<br />

Extremely thermally<br />

stable, particularly for<br />

applications in tank and<br />

equipment construction<br />

Physiologically safe,<br />

particularly for applications<br />

in the food<br />

industry<br />

Extremely thermally<br />

stable, particularly for<br />

use in the construction<br />

of ventilation systems

13/24 <strong>PLASTICS</strong><br />

PP BOARDS<br />

Extruded<br />

Item No.<br />

natural<br />

Item No.<br />

grey<br />

Thickness<br />

mm<br />

Density: 0.92 g/cm 3<br />

Service temperature: +/-0 °C to +80 °C,<br />

without mech. stress up to +100 °C<br />

Colour: natural, not UV-resistant,<br />

grey, UV-resistant to a limited extent<br />

Length<br />

mm<br />

Width<br />

mm<br />

Weight/unit<br />

kg<br />

€/kg<br />

natural<br />

10030727 180810 1 2000 1000 1.800 5.56 5.56<br />

180990 386910 2 2000 1000 3.600 5.05 5.05<br />

404820 180830 3 2000 1000 5.500 5.05 5.05<br />

181010 387000 4 2000 1000 7.300 5.05 5.05<br />

181020 180850 5 2000 1000 9.200 5.05 5.05<br />

404830 387010 6 2000 1000 11.000 5.05 5.05<br />

181040 180870 8 2000 1000 14.600 5.05 5.05<br />

404840 387020 10 2000 1000 18.300 5.05 5.05<br />

181060 180890 12 2000 1000 22.000 5.05 5.05<br />

404850 404790 15 2000 1000 27.500 5.05 5.05<br />

181080 180910 20 2000 1000 36.400 5.05 5.05<br />

404860 404800 25 2000 1000 45.800 5.05 5.05<br />

181100 180930 30 2000 1000 54.900 5.05 5.05<br />

10002777 569140 35 2000 1000 64.500 6.46 6.46<br />

620030 180950 40 2000 1000 73.200 6.46 6.46<br />

404810 50 2000 1000 92.500 8.29<br />

Pressed<br />

Item No.<br />

natural<br />

Item No.<br />

grey<br />

Thickness<br />

mm<br />

Density: 0.92 g/cm 3<br />

Service temperature: +/-0 °C to +80 °C,<br />

without mech. stress up to +100 °C<br />

Colour: natural, not UV-resistant,<br />

grey, UV-resistant to a limited extent<br />

Length<br />

mm<br />

Width<br />

mm<br />

Weight/unit<br />

kg<br />

€/kg<br />

natural<br />

4403220 4403110 10 2000 1000 18.200 9.23 9.23<br />

4403230 4403120 12 2000 1000 21.800 9.23 9.23<br />

4403240 4403130 15 2000 1000 27.300 8.20 8.20<br />

4403250 4403140 20 2000 1000 36.400 8.20 8.20<br />

4403260 4403150 25 2000 1000 45.500 8.20 8.20<br />

4403270 4403160 30 2000 1000 54.600 8.20 8.20<br />

4403280 4403170 40 2000 1000 72.800 8.20 8.20<br />

1091670 4403180 50 2000 1000 91.000 8.20 8.20<br />

470060 180970 60 2000 1000 109.200 8.20 8.20<br />

4403290 4403190 70 2000 1000 127.400 8.20 8.20<br />

4403300 4403200 80 2000 1000 145.600 8.20 8.20<br />

4403310 4403210 90 2000 1000 163.800 8.77 8.77<br />

569650 620040 100 2000 1000 182.000 8.77 8.77<br />

Shop<br />

€/kg<br />

grey<br />

€/kg<br />

grey<br />

plastics@reiff-group.com / www.reiff-tp.com

PP ROUND RODS<br />

Extruded<br />

Density: 0.92 g/cm 3<br />

Service temperature: +/-0 °C to +80 °C,<br />

without mech. stress up to +100 °C<br />

Colour: natural, not UV-resistant,<br />

grey, UV-resistant to a limited extent<br />

Item No.<br />

natural<br />

Item No.<br />

grey<br />

All prices indicated in this<br />

catalogue are subject to<br />

federal VAT.<br />

Length<br />

mm<br />

Diameter<br />

mm<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

Weight/m<br />

kg<br />

<strong>PLASTICS</strong> 13/25<br />

€/kg<br />

natural<br />

10044170 2000 8 0.050 10.40<br />

181140 2000 10 0.070 10.40<br />

404880 2000 12 0.120 10.40<br />

569200 181160 2000 15 0.160 10.40 10.40<br />

181240 404890 2000 20 0.300 10.40 10.40<br />

569210 181180 2000 25 0.450 10.40 10.40<br />

404920 404900 2000 30 0.650 8.29 8.29<br />

620050 569150 2000 35 0.880 8.29 8.29<br />

181260 181200 2000 40 1.150 8.29 8.29<br />

569220 569160 2000 45 1.460 8.29 8.29<br />

404930 404910 2000 50 1.800 8.29 8.29<br />

569230 569170 2000 55 2.250 8.29 8.29<br />

470040 181220 2000 60 2.590 8.29 8.29<br />

569180 2000 65 3.250 8.29<br />

569240 470050 2000 70 3.520 8.29 8.29<br />

10012252 10050725 2000 75 4.150 8.29 8.29<br />

569250 410870 2000 80 4.600 8.29 8.29<br />

575020 427660 2000 90 6.040 8.29 8.29<br />

575030 574980 2000 100 7.200 8.29 8.29<br />

10028410 10062039 2000 110 8.990 8.29 8.29<br />

992710 2000 150 16.800 8.29<br />

10066506 2000 200 29.000 8.29<br />

€/kg<br />

grey

13/26 <strong>PLASTICS</strong><br />

TECHNICAL SEMI-FINISHED PRODUCTS<br />

PA<br />

Product description for PA (polyamide)<br />

Material density:<br />

PA 6 1.14 g/cm 2<br />

Service temperature:<br />

PA 6 –40 °C to +85/70 °C (5000/20.000 hours)<br />

According to grade, e.g. PA 4.6 (Ertalon 4.6) –40 °C to +155/135 °C<br />

Differences in PA types depend on their crystallinity and water<br />

content. A high degree of crystallinity makes polyamides rigid<br />

and hard.<br />

Very tough due to moisture absorption.<br />

Main properties of polyamides:<br />

• High mechanical strength, rigidity, hardness and toughness<br />

• Good fatigue strength<br />

• High mechanical damping capacity<br />

• Good sliding and emergency running properties<br />

• Very high wear resistance<br />

• Good electrical insulating properties<br />

• Good resistance to high-energy radiation (gamma and X rays)<br />

• Good cutting properties<br />

The wear resistance and sliding properties can be improved by<br />

making modifications involving oil or solid lubricants. The strength<br />

and modulus of elasticity are achieved via modifications with glass<br />

fibres.<br />

Comment:<br />

As PA absorbs moisture, these plastics must be designed to permit<br />

larger tolerances.<br />

Never use PA against PA in sliding applications (stick-slip effect).<br />

Grades:<br />

Extruded materials:<br />

• PA 6 colour natural/black<br />

• PA 66 colour natural/black<br />

• Ertalon 4.6 (polyamide 4.6) reddish brown<br />

• PA 66 GF 30 black<br />

• Nylatron GS anthracite<br />

Cast materials:<br />

• PA 6 cast colour natural/black<br />

• PA 6 heat-stabilised (Ertalon XAU) black<br />

• PA 6 oil (Ertalon LFX) green<br />

• Nylatron 901 blue<br />

• Nylatron GSM anthracite<br />

• Nylatron NSM grey<br />

• Nylatron LFG (self-lubricating)<br />

Approved under foodstuffs legislation<br />

• Nylatron 703 XL (optimum wear resistance – with increased<br />

dynamic resilience)<br />

(Request a separate detailed product description)<br />

Application:<br />

Machine tools, precision engineering such as bearing bushes,<br />

toothed wheels, wearing parts, tensioning and conveyor rollers,<br />

pulley blocks, chain wheels, etc.<br />

Processing:<br />

Good machining possible (long cut,<br />

see machining information)<br />

Dimensions:<br />

Round rods:<br />

5 – 500 mm ∅ (according to grade)<br />

Hollow bars:<br />

Outer diameter 20 – 500 mm (according to grade)<br />

Boards:<br />

0.5 – 100 mm thickness (according to grade)<br />

Dimensions 610 x 1000/3000 mm<br />

According to grade 1220 x 2000 mm<br />

Please observe the detailed list of dimensions for each grade.<br />

plastics@reiff-group.com / www.reiff-tp.com

TECHNICAL SEMI-FINISHED PRODUCTS<br />

PA<br />

Polyamide extruded materials<br />

PA 6 (polyamide) extruded material<br />

Material density: 1.14 g/cm 3 , colour natural/black<br />

Service temperature:<br />

–40 °C to +85/70 °C (5000/20.000 hours)<br />

This material offers an optimum combination of mechanical<br />

strength, rigidity, toughness and mechanical damping, along with<br />

very good wear resistance, good electrical insulating properties<br />

and good chemical resistance. As a result, PA 6 should be viewed<br />

as a "universal" material for construction and repairs.<br />

PA 66 (polyamide) extruded material<br />

Material density: 1.14 g/cm 3 , colour natural/black<br />

Service temperature:<br />

–30 °C to +95/80 °C (5000/20.000 hours)<br />

Material with a higher strength, rigidity, temperature resistance<br />

and wear resistance than PA 6, as well as better creep strength.<br />

However, PA 66 has a lower impact strength and poorer<br />

mechanical damping properties.<br />

Ertalon 4.6 (polyamide 4.6) extruded material<br />

Material density: 1.18 g/cm 3 , colour reddish brown<br />

Service temperature:<br />

–40 °C to +155/135 °C (5000/20.000 hours)<br />

Compared to standard PA types, Ertalon 4.6 retains its rigidity and<br />

creep strength better over a wide temperature range, as well as<br />

offering higher thermal ageing resistance.<br />

The main applications for this material can be found in the temperature<br />

range between 80° and 150 °C, where the properties of PA6/<br />

PA 66/POM/PET no longer suffice.<br />

Also, page through online!<br />

www.reiff-tp.com<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/27<br />

PA 66 – GF 30 (polyamide 6.6 30 % glass-reinforced) extruded<br />

material<br />

Material density: 1.29 g/cm 3 , colour black<br />

Service temperature:<br />

–20 °C to +120/110 °C (5000/20.000 hours)<br />

PA 66 with 30 % glass-fibre reinforcement offers higher strength,<br />

rigidity, creep strength and dimensional stability than nonreinforced<br />

PA 66, whilst retaining very high wear resistance. Can<br />

be used at higher top service temperatures.<br />

Nylatron GS (polyamide 6.6 with MoS2) extruded material<br />

Material density: 1.15 g/cm 3 , colour anthracite<br />

Service temperature:<br />

–20 °C to +95/80 °C (5000/20.000 hours)<br />

Material with a slightly higher strength, hardness and dimensional<br />

stability than PA 66, but whose impact strength is reduced a<br />

little. The modification with MoS2 improves frictional and wear<br />

behaviour.<br />

For further information, see the technical data sheet.

13/28 <strong>PLASTICS</strong><br />

TECHNICAL SEMI-FINISHED PRODUCTS<br />

PA<br />

Cast polyamide materials<br />

PA 6 cast (cast polyamide) cast material<br />

Material density: 1.15 g/cm 3 , colour natural/black<br />

Service temperature:<br />

–30 °C to +105/90 °C (5000/20.000 hours)<br />

This material has a similar property profile to PA 66.<br />

It combines high mechanical strength, rigidity and hardness with<br />

good creep strength, wear resistance, thermal resistance and<br />

cutting properties.<br />

The casting method offers a wider range of dimensions.<br />

PA heat-stabilised (Ertalon 6 XAU) cast material<br />

Material density: 1.15 g/cm 3 , colour black<br />

Service temperature:<br />

–30 °C to +120/105 °C (5000/20.000 hours)<br />

Heat-stabilised PA provides higher thermal ageing resistance,<br />

which means it can be used at continuous service temperatures<br />

that are 15 to 30 °C higher than standard.<br />

Particularly recommended for sliding elements and other wearing<br />

parts where service temperatures of over 60 °C arise.<br />

Polyamide oil (Ertalon LFX) cast material<br />

Material density: 1.135 g/cm 3 , colour green<br />

Service temperature:<br />

–20 °C to +105/90 °C (5000/20.000 hours)<br />

An internally lubricated PA that was specially developed for highly<br />

stressed, slow-moving dry-running sliding elements. The material<br />

offers an extremely low coefficient of sliding friction with very high<br />

wear resistance.<br />

Technical information:<br />

In Chapter 14 "Technical Knowledge" starting<br />

on page 93 we inform you in detail.<br />

Nylatron MC 901 (polyamide 6) cast material<br />

Material density: 1.15 g/cm 3 , colour blue<br />

Service temperature:<br />

–30 °C to +105/90 °C (5000/20.000 hours)<br />

The material is tougher, more flexible and has a higher fatigue<br />

strength than PA 6 cast, making it particularly well suited for<br />

toothed wheels, pinions, gear racks, etc.<br />

Nylatron GSM (polyamide 6 with MoS2) cast material<br />

Material density: 1.16 g/cm 3 , colour anthracite<br />

Service temperature:<br />

–30 °C to +105/90 °C (5000/20.000 hours)<br />

MoS2 particles improve frictional and wear behaviour without<br />

having an adverse effect on the high impact and fatigue strength.<br />

Suitable for pulley blocks, sliding elements, chain wheels or<br />

toothed wheels.<br />

Nylatron NSM (polyamide 6 with solid lubricant) cast material<br />

Material density: 1.15 g/cm 3 , colour grey<br />

Service temperature:<br />

–30 °C to +105/90 °C (5000/20.000 hours)<br />

A material with an evenly embedded solid lubricant and excellent<br />

sliding properties, combined with outstanding wear resistance<br />

and an extremely dynamic load-carrying capacity (PV limit value<br />

5x higher than with a conventional cast PA). Particularly suitable<br />

for higher sliding speeds, dry-running bearings and wearing parts.<br />

Nylatron 703 XL (polyamide 6 with solid lubricant) cast material<br />

Material density: 1.11 g/cm 3 , colour bluish grey<br />

Service temperature:<br />

–20 °C to +105/90 °C (5000/20.000 hours)<br />

A material with outstanding wear resistance and precise motion<br />

control.<br />

Not prone to the stick-slip effect – minimal coefficient of sliding<br />

friction.<br />

Nylatron LFG (PA 6 + oil)<br />

Material density: 1.14 g/cm 3 , colour blue<br />

Service temperature:<br />

–20 °C to +105/90 °C (5000/20.000 hours)<br />

Nylatron LFG (Lubricated Food Grade) is self-lubricating in the<br />

truest sense of the word and has a composition that complies with<br />

foodstuffs legislation. This material was specially developed for<br />

highly stressed, slow-moving dry-running sliding elements in the<br />

food industry. Compared to conventional types of cast polyamide,<br />

Nylatron LFG offers lower maintenance costs and a longer service<br />

life.<br />

Shop<br />

plastics@reiff-group.com / www.reiff-tp.com

PHYSICAL PROPERTIES<br />

SEMI-FINISHED PRODUCTS<br />

TECHNICAL <strong>PLASTICS</strong><br />

PA guide values<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/29<br />

Properties Testing Units PA 6 PA 66 PA 4.6 PA 66 GF30<br />

methods ERTALON ® ERTALON ® ERTALON ® ERTALON ®<br />

ISO/(IEC) 6 SA 66 SA 4.6 66 GF30<br />

Colour – –<br />

Natural<br />

(white)/<br />

black<br />

Natural<br />

(cream)/<br />

black<br />

Reddish<br />

brown black<br />

Density 1183 g/cm3 Water absorption<br />

1.14 1.14 1.18 1.29<br />

– after 24/96 h storage in water at 23 °C 62 mg 86/168 40/76 90/180 30/56<br />

62 % 1.28/2.50 0.60/1.13 1.30/2.60 0.39/0.74<br />

– when saturated in normal atmospheric<br />

conditions 23 °C/50 % RH<br />

– % 2.6 2.4 2.8 1.7<br />

– when saturated in water at 23 °C<br />

Thermal properties (2)<br />

– % 9 8 9.5 5.5<br />

Melting point – % 220 255 295 255<br />

Thermal conductivity at 23 °C<br />

Linear coefficient of thermal expansion:<br />

– W/(K · m) 0.88 0.88 0.30 0.30<br />

– average value between 23 and 60 °C – m(m · K) 90 · 10 –6 80 · 10 –6 80 · 10 –6 50 · 10 –6<br />

– average value between 23 and 100 °C – m(m · K) 105 · 10 –6 95 · 10 –6 90 · 10 –6 60 · 10 –6<br />

Thermal stability temperature:<br />

– method A: 1.8 MPa<br />

Upper service temperature limit in air:<br />

+ 75 °C 70 85 160 150<br />

– temporary (3) – °C 160 180 200 240<br />

– continuous: for 5000/20.000 h (4) – °C 85/70 95/80 150/130 150/130<br />

Lower service temperature (5)<br />

Burning behaviour (6)<br />

-40 -30 -40 -20<br />

– "oxygen index" 4589 % 25 26 24 –<br />

– according to UL 94 (thickness of 3/6 mm)<br />

Mechanical properties at 23 °C<br />

Tensile test (8):<br />

– – HB, HB HB/V-2 HB, HB HB, HB<br />

– yield stress (9) + 527 MPa 76 90 100 100<br />

++ 527 MPa 45 55 55 75<br />

– elongation at break (9) + 527 % > 50 >40 25 5<br />

++ 527 % > 100 >100 > 100 12<br />

– tensile modulus of elasticity (10) + 527 MPa 3.250 3.450 3.300 5.900<br />

Compression test (11):<br />

++ 527 MPa 1.400 1.650 1.300 3.200<br />

– compressive stress at 1/2/5 %<br />

nominal deformation by compression (10)<br />

Tensile creep test (8):<br />

+ 604 MPa 24/46/80 25/49/92 23/45/94 28/55/90<br />

– stress that leads to an elongation<br />

of 1 % after 1000 h<br />

+ 899 MPa 18 20 22 26<br />

– (�1/1000) ++ 899 MPa 7 8 7.5 18<br />

Charpy impact strength (12) + 179/1eU kJ/m2 No breakage No breakage No breakage ≥ 50<br />

Charpy notch toughness + 179/1eA kJ/m2 5.5 4.5 8 6<br />

Izod-test toughness + 180/2A kJ/m2 5.5 4.5 8 6<br />

++ 180/2A kJ/m2 15 11 25 11<br />

Ball indentation hardness (13) + 2039/-1 N/mm2 150 160 165 165<br />

Rockwell hardness (13)<br />

Electrical properties at 23 °C<br />

+ 2039/-2 – M 85 M 88 M 92 M 76<br />

Dielectric strength (14) + (60243) kV/mm 25 27 25 30<br />

++ (60243) kV/mm 16 18 15 20<br />

Volume resistivity + (60093) Ω · cm > 1014 > 1014 > 1014 > 1014 ++ (60093) Ω · cm > 1012 > 1012 > 1012 > 1013 Surface resistivity + (60093) Ω > 1013 > 1013 > 1013 > 1011 ++ (60093) Ω > 1012 > 1012 > 1012 > 1012 Dielectric constant εr: – at 100 Hz + (60250) – 3.9 3.8 3.8 3.9<br />

++ (60250) – 7.4 7.4 7.4 6.9<br />

– at 1 MHz + (60250) – 3.3 3.3 3.4 3.6<br />

++ (60250) – 3.8 3.8 3.8 3.9<br />

Dielectric power factor tan �: – at 100 Hz + (60250) – 0.019 0.013 0.009 0.012<br />

++ (60250) – 0.13 0.13 0.13 0.19<br />

– at 1 MHz + (60250) – 0.021 0.020 0.019 0.014<br />

++ (60250) – 0.06 0.06 0.06 0.04<br />

Comparative tracking index (CTI) + (60112) – 600 600 400 475<br />

++ (60112) – 600 600 400 475<br />

+ values for dry material; ++ values for material stored up to saturation in normal atmospheric conditions 23 °C/50 % RF (largely taken from the relevant literature)<br />

Note: 1 g/cm 3 = 1000 kg/m 3 ; 1 MPa = 1 N/mm 2 ; 1 kV/mm = 1 MV/m<br />

For ERATLON 6 SA, ERATLON 66 SA, ERATLON 4.6 and ERATLON 66 GF 30 there is no "yellow UL card".

13/30 <strong>PLASTICS</strong><br />

PHYSICAL PROPERTIES<br />

SEMI-FINISHED PRODUCTS<br />

TECHNICAL <strong>PLASTICS</strong><br />

PA guide values<br />

Properties Testing Un- PA 6 + oil PA 6 PA 6 PA 6 + oil<br />

methods its ERTALON ® ERTALON ® ERTALON ® NYLATRON ®<br />

ISO/(IEC) LFX 6 XAU+ 6 PLA LFG<br />

Colour – – Green black<br />

Natural<br />

(ivory)/black<br />

Natural (ivory)<br />

or blue<br />

(RAL 5002)<br />

Density 1183 g/cm3 Water absorption<br />

1.135 1.15 1.15 1.135<br />

– after 24/96 h storage in water at 23 °C 62 mg 44/83 47/89 44/83 44/83<br />

62 % 0.66/1.24 0.69/1.31 0.65/1.22 0.66/1.24<br />

– when saturated in normal atmospheric<br />

conditions 23 °C/50 % RH<br />

– % 2 2.2 2.2 2<br />

– when saturated in water at 23 °C<br />

Thermal properties (2)<br />

– % 6.3 6.5 6.5 6.3<br />

Melting point – % 220 220 220 220<br />

Thermal conductivity at 23 °C<br />

Linear coefficient of thermal expansion:<br />

– W/(K · m) 0.28 0.29 0.29 0.28<br />

– average value between 23 and 60 °C – m(m · K) 80 · 10 –6 80 · 10 –6 80 · 10 –6 80 · 10 –6<br />

– average value between 23 and 100 °C – m(m · K) 90 · 10 –6 90 · 10 –6 90 · 10 –6 90 · 10 –6<br />

Thermal stability temperature:<br />

– method A: 1.8 MPa<br />

Upper service temperature limit in air:<br />

+ 75 °C 75 80 80 75<br />

– temporary (3) – °C 165 180 170 165<br />

– continuous: for 5000/20.000 h (4) – °C 105/90 120/105 105/90 105/90<br />

Lower service temperature (5)<br />

Burning behaviour (6)<br />

-20 -30 -30 -20<br />

– "oxygen index" 4589 % – 25 25 –<br />

– according to UL 94 (thickness of 3/6 mm)<br />

Mechanical properties at 23 °C<br />

Tensile test (8):<br />

– – HB, HB HB/HB HB, HB HB, HB<br />

– yield stress (9) + 527 MPa 70 83 85 70<br />

++ 527 MPa 45 55 55 45<br />

– elongation at break (9) + 527 % 25 25 25 25<br />

++ 527 % > 50 > 50 > 50 > 50<br />

– tensile modulus of elasticity (10) + 527 MPa 3.000 3.400 3.500 3.000<br />

Compression test (11):<br />

++ 527 MPa 1.450 1.650 1.700 1.450<br />

– compressive stress at 1/2/5 %<br />

nominal deformation by compression (10)<br />

Tensile creep test (8):<br />

+ 604 MPa 22/43/79 26/51/92 26/51/92 22/43/79<br />

– stress that leads to an elongation<br />

of 1 % after 1000 h<br />

+ 899 MPa 18 22 22 18<br />

– (�1/1000) ++ 899 MPa 8 10 10 8<br />

Charpy impact strength (12) + 179/1eU kJ/m2 ≥ 50 No breakage No breakage ≥ 50<br />

Charpy notch toughness + 179/1eA kJ/m2 4 3.5 3.5 4<br />

Izod-test toughness + 180/2A kJ/m2 4 3.5 3.5 4<br />

++ 180/2A kJ/m2 7 7 7 7<br />

Ball indentation hardness (13) + 2039/-1 N/mm2 145 165 165 145<br />

Rockwell hardness (13)<br />

Electrical properties at 23 °C<br />

+ 2039/-2 – M 82 M 87 M 88 M 82<br />

Dielectric strength (14) + (60243) kV/mm 22 29 25 22<br />

++ (60243) kV/mm 14 19 17 14<br />

Volume resistivity + (60093) Ω · cm > 1014 > 1014 > 1014 > 1014 ++ (60093) Ω · cm > 1012 > 1012 > 1012 > 1012 Surface resistivity + (60093) Ω > 1013 > 1013 > 1013 > 1013 ++ (60093) Ω > 1012 > 1012 > 1012 > 1012 Dielectric constant εr: – at 100 Hz + (60250) – 3.5 3.6 3.6 3.5<br />

++ (60250) – 6.5 6.6 6.6 6.5<br />

– at 1 MHz + (60250) – 3.1 3.2 3.2 3.1<br />

++ (60250) – 3.6 3.7 3.7 3.6<br />

Dielectric power factor tan �: – at 100 Hz + (60250) – 0.015 0.015 0.012 0.015<br />

++ (60250) – 0.15 0.15 0.14 0.15<br />

– at 1 MHz + (60250) – 0.016 0.017 0.016 0.016<br />

++ (60250) – 0.05 0.05 0.05 0.05<br />

Comparative tracking index (CTI) + (60112) – 600 600 600 600<br />

++ (60112) – 600 600 600 600<br />

+ values for dry material; ++ values for material stored up to saturation in normal atmospheric conditions 23 °C/50 % RF (largely taken from the relevant literature)<br />

Note: 1 g/cm 3 = 1000 kg/m 3 ; 1 MPa = 1 N/mm 2 ; 1 kV/mm = 1 MV/m<br />

For ERATLON LFX, ERATLON 6 XAU+, ERATLON 6 PLA and NYLATRON LFG there is no "yellow UL card".<br />

plastics@reiff-group.com / www.reiff-tp.com

PHYSICAL PROPERTIES<br />

SEMI-FINISHED PRODUCTS<br />

TECHNICAL <strong>PLASTICS</strong><br />

PA guide values<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/31<br />

Properties Testing Un- PA 6 PA 6 + MOS2 PA 6 + S* PA 66 + MOS2 methods its NYLATRON ® NYLATRON ® NYLATRON ® NYLATRON ®<br />

ISO/(IEC) MC 901 GSM NSM GS<br />

Colour – – blue Anthracite grey Anthracite<br />

Density 1183 g/cm3 Water absorption<br />

1.15 1.16 1.14 1.15<br />

– after 24/96 h storage in water at 23 °C 62 mg 49/93 52/98 40/76 46/85<br />

62 % 0.72/1.37 0.76/1.43 0.59/1.12 0.68/1.25<br />

– when saturated in normal atmospheric<br />