Solutions for POY manufacturing - Oerlikon Barmag - Oerlikon Textile

Solutions for POY manufacturing - Oerlikon Barmag - Oerlikon Textile

Solutions for POY manufacturing - Oerlikon Barmag - Oerlikon Textile

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

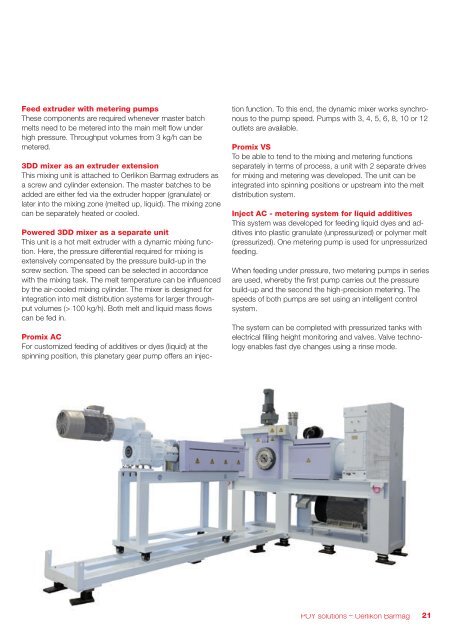

Feed extruder with metering pumps<br />

These components are required whenever master batch<br />

melts need to be metered into the main melt flow under<br />

high pressure. Throughput volumes from 3 kg/h can be<br />

metered.<br />

3DD mixer as an extruder extension<br />

This mixing unit is attached to <strong>Oerlikon</strong> <strong>Barmag</strong> extruders as<br />

a screw and cylinder extension. The master batches to be<br />

added are either fed via the extruder hopper (granulate) or<br />

later into the mixing zone (melted up, liquid). The mixing zone<br />

can be separately heated or cooled.<br />

Powered 3DD mixer as a separate unit<br />

This unit is a hot melt extruder with a dynamic mixing function.<br />

Here, the pressure differential required <strong>for</strong> mixing is<br />

extensively compensated by the pressure build-up in the<br />

screw section. The speed can be selected in accordance<br />

with the mixing task. The melt temperature can be influenced<br />

by the air-cooled mixing cylinder. The mixer is designed <strong>for</strong><br />

integration into melt distribution systems <strong>for</strong> larger throughput<br />

volumes (> 100 kg/h). Both melt and liquid mass flows<br />

can be fed in.<br />

Promix AC<br />

For customized feeding of additives or dyes (liquid) at the<br />

spinning position, this planetary gear pump offers an injec-<br />

tion function. To this end, the dynamic mixer works synchronous<br />

to the pump speed. Pumps with 3, 4, 5, 6, 8, 10 or 12<br />

outlets are available.<br />

Promix VS<br />

To be able to tend to the mixing and metering functions<br />

separately in terms of process, a unit with 2 separate drives<br />

<strong>for</strong> mixing and metering was developed. The unit can be<br />

integrated into spinning positions or upstream into the melt<br />

distribution system.<br />

Inject AC - metering system <strong>for</strong> liquid additives<br />

This system was developed <strong>for</strong> feeding liquid dyes and additives<br />

into plastic granulate (unpressurized) or polymer melt<br />

(pressurized). One metering pump is used <strong>for</strong> unpressurized<br />

feeding.<br />

When feeding under pressure, two metering pumps in series<br />

are used, whereby the first pump carries out the pressure<br />

build-up and the second the high-precision metering. The<br />

speeds of both pumps are set using an intelligent control<br />

system.<br />

The system can be completed with pressurized tanks with<br />

electrical filling height monitoring and valves. Valve technology<br />

enables fast dye changes using a rinse mode.<br />

<strong>POY</strong> solutions – <strong>Oerlikon</strong> <strong>Barmag</strong><br />

21