Solutions for POY manufacturing - Oerlikon Barmag - Oerlikon Textile

Solutions for POY manufacturing - Oerlikon Barmag - Oerlikon Textile

Solutions for POY manufacturing - Oerlikon Barmag - Oerlikon Textile

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Cross flow quenching system – one unit <strong>for</strong> (almost)<br />

everything<br />

This quenching system is the number one choice <strong>for</strong> all<br />

commodity applications. Robust, easy to use, suitable<br />

<strong>for</strong> a broad range of titers and all standard polymers, the<br />

<strong>Oerlikon</strong> <strong>Barmag</strong> cross flow quenching system feels at<br />

home in almost all <strong>POY</strong> spinning processes. As a result of<br />

the specially constructed rectifier, which corresponds to all<br />

requirements in terms of even and laminar airflow, extremely<br />

high yarn qualities can be achieved.<br />

EvoQuench – something innovative from the<br />

technology leader<br />

In contrast to the cross flow, the air here is symmetrically<br />

guided from the outside of the thread bundle to the inside.<br />

This ensures optimal flow cooling of the thread along the<br />

entire length of the filament surface. The EvoQuench system<br />

was developed <strong>for</strong> micro-fiber yarns all the way down to<br />

0.3 dpf, but also covers a good range of commodity yarns.<br />

With more than 3500 installed positions the EvoQuench<br />

system is on its way to become a sales hit made by <strong>Oerlikon</strong><br />

<strong>Barmag</strong>.<br />

EvoQuench zigzag<br />

A spinning system configured with the zigzag version of<br />

the EvoQuench quenching unit is extremely compact and<br />

simultaneously highly-efficient. When combined with an 88mm<br />

spin pack, <strong>for</strong> example, it can produce ten filaments of<br />

outstanding quality on a spinning position of just one meter<br />

in width.<br />

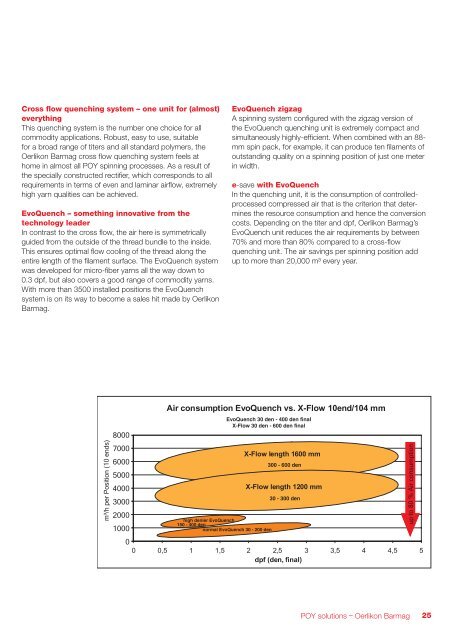

e-save with EvoQuench<br />

In the quenching unit, it is the consumption of controlledprocessed<br />

compressed air that is the criterion that determines<br />

the resource consumption and hence the conversion<br />

costs. Depending on the titer and dpf, <strong>Oerlikon</strong> <strong>Barmag</strong>’s<br />

EvoQuench unit reduces the air requirements by between<br />

70% and more than 80% compared to a cross-flow<br />

quenching unit. The air savings per spinning position add<br />

up to more than 20,000 m³ every year.<br />

<strong>POY</strong> solutions – <strong>Oerlikon</strong> <strong>Barmag</strong><br />

25