Intregated water management system at Latur - SPML

Intregated water management system at Latur - SPML

Intregated water management system at Latur - SPML

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

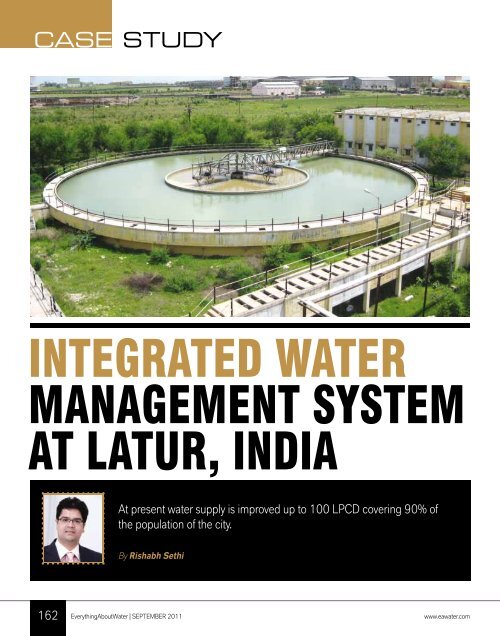

Case StudyL<strong>at</strong>ur, loc<strong>at</strong>ed in the Mar<strong>at</strong>hwada region of Maharashtra is headquarter forL<strong>at</strong>ur district. With an area of 32.56 sq km, it has popul<strong>at</strong>ion of over five Lacpeople which is growing steadily. Being the district headquarters, L<strong>at</strong>ur isan important administr<strong>at</strong>ive centre th<strong>at</strong> houses many regional offices of thest<strong>at</strong>e government. The presence of reputed educ<strong>at</strong>ional institutes coupledwith quality healthcare facilities and infrastructure services makes the city an<strong>at</strong>tractive destin<strong>at</strong>ion. Apart from the resident popul<strong>at</strong>ion, L<strong>at</strong>ur has a flo<strong>at</strong>ingpopul<strong>at</strong>ion of about 25-30 thousands th<strong>at</strong> visit the city everyday for varioustrade and commerce rel<strong>at</strong>ed activities.www.spml.co.inThe ChallengeThe <strong>w<strong>at</strong>er</strong> supply to the L<strong>at</strong>ur city was earlier managed by L<strong>at</strong>ur MunicipalCorpor<strong>at</strong>ion (LMC) and had faced major problems in terms of supplying<strong>w<strong>at</strong>er</strong> to its citizens due to source limit<strong>at</strong>ions and very poor <strong>w<strong>at</strong>er</strong> supplyaccounting. The <strong>w<strong>at</strong>er</strong> supply to the city during the normal season was 75litre per capita daily (LPCD) with availability of <strong>w<strong>at</strong>er</strong> for 1 hour once in 10days to about 70% of the popul<strong>at</strong>ion. During the summer season, the <strong>w<strong>at</strong>er</strong>supply was further reduced to about 40 LPCD and 30 to 40 tankers per daywere engaged to manage shortfall of <strong>w<strong>at</strong>er</strong> supply. The residents were facingextreme <strong>w<strong>at</strong>er</strong> shortage and many times, violence erupted for <strong>w<strong>at</strong>er</strong>. In termsof coverage, about 30% of the popul<strong>at</strong>ion was still not covered by piped<strong>w<strong>at</strong>er</strong> supply. From LMC, the <strong>w<strong>at</strong>er</strong> <strong>management</strong> function was transferred toMaharashtra Jeevan Pradhikaran (MJP) to infuse oper<strong>at</strong>ional improvementsand finance for various capital schemes.L<strong>at</strong>ur W<strong>at</strong>er Supply SystemThe <strong>w<strong>at</strong>er</strong> supply <strong>system</strong> of the city consists of intake works from 3 loc<strong>at</strong>ionsnamely, Sai head works, Nagzari head works and Dhanegaon head works.The Sai head works scheme is loc<strong>at</strong>ed <strong>at</strong> a distance of 8 km from the city andhas weir on the river Manjra. The Nagzari KT weir is loc<strong>at</strong>ed <strong>at</strong> a distance of 12km on the Manjara river and the two sources together can supply about 35MLD <strong>w<strong>at</strong>er</strong> to the city. There has been number of up-grad<strong>at</strong>ion and expansionafter the original scheme by works executed under Stage-II, Part-I (1970) andStage-III (1989) and Stage-IV, Part-II (2001). The 3 rd source Dhanegaon wascommenced in 2005 and is loc<strong>at</strong>ed <strong>at</strong> a distance of 60 km from the city withintake on Manjara Dam. LMC has undertaken a source augment<strong>at</strong>ion projectunder stage V. This scheme involved bulk <strong>w<strong>at</strong>er</strong> transmission over 65 km toaddress the ever increasing demands. There has been rehabilit<strong>at</strong>ion of old<strong>w<strong>at</strong>er</strong> works and distribution <strong>system</strong>s expansion.Distribution and CoverageThe <strong>w<strong>at</strong>er</strong> is processed by three <strong>w<strong>at</strong>er</strong> tre<strong>at</strong>ment plants with an aggreg<strong>at</strong>edesigned capacity of 109 MLD and utilized capacity of 50 MLD (approx).The tre<strong>at</strong>ed <strong>w<strong>at</strong>er</strong> is pumped by six pumping st<strong>at</strong>ions to eleven elev<strong>at</strong>edservice reservoirs (ESRs) loc<strong>at</strong>ed <strong>at</strong> different parts of the city. The capacityof these ESRs put together is 25.50 ML with 12 hours storage. Thedistribution network has 95 km of transmission mains and 476 km ofdistribution lines.www.ea<strong>w<strong>at</strong>er</strong>.comEverythingAboutW<strong>at</strong>er | September 2011163

Case Study<strong>SPML</strong> Role in W<strong>at</strong>er ManagementThrough Maharashtra Jeevan Pradhikaran’s initi<strong>at</strong>ive and open particip<strong>at</strong>ion,<strong>SPML</strong> has undertaken the responsibility of <strong>w<strong>at</strong>er</strong> supply to the city for 10years. A new company in the name of L<strong>at</strong>ur W<strong>at</strong>er Supply ManagementCompany Ltd. was established by <strong>SPML</strong> for the purpose.The main fe<strong>at</strong>ures of the project assigned to <strong>SPML</strong> were: Take over the existing assets from source to tap Carry out oper<strong>at</strong>ions, maintenance and repair of the existing resources Deploy staff for oper<strong>at</strong>ion, maintenance and network expansionincluding key employees on deput<strong>at</strong>ion from MJP and LMC Provide minimum average <strong>w<strong>at</strong>er</strong> supply to residents <strong>at</strong> adequ<strong>at</strong>epressure Ensure daily and pressurized <strong>w<strong>at</strong>er</strong> supplies within contract period Increase the number of new connections Ensure meter install<strong>at</strong>ion to 100% existing connections Collect revenue as cost of <strong>w<strong>at</strong>er</strong> etc. based on the tariffs fixed as per the<strong>management</strong> contract Implement billing and revenue collection <strong>system</strong> Cre<strong>at</strong>e consumer awarenessAfter signing the contract in June 2008 and further taking over the oper<strong>at</strong>ionsand <strong>management</strong>, <strong>SPML</strong> has rapidly changed the entire scenario, conductedsurvey and research and adopted world class technology to manage the<strong>w<strong>at</strong>er</strong> supply to the s<strong>at</strong>isfaction of the residents. At present <strong>w<strong>at</strong>er</strong> supply isimproved up to 100 LPCD covering 90% of the popul<strong>at</strong>ion of the city. The<strong>w<strong>at</strong>er</strong> supply dur<strong>at</strong>ion is improved significantly from one hour once in 10days to altern<strong>at</strong>e days for 3 to 4 hours. With the aim to make <strong>w<strong>at</strong>er</strong> availablefor 24x7 to the 100% of the popul<strong>at</strong>ion, <strong>SPML</strong> has worked relentlesslytowards improving the situ<strong>at</strong>ion. The efforts made in the right direction haveproduced good results.Some of the important initi<strong>at</strong>ives taken by <strong>SPML</strong> are: Implemented modern distribution <strong>management</strong> and reduced lostrevenue Efficient oper<strong>at</strong>ion & maintenance by institutional strengthening,business process and distribution improvement Implemented st<strong>at</strong>e of the art inform<strong>at</strong>ion technology, <strong>management</strong>reporting and audit process Adopted effective utility <strong>management</strong>, cost benefits and sustainablemethodologies Established adequ<strong>at</strong>e infrastructure like zonal offices, billing andcollection centres in all zones, efficient consumer service and complaintredressal, appropri<strong>at</strong>e tariff structure Implemented billing software ‘Aquajal’ for error free billing and‘W<strong>at</strong>ergems’ software for hydraulic analysis Established online billing centers connected with 55 kms OFC cables Used GIS & s<strong>at</strong>ellite images for household identific<strong>at</strong>ion and more than35000 properties has already been identified Used mobile vans for on the spot bill gener<strong>at</strong>ion and collection Established customer care centre with toll free number Conducted energy and <strong>w<strong>at</strong>er</strong> audit and implemented therecommend<strong>at</strong>ion to achieve energy saving and cost reduction Development of District Metered Area (DMA) for active leakage control,utiliz<strong>at</strong>ion of Flow Control Valve (FCV) for regul<strong>at</strong>ing the flow of <strong>w<strong>at</strong>er</strong> Implemented Supervisory Control and D<strong>at</strong>a Acquisition (SCADA) forthe projected achievement of 24x7 <strong>w<strong>at</strong>er</strong> supply <strong>system</strong> 100% metering to achieve reduction in NRW, cost optimiz<strong>at</strong>ion andenhanced revenue collection Conducted consumer awareness programs about the conserv<strong>at</strong>ion,supply, quality and distribution of <strong>w<strong>at</strong>er</strong>.The Results: Better Services and EffectiveControlThe changes brought by <strong>SPML</strong> has resulted in altern<strong>at</strong>e day <strong>w<strong>at</strong>er</strong> supply, amajor achievement for the complete s<strong>at</strong>isfaction of the residents, reductionin non revenue <strong>w<strong>at</strong>er</strong>, almost complete control on <strong>w<strong>at</strong>er</strong> wastage by pipelineand valve replacement and repair and clearing choked lines, improvement inthe quality of <strong>w<strong>at</strong>er</strong> being supplied presently. The use of <strong>SPML</strong>AQUA, an inhousetechnique developed on robust Microsoft technologies pl<strong>at</strong>form andOracle Sp<strong>at</strong>ial D<strong>at</strong>abase, the <strong>system</strong> seamlessly manages the entire gamut ofservices such as billing and CIS, finance <strong>management</strong>, asset <strong>management</strong>,oper<strong>at</strong>ions and maintenance, GIS, asset network <strong>management</strong> and demand<strong>management</strong>.<strong>SPML</strong>AQUA is the only enterprise solution for utilities th<strong>at</strong> has an inbuiltCRM and revenue <strong>management</strong> <strong>system</strong>. The <strong>system</strong> improves the efficiencyof all oper<strong>at</strong>ions and eventually enables <strong>SPML</strong> to take real-time and informeddecisions.Moreover <strong>SPML</strong> has been successful in convincing residents to pay forthe services. Induced awareness in reducing the wastage and moreoveran ownership of the city <strong>w<strong>at</strong>er</strong>. Things have changed as the residents haveunderstood the difference between government run <strong>w<strong>at</strong>er</strong> supply <strong>system</strong>and a professionally run <strong>system</strong>. The people now feel confident to come to<strong>SPML</strong> for their complaints and get immedi<strong>at</strong>e and efficient response, a mostsignificant achievement of <strong>SPML</strong>.About the AuthorRishabh Sethi is Executive Director <strong>at</strong> <strong>SPML</strong> Infra Limited. He is spearheadingbusiness development and project <strong>management</strong> in the company’s <strong>w<strong>at</strong>er</strong> andenvironment verticals. He is credited for establishing a robust IT infrastructure forthe organis<strong>at</strong>ion, including the implement<strong>at</strong>ion of an Enterprise Resource Planning<strong>system</strong> through SAP. New technologies have helped <strong>SPML</strong> optimize costs, enhancedesign and maintain consistent quality conformance. He is also leading thecompany towards a Strong W<strong>at</strong>er & Environment Business in the areas of O&M ofMunicipal W<strong>at</strong>er Systems, Sewage & Effluent Tre<strong>at</strong>ment Plants and Municipal SolidWaste Management. Prior to his current role, he was working with A.T. Kearneyin New York. He is a gradu<strong>at</strong>e in Industrial Engineering and Economics fromNorthwestern University, USA.To know more about the author, you can write to us <strong>at</strong> mayur@ea<strong>w<strong>at</strong>er</strong>.com164 EverythingAboutW<strong>at</strong>er | September 2011 www.ea<strong>w<strong>at</strong>er</strong>.com