Download - English - Hamon

Download - English - Hamon

Download - English - Hamon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

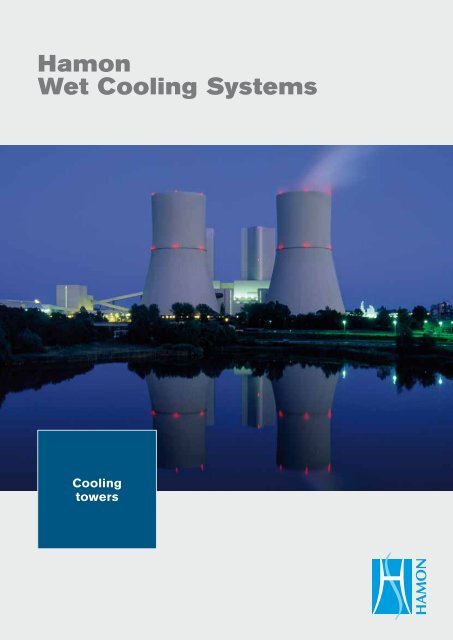

<strong>Hamon</strong>Wet Cooling SystemsCoolingtowers1

Why wet cooling?Wet cooling offers an outstanding performanceby taking full advantage of the ambient airhumidity. Wet cooling, also called evaporativecooling, enables to obtain a re-cooled watertemperature at least 20°C lower as comparedto a radiator. As turbine output and hence powerplant output increases by 0.3 to 1 % per degreeof better cooling, wet cooling is a technologythat can generate outstanding fuel saving andcarbon emission reduction.<strong>Hamon</strong> field ereDoes wet cooling use a lot of water?One to two percent of the water is evaporatedonly. For this reason, a closed loop circuit witha cooling tower needs make-up water from anexternal source (river , lake, sea).The make-up flow depends on the raw water hardnessand is limited to maximum 4% in most cases.The water that is not evaporated is returned tothe external source. During its transit in the coolingsystem, the water is never in contact with anyfluid from the factory process and therefore cannotbe polluted by it.Can a cooling tower be more advantageousthan a once-through sea cooling?As explained on page 10, a case by case economicand impact study should be done for eachcase comparing once-through and closed loopcooling. Conclusion will probably show howcooling tower would be much more attractive!Network<strong>Hamon</strong> Thermal Europe with itsengineering department and R&Dcenter supports a network offactories and sister companies,which locally assure contracting,procurement and field services.<strong>Hamon</strong> offices are based in theUK, Germany, Spain, Italy, Poland,Russia, Spain, Turkey, US, Australia,South Africa, United Arab Emirates,China, India, Korea, Indonesia,Thailand, Vietnam, Brazil,Colombia...<strong>Hamon</strong>: more than 100 years experienceNumerous installations and equipment–more than5400 references–operating world wide in a widerange of industrial plants are evidence of <strong>Hamon</strong>’scapabilities and experience. Whatever the industryyou name, <strong>Hamon</strong> has supplied cooling towersfor it: power plant, refinery and down stream petrochemicalplant, fertiliser, paper industry, steelmill, sugar mill, zinc smelter and other metallurgicalinstallation, chemical plant, etc.OfficeFactory2

cted cooling towers: engineered by expertsOur commitment to the industry<strong>Hamon</strong> Thermal aims at offering the best economicalsolution for the whole lifetime of field erected coolingtowers. <strong>Hamon</strong> cares for most of the industries andits expertise covers: Thermal, hydraulic and structural design Noise and plume abatement as well as otherenvironmental aspects Selection of associated equipment such as:pumps, piping, electrical and instrumentation,water treatment, lighting, etc, Civil work construction and mechanical erection Commissioning, testing and auditing Upgrading, repair and maintenance Dismantling and recycling (also PVC film)Depending on the application requirements, theequipment is designed to customer preferred combinationfor efficiency, long-life expectancy, power savingand respect of environmental local regulations.In order to meet these specifications a wide choiceof solutions is available in layout,arrangement, structure, internals and mechanicalequipment.3

Fan assisted natural draftBest solution when Available plot area and/or height are limited Important heat load variation are expectedIn the seventies and earlyeighties, many large power plantswere built and equipped with tallnatural draft cooling towers(NDCT) in Europe, US, SouthAfrica, India, China, etc.NDCT Refurbishment Restoration or improvement of the CT performance Experienced teams used to work during limited shutdowns Removal and replacement of asbestos cement sheet Recycling and re-use of PVCNowadays, many natural draftcooling tower projects have beenlaunched worldwide as this typeof tower is now regarded asenviron mentally friendly thanksto the power saving that theygenerate.Flue gas dispersion through NDCT Applicable in thermal power plants No large chimney necessary Better flue gas dispersion <strong>Hamon</strong> design4

Natural draft cooling towersBeyond the power saving, NDCT offers thefollowing advantages: limited plot area no mechanical noise (no fan) limited maintenance high longevity (generally more than plant lifeexpectancy)The payback period of an NDCT is 8 to 16 yearsdepending on several factors. The main one is thelocal con struction cost, which may dramatically varyfrom one country to another. <strong>Hamon</strong> can either supplythe turnkey tower or the thermal part with serviceslike civil work design, construction steering,supervision, erection...<strong>Hamon</strong> has designed and built more than 300 NDCTand has a wide experience even for high seismic andsevere weather conditions.<strong>Hamon</strong> is at your disposal to help you developing yourproject any where on the globe, preparing budgetproposal, civil work in cluded, and selecting the mostappropriate solution for perform ance, heat transfermedia, noise reduction, etc.5

Different types of structuresWoodConcreteSteelFRP6

Mechanical draft cooling towersThanks to its flexibility and cost effectiveness, themechanical draft cooling tower (IDCT) ideally answersmost cooling duties and plant requirements.With approximately 5000 references in this type oftower, <strong>Hamon</strong> has come across most of the applicationrequirements and has developed the technologyto meet them. Each customer takes full advantage ofthis technology data base and enjoys a product that isfine tuned and fills his requirements and budget.We build any size of IDCT with any type of structure(steel, wood, FRP, prefab concrete, cast concrete)and many heat exchange surfaces (from splash gridsto high performance film). All system elements, beyondcustomer specific requirements guide our design: water quality air environment (chemicals, dust, ...) noise and plume limitation available plot area local labor costsAll our equipment is supplied with an O&M manualthat clearly specifies operation, maintenance, healthand safety requirements and recommendations.For all cooling towers, we clearly advise the impact onthe environment such as performance, drift loss,noise level, etc. In order to help in the prevention oflegionella, our cooling tower designs follow the bestpractices and allow cleaning and access to theinternal parts of the tower.7

Temperature4030201003110%20%1 Inlet2 Exit wet section - supersaturated air -visible plume3 Exit dry section - heated and dry air4 Exit cooling tower - no saturated airAbsolute humidity440%60%Mixing line80%2100%SaturationPrinciple of plume abatementOutlet air of the wet section ofthe cooling tower B is mixed withthe air heated C by the finnedtube bundles installed in the wallsabove the wet section. Outlet aircharacteristics D will then bepositioned on the line linkingpoints B and C. If the line linkingpoints D and A does not crossthe 100% humidity curve, noplume will be visible.8

Plume abated cooling towersA plume abated cooling tower (PABCT) is the bestavailable solution where local constraints are suchthat the presence of plume is not accepted in normalconditions (along motorways, airports, close to residentialareas...).In this area, also called hybrid or wet/dry, <strong>Hamon</strong>’stechnology is unrivaled.Mechanical DraftThe first option is an IDCT offering the same flexibility,adaptability and all features listed in the previous pages.Compared to other technical solutions, it combinesthe following advantages: no plume visibility outstanding performance of an evaporative coolingtower cost attractivenessFan Assisted Natural Draft (Circular Hybrid)Circular hybrid cooling towers are the best technicalsolutions for large heat loads and stringent plumeabatement requirements. It combines the followingadvantages among others: compact arrangement / space saving limited height use of natural draft strong upward draft no washdown9

Sea waterWhen close to the sea shore, many plants arecooled by a once-through sea water system.The investment for such a system is huge and theheat rejection back to the sea can either generatehot water recirculation and/or impact the seaecosystem beyond acceptable levels. Replacingthe once-through system by a cool ing tower circuittremendously reduces both initial investmentcosts and sea environmental impact of the powerplant. The design of the cooling tower will take,among others, the salt concentration into account.Special care is given to construction materials(structure in concrete, protection for mechanicalparts, etc.) and fill media type. <strong>Hamon</strong> sea watercooling towers are cooling millions of cubic metersin many places in the world. All designarrangements are available with sea water:NDCT, FANDCT, IDCT, PACT.Emergency cooling tower for NPP’sThe safe cooling of the nuclear island is a mustbecause this is the ultimate heat discharge in theprocess.<strong>Hamon</strong> has been closely involved in the developmentof emergency cooling towers and has already deliveredseveral ones.For new applications HAMON recommends in generalEmergency Cooling Towers being built of small cellular modules in reinforcedconcrete with forced draft fans with up to 4-foldredundancy with water storage of minimum 2 days which consider the applicable hazards and aredesigned for extreme climate conditions which integrate in the housing the additionalequipment like pumps, piping, valves, electrical, etc. almost completely built of non flammableconstruction materialsFor existing plants, the technical solution must bedeveloped according to the actual needs and situation.10

Special applicationsNoise attenuationIn order to limit the noise level, actions can be takenat three level: at the source with low noise fans and mechanicaldevices at the emission area with louvers, baffles,motor enclosures, special casing type between the noise source and the reception pointwith screens, walls or embankmentsCooling towers for acid solutions<strong>Hamon</strong> has developed cooling solutions for low pHwaters. Forced draft has been selected for easy accessand maintenance.District coolingWorking on broadly similar principles to district heating,district cooling delivers chilled water to buildings.For this application widely spread in the Gulf area,<strong>Hamon</strong> has already supplied more than 150 cells.Architectural cooling towersCooling towers can be adapted to an architecturalproject for a better integration in the environment.11

AB<strong>Hamon</strong> has a wide range of heattransfer media suitable for: any industrial water sea water low pH solution TSE (treated sewage effluent)CDEFG

Heat transfer mediaThe GOLDENGRIDS A, the real splash fill, is theall purpose solution suitable for most water qualities,including sea water and heavily contaminated water.This heat transfer media consists of trays hung frombeams located above the water distribution. The grids,their supports and spacers are made of polypropylene;the wires according to the water aggressiveness arein SS316 or in a more exotic alloy.The TRICKLEFILL B offers what is probably thehighest resistance to scaling and fouling worldwide.Using <strong>Hamon</strong>’s well proven technology of non-contactsheets, this vertical core fill is designed with widesheet spacing. The sheets are smooth and incorporatea number of large square holes. The holes inducebeneficial turbulence for heat transfer, whilst no foulingor scaling occurs on the supports.The strips (resulting from perforation) make this packact partly like a grid type. Therefore it is an excellentalternative to “mesh” or “3D grids”. It can be producedPVC and PP.The MESH type C fill combines splash and film heatexchange process with the advantages of low foulingcapability of the splash fill and the good thermalefficiency of the film fill. It is well adapted to any inducedor natural draft cooling tower using poor industrial waterquality. Water with high concentrations of suspendedfibres is not recommended.The COOLFREE D is the most advanced film fillcombining low-fouling and low-scaling properties whilstretaining good thermal performance. The mainapplication is for cooling towers using very poor waterquality, in some cases even without water treatment.It is also very good for film fill cross-flow coolingtowers.The CLEANFLOW E film fill has been qualifiedworldwide as the best film fill combining low foulingproperties with good thermal performance. It is welladapted to any induced draft or natural draft coolingtower using poor quality industrial water. It is alsosuitable for other severe applications such aslaminated decanting and gas cleaning.The CLEANFLOW PLUS F is the improved technologyof the cleanflow fill by increasing its thermalperform ance whilst retaining its fouling resistance.It is well adapted to any induced or natural draft coolingtower using poor industrial water quality, in particularsea water.The COOLFILM G is probably the most thermallyefficient fill worldwide. It is well adapted to anyinduced draft or natural draft cooling tower usingnormal industrial water quality.13

1 Fan stack2 Motor-fan groupSpare Parts<strong>Hamon</strong> design and manufacture their own products(fan stacks, heat exchange media, drift eliminators,distribution elements). The Spares Parts Departmentof <strong>Hamon</strong> Cooling Systems division will help all clientsselect the appropriate part for any <strong>Hamon</strong> coolingtower or from other manufacturers.123 Drift eliminators344 Distribution55 Heat exchange media14

ServiceMaintenanceA preventive maintenance program is essential toensure smooth operation avoiding unexpected costlyshut downs and problems associated with legionella.Repair – Refurbishment – UpgradeFurthermore, for several reasons (ageing tower,increased power need, technical improvements, etc.)other works are required during the life time of thecooling tower.Thanks to the outstanding cooling tower competenceof its site teams, <strong>Hamon</strong> can consider any type ofrepairs, refurbishment and upgrades.Customers recognize <strong>Hamon</strong> for its finely tunedservice assuring: short shutdowns reliable diagnosis focus on the action neededOur test team consisting of high level, experiencedthermal Engineers can perform any test:performance, fan flow, hydraulic, noise, vibrations.15

<strong>Hamon</strong> Thermal Europe (Be)Belgium+32 10 39 05 00info.hteb@hamon.com<strong>Hamon</strong> Thermal Europe (Fr)France+33 1 55 87 78 78info.htef@hamon.com<strong>Hamon</strong> Thermal GermanyGermany+49 234 93550info.htg@hamon.com<strong>Hamon</strong> Thermal Europe (It)Italy+39 2 39325888info.htei@hamon.comEsindusSpain+34 91 767 09 66esindus@esindus.es<strong>Hamon</strong> Thermal EuropeRussia+7 812 313 51 11info.htefru@hamon.com<strong>Hamon</strong> TermalTurkey+90 232 4463877info.htcs@hamon.com<strong>Hamon</strong> UKUnited Kingdom+44 1482 787 767info.huk@hamon.com<strong>Hamon</strong> South AfricaSouth Africa+27 11 394 30 10info@hamon.co.za<strong>Hamon</strong> do BrasilBrazil+55 11 3326 9955comercial@hamon.com.br<strong>Hamon</strong> Esindus LatinoamericaChile+56 2 520 9515info@hamonesindus.com<strong>Hamon</strong> Middle EastKingdom of Bahrain+973 1751 8709info.hme@hamon.com<strong>Hamon</strong> Cooling TowerCompany (FZCO)United Arab Emirates+971 4 609 16 75info.hctc@hamon.com<strong>Hamon</strong> Shriram CottrellIndia+91 22 6150 6700info.hther@hamon.com<strong>Hamon</strong> Thermal (Tianjin)China+86 10 8426 0988chinainfo@rc-drycooling.com<strong>Hamon</strong> IndonesiaIndonesia+62 21 758 80080 - 90info.hindo@hamon.com<strong>Hamon</strong> KoreaSouth Korea+82 2 3473 1284info@hamonkorea.com<strong>Hamon</strong>-B. GrimmThailand+66 2 710 3372-6info.hbg@hamon.com<strong>Hamon</strong> VietnamVietnam+84 4 39 343 960info.vietnam@hamon.com<strong>Hamon</strong> AustraliaAustralia+61 2 9467 0600info.ha@hamon.comThe <strong>Hamon</strong> Group is a world player in engineering and contracting(design, installation and project management).Its activities include the design, the manufacturing of critical components,the installation and the after-sale services of cooling systems, process heatexchangers, air pollution control (APC) systems, HRSG’s and chimneys,used in power generation, oil & gas and other heavy industries like metallurgy,glass, chemicals.www.hamon.com201306 [01]16Integrated Solutions for a Clean Environment