Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

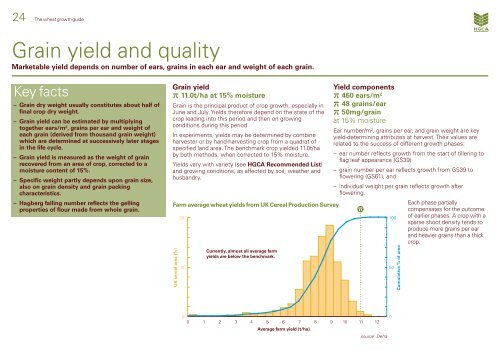

24 The wheat growth guide<strong>Grain</strong> <strong>yield</strong> <strong>and</strong> <strong>quality</strong>Marketable <strong>yield</strong> depends on number of ears, grains in each ear <strong>and</strong> weight of each grain.Key facts– <strong>Grain</strong> dry weight usually constitutes about half offinal crop dry weight.– <strong>Grain</strong> <strong>yield</strong> can be estimated by multiplyingtogether ears/m 2 , grains per ear <strong>and</strong> weight ofeach grain (derived from thous<strong>and</strong> grain weight)which are determined at successively later stagesin the life cycle.– <strong>Grain</strong> <strong>yield</strong> is measured as the weight of grainrecovered from an area of crop, corrected to amoisture content of 15%.– Specific weight partly depends upon grain size,also on grain density <strong>and</strong> grain packingcharacteristics.– Hagberg falling number reflects the gellingproperties of flour made from whole grain.<strong>Grain</strong> <strong>yield</strong>11.0t/ha at 15% moisture<strong>Grain</strong> is the principal product of crop growth, especially inJune <strong>and</strong> July. Yields therefore depend on the state of thecrop leading into this period <strong>and</strong> then on growingconditions during this period.In experiments, <strong>yield</strong>s may be determined by combineharvester or by h<strong>and</strong>-harvesting crop from a quadrat ofspecified l<strong>and</strong> area. The benchmark crop <strong>yield</strong>ed 11.0t/haby both methods, when corrected to 15% moisture.Yields vary with variety (see <strong>HGCA</strong> Recommended List)<strong>and</strong> growing conditions, as affected by soil, weather <strong>and</strong>husb<strong>and</strong>ry.Farm average wheat <strong>yield</strong>s from UK Cereal Production SurveyUK cereal area (%)2010Currently, almost all average farm<strong>yield</strong>s are below the benchmark.Yield components460 ears/m 248 grains/ear50mg/grainat 15% moistureEar number/m 2 , grains per ear, <strong>and</strong> grain weight are key<strong>yield</strong>-determining attributes at harvest. Their values arerelated to the success of different growth phases:– ear number reflects growth from the start of tillering toflag leaf appearance (GS39)– grain number per ear reflects growth from GS39 toflowering (GS61), <strong>and</strong>– individual weight per grain reflects growth afterflowering.Each phase partiallycompensates for the outcome100 of earlier phases. A crop with asparse shoot density tends toproduce more grains per ear<strong>and</strong> heavier grains than a thickcrop.50Cumulative % of area000 1 2 3 4 5 6 7 8 9 10 11 12Average farm <strong>yield</strong> (t/ha)source: Defra

25 The wheat growth guide <strong>Grain</strong> <strong>yield</strong> <strong>and</strong> <strong>quality</strong>Final distribution of dry matter18.4t/ha dry matter with51% Harvest IndexHarvest Index is the ratio between grain <strong>yield</strong> on a drybasis <strong>and</strong> the total crop dry weight at harvest. This ratio isvariable.Final dry matter distributionChaff2.1t/haLeaves <strong>and</strong> deadshoots 2.1t/haStructural stem5.7t/ha<strong>Grain</strong>9.4t/haSoluble stemreserves 0.2t/haThe benchmark dry matter of the harvest-ripe crop is18.4t/ha, of which 9.4t/ha is grain (equivalent to 11.0t/haat 15% moisture).The remaining 9.0t/ha of dry matter includes straw, chaff<strong>and</strong> stubble, but only about half of this can be baled asstraw, even when the height of the combine cut is low.Much variability in crop dry weight comes through variableproduction of non-harvestable material. Plant breedershave been most successful in increasing harvest index;growers have been most successful in increasing totalcrop dry matter.Specific weight78kg/hlCrops with a large grain weight tend to have high specificweight. This is also influenced by:– the density of individual grains– the range of grain sizes– characteristics of grain surfaces that affect packing.Specific weight indicates the weight of grain that can beloaded onto lorries or ships. A typical requirement formilling or export is 76kg/hl; samples below this st<strong>and</strong>ardare likely to incur price penalties or even exclusion fromthe intended market. Late harvesting can reduce specificweight through weathering.Hagberg falling number270Hagberg falling number is a measure of the hot pasteviscosity of a wholemeal water suspension. The minimumvalue possible is 60.Values required:– above 250 for breadmaking– above 225 for export.Lower viscosity results from starch breakdown by theenzyme alpha-amylase. This may form during or afterripening.Enzyme activity is mainly associated with initiation ofgermination, <strong>and</strong> hence with sprouting. Alpha-amylasemay also form in cool, wet weather during ripening, evenin the absence of visible sprouting. Green grains on latetillers, or grains damaged by orange blossom midge alsohave high alpha-amylase.Effects of husb<strong>and</strong>ry on Hagberg falling number tend to besmall <strong>and</strong> inconsistent compared to the effects of variety<strong>and</strong> weather.Varietal differences in specific weight, dormancy <strong>and</strong>Hagberg falling number are indicated in the <strong>HGCA</strong>Recommended List. Group 1 wheats generally are classedas ‘very high’.What does it mean?By GS91 management can only protect against losses of<strong>yield</strong> or <strong>quality</strong>. Depending on intended market <strong>and</strong> likelyrisks, consider:– combining as soon as the crop is ripe– assessing Hagberg falling number pre-harvest onh<strong>and</strong>-threshed, air-dried grain– harvesting at high moisture to optimise chances ofhigh Hagbergs.