MOS 2200 - SAM Electronics GmbH

MOS 2200 - SAM Electronics GmbH

MOS 2200 - SAM Electronics GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

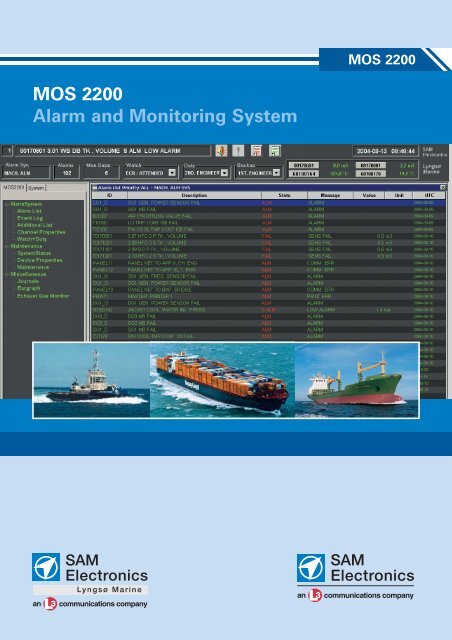

<strong>MOS</strong> <strong>2200</strong><br />

Alarm and Monitoring System<br />

<strong>MOS</strong> <strong>2200</strong>

<strong>MOS</strong> <strong>2200</strong> Overview of Components & Features<br />

Main Benefits of <strong>MOS</strong> <strong>2200</strong><br />

Cost Efficient<br />

■ Placing near the process<br />

reduces cabling<br />

■ Unmanned machinery<br />

notation saves labor costs<br />

■ Self-diagnostic features<br />

improve crew maintenance<br />

■ Integration of engineer<br />

calling system/dead-man-<br />

alarm system and fire<br />

alarm indication reduces<br />

total cost<br />

Flexible<br />

■ Free mix of signals and<br />

functions<br />

■ Open platform for interfacing<br />

to external systems<br />

■ Modular design enables<br />

easy adaption/extension<br />

■ Cargo alarm system<br />

whether as integrated or<br />

stand-alone solution<br />

<strong>MOS</strong> <strong>2200</strong><br />

Alarm and Monitoring System<br />

User-Friendly<br />

■ Fast access to information<br />

anywhere on the ship<br />

■ Unified user interface on all<br />

devices<br />

■ Windows® oriented user<br />

interface on operator<br />

workstations<br />

Safe and Reliable<br />

■ Use of class approved<br />

equipment and functions<br />

■ High level of redundancy<br />

■ Hardware developed especially<br />

for marine applications<br />

System Operating Display (SOD) Reporting<br />

Windows® Oriented Display of:<br />

Alarm Lists<br />

Alarm Groups<br />

Graphical Trends<br />

Bar Graphs<br />

Main Engine Exhaust Gas Temperature Deviation<br />

Advanced Self-Diagnostic Features<br />

Alarm and Monitoring<br />

The <strong>MOS</strong> <strong>2200</strong> is especially designed<br />

to meet the high demands of marine<br />

applications. It is approved as a<br />

■ Machinery alarm system for all kinds<br />

of vessels and<br />

■ Integrated or stand-alone cargo<br />

alarm system for tankers.<br />

Basic System Setup<br />

The <strong>MOS</strong> <strong>2200</strong> is divided into four<br />

levels<br />

■ Outstation<br />

■ Reporting<br />

■ Duty alarm system<br />

■ Operator workstation<br />

The outstation level consists of a<br />

number of cabinets for collecting and<br />

processing of data from the process<br />

they are monitoring. For logging<br />

functions an alarm and event printer<br />

is connected.<br />

The duty alarm system provides<br />

operator panels in engine or cargo<br />

control room from where alarms can<br />

be viewed and acknowledged.<br />

In addition a bridge panel can be added<br />

for transfer of watch station.<br />

Alarm & Event Printers for:<br />

Logging of All Alarms<br />

Logging of All Events<br />

Journal Printer for:<br />

User-Defined Manual Printouts<br />

Pre-Defined Cyclical Printouts<br />

Graphical Trend Printouts

The Standardized and<br />

Cost Efficient Solution<br />

In order to transfer unacknowledged<br />

alarms to engineers on duty further<br />

panels are placed in the accommodation<br />

area and public spaces.<br />

For more convenient operation the<br />

system can be extended with System<br />

Operating Displays (SOD). Based on<br />

standard PC-hardware these enable<br />

the display of alarms and sensor<br />

parameters in a Windows® oriented<br />

user interface. The system is operated<br />

via keyboard and trackball.<br />

To each SOD a printer can be connected<br />

for printing of reports, like pre-defined<br />

data logs (journals) and selected manual<br />

printouts.<br />

The <strong>MOS</strong> <strong>2200</strong> is based on the standard<br />

hard- and software platform of the<br />

<strong>2200</strong> Automation series.<br />

Duty Alarm System Field Processing Device (FPD)<br />

Duty/Back-up Selection<br />

Alarm Announcement/Acknowledgement<br />

Assist Call (Engineer Calling System)<br />

Integrated Dead Man Alarm System<br />

System Adjustments<br />

Self Diagnostic Features<br />

Redundant Communication Network<br />

Redundant System Net<br />

<strong>MOS</strong> <strong>2200</strong> –<br />

Overview of Components, Location & Features<br />

Redundant Alarm Net<br />

Engine Room<br />

Area<br />

System Operating<br />

Displays (SOD)<br />

Reporting<br />

Duty Alarm System<br />

Engine Control Room<br />

Cargo Conrol Room<br />

Alarm and Event<br />

Printer<br />

ECR/CCR<br />

Panel<br />

Outstations<br />

Field Processing Device (FPD)<br />

FPD<br />

LOP<br />

I/OS<br />

FPD<br />

LOP<br />

I/OS<br />

FPD<br />

I/OS<br />

Accommodation/<br />

Public Spaces<br />

Accommodation<br />

Panel<br />

Independent Units<br />

Free Mix of 200 Digital and Analog I/Os per FPD<br />

Free Distribution of FPD close to the process<br />

Redundant Communication Networks<br />

Local Information access via LOP<br />

Connection to External Systems<br />

Integrated 24V DC UPS<br />

Wheelhouse<br />

Console<br />

Journal<br />

Printer<br />

Bridge<br />

Panel<br />

Connection to External Systems<br />

- Voyage Data Recorder<br />

-Tank Level System<br />

- Light Columns<br />

-Loading Calculator<br />

-Maintenance System<br />

- etc.

<strong>MOS</strong> <strong>2200</strong><br />

Competence in Automation<br />

Lyngsø Marine A/S and <strong>SAM</strong> <strong>Electronics</strong><br />

Automation Division are among the<br />

world’s major suppliers of marine equipment<br />

with a long tradition in ship automation<br />

starting from the very beginning<br />

of ship-based computer technology in<br />

the 1950‘s.<br />

Starting with a cooperation we have<br />

achieved true PartnerShip. In the process<br />

we have successfully merged our<br />

worldwide activities in<br />

■ Sales<br />

■ R&D and<br />

■ Service<br />

based on a harmonized product portfolio<br />

and a common product family.<br />

Choose the Automation Specialists –<br />

Lyngsø Marine and <strong>SAM</strong> <strong>Electronics</strong><br />

Lyngsø Marine A/S<br />

2, Lyngsø Allé<br />

2970 Hørsholm . Denmark<br />

Phone: +45 45 16 62 00<br />

Fax: +45 45 16 62 62<br />

info@lyngsoe.com<br />

www.lyngsoe.com<br />

As a result our PartnerShip offers a<br />

wide range of cutting-edge automation<br />

solutions designed and produced with<br />

the aim of providing optimal<br />

■ Cost efficiency<br />

■ User-friendly operation<br />

■ Flexibility<br />

■ Reliability<br />

■ Safety<br />

All this is backed by<br />

■ A worldwide service organisation<br />

■ Regional competence centers.<br />

Our more than 10.000 installations<br />

worldwide are your guarantee for<br />

proven systems with unrivalled performance<br />

–- all over the world for all kinds<br />

of vessels.<br />

<strong>SAM</strong> <strong>Electronics</strong> <strong>GmbH</strong><br />

Automation, Navigation and Communication<br />

Behringstrasse 120<br />

22763 Hamburg . Germany<br />

Phone: +49 40 88 25 24 84<br />

Fax: +49 40 88 25 41 16<br />

Automation@sam-electronics.de<br />

www.sam-electronics.de<br />

Printed in Germany · Technical alterations reserved · DS 2.013.07/2007