Material Handling Equipment - Industrial and Systems Engineering

Material Handling Equipment - Industrial and Systems Engineering

Material Handling Equipment - Industrial and Systems Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

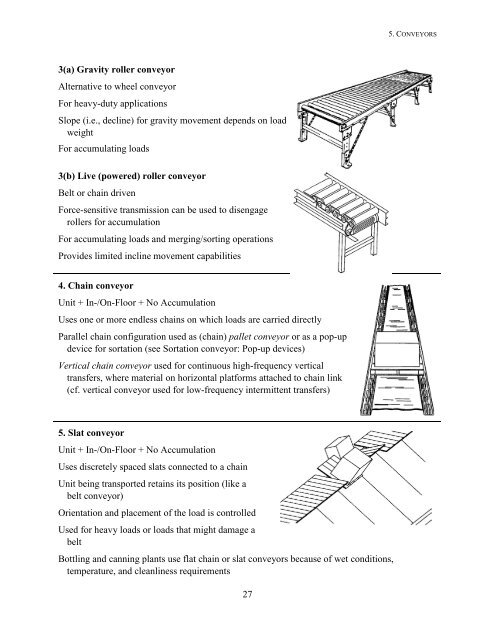

5. CONVEYORS3(a) Gravity roller conveyorAlternative to wheel conveyorFor heavy-duty applicationsSlope (i.e., decline) for gravity movement depends on loadweightFor accumulating loads3(b) Live (powered) roller conveyorBelt or chain drivenForce-sensitive transmission can be used to disengagerollers for accumulationFor accumulating loads <strong>and</strong> merging/sorting operationsProvides limited incline movement capabilities4. Chain conveyorUnit + In-/On-Floor + No AccumulationUses one or more endless chains on which loads are carried directlyParallel chain configuration used as (chain) pallet conveyor or as a pop-updevice for sortation (see Sortation conveyor: Pop-up devices)Vertical chain conveyor used for continuous high-frequency verticaltransfers, where material on horizontal platforms attached to chain link(cf. vertical conveyor used for low-frequency intermittent transfers)5. Slat conveyorUnit + In-/On-Floor + No AccumulationUses discretely spaced slats connected to a chainUnit being transported retains its position (like abelt conveyor)Orientation <strong>and</strong> placement of the load is controlledUsed for heavy loads or loads that might damage abeltBottling <strong>and</strong> canning plants use flat chain or slat conveyors because of wet conditions,temperature, <strong>and</strong> cleanliness requirements27