Agro-Tech Book - Agriculture Support Programme

Agro-Tech Book - Agriculture Support Programme

Agro-Tech Book - Agriculture Support Programme

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

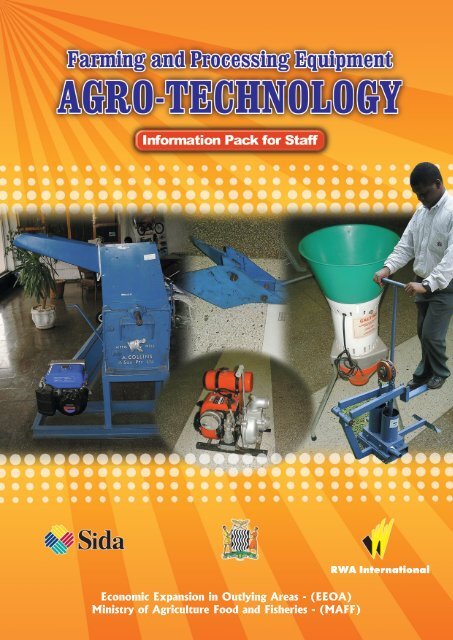

Economic Expansion in Outlying Areas - (EEOA)<br />

Ministry of <strong>Agriculture</strong> Food and Fisheries - (MAFF)<br />

RWA International

2<br />

The Economic Expansion in Outlying Areas (EEOA) <strong>Programme</strong> is<br />

funded by Sida/Sweden and implemented by RWA International,<br />

United Kingdom in association with Terra Nova AB, Sweden and Moses<br />

Banda & Company, Zambia on the basis of a contract with the Ministry<br />

of <strong>Agriculture</strong>, Food & Fisheries, Zambia.<br />

This publication is one of a series of extension materials commissioned<br />

by EEOA and prepared by Mano/Arulussa. Other topics included in<br />

this series are: Farming Systems; Maize; Groundnuts; Beans; Sweet<br />

Potatoes, Tomatoes, Sunflower, Marketing and <strong>Agro</strong>-Processing.<br />

Copies of these publications may be obtained from:<br />

The National Coordinator, EEOA, P.O. Box 50181 RW Lusaka, Zambia<br />

Telephone: ##260-1-253523; Fax: 253532; e-mail: eeoa@zamnet.zm<br />

or<br />

E.E.O.A.<br />

RWA International, Beckets House, 34 Market Place, Ripon,<br />

North Yorkshire, HG4 1BZ, UK.<br />

Telephone: ##44 -1765-600455; Fax: 600344;<br />

e-mail: rwaripon@rwainternational.com<br />

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any<br />

form or by any means without the prior permission of the copyright owner.<br />

© EEOA Box 50181 RW, Lusaka, Zambia<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment

Farming and Processing Equipment<br />

AGRO-TECHNOLOGY<br />

In this Information Pack some of the equipment that can be used for ploughing, cultivation,<br />

irrigation and processing is discussed. At the end there is a list summarising the equipment<br />

and showing where it can be bought.<br />

Irrigation Equipment<br />

Irrigation can be done in many different ways depending on where the water comes from,<br />

how the land is shaped, what sort of power is used and how much money is spent.<br />

If the water comes in a stream and can be diverted into a furrow, so that it �ows above<br />

the crop, then it can be directed into the �eld and used in “FLOOD” irrigation. This is the<br />

cheapest way to irrigate but it can be done only when the water can be put into a furrow<br />

above the crop. It is wasteful of water, particularly in sandy soils.<br />

If the water cannot be diverted to �ow by gravity above the crop then it must be pumped.<br />

It can then be diverted to the crops by furrows. Or, it can be pumped into a tank from which<br />

it can �ow to the crops by pipe, or directly to a basin dug around the crops. This is called<br />

a “HOSE AND BASIN” system. Such a system does not require pressure except to reach<br />

the tank.<br />

A “PIDDLE” system is one in which holes are drilled in pipes so that the water comes out<br />

next to the plants. It can be fed from a pump or a tank and does not waste the water. Such<br />

a system can cost $150 per hectare without the pump.<br />

A “DRIP” system has smaller outlets for the water by each planting station so that the<br />

water drips into the soil and wets only a small area at the surface so that weeds do not grow<br />

and there is little evaporation. The system requires a low pressure of 1 atmosphere (1 bar or<br />

15psi) and provides the most ef�cient use of water. Drum kits or bucket systems are drip<br />

lines attached to a drum or bucket that must be �lled to distribute the water to the plants.<br />

Drip lines cost about US$ 900 per ha. depending on the interrow spacing. Where drip lines<br />

are used with very low pressure, such as from a drum elevated only 2-3 metres, the drip<br />

lines must not be longer than 20m.<br />

E.E.O.A.<br />

“MICRO-JET” sprinkler systems give better distribution of water to the root zone but allow<br />

more weeds to grow. They are more expensive than drip and require a pressure of only 1<br />

atmosphere. They will cost about US$ 1,000 per ha.<br />

“SPRINKLERS” are more expensive to buy but fewer are required per hectare. They can<br />

be spaced up to 18 metres apart and require a pressure of at least 2.5 atmospheres at<br />

the sprinkler nozzle to work properly. The sprinklers are supplied from a pressurised<br />

pipe, usually aluminium (prone to theft!), thin walled galvanized iron (relatively heavy) or<br />

polyethylene/ aluminium combinations. The pipes and sprinklers are moved at regular<br />

intervals; e.g. every 8 hrs where the irrigation rate is 6mm of water/hr. This combination is<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

3

fairly common in Zambia and applies 50mm water every week.<br />

PUMPS<br />

There are many different kinds of pumps, some are operated by human power, others by<br />

wind power and others by diesel, petrol or electric motors.<br />

Human powered pumps<br />

“DIAPHRAGM PUMPS” are made in Zambia using wood, and small amounts of metal with<br />

rubber/plastic parts. They are operated by a handle and can be used for low-lift situations.<br />

They cost US$117 and are available from TDAU at the University of Zambia.<br />

“TREADLE PUMPS” are operated by standing on one peddle and then the other alternately.<br />

There are models for high lift and others for low lift. High lift models do not pump as much<br />

water per step as low lift, so the height to which water is to be pumped is important in<br />

choosing a pump. Check how much pipe is supplied with the pump. A non-collapsible suction<br />

pipe is needed and a delivery pipe which can be collapsible.<br />

Pumps cannot suck water more than about 6 metres no matter how strong the operator is.<br />

The suction side of a pump is always more problematical than the delivery side because small<br />

leaks allow air to enter, which prevents the water from entering the pump. The pump should<br />

always be as close as possible to the water to avoid these problems.<br />

When dirt is allowed to enter the pump it will cause damage and stop the pump from working<br />

well. Make sure that the suction pipe does not pull<br />

mud, sand and dirt into the pump. It is best to<br />

have a foot valve with a sieve to protect the pump<br />

and keep it primed when not in use.<br />

Treadle pumps need to be pumped for 2 to 4 hours<br />

per day twice a week for one tenth of a lima of<br />

crop, depending on the maturity of the crop and<br />

the weather.<br />

ZEEOA HPRESS TREADLE PUMP<br />

4<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment

A “DEEP WELL PUMP” is a means of raising water from a well using rubber washers on a rope<br />

in a pipe. Turning the handle at the top of the well causes the rope with washers on it to<br />

pass up the pipe lifting the water with it. The out�ow can be diverted into a furrow. Do not<br />

try to put the water into a pipe on the surface since no pressure can be generated by this<br />

kind of pump at the outlet.<br />

The pump can deliver about 5,000 litres per hour to a head of 4 metres.<br />

Wind powered pumps - windmills<br />

Windmills cost around US$2,500 and will pump from a borehole or a well. They must be<br />

placed where there is enough wind and they will pump only when there is wind, so they should<br />

deliver into a tank so as to catch the water by night as well as by day. It is advisable to �t<br />

them with a manually operated handle to pump even small amounts of water to keep seedlings<br />

alive when there is calm weather.<br />

A large windmill could irrigate up to 5 hectares if it is well placed for wind and water<br />

source.<br />

Windmills can be damaged by high winds in storms and so should be “locked” to prevent<br />

rotation during storms.<br />

Motorised pumps<br />

Pumps with engines are usually “centrifugal” pumps using one or more “impellers” that spin<br />

very fast to give pressure. There are also “mono” pumps for boreholes that operate on a<br />

screw principle forcing water upwards through a pipe.<br />

There are many different speci�cations for these pumps so farmers must to describe to<br />

the sales agent what the needs are exactly in order to have the correct kind provided. The<br />

agent will need to know:<br />

the amount of money available to purchase the equipment<br />

the size of the area to be irrigated<br />

the type of soil (sandy-clay)<br />

the elevation of the top of the water supply in relation to the elevation of the �eld<br />

the �ow rate of the supply<br />

the topography (contours/slopes) of the �eld<br />

the range (rotations!) of crops to be grown<br />

the availability (and distances) of ZESCO<br />

E.E.O.A.<br />

When a competent agent has all the above information, he can make sensible proposals to<br />

the farmer who can then select a design which will suit him best. He can decide what kind<br />

of irrigation system is to be used. Will it be �ood or drip or sprinkler because the different<br />

pressure requirements will dictate what kind of pump is needed.<br />

Standard pumps with petrol or diesel engines are useful for �ood irrigation or �lling tanks.<br />

Check with neighbours to �nd their experience of pumps and see what is available in your<br />

area. All pumps require spares so it is important that there is an agent nearby.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

5

OX-Drawn Equipment<br />

ZEEOA PETROL PUMP<br />

Ploughs, rippers, cultivators, ridgers and planters.<br />

Ox drawn ploughs are all very similar although some are heavier and stronger than others<br />

are. They all need to have new “points” with nuts and bolts for �xing to the share as the<br />

share points become worn out with use. Ploughs have different sizes of shares ranging from<br />

8 inches (200mm) to 12 inches (300mm), depending on how deep you want to plough. The<br />

ploughing depth usually depends on how heavy the soil is. Heavier ploughs can plough more<br />

deeply but will require strong oxen or even more than two to pull them.<br />

Ploughs should be used with caution as their repeated use causes destruction of the land!<br />

ZEEOA PLOUGH<br />

The Magoye “Ripper”<br />

E.E.O.A.<br />

This is really a furrowing tool which is bolted onto most standard plough beams. It was<br />

developed in Zambia and is one of the best agricultural inventions from this region. It is<br />

particularly suited for “Conservation Tillage” where only the planting furrow is subject to<br />

deep cultivation. In lighter (sandy) soils it can be used in the dry season, even though more<br />

6<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment

than one “pass´may be required to achieve an acceptable depth. The furrows are made only<br />

at the chosen crop row spacing (usually from 70-90cm) and the interrow is NOT ploughed.<br />

Cultivators and ridgers are then used to control weeds and build up ridges around the crop.<br />

Where farmers use the Magoye Ripper they can “dry plant” before the rains or make a<br />

planting furrow in even heavy soil immediately after the �rst rains. A strong pair of well<br />

trained oxen in one day can “rip” suf�cient furrows to plant a hectare. The yield losses due<br />

to the customary delays in planting have been well documented as costing the farmer the<br />

equivalent of 50kg of maize/ha for each day late after the �rst planting rain!!<br />

Wing Extension attachments for the Magoye Ripper can serve as ef�cient weeding and<br />

ridging accessories<br />

Ridging Bodies can be attached to most ploughs. Check what attachments are available for<br />

the plough you choose. There are also b attachments available though the technology has<br />

not yet been fully proven in the �eld.<br />

ZEEOA RIPPER<br />

Planters that can be pulled by oxen are also available. These allow for faster planting and<br />

fertilser application so long as they are operating properly. Check that they can plant the<br />

seed that you want to use. Sometimes different planter plates have to be bought to allow<br />

certain seeds to be planted.<br />

ZEEOA SEED PLANTER<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

7

Cultivators should be adjustable to cover more or less of the inter-row space according to<br />

which crop is grown and how mature it is when the cultivator is used. Hiller blades can be<br />

attached to outer tines to cover the weeds in the crop lines.<br />

Processing equipment<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

ZEEOA CULTIVATOR OR<br />

CULTIVATOR 2<br />

Lifters are attachments with<br />

a blade for under-cutting<br />

groundnuts so they can be easily<br />

separated from the soil.<br />

Oil expellers<br />

Machines for expelling oil from sun�ower, groundnuts or sesame can be operated by hand.<br />

Screw presses have greater capacity but need electric or diesel motors and are more<br />

expensive to operate and therefore can be justi�ed only when a large amount of seed can<br />

be bought and a large market for oil exists.<br />

A comparison of costs is attached.<br />

Ram Press and Oil Press 2<br />

8

Shellers<br />

There are many devices used for shelling maize from simple hand held collars for one cob<br />

at a time to motorised machines which can shell several tons per hour. Some machines can<br />

also shell groundnuts and some will shell only groundnuts. Do not buy machines with a higher<br />

capacity than you need unless you think the business will de�nitely expand.<br />

A comparison of the prices and capacity of available machines is attached.<br />

Mills<br />

There are hand-operated mills and motorised mills. Do not forget the cost of maintenance<br />

of machinery and specially of diesel engines if thinking about buying a motorised mill.<br />

ELECT MILL<br />

HIPPO MILL<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

9

SUNFLOWER PROCESSING<br />

Introduction<br />

Processing Sun�ower oil provides a good opportunity for increasing income from Sun�ower<br />

production.<br />

Between 10-18 litres of oil can be expressed from 50kgs of clean seed. As a rule of thumb,<br />

Improved varieties and hybrids should yield at least 15 kgs of oil.<br />

Many farmers, particularly in Eastern and Central Provinces operate the Yenga hand press<br />

to express and sell oil locally. These farmers express oil from their own sun�ower and that<br />

of farmers who have grown the crop, usually in exchange for the cake which is a valuable<br />

stock feed.<br />

press<br />

The Yenga Press<br />

The Yenga Press is operated by hand and can be pro�table if there is a supply of good seed<br />

and a reliable market for the oil.<br />

Before investing in a Yenga press, farmers should check out the availability and price<br />

of commercially and locally expressed cooking oil being sold by traders and marketeers.<br />

E.E.O.A.<br />

They should also �nd out whether many other farmers are expressing oil and have already<br />

satis�ed local demand. A good local supply of clean improved seed with a high oil content is<br />

essential.<br />

Farmers investing in a Yenga press should therefore consider growing their own Sun�ower<br />

to ensure they have adequate supplies. Africare provides a detailed owner’s manual for the<br />

Yenga Press and any farmer considering investing in a press should obtain this lea�et to �nd<br />

out what is involved.<br />

Important facts about operating the press:<br />

* It takes 5-7 hours to press 50 kgs of seed. A reasonable average from clean soft-shelled<br />

seed of improved varieties is 12 litres of oil from each 50kg bag.<br />

10<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment

* Dirt, dust and all waste matter must be removed from the seed by winnowing it. Dirt<br />

particles will wear out the piston. If seed from other farmers is being purchased for<br />

expelling, it should be carefully checked �rst. Some local varieties have a very low oil<br />

content and hard shells. A good test is to see how much oil can be expressed from a 5 litre<br />

tin of seed. Seed with acceptable oil yield will 1/2 �ll a 750ml saladi bottle and good seed<br />

will 3/4 �ll it.<br />

* It is best for 2 people to work the press. One prepares the seed and the second operates<br />

the press. Before pressing seed should be warmed in the sun for 15 minutes as this will<br />

increase the extraction rate. If there is no sun the seed can be warmed over a �re in a �at<br />

metal container. Seed should be warm to touch and not hot or burnt.<br />

* The press should be properly set before operation commences, and as regularly as<br />

required, by adjusting the restrictor. The press should only be operated by 1 person and the<br />

handle should be moved up and down smoothly.<br />

* The press should be lubricated twice a week with clari�ed oil and should be cleaned each<br />

time 10 bags has been crushed. Boiling water is poured over the cage cylinder, and then<br />

scrubbed with a brush. A knife is then used to remove residues caught between the cage<br />

bars and the cage is rinsed again with boiling water.<br />

* Oil coming out of the press will be grey. Oil can be clari�ed by allowing it to settle for 72<br />

hours. The particles settle and the clear oil is carefully decanted off. This is the best and<br />

most simple method of clari�cation.<br />

• Simple daily records should be kept of:<br />

• the amount of seed bought; from whom and how much paid (or contractually committed)<br />

• the amount of seed crushed<br />

• the source of the seed<br />

• the quantity of oil (and colour)<br />

• the labour used (cost)<br />

• the quantity of oil sold – and income (credit or cash or barter)<br />

• quantity of cake produced<br />

E.E.O.A.<br />

• the quantity of cake sold – and income (credit or cash or barter)<br />

• Balances of Seed; oil; cake; cash<br />

• Any problems and what action taken<br />

The Sundhara Press, available from Jung & Co Kitwe ( tel 02 212851; 02 210476) extracts<br />

18 litres of oil from 50 kgs of hybrid seed and is run by a 10 hp diesel or electric motor.<br />

The expeller costs $5,150 ( 3 phase electric motor) and has an output of 200 litres of crude<br />

oil a day. The screw worm wears out after 50-70 tons of sun�ower has been expelled. This<br />

reduces extraction rates and the worms then have to be re-faced by the manufacturer.<br />

Operators should have 2 spare worms so processing is not delayed during re-facing.<br />

The business is really only suited to entrepreneurs who have large retail outlets and who<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

11

are used to operating machinery. Electric motors are cheaper and more ef�cient than diesel<br />

engines for providing power.<br />

Cake<br />

Cake is the remainder of the seed after it has been crushed and the oil extracted. It still<br />

contains small amounts of oil and is a valuable feed for animals. It can be broken into small<br />

particles and fed to chickens or mixed with meal and fed to pigs and cattle. Meal is valuable<br />

and can be sold to other farmers.<br />

SUNFLOWER PROCESSING BUDGETS<br />

Cost of running the press.<br />

The cost of buying the machine is the biggest hurdle in running an oil pressing business.<br />

The cost of the press must be covered by sales of oil before the press stops working from<br />

being too old. A Yenga should be able to process 15 tons (300 bags) of sun�ower in its life.<br />

If the owner has borrowed money to buy the press, and is paying interest, it should be paid<br />

off as soon as possible. Here we assume that no money was borrowed.<br />

If the press costs K540,000, and processes 15 tons before it is useless, it means that<br />

K1,800 (15TX20bags=300bags --– K540,000/300=K1,800) is needed from each bag to pay<br />

for the press.<br />

It also costs money to keep it maintained and repaired. This may be K75 per bag.<br />

The running cost of the press is then K1,875 per bag without counting interest.<br />

Interest may be 60% per year and if we assume the life of the machine is 2 years, then the<br />

interest payable will be approximately 60% if repayments are spread over the 2 years. This<br />

would amount to (0.6X540,000)=K324,000<br />

Thus, the cost of interest, per bag processed = K1,080 --- (324,000/300= 1,080)<br />

In addition the owner may be paying a worker to operate the press. This may be K3,000 per<br />

day during which one bag can be processed.<br />

Therefore the cost of operating the press to process one 50 kg bag will be K5,955<br />

(1,800+75+1080+3000=5,955)<br />

Cost of the seed<br />

E.E.O.A.<br />

A press owner may process his own seed or buy it from someone else; either way it has a<br />

cost. It will be cheaper at harvest than later in the year and may range from K15,000 to<br />

more than K25,000. Assuming that it cost K20,000 per bag the total cost of processing the<br />

oil and cake will be it will now be K25,955 --- (20,000+5,955)<br />

How much oil will be produced?<br />

The Yenga press is not as ef�cient as a mechanical screw press at extracting oil and the oil<br />

content of the seed is also variable. You can expect about 10 to 13 litres (13 to 17 bottles<br />

of 750 mls) from a bag of seed.<br />

The sale of this oil must cover the cost of processing the bag.<br />

12<br />

• If 13 bottles are produced for sale, then the selling price per bottle must be at least<br />

(zero pro�t) K1,996.54 (K25,955/13 bottles)<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment

• If 15 bottles are produced for sale, then the selling price per bottle must be at least<br />

(zero pro�t) K1,730.33 (K25,955/15 bottles)<br />

• If 17 bottles are produced for sale, then the selling price per bottle must be at least<br />

(zero pro�t) K1,526.76 (K25,955/17 bottles)<br />

Oil sales<br />

The price of oil will change through the year depending on the cost of seed, the amount of<br />

oil that others are trying to sell and the amount of money that customers have.<br />

At a selling price of K2,700 per bottle, a bag producing 15 bottles, will produce K40,500<br />

worth of oil and therefore give a margin of K14,545 (40,500-25,955) per bag.<br />

The margin is K969.67 per bottle (K14,545/15 bottles)<br />

Value of Cake<br />

The cake is very valuable provided there is a market! Cake can be valued at K400/kg and<br />

as approximately 30Kg are produced per 50kg of Sun�ower processed, the value of cake<br />

from one bag of seed can be K12,000 (30kgXK400).<br />

If the processor can sell his cake for K12,000 per bag processed, the total gross pro�t<br />

jumps to K26,545 (14,545+12,000).<br />

It is therefore most important to secure a regular market for the cake!!!<br />

Riskiness<br />

The business has its risks as explained above.<br />

The level of pro�t will depend on:<br />

• The selling price of the oil (who pays for the bottle? -- customers exchange bottles!)<br />

• The price paid for the seed delivered to the press<br />

• The extraction rate i.e. the number of bottles of saleable oil produced per bag<br />

• The amount paid for operating labour<br />

• The selling price of the cake – there may be no local market so the owner may have to<br />

transport the cake at a cost, or feed it to livestock!<br />

E.E.O.A.<br />

If we assume zero selling price for the cake, the 15 bottles of oil must sell for over K1,730<br />

per bottle in order to make a pro�t if seed is bought at K20,000 per bag. If oil is sold at<br />

K2,000 per bottle and only 13 bottles are produced, no more than K20,045 (13 bottlesX<br />

K2,000 – K5,955) must be paid for each 50kg of seed<br />

Keeping Records<br />

Make sure that press owners keep records so that they know if they are making or losing<br />

money.<br />

Make a cost and sales sheet like the form attached to keep records on.<br />

Examples of costs and returns are shown in the tables below.<br />

Oil Press Costs and Returns<br />

Press Owner’s name: Bwalya Mulenga Press type:Yenga<br />

Price paid:K540,000 Date purchased: 31 st February 2006 from Mafuta<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

13

A - Cost of maintenance:<br />

Date Operation Cost Accum Cost<br />

1 st<br />

2 nd<br />

Etc.<br />

B - Cost of repairs<br />

Date Operation Cost Accum Cost<br />

1 st<br />

2 nd<br />

Etc.<br />

C - Monthly Processing Record for month of _____________2001<br />

Date Names of Workers Kwacha Bags Litres Accum Accum<br />

Cost pressed Oil Bags Litres<br />

1 st<br />

2 nd<br />

etc<br />

(Kwacha “cost” can be what is “paid “ to workers or, total cost e.g. to include food, leave pay<br />

etc. or, to include the value of family labour)<br />

D - Monthly Seed Movement for month of ________2001<br />

E.E.O.A.<br />

Opening balance ___ bags. Opening value K_______ Average Opening value/bag K_______<br />

Date Bags Bags Bought from Cost Total Balance Balance Average<br />

Pressed Bought per Cost Value (bags) Value of<br />

Today Today bag of Seed Seed<br />

1 st<br />

2 nd<br />

etc<br />

31 st NB No1 – include owner produced S/F seed as “sales” from farm to the “business”<br />

14<br />

No. 2 - check totals and arithmetic!<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment

E - Monthly Oil Movement for month of ________2001<br />

Opening balance ____ litres =____ bottles.<br />

Date Bottles Bottles Total Value of Accum. Accum. Average<br />

produced Sold Bottles today’s Bottles Sales Value bottle price<br />

Stock sales sold<br />

1 st<br />

2 nd<br />

etc<br />

F - Monthly Cake Movement for month of ________2001<br />

Opening balance ____ Kg.<br />

Date Kgs Kgs Total Value of Accum. Accum. Average<br />

produced Sold Kgs today’s Kgs Sales Value price per Kg<br />

Stock sales sold<br />

1 st<br />

2 nd<br />

etc<br />

CALCULATION OF MARGIN<br />

The margin for the period is the difference between: the “value of sales plus stocks at<br />

the end of the period” and, the “operating costs plus purchases plus value of stocks at the<br />

beginning of the period”.<br />

CALCULATION OF MARGIN USING MONTHLY RECORDS<br />

(considering “July” as an example)<br />

E.E.O.A.<br />

Start with Oil Sales during the month (from Table “E” Accumulative sales value at end of<br />

month minus accumulative sales value at beginning of month - assume K720,600)<br />

K720,600<br />

ADD Cake Sales during the month (from Table “F” Accumulative sales value at end of<br />

month minus accumulative sales value at beginning of month - assume K298,600)<br />

K298,600<br />

ADD<br />

Value of oil stocks (from Table “E” = the total bottles remaining unsold in stock at the end<br />

of the month). (assume 42 bottles at the most recent selling price per bottle, say K2,800=<br />

K117,600)<br />

K117,600<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

15

ADD<br />

Value of seed stocks (from table “D” = the balance of bags at the end of the month). (assume<br />

12 bags at the most recent buying price, say K26,500 = K318,000)<br />

K318,000<br />

ADD<br />

Value of cake stocks (from table “F” = total kgs stock at the end of the month).<br />

(assume 120kgs at the most recent selling price, sayK400 = K48,000)<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

K48,000<br />

K720,600+K298,600+K117,600+K318,000+K48,000 = K1,502,800<br />

(consider this �gure as “x”)<br />

Now,<br />

SUBTRACT from “x”, the closing stock Balances for the previous month (= opening balances<br />

for present month; e.g. when calculating for July, the opening balance at beginning of July<br />

is equal to the closing balance at the end of June). Use Tables C,D,E & F (consider K154,800<br />

for calculation purposes)<br />

K1,502,800 – K154,800= K1,348,000<br />

NOW, SUBTRACT the following purchases and operating costs:<br />

Total Purchases in month (from Table “D”) – (assume K620,000) – K620,000<br />

Total Maintenance in month (from Table “A”) – (assume K26,200) – K 26,200<br />

Total Repairs in month (from Table “B”) - (assume K34,200) - K 34,200<br />

Total Labour cost in month (from Table “C”) - (assume K230,500) - K230,500<br />

K1,348,000-K910,900 = K437,100 (the “MARGIN”)<br />

Sub total = K910,900<br />

Each month take the margin away from the cost of the press and see how much is still<br />

remaining to cover the cost of it.<br />

When all the monthly margins have covered the full cost of the press, you are making real<br />

pro�t.<br />

16<br />

SAVE UP TO BUY A NEW ONE!

HAMMER MILL PROCESSING and COSTS<br />

Introduction<br />

Processing maize into Roller Meal provides a good opportunity for increasing income from<br />

maize production and from other people’s maize.<br />

Roller meal is the product obtained when whole maize grain is milled by any process. “Breakfast<br />

Meal” is the product obtained from maize after most of the germ and seed coat has<br />

been removed. This process requires a more sophisticated machine or set of machines.<br />

There are roller mills on the market which can produce a product very similar to commercial<br />

breakfast meal but they cost much more than a “Hammer Mill” and require a high standard<br />

of management for successful operation.<br />

The hammer mill is a simple robust machine which consists of a set of “hammers” which are<br />

attached to a steel shaft which rotates very fast so that it smashes the maize grains. The<br />

smashed pieces then pass through a “screen” or sieve. Eventually all the maize is smashed<br />

suf�ciently that all of it is able to pass through the screen. These particles after passing<br />

through the screen are called “roller meal”.<br />

Roller meal is more nutritious than breakfast meal as a signi�cant part of the protein and<br />

minerals is removed as “maize bran” during the processing of breakfast meal.<br />

DESIGNS of HAMMER MILLS<br />

Most hammer mills are based on the same simple principle – maize is fed into a chamber in<br />

which a row (or rows) of hammers rotate at approximately 3,600 rpm. This requires a motor<br />

of 5.6 kilowatt or 7.5 horse power (HP) for a throughput of 200kg/hr. The motor can be<br />

fuel driven – usually diesel (D), or electrically powered (E) which is cheaper to buy and to<br />

operate.<br />

Common hammer mill sizes and capacities are;<br />

OUTPUT MOTOR SIZE Litres of diesel/hr Cost of Mill($)<br />

200kg/hr 7.5HP 1.3 2,111(E); 2,328(D)<br />

E.E.O.A.<br />

400kg/hr 15-16HP 2.6 2,715(E); 5,563(D)<br />

600-700kg/hr 25HP 6.1 3,700(E);7,100(D)<br />

DECIDING TO BUY and OPERATE A HAMMER MILL<br />

The �rst consideration is: “is there suf�cient market?” This entails looking at the “competition”,<br />

the population and their ability/willingness to buy roller meal or milling services and<br />

for how much of the year. Normally it is not worthwhile buying maize, transporting it to the<br />

mill, processing it and then transporting any signi�cant distance to market.<br />

The next decision is the size (capacity of the mill) – this will depend on the expected market<br />

demand. The choice of motors is the next decision – electric motors are cheaper but there<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment 17

may not be any ZESCO near the site for the mill.<br />

The mill will require a secure and rainproof room and it is advisable to have an adjacent<br />

rainproof store for storage of maize, meal, sacks, spares – fuel should be kept in the mill<br />

room to avoid it tainting the maize.<br />

SITING of the MILL<br />

The operator needs to consider the following when choosing a site for the mill:<br />

18<br />

Drainage during the rainy season<br />

Security – near the owner’s house?<br />

Accessibility by the customers and vehicles<br />

ZESCO supply<br />

COSTS OF OPERATING A HAMMER MILL<br />

CAPITAL COSTS<br />

Purchase of the Mill – this is the biggest expenditure and the operator should allow for:<br />

Transport to the site<br />

Installation e.g. concrete base<br />

Exhaust pipe<br />

Raised platform for easy loading of the mill<br />

Electrical installation ( a 3 phase supply would be necessary)– cables; switches and<br />

starter (may or may not be included in price and should have “protection” for Zesco<br />

power �uctuations)<br />

Buildings for the mill and storage facilities – these are variable and allowance should be<br />

made for construction, repair or rental<br />

OPERATING COSTS<br />

E.E.O.A.<br />

These comprise: fuel (or ZESCO charges); service parts; spares; maintenance charges;<br />

labour and sacks<br />

Fuel see the table above for fuel consumption (this will deteriorate with age)<br />

Engine oil allow for 15ml/hr<br />

Filters change the diesel and oil �lters after every 250 hours of operation – allow<br />

$29/change<br />

Change the air cleaner elements after every 500 hours – allow $55<br />

Change the hydraulic oil �lters after every 1,000 hours – allow $102<br />

Belts allow for $11/2,000hrs or every year (NB always change ALL the belts)<br />

Labour allow for a team of 2 people<br />

Mill Screens allow for $15/1,000hrs<br />

Sieving Screen ( for cleaning maize before milling) allow $50/2,000hrs<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment

OPERATING BUDGET<br />

This will be considered per hour of operation for a 400kg/hr mill using a diesel engine<br />

Note that the 400kg �gure is for a constant �ow of maize. In practice, a �gure of 300 kg/hr<br />

of product is a reasonable output and the following calculations are based on 300kg/hr:<br />

The costs are calculated in $US so that costs in Kwacha can be derived by converting at the<br />

current exchange rate.<br />

COST OF PROCESSING 300KG OF MAIZE (1 HOUR OF OPERATING)<br />

USING A DIESEL POWERED ENGINE<br />

$US<br />

Capital cost depreciated over 10,000 hrs ($5,563/10,000) 0.5563<br />

Cost of building dep.over 10,000 hrs ($1,600/10,000) 0.16<br />

Diesel (2.6litres @ 0.9$/l) 2.34<br />

Engine oil (.015litres@$3/l) 0.045<br />

Filters – diesel and oil ($29/250hrs) 0.1303<br />

- air cleaner elements ($55/500hrs) 0.11<br />

- hydraulic oil �lters ($102/1,000hrs) 0.102<br />

Belts ($11/2000hrs) 0.0055<br />

Labour ( 2 workers @ $1.5 each/7hrs working day) 0.4286<br />

Screens ($15/1,000hrs) 0.015<br />

Sieving screen ($50/2,000hrs) 0.025<br />

Total cost for 300kg = $3.9177 = $0.01306/kg = $0.235/Tin of 18kg<br />

At a Kwacha/dollar exchange rate of 3,500 this is K822=50<br />

KEEPING RECORDS and CONTROL!<br />

This is WITHOUT any PROFIT!!!<br />

E.E.O.A.<br />

A Daily Log Sheet is presented overleaf.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment 19

BUNGA ENTERPRISES DAILY CONTROL SHEET<br />

For: Weekday_ / /02 Sign. of Supervisor@____hrsam Sign. of Supervisor@____hrspm<br />

STOCK CONTROL<br />

MAIZE brought forward from yeaterday ____ kgs@K__Kg =K_______<br />

Add: ___kgs from___________ (Inv No--) total cost =K ______<br />

Add: ___kgs from___________ (Receipt No--) total cost =K ______<br />

Add: ___kgs from___________ (Inv No--) total cost =K ______<br />

Add: ___kgs from___________ (Credit sale No--) total cost =K ______<br />

Sub total(A)_____kgs Sub total (B) =K_______<br />

Subtract ____Kgs processed @K____/kg =K_______<br />

Subtract ____Kgs processed @K____/kg =K_______<br />

Subtract ____Kgs sold @K____/kg =K_______<br />

Subtract ____Kgs sold @K____/kg =K _______<br />

Sub total(C) _____Kgs Sub total (D) =K_______<br />

CLOSING BALANCES= ________Kg(=A-C) __________ K (=B-D)<br />

MEAL brought forward from yeaterday ____ kgs@K__/Kg =K_______<br />

Add: ___kgs processed___________ (Inv No--) total value =K ______<br />

Add: ___kgs processed___________ (Inv No--) total value =K ______<br />

Add: ___kgs processed___________ (Inv No--) total value =K ______<br />

Add: ___kgs processed___________ (Inv No--) total value =K ______<br />

Sub total(A)_____kgs Sub total(B) =K_______<br />

Subtract ____Kgs sold @K____/kg =K_______<br />

Subtract ____Kgs processed @K____/kg processed =K_______<br />

Subtract ____Kgs sold @K____/kg =K_______<br />

20<br />

E.E.O.A.<br />

Subtract ____Kgs processed @K____/kg processed =K_______<br />

Subtract ____Kgs sold @K____/kg =K _______<br />

Sub total(C) _____Kgs Sub total(D) =K_______<br />

CLOSING BALANCES= ________Kg (=A-C) K__________ (=B-D)<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment

Hrs �nish_______<br />

Hrs start_______<br />

BUNGA ENTERPRISES DAILY OPERATIONS RECORD<br />

For: Weekday_ / /01 Sign of Supervisor____@___hrsam Sign of Supervisor____@___hrspm<br />

Next service (changing_______________________________) due on ___/__<br />

Engine oil checked by ______ @_____hrs; ___litres oil added<br />

Belts, screen checked and nipples greased by_______ @_____htrs<br />

Hrs<br />

used<br />

OPERATION<br />

___kgs/client<br />

Receipt/Inv<br />

Ref No<br />

Litres fuel<br />

Added/by:<br />

E.E.O.A.<br />

Kgs of maize milled=________ Kg(E) - Fuel used to �ll up= ______litres(F)<br />

Total hrs = _____ (G) Total fuel used in day =________(H)<br />

Fuel consumption/hr for the day =____L(H/G) – Kgs per l fuel=___ Kgs(E/H)<br />

Supervisors comments<br />

Breakdowns<br />

Service<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment 21

<strong>Agro</strong>-<strong>Tech</strong> Equipment Suppliers<br />

22<br />

Category Item Make or Model Price * Power source Regular spares Weight Dimensions Capacity Life Supplier<br />

Guide (K) Kg LxWxH. mm Expectancy<br />

Irrigation<br />

Manpowered Treadle Pump River Pump ( Sams) 195,000 Treadle Valve rubbers 20-25 1000x350 3,300 l/hr 5-10yrs. Internatinal Development<br />

Enterprises<br />

Treadle Pump Pressure Pump ( Saro) 275,000 Treadle Valve rubbers 30-35 1000x255-356 3,000 l/hr 5-7yrs. Internatinal Development<br />

Enterprises<br />

Treadle Pump Modified Pump ( Sams) 195,000 Treadle Valve rubbers 15-20 1000x255-356 3,300 l/hr 5yrs. Internatinal Development<br />

Enterprises<br />

Deep well pump Forcelift Manual Rubber Cups and 1400x1200x1000 5,000 l/hr 4 years TDAU<br />

Nylon ropes<br />

Deep well pump Forcelift Manual Rubber Cups and 1200x300x1300 3,000 l/hr 3-4yrs Aqua<strong>Agro</strong> Ltd.<br />

Nylon ropes<br />

Diaphragm pump TDAU Manual Inner tube 1500x350x1000 3,000 l/hr 5 years TDAU<br />

Drip Irrigation- Drum Kit ID-Drip system- 155,000 Manual None 100-120 sqr. Mts. 5yrs. Internatinal Development<br />

(Southn Africa) Enterprises<br />

Drip Irrigation-Bucket Kit ID-Drip system Manual None 104 plants 5yrs. Internatinal Development<br />

(South Africa) Enterprises<br />

Deep Well Hand Pump India MarkII Manual Repair Kit 15kg 1600x400x1400 .5lts/stroke 5-6yrs Aqua<strong>Agro</strong> Ltd.<br />

and Valves<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

Bucket Kit Bucket Kit Manual 104 plants/fill 3-4yrs Aqua<strong>Agro</strong> Ltd.<br />

Cultivation<br />

Rippers Magoye Ripper 150,000 Animal Tines, Separators, 15 2000x800x1000 0.15-0.25ha/h 4-5yrs Saro Engineering<br />

Wheels, Nuts<br />

Ripper attachment to plough Saswaz 75,000 Animal Tines, Separators, 400x450x300 0.15-0.25ha/h 3-4yrs Saswaz<br />

Wheels, Nuts<br />

Magoye Ripper Sams 65,000 Animal Tines, Separators, 10 2000x1200x1199 .15-.25ha/h 4-5yrs Sams Co-op. Society<br />

Wheels, Nuts<br />

Ploughs Ploughing- Double Board Zimbambwe 720,000 Animal Shears and Nuts 120 2000x1200x1200 0.1-0.2ha/h 10yrs Handymans Paradise<br />

Plough MDM 350,000 Animal Shears and Nuts 25 1800x800x1200 0.05-0.1ha/h 5-7yrs MDM Engineering Co.<br />

Plough Saswaz 286,000 Animal Shears and Nuts 20-25 1800x800x1201 0.05-0.1ha/h 5-7yrs Saswaz<br />

Ridger Plough Zim 1,340,000 Animal Shears and Nuts 40-45 1800x800x1202 0.15-0.25ha/h 5-7yrs ZCF<br />

Plough Zim 345,000 Animal Shears and Nuts 40 1800x800x1203 0.05-0.1ha/h 5-7yrs ZCF

<strong>Agro</strong>-<strong>Tech</strong> Equipment Suppliers<br />

Category Item Make or Model Price * Power source Regular spares Weight Dimensions Capacity Life Supplier<br />

Guide (K) Kg LxWxH. mm Expectancy<br />

Ploughs Ridger-attachment only Saswaz 72,000 Animal Shears and Nuts 40-45 400x450x300 5-7yrs Saswaz<br />

Harrows Zig-zag Harrow-Clearing MDM 395,000 Animal Harrow Spikes 20 2000x1000x200 0.5-1ha/h 3-5yrs MDM Engineering Co.<br />

Cultivator- Weeding MDM 420,000 Animal Harrow Spikes 30 2000x900x1000 0.10-0.20ha/h 3-5yrs MDM Engineering Co.<br />

Zig-zag Harrow-Clearing Saswaz 176,000 Animal Harrow Spikes 20 2000x1000x200 0.5-1ha/h 10yrs Saswaz<br />

Cultivator- Weeding Saswaz 300,000 Animal Harrow Spikes 30 2000x900x1000 0.3-0.5ha/h 7yrs Saswaz<br />

Cultivation<br />

Planters Planter/Fertiliser Applicator Zim 2,952,000 Manual/Animal Shears,Nuts 20-25 2000x600x800 10kgfert/8kg seed 5-7yrs ZCF<br />

and wheels<br />

Planter/Fertiliser Applicator Zim 520,000 Animal Shears,Nuts 20-25 2000x600x801 10kgfert/8kg seed 5-7yrs Handymans Paradise<br />

and wheels<br />

Planter / attachment Saswaz 227,000 Animal Shears and Nuts 25-30 600x700x800 8-10kg Seed 5yrs Saswaz<br />

Lifters Groundnut Lifters Saro 550,000 Animal Sheni <strong>Agriculture</strong> Supplies<br />

Processing<br />

Oil expellers Ram Press Saro 672,000 Manual Piston 20 500x250x800 15lts/50kg-s/flower 2-4yrs Saro Engineering<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment 23<br />

Yenga Press Yenga ( Sams) 650,000 Manual Restrictor 30-35 280x1650x450 100-150kg/day 3-5yrs Sheni <strong>Agriculture</strong> Supplies<br />

Oil Expeller Sams 9,000,000 Manual Worm screws 1500kg/day 5-7yrs. Sheni <strong>Agriculture</strong> Supplies<br />

Yenga Press Saswaz 520,000 Manual Barrels and Piston 30-35 280x1650x450 10kg/h 3-5yrs Saswaz<br />

Oil Expeller Zim 3,188,000 Manual Worm screws 5-7yrs. ZCF<br />

Oil Expeller Chinese 3,240,000 Electrical Belt, Shaft Bars, 140Kg. 998x520x660 1 tonne/24hrs. 5-7yrs. Camco Equipment<br />

Rings<br />

Oil Expeller Chinese 6,288,000 Electrical or Diesel Worm screws 140 660x520x998 50kg./h 10yrs AFE<br />

Shellers “crocodile” Maize Sheller Crocodile- (Saro) Manual None 10 200x100x350 20kg/h 4yrs Saro Engineering<br />

Maize sheller Sams 1,800,000 Manual Sieves 68kg 1400x860x500 200kg/h-output 4yrs Sams Co-op. Society

<strong>Agro</strong>-<strong>Tech</strong> Equipment Suppliers<br />

24<br />

Category Item Make or Model Price * Power source Regular spares Weight Dimensions Capacity Life Supplier<br />

Guide (K) Kg LxWxH. mm Expectancy<br />

Shellers Maize shelller Zim 2,392,000 Manual Sieves 60-70 250kg/h 5yrs ZCF<br />

Dehuller Turning and Metals 4,000,000 Diesel and Electrical Bearings, 450kg/h 5yrs Turning and Metals Ltd.<br />

Sieve and Filters<br />

Dehuller-Maize, Rice Sams 5,000,000 Electrical or Diesel Bearings, 145 1180x1460x930 200kg/h 5-7yrs Sams Co-op. Society<br />

and Sorghum Sieve and Filters<br />

Groundnut sheller Saro 620,000 Manual Seives and 40 600x300x700 300kg/h 5yrs. Saro Engineering<br />

Hammers<br />

Groundnut sheller Saro 950,000 Manual Seives and 39 600x300x699 300kg/h 5yrs Sheni <strong>Agriculture</strong> Supplies<br />

Hammers<br />

Groungnut sheller Sams 1,800,000 Manual Seives and 60 1320x570x600 60-85kg/h- 5yrs Sams Co-op. Society<br />

Hammers Output<br />

Maize and Rice Dehuller Kalonthoho 3,900,000 Diesel Bearings, Sieve 120 800Wx1000 H 380Kg./h 5-8yrs. Kalontho Engineering<br />

and Filters<br />

Rice and Maize Dehuller Saro 13,000,000 Electrical or Diesel Bearings, Sieve 400-500kg/h 5-7yrs Sheni <strong>Agriculture</strong> Supplies<br />

and Filters<br />

Mills Grinding Mill 400,000 Manual Hammers 100kg/h 5yrs ZCF<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

Hand Grinding Mill Tamsa 2,116,000 Manual Roter and Starter 80 1200x750x1500 70kg./h 10yrs AFE<br />

Mills Domestic Mill Tamsa 1,200,000 Electrical Bar sieves 10 1000 high and 70kg./h 2-3yrs. AFE<br />

300 diametre<br />

Hammermill Sams Electrical Hammers and screens 5 400 Diametre 2-3yrs. Saro Engineering<br />

x1000high<br />

Hammermill Turning and Metals 4,800,000 Diesel or Electrical Filters and Various Variuoss 605kg/h 5yrs Turning and Metals Ltd.<br />

Hammers<br />

Maize Mill Saro 11,000,000 Diesel or Electrical Filter 1000high and 70kg./h 5yrs Sheni <strong>Agriculture</strong> Supplies<br />

300 diametre<br />

Hammermill Yamaha EHM300 16,096,000 Petrol Hammers 250 1200x500x1600 700kg/h 5yrs. Power Equipment<br />

and screens<br />

Peanut Butter Machine Tamsa Electrical 70kg 530x2602x800 25kg./h 4-5yrs AFE<br />

*Note: Prices can change at any time. These prices are approximate and assume an exchange rate of K4,000 to US$1.00.

<strong>Agro</strong>-<strong>Tech</strong> Equipment Suppliers - Branches<br />

Organisation Branch/ Outlet Town Province Comment<br />

AFE (African Farming Equipment) AFE Lusaka Lusaka Several outlets available in major districts of Zambia<br />

AFE Kabwe Central<br />

AFE Chipata Eastern<br />

Sams (Small-Scale Agric Mech Services) Sheni <strong>Agriculture</strong> Chipata Eastern Equipment Manufactured by Sams in Lusaka<br />

Brother Willys Petauke Eastern<br />

Bodmas Stores Sinda Eastern<br />

Sun Enterprises Katete Eastern<br />

Nyimba Farmers Association Nyimba Eastern<br />

Burley Farms Kabwe/ Mkushi Central<br />

M&D Enterprises Kapiri Mposhi Central<br />

Imatongo Marketing Senanga Western<br />

Kalabo Rice Promotion Kalabo Westerrn<br />

Mongu Nutrition Group Mongu Western<br />

Makondu Rural Development Trust Zambezi North Western<br />

Kabompo Farmers Association Kabompo North Western<br />

Saswaz AfriCare field offices act as Outlets for Saswaz Saswaz is an Association of small-scale rural workshop owners/ relailers<br />

Aqua<strong>Agro</strong> Industrial Equipment Kitwe Copperbelt<br />

Handyman’s Paradise Handymans- Cha Cha Cha Rd. Lusaka Lusaka<br />

Handymans- Lumumba Rd. Lusaka Lusaka<br />

Handymans-Freedom Way Lusaka Lusaka<br />

Handymans- Northmead Lusaka Lusaka<br />

Handymans Ndola Copperbelt<br />

ZCF- Farmers Shop ZCF Lusaka Lusaka<br />

ZCF Mumbwa Central<br />

ZCF Kabwe Central<br />

International Development Enterprise IDE- Kapiri Kapiri Mposhi Central IDE has trained manufactures in Lusaka, Chipata, Mufulira<br />

and Kafue.<br />

IDE-Choma Choma Southern Among the major manufacturers are SAMS, Saro, Knight<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment 25<br />

Engineering, Chokwadi and Mailo.<br />

IDE-Petauke Petauke Eastern<br />

IDE-Chipata Chipata Eastern<br />

IDE-Monze Monze Southern<br />

Saro Engineering Lutanda Kitwe C/bvelt<br />

Sheni Chipata Eastern<br />

Vandoma L/stone Southern

<strong>Agro</strong>-<strong>Tech</strong> Equipment Suppliers - Addresses<br />

26<br />

Supplier Physical Address Postal Address Town Tel. Fax<br />

AFE Freedom Way, South End Box 31505 Lusaka 228995-8 223361<br />

Aqua<strong>Agro</strong> Ltd. Plot. 3134, Buyantanshi Rd, Heavy Industrial Area. Box 30457 Lusaka 244477 244464<br />

Camco Equipment Sentor Motors, Great North Road Box 39558 Lusaka 254799/ 702668 254799<br />

Handymans Paradise Freedom Way, City Centre Box 33518 Lusaka 224663/236181 225617<br />

Internatinal Development Enterprises Plot.211 Belvedere House, Katunjila Rd. Box 350040 Lusaka 223590 237685<br />

Kalontho Engineering Plot. 1541, kafulafuta Rd., Kitwe Box 22301, Kitwe 02-214106/224048 217168<br />

MDM Engineering Co. 1566, Miseshi Rd, Heavy Industrial Area Box 21997 Lusaka 214126 214146<br />

Power Equipment North End, Cairo Rd. Box 32699 Lusaka 228035-8 235021<br />

Sams Co-op. Society TBZ Building, Mungwi Rd- Opp. BP Private Bag.W47 Lusaka 233229 233229<br />

Saro Engineering Plot.8617,Los Angeles Rd. Box 35168 Lusaka 287412-5 287416<br />

288846<br />

Saswaz Mungwi Rd, Opposite BP Depot Lusaka 287678 287678<br />

Shepherd <strong>Agriculture</strong> Zambia Mungwi Rd (Parmalat Building) Box 39123 Lusaka 233202 286321<br />

293655<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

Sheni <strong>Agriculture</strong> Supplies Second-Class area Box 510110 Chipata 21528 21529<br />

Turning and Metals Ltd. Plot. 3140, Buyantanshi Rd., Heavy Industrial Area Box 31609 Lusaka 244011 244789<br />

<strong>Tech</strong>nology Development and Advisory Unit (TDAU) University of Zambia. Great East Road. Box 32379 Lusaka 293869 293869<br />

ZCF North End, Cha Ccha cha Rd. Box 33579 Lusaka 238901/2 220521

NOTES<br />

E.E.O.A.<br />

AGRO-TECHNOLOGY: Farming and Processing Equipment<br />

27