Vol. 5, Issue 1, March 2010 - Cosmile.org

Vol. 5, Issue 1, March 2010 - Cosmile.org

Vol. 5, Issue 1, March 2010 - Cosmile.org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

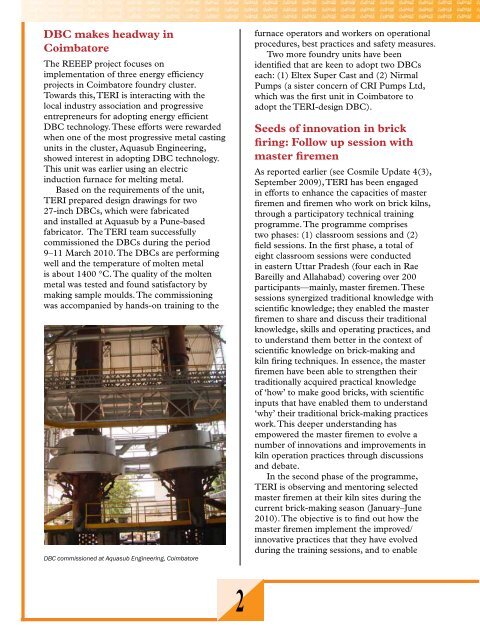

DBC makes headway inCoimbatoreThe REEEP project focuses onimplementation of three energy efficiencyprojects in Coimbatore foundry cluster.Towards this, TERI is interacting with thelocal industry association and progressiveentrepreneurs for adopting energy efficientDBC technology. These efforts were rewardedwhen one of the most progressive metal castingunits in the cluster, Aquasub Engineering,showed interest in adopting DBC technology.This unit was earlier using an electricinduction furnace for melting metal.Based on the requirements of the unit,TERI prepared design drawings for two27-inch DBCs, which were fabricatedand installed at Aquasub by a Pune-basedfabricator. The TERI team successfullycommissioned the DBCs during the period9–11 <strong>March</strong> <strong>2010</strong>. The DBCs are performingwell and the temperature of molten metalis about 1400 °C. The quality of the moltenmetal was tested and found satisfactory bymaking sample moulds. The commissioningwas accompanied by hands-on training to theDBC commissioned at Aquasub Engineering, Coimbatorefurnace operators and workers on operationalprocedures, best practices and safety measures.Two more foundry units have beenidentified that are keen to adopt two DBCseach: (1) Eltex Super Cast and (2) NirmalPumps (a sister concern of CRI Pumps Ltd,which was the first unit in Coimbatore toadopt the TERI-design DBC).Seeds of innovation in brickfiring: Follow up session withmaster firemenAs reported earlier (see <strong>Cosmile</strong> Update 4(3),September 2009), TERI has been engagedin efforts to enhance the capacities of masterfiremen and firemen who work on brick kilns,through a participatory technical trainingprogramme. The programme comprisestwo phases: (1) classroom sessions and (2)field sessions. In the first phase, a total ofeight classroom sessions were conductedin eastern Uttar Pradesh (four each in RaeBareilly and Allahabad) covering over 200participants—mainly, master firemen. Thesesessions synergized traditional knowledge withscientific knowledge; they enabled the masterfiremen to share and discuss their traditionalknowledge, skills and operating practices, andto understand them better in the context ofscientific knowledge on brick-making andkiln firing techniques. In essence, the masterfiremen have been able to strengthen theirtraditionally acquired practical knowledgeof ‘how’ to make good bricks, with scientificinputs that have enabled them to understand‘why’ their traditional brick-making practiceswork. This deeper understanding hasempowered the master firemen to evolve anumber of innovations and improvements inkiln operation practices through discussionsand debate.In the second phase of the programme,TERI is observing and mentoring selectedmaster firemen at their kiln sites during thecurrent brick-making season (January–June<strong>2010</strong>). The objective is to find out how themaster firemen implement the improved/innovative practices that they have evolvedduring the training sessions, and to enable2