Vol. 5, Issue 1, March 2010 - Cosmile.org

Vol. 5, Issue 1, March 2010 - Cosmile.org

Vol. 5, Issue 1, March 2010 - Cosmile.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

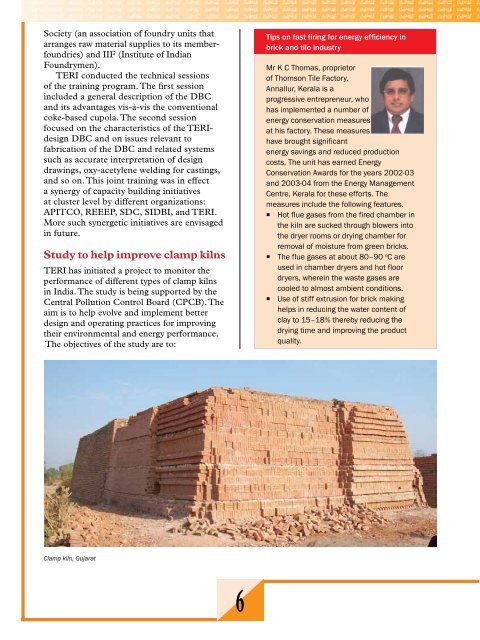

Society (an association of foundry units thatarranges raw material supplies to its memberfoundries)and IIF (Institute of IndianFoundrymen).TERI conducted the technical sessionsof the training program. The first sessionincluded a general description of the DBCand its advantages vis-à-vis the conventionalcoke-based cupola. The second sessionfocused on the characteristics of the TERIdesignDBC and on issues relevant tofabrication of the DBC and related systemssuch as accurate interpretation of designdrawings, oxy-acetylene welding for castings,and so on. This joint training was in effecta synergy of capacity building initiativesat cluster level by different <strong>org</strong>anizations:APITCO, REEEP, SDC, SIDBI, and TERI.More such synergetic initiatives are envisagedin future.Study to help improve clamp kilnsTERI has initiated a project to monitor theperformance of different types of clamp kilnsin India. The study is being supported by theCentral Pollution Control Board (CPCB). Theaim is to help evolve and implement betterdesign and operating practices for improvingtheir environmental and energy performance.The objectives of the study are to:Tips on fast firing for energy efficiency inbrick and tile industryMr K C Thomas, proprietorof Thomson Tile Factory,Annallur, Kerala is aprogressive entrepreneur, whohas implemented a number ofenergy conservation measuresat his factory. These measureshave brought significantenergy savings and reduced productioncosts. The unit has earned EnergyConservation Awards for the years 2002-03and 2003-04 from the Energy ManagementCentre, Kerala for these efforts. Themeasures include the following features.P Hot flue gases from the fired chamber inthe kiln are sucked through blowers intothe dryer rooms or drying chamber forremoval of moisture from green bricks.P The flue gases at about 80–90 o C areused in chamber dryers and hot floordryers, wherein the waste gases arecooled to almost ambient conditions.P Use of stiff extrusion for brick makinghelps in reducing the water content ofclay to 15–18% thereby reducing thedrying time and improving the productquality.Clamp kiln, Gujarat6