R10-04CPSS Parker Pneumatic Regulator Datasheet - MRO Stop

R10-04CPSS Parker Pneumatic Regulator Datasheet - MRO Stop

R10-04CPSS Parker Pneumatic Regulator Datasheet - MRO Stop

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

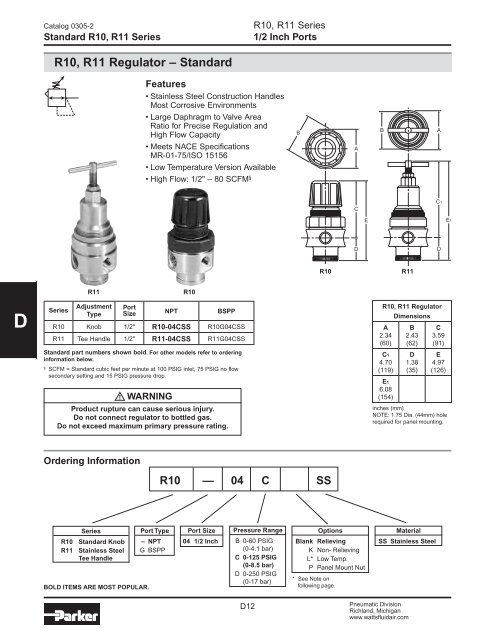

Catalog 0305-2Standard <strong>R10</strong>, R11 Series<strong>R10</strong>, R11 Series1/2 Inch Ports<strong>R10</strong>, R11 <strong>Regulator</strong> – StandardFeatures• Stainless Steel Construction HandlesMost Corrosive Environments• Large Daphragm to Valve AreaRatio for Precise Regulation andHigh Flow CapacityBBA• Meets NACE SpecificationsMR-01-75/ISO 15156A• Low Temperature Version Available• High Flow: 1/2" – 80 SCFM §CC1EE1DD<strong>R10</strong>R11R11<strong>R10</strong>DSeriesAdjustmentTypePortSize NPT BSPP<strong>R10</strong> Knob 1/2" <strong>R10</strong>-04CSS <strong>R10</strong>G04CSSR11 Tee Handle 1/2" R11-04CSS R11G04CSSStandard part numbers shown bold. For other models refer to orderinginformation below.§SCFM = Standard cubic feet per minute at 100 PSIG inlet, 75 PSIG no flowsecondary setting and 15 PSIG pressure drop.! WARNINGProduct rupture can cause serious injury.Do not connect regulator to bottled gas.Do not exceed maximum primary pressure rating.<strong>R10</strong>, R11 <strong>Regulator</strong>DimensionsA2.34(60)C14.70(119)E16.08(154)B2.43(62)D1.38(35)C3.59(91)E4.97(126)inches (mm)NOTE: 1.75 Dia. (44mm) holerequired for panel mounting.Ordering Information<strong>R10</strong> — 04 C SSSeriesPort TypePort SizePressure RangeOptionsMaterial<strong>R10</strong> Standard KnobR11 Stainless SteelTee HandleBOLD ITEMS ARE MOST POPULAR.– NPTG BSPP04 1/2 InchB 0-60 PSIG(0-4.1 bar)C 0-125 PSIG(0-8.5 bar)D 0-250 PSIG(0-17 bar)Blank RelievingK Non- RelievingL* Low Temp.P Panel Mount Nut* See Note onfollowing page.SS Stainless SteelD12<strong>Pneumatic</strong> DivisionRichland, Michiganwww.wattsfluidair.com

Catalog 0305-2Technical Specifications – <strong>R10</strong>, R11<strong>R10</strong>, R11 SeriesAir Line <strong>Regulator</strong>sOperationACDB<strong>R10</strong>HFEABHCDBR11FELWith the adjusting knob / Tee Handle (A) turned fully counterclockwise(no spring load), and pressure supplied to theregulator inlet port, the valve poppet assembly (B) is closed.Turning the adjusting knob clockwise applies a load to controlspring (C). This load causes the diaphragm (D) and the valvepoppet assembly (B) to move downward allowing flow acrossthe seat area (E) created between the poppet assembly andthe seat. Pressure in the downstream line is sensed below thediaphragm (D) and offsets the load of spring (C). As downstreampressure rises, poppet assembly (B) and diaphragm (D) moveupward until the area (E) is closed and the load of the spring (C)and pressure under diaphragm (D) are in balance. A reducedoutlet pressure has now been obtained, depending on springload. Creating a demand downstream, such as opening a valve,results in a reduced pressure under the diaphragm (D). The loadof control spring (C) now causes the poppet assembly to movedownward opening seat area (E) allowing air to flow to meet thedownstream demand. The flow of downstream air is metered bythe amount of opening (E).Should downstream pressure exceed the desired regulatedpressure, the excess pressure will cause the diaphragm (D) tomove upward against control spring (C), open vent hole (F), andvent the excess pressure to atmosphere through the hole in thebonnet (H). (This occurs in the relieving type regulator only.)Technical InformationCAUTION:REGULATOR PRESSURE ADJUSTMENT –The working range of knob adjustment is designed to permitoutlet pressures within their full range. Pressure adjustmentbeyond this range is also possible because the knob is not alimiting device. This is a common characteristic of most industrialregulators, and limiting devices may be obtained only by specialdesign.For best performance, regulated pressure should always be setby increasing the pressure up to the desired setting.* Note: “Low Temperature” option is intended for applications wherethe ambient temperature may be down to -40° C/F. Airsupply must be free of moisture to prevent ice formation andmalfunction of units. These units contain EPDM seals. Makesure any oils in the airstream are compatible.<strong>R10</strong>, R11 <strong>Regulator</strong> Kits & Accessories<strong>R10</strong> Bonnet Kit (Knob Included) ....................................CK<strong>R10</strong>YSSR11 Bonnet Kit.................................................................CKR11YSSGauge (Stainless) –160 PSIG (0 to 1100 kPa), 2" Face.......................K4520N14160SSPanel Mount Bracket (Stainless).................................... <strong>R10</strong>Y57-SSPanel Mount Nut –Stainless ...................................................................... <strong>R10</strong>X51-SSPlastic..............................................................................<strong>R10</strong>X51-PPipe Nipple –1/2" 316 Stainless Steel................................................. 616A28-SSService Kit –Relieving........................................................................RK<strong>R10</strong>YSSNon-Relieving.............................................................. RK<strong>R10</strong>KYSSSprings –0-60 PSIG Range......................................................SPR-388-1-SS0-125 PSIG Range....................................................SPR-389-1-SS0-250 PSIG Range....................................................SPR-390-1-SSSpecificationsGauge Port .............................................................................1/4 InchPressure Drop - bar6543210Pressure Drop - PSIG10090807060504030Flow Characteristics201/2 Inch Ports10100 PSIG (6.9 bar Primary Pressure00 10 20 30 40 50 60 70 80 90 100Flow - SCFM0 5 10 15 20 25 30 35 40 453Flow - dm /snOperation ....................................................Fluorocarbon DiaphragmPort Threads ...........................................................................1/2 InchPressure & Temperature Ratings –<strong>R10</strong> ......................................................... 300 PSIG Max (20.7 bar)0°F to 150°F (-18°C to 66°C)R11 ......................................................... 300 PSIG Max (20.7 bar)0°F to 180°F (-18°C to 82°C)Option “L” Minimum Operating Temperature.................. -40° C/FNote: Air must be dry enough to avoid ice formation attemperatures below 32°F (0°C).Weight .......................................................................1.79 lb. (0.81 kg)Materials of ConstructionAdjustment Mechanism / Springs .....................316 Stainless SteelBody .....................................................................316 Stainless SteelBonnet / Tee Handle (R11)...................................316 Stainless SteelBonnet / Knob (<strong>R10</strong>) ................................................................ AcetalBottom Plug .........................................................316 Stainless SteelPoppet ..................................................................316 Stainless SteelSeals .............................................................................. FluorocarbonDD13<strong>Pneumatic</strong> DivisionRichland, Michiganwww.wattsfluidair.com