Infrared Sources - Photonic Sourcing

Infrared Sources - Photonic Sourcing

Infrared Sources - Photonic Sourcing

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Infrared</strong><strong>Sources</strong>for Gas Detectionand Monitoring

Leister Process Technologies, SwitzerlandLeister OverviewLeister Process Technologies has over 50 years experience in thedevelopment, production and worldwide distribution of technicalproducts.The Axetris Division of Leister is a designer and manufacturer ofmicro-technology (MEMS) based components and modules inthe areas of micro-optics, infrared sources for gas detection andmass-flow sensors / controllers.As an ISO 9001:2000 certified and ISO TS 16949 compliantcompany our production processes, dedicated manufacturingequipment and specialized characterization tools, make us a reliablemanufacturer.Axetris offer a wide range of high-quality off-the-shelf products aswell as custom solutions for its OEM customers. Our engineeringand manufacturing team combines broad experience in design,simulation, fabrication and characterization from chip level tocomplex integrated electronic modules. Our manufacturing facilitiesin Switzerland include a world-class class 100 clean roomwith state-of-the-art micro-technology processing capabilities. Asa partner to our OEM customers we support them from conceptto volume production.2

<strong>Infrared</strong> source product range overviewAxetris IR sources are micro-machined, electrically modulated thermal infrared emitters featuring true black body radiation characteristics,low power consumption, high emissivity and a long lifetime. The patented design is based on a resistive heating element integratedonto a thin dielectric membrane which is suspended on a micro-machined silicon structure.The sources are packaged in compact TO-39 cans and are available with protective cap or with reflector. They can be fitted either withSapphire, CaF 2 or BaF 2 windows.Axetris IR sources are ideally suited for compact IR gas detection modules where a high emissivity, high reliability and low power consumptionare key requirements.Benefits• True black body radiation (2 to 16 µm)• High emissivity• Fast electrical modulation (no chopper wheel needed)• High modulation depth• High electrical input to optical output efficiency• Low power consumption• Long lifetime<strong>Infrared</strong> Gas Detection Applications• Non-Dispersive <strong>Infrared</strong> (NDIR) or Photo-Acoustic <strong>Infrared</strong>• Target gases: CO, CO 2, NOx, NH 3, SO 2, SF 6, anesthesiaagents, refrigerants• Medical: Capnography, anesthetic, respiration monitoring• Automotive / Transportation: Combustion gas analyzers,breath alcohol testing, cabin comfort• HVAC: Demand controlled ventilation, fire detection,refrigerant monitoring• Safety & Industry: Combustion gas analyzers,gas detection in fluids, incubators3

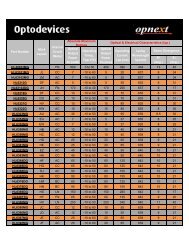

IR Source Product RangeArticle no. Article description Header type Window type Product photo600.347 EMIRS200_T_40/53_0 Protective cap none600.409 EMIRS200_T_40/53_S Protective cap Sapphire601.418 EMIRS200_T_40/53_BaF2 Protective cap BaF 2601.419 EMIRS200_T_40/53_CaF2 Protective cap CaF 2600.451 EMIRS200_R_60/55_0 Reflector none600.411 EMIRS200_R_60/55_S Reflector Sapphire601.479 EMIRS200_R_60/55_BaF2 Reflector BaF 2601.615 EMIRS200_R_60/55_CaF2 Reflector CaF 2Custom designProtective cap orcustom design reflectorSapphireBaF 2CaF 2Electrical/Optical characteristics (Tc=25°C)Parameter Min Typical Max Unit ConditionsCold Resistance 35 45 55 ΩHot Resistance 72 Ω 450 mWElectrical input power 450 mW end of heating cycleOperating voltage 5.7 V 450 mWOperating current 80 mA 450 mWHeating time constant 11 msCooling time constant 17 msWorking temperature 456 °CEmissivity 0.95 2 µm to 16 µmLifetime > 10 years Mean Time To Failure (MTTF)Heating area 2.1x1.8 mm²Case Temperature 47 °C 50% duty cycle, 30 Hz, 450 mWTechnical data and specifications are subject to change without prior notice4

BenefitsTrue black body radiation (wavelength from 2 µm to 16 µm)Emission Spectrum vs. WavelengthMeasured emission spectrumBlack-body radiationMicroscopic image of the MEMS chip packaged on a TO39 header (leftside). Temperature distribution of the heated membrane (right side).High emissivityA unique thin film process creates a pure black body structurewith emissivity close to 1.Black dendritic surface structureFast electrical modulation and high modulation depthThe thin and low mass membrane, only achievable by MEMStechnology, makes the IR source fast and dynamic.Modulation Depth EmissivityRelative Emission2600 mW550 °C450 mW456 °C350 mW366 °C4 6 8 10 12 14 16Wavelength [µm]Emissivity vs. WavelengthWavelength [µm]Modulation Depth vs. FrequencyModulation Frequency [Hz]Front and backside of the IR Source MEMS chip(overall size: 3.2x3.2 mm 2 , membrane size 2.1x1.8 mm 2 )5

High electrical input to optical output efficiencyThe IR source has excellent electrical to optical conversion efficiency. Reasons are on one hand the black surface which guaranteesmaximized energy emissivity and on the other hand optimized heat flux management.750650550Input Power vs. TemperatureT [ºC]450350250150membrane temperature50300 400 500 600 700 800P [mW]Efficiency optimization by heat flux simulationReliability of the MEMS structureThe semiconductor manufacturing technology guarantees highly reliable quality of the IR source. Adding to the elaborate qualitycontrol system during wafer level manufacturing every single IR source is subject to a final burn-in test.Mean Time to Failure formembrane breakage1'000'000100'000MTTF [hours]10'0001000Operation mode: DCOperation mode: Pulse100450 550 650 750P [mW]The Mean Time To Failure (MTTF) for membrane breakage of theIR source is based on a statistical analysis of lifetime data collectedfrom several years of reliability testing. Reliability of the membranebreakage depends strongly on the electrical input powerand the operation mode.Running an IR source for example with 600 mW DC results in alifetime of 70'000 operating hours.Processed wafer before dicing6

Application Specific Design OptionsAxetris offers custom design services for its OEM customers to meet their specific product requirements. The reflector for exampleoptimizes the angular distribution of radiation and therefore the optical signal. A Sapphire, CaF 2 or BaF 2 window improves the signal tonoise ratio, protects the source of contamination and acts as a spectral lowpass filter.Custom Reflector• Custom optimization of the emissionRelative Emission vs. Angle108with reflectorwithout reflectorReflector collimates IR radiation on axisWindow• Protection against explosive gases• Spectral lowpass filter complements detector filter• Eliminates background signal and improves S/N ratio• Protection of the IR source in harsh environments• No parasitic influence of the sample gas% Transmission Relative Emission642010090807060504030-80 -60 -40 -20 0 20 40 60 80Angle [º]Window Spectral TransmissionCaF 2BaF 220Sapphire1002 3 4 5 6 7 8 9 10 11 12Wavelength [µm]13 14 15 16IR source with reflector and window7

ContactISO 9001:2000 certifiedHeadquartersUSALeister Process TechnologiesAxetris DivisionSchwarzenbergstrasse 10CH-6056 Kaegiswil/Switzerlandphone: +41 41 662 74 74fax: +41 41 662 75 25axetris@leister.comwww.leister.com/axetrisLeister Technologies, LLCAxetris Division1253 Hamilton ParkwayItasca, IL 60143/USAphone: +1 630 760 1000fax: +1 630 760 1001sales@leisterusa.comwww.leister.com/axetris© Copyright by LeisterFlyer F60/07.2008