SAOMAD st3a TENONER - Maginn Machinery

SAOMAD st3a TENONER - Maginn Machinery

SAOMAD st3a TENONER - Maginn Machinery

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TENONING MACHINEST- 3ABEFORE STARTINGWORK, READ CAREFULLYTHIS BOOKLETINSTRUCTIONS FOR USE AND MAINTENANCE

TENONING MACHINE ST-3ARECORD DATA STAMPED ON THEMACHINE NOMEPLATEMOD.KW.12SERIAL NUMMBERVolt380YEAR OF MANUF.Hz50WEIGHTAmpere29MACHINE DELIVERY DATE<strong>SAOMAD</strong> AUTHORIZED WORKSHOP TOPROVIDE ANY NECESSARY TECHNICALSERVICE2

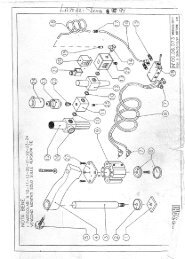

GENERAL FEATURETENONING MACHINE ST-3APLACETenoning machine is supplied in perfect working conditions, tested in our factory. Place the tenoningmachine on a concrete floor. To obtain a good levelling, use a “bolla” on the table. Lock with two boltsthe machine on the floor.ELECTRICAL WIRING CONNECTIONS:Check that the rated voltage of the machine corresponds to the main voltage supply available at theinstallation site.INSTALLATION:All parts of the supplied tenoning machine are protected by rustproof; befor using, clean perfectly themachine. To set in motion on switches and check that rotation way of the spindle will be the sameindicated by stickers applied on carters.LUBRICATION:The tenoning machine is equipped with tinning bearings and no lubrication is needed. The screw to getup the spindle need a lubrication made by grasy with lithium (viscosity 32 or 14 cSt – es. SHELL AV2or MOBIL VECTRA n. 2). Lubricate every 8 working days all deplacement device of the machine.Cut off circular sawØ saw shaft..................... ...........................................................................mm. 30Motor power...............................................................................................Hz. 4Rpm circular saw........................................................................................r.p.m. 3000Ø blade.........................................................................................................mm. 400 ( max. 450 )Cutting heght..............................................................................................mm. 125 (max. 350)Blade Horizontal positioning................................................................... mm.150Tenoning splindle 320Ø shaft...........................................................................................................mm.50Shaft useful lenght......................................................................................mm. 320Useful stroke................................................................................................mm. 270Rpm shaft................ ................................................................................... r.p.m.. 3600Ømax tools...................................................................................................mm 350 (380)3

TENONING MACHINE ST-3AINTRODUCTION4This manual provides information and adviceconsidered necessary for gaining familiarity with theST3A and for proper use and normal maintenanceoperations. This machine is manifactured by<strong>SAOMAD</strong> in reschigliano di Campodarsego (Padova- Italy). The included information of this manualdoes not provide a complete, detailed descriptionof the components or an explanation of theiroperation. The operator will nevertheless find all theinformation that will normally be necessary for safeuse and proper upkeeping of the machine.The longtermendurance and economic running conditionsof the machine will depend upon how well theoperations described in this booklet are observedand fulfilled.Failure to observe the provisions described in theinstructions that follow, neglect, poor and/orincorrect use of the machine may determine thecancellation of the warranty on behalf of theManufacturer. At the moment of purchase, checkthat the machine is complete in all its parts. Anycomplaints must be forwarded in writing within 8(eight) days from reception of the machine.WARRANTY<strong>SAOMAD</strong> guarantees all its products for a periodof 12 (twelve) months from purchase’s date. Thiswarranty covers only repair or substitution, free ofcharge, referring to any parts (excluding electricalparts) that are found to be defective after havingbeen inspected by the Technical Department of theManufacturer.This warranty, excluding allresponsabilities relating to direct or indirect losses,is limited only to coverage for defects of materials,ceasing validity in the event that these parts showsigns of tampering, dismantling or repair byunauthorised personnel. All returned parts orequipment, even if covered by this warranty, are tobe delivered free port.EXCEPTIONS TO WARRANTYBesides the terms specified on the sales contract,this warranty does not include damage to themachine caused by neglect, carelessness, incorrectuse of the machine and errors during manoeuvre bythe operator. Likewise, the warranty does not covertools and consumption materials that may have beebsupplied together with the machine. Any tamperingwith safety devices installed on the machine willimmediately free the Manufacturer from allresponsibilities. The warranty will also cease validityin the event that non-original spare parts are usedon the machine.DESCRIPTION OF THE MACHINE:The ST-3A tenoning machine bears the CE stampto show its conformity with European Communitystandards described in the EEC 89/392 regulationand subsequent amendments, as stated in thedeclaration of conformity supplied together with themachine. The tenoning machine is a piece ofequipment suitable for carrying out specific tenoningand butt-end machining operations on semi-finishedwooden components only.SAFETYThe user should provide all the necessary training toits staff relatingto the risks of injury, the safety devicesprovided to prevent harm to the operator, risks ofnoise pollution and the general safety regulationsestablished by directives and laws in force in thecountry in which the machine will be used.Operator safety has beeb one of the greatestconcerns of the Manufacturer of this machine. Whendesigning a new machine, we strive to predict allpossible hazard situations and therefore adoptappropriate safety devices into the project.Nonetheless, the number of accidents caused bylessness and improper use of machines remains high.We therefore recommend that this manual is readcarefully, paying special attention to the rules forsafety and to all those operations which may gene-

TENONING MACHINE ST-3Arate particularly dangerous situations.<strong>SAOMAD</strong> declines all responsability for failure onbehalf of the user to observe the rules for safetyand prevention described in this manual.<strong>SAOMAD</strong> declines also all responsibility fordamage and loss caused by improper use of, orunauthorised alterations to the tenoning machine.Pay special attention to this symbol whenever itappears throughout the manual, as it indicatespossibly hazardous situations. Hazards may bedivided into three categories:SAFETY SIGNSThis tenoning machine has been built with all thepossible safety devices to protect the operators usingit. Despite this fact, there are other additional hazardswhich are pointed out by the presence of stickersbearing special symbols applied onto the machine.These symbols provide an essential indication of thevarious unsafe and hazard situations. these shouldbe kept clean to make them clearly visible andsubstituted immediately if they have fallen off or beenruined.DANGERfig.1-5This signals the greatest hazard level and warnsthe operator that the operations described maycause serious harm, death or long-term disabilities,if not correctly executed.1-.Before starting work on the machine, read theinstruction manual carefully.2-.Before setting out to perform any servicemaintenance, stop the machine and refer to theinstruction manual.3 -.It is absolutely forbidden to climb on top of themachine, as tehre is a risk of falling off.fig.2-5WARNINGThis sign warns the operator that the operationsdescribed may cause serious harm, death or longtermdisabilities, if not correctly executed.The“Beware” sign identifies a slightly lower risk factorthan that of the DANGER sign.CAUTIONfig.3-5This sign warns the operator that the operationsdescribed may cause harm to people or damageto the machine, if not correctly executed. The“caution” sign indicates that the risk level is lowerthan that of both the DANGER and theWARNING signs.4 -.Hazardous noise levels. Wear suitable protectiveheadsets.5 -.Safety gloves are to be used when replacingmachine tools or the saw.6 -.Danger of cuts to hands. Take special care duringcutting and tenoning work.7 -.Danger of crushing to hands. Pay careful attentionto piece stopper elements.8 -High voltage. Disconnect the mains power supplybefore carrying out maintenance operationsCAUTIONfig.4-55

TENONING MACHINE ST-3Afig.1-6SUITABLE CLOTHINGWhile using the machine, the operatorshould wear appropriate protectiveclothing, as there are moving parts on themachine which may create dangeroussituations. Avoid wearing loose clothing, with widesleeves, trousers or overalls that are too long or toowide. Special attention is to be paid to belts, scarves,cloth ribbons, half-belts, necklaces, bracelets, longhair, etc, as these may cause serious injury duringuse of the machine if they get caught up in the movingparts. Moccasins, clogs, slippers or other kinds ofinappropriate footwear should absolutely not beworn. Operator should always wear suitable, safeclothing such as protective shoes, goggles, gloves,facemasks against dust, and so on.ECOLOGY AND POLLUTIONTake all necessary precautions forprotection against noise pollution bywearing suitable soundproof headsets.With regard to use and disposal ofproducts for cleaning and maintenance operations,take care to respect the environmental laws andregulations in force in the country of use, as well asthe recommendationsprovided by the manufacturerof such products.If the machine has to be dismantled, because it is nolonger to be used, follow all the anti-pollutionregulations established by the competent authoriesin the country of use of the machine. If necessary,carry out all the necessary legal procedures relatingto disposal of machinery.SAFE CONDITIONS FOR USEThe machine must not be started up bystaff who have not read and fullyunderstood the instructions laid out inthis booklet, nor staff members who donot have the necessary skill to run it, or are not ingood health. The tenoning machine is to be usedsolely by sufficiently mature operators who are ingood physical and mental mental conditions.Before starting the machine, check that all installedsafety devices are in proper working conditions.Before starting work operations, the operator shouldtake the time to get suitably acquainted with thecontrol devices and their operating principles.During machine operation, the operator MUST standalongside the machine, behind the stop square asthis is the only position from which an operator willbe able to work properly. The operator must alwaysconclude all tenoning operations before moving fromthis position.Before starting the machine, make sure there are nochildren, animals or other people near the machine.The machine can be run only by an electric-driven6

TENONING MACHINE ST-3ASAFE MAINTENANCE OPERATIONCONDITIONSmotor. pay special attention to the various electricmotors and components. Do not touch moving partsor stand in their way during operation. Do not standwithin the area of operation of the machine or wherethere are moving parts. Make sure that all safetydevices are in perfect working order. the area withinwhich the machine is used is to be considered as“dangerous”, especially for people who have notreceived training on how to use the machine.Theoperator has to make absolutely sure there are nopeople and/or animals within a certain distance fromthe machine, in order to safeguard them against therisk of:- being hit by objects flung out of the machine- contact with moving elements of the machine- inhalation of dust or gas.In the event of “exposure” of a person to danger,that is, if this person is standing within the “dangerzone”, the operator must immediately switch themachine off and possibly ask the intruder to moveaway to a greater distance. It is absolutely essentialto take precautions against risks of breathing dustproduced during the work process. It is particularynecessary to wear protective clothing, cut-proofgloves and antislip, squeezeproof shoes whileperforming maintenance or servicing operations. Ifit is absolutely necessary to operate near mainelectric power lines, all elements of the machineshould be kept at a safe distance from these cables.If in doubt regarding suitable safety distances,contact the local electric energy authority. As themachine has been made mostly of metalcomponents, if any of these parts comes into contactwith a live electric wire or if a spark is generatedbetween a power line and the tenoning machine, thismay create a dangerous, or even fatal situation forthe machine operator. it is absolutely forbidden toabandon the machine while it is in operation. Beforean operator can move away from the machine, thismust be completely switched off.In situations of particularly serious danger, theoperator must press the emergency mushroom likeSTOP button located on the control panel.- Regularly check that the machine is notmissing any of its fundamentalcomponents or safety devices.- Regularly check that screws, nuts andjoints aretightly fastened down.- take scrupulous care to use lubricants conformingclosely to those recommended.- All spare parts must correspond to specificationsdefined by the machine manufacturer. Use onlyoriginal spare parts.- It is absolutely forbidden to remove or tamper withsafety devices installed on the machine.- Machine maintenance operations are to beperformed only by skilled staff and following theinstructions described in this manual.- Do not carry out any maintenance or even cleaningoperations without having first disconnected themains power supply.- Take utmost care to perform maintenanceoperations exactly as described in this manual.Arrange for skilled staff to perform substitution ofdamaged or worn parts of the machine. Theinstruction manual should be read, understood andkept in suitable conditions of use, for future referencefor the entire working life of the machine.DELIVERYIn the event of future necessity to movethe machine for particulary long distances,it may be loaded either on a rail wagonor a lorry. The machine is normallydelivered in heat-shrunk nylon packaging and placedin a vertical position on a wooden pallet. This makesit easiet to move, load and unload the machine bymeans of ordinary lift truck of suitable load capacity.Instead, if the machine needs to be moved afterhaving removed it from the pallet, it will be necessaryto do so by means of an overhead crane system,using ropes or chains of suitable strenght hookedonto the four hook-up points located at the base ofthe machine and identified by means of a hooksymbol.7

TENONING MACHINE ST-3ACAUTIONBefore lifting the machine, make sure that all mobileelements of the machine are well clamped down.Make sure that the load capacity of the crane lift issufficient to lift the machine. Lift the machine withutmost care and move it about easily, without joltingor banging against other objects.DANGERLifting and transport operations may be dangerousif not carried out with utmost care. It is thereforenecessary to keep intruders away from the area ofmanoeuvre, provide a clean, clear space and markthe limits of the transfer area. Check that theequipment used for these operations is in properworking order and suitable for the specific job.Never touch the machine while it is suspended inthe air and avoid coming within a normal safetydistance. During machine transport do not lift themachine more than 20 cm from the floor. Make surethat the area in which these operations are takingplace are free from obstruction and a suitable“escape zone” is available, that is, a sufficiently cleararea where it is possible to take shelter in case themachine should fall duting movement.WARNINGThe floor where the machine is to be installed shouldbe perfectly horizontal, to avoid the possibility ofshifting loads. These ropes are to be firmly fastenedto the machine and well taut onto the fastening pointson the lorry loading floor. Having reached thedestination, before loosening the ropes holding themachine to the lorry loading.Then , unpack themachine and dispose of the packaging materials byseparating the various elements, e.g. nylon, woodand so on, respecting the anti-pollution laws currentlyin force in the country where the machine is to beinstalled. After having checked that the machine hasnot undergone any damage, make all the necessarypreparations for its installation position.INSTALLATIONIn the choice of the position for machineinstallation, it is best to consider thefollowing conditions:- check that that the chosen location iswell-sheltered from climatic agents and not toodamp;- make sure that the floor is perfectly flat andhorizontal, with nonslip treated surface and capableof bearing the entire weight of the machine;- check that there is ample manoeuvring spacesurrounding the machine and free from obstruction;- ensure that the room where the machine is installedis well guarded or closed, preventing access to themachine to children or other people who have notbeen trained to use it.- check that there is adequate lighting (and compliantwith relative standards);- make sure the machine is located near the mainpower switch (and fitted with a surge cut-off device);- check that the eletric power line includes anearthing system in compliance with safety standards;- make sure the room temperature is kept within the+ 10° to 40° C range:- make sure the work environment does not containany explosive gases;CLEANING THE MACHINEBefore installing the machine, all theenamelled surfaces need to be thoroughlycleaned from oily residues (used toprotect the machine during transport)with alkaloid-type detergents (mineral turpentine ornaphtha). These should not be sprayed directly ontothe machine, but poured onto a dry cloth, which is8

TENONING MACHINE ST-3Ato be disposed of according to anti-pollutionregulations after its use.ELECTRICAL WIRING CONNECTIONSsuitable pneumatic air supply system. Minimumpressure must be 6 bar, under this machine will notwork. To check pressure use pressure gauge in thecontrol panel of the machine.ASSEMBLAGE ALUMINIUM GUIDE:WARNINGOperations involving electrical wiring connectionson the machine are to be carried out only by skilled,authorised electricians capable of determining thecorrecy wire cross-section for mains powerconnection cables. This also implies taking intoaccount the total power consumption and currentabsorption when calculating the wire cross-sections.First of all, check that the rated voltage of the machinecorresponds to the main voltage supply available atthe installation site.CONNECTION TO SUCTIONSYSTEMConnect the discharge outlests forexpelling sawdust and chips to the suction systemavailable at the installation site by means of flexibleducts fastened with pipe clamps. These consist ofthe following:- A 120-mm diam. outlet for discharge of sawdustfrom the circular saw- A 148-mm diam. outlet for discarge of chips fromthe upper horizontal tenoning unit.CONNECTION TO PNEUMATIC SYSTEMThe machine is equipped with apneumatic clamp control units and themachine will need to be connected to aPlace the rod on the working table, insert in its seatand fix it. The rod can be extend just 2.50 m.In the case of small piece works, take away the rodto easy working.GENERAL INSPECTIONBefore starting up the machine for productionpurposes, it must first ben carefully checked toensure that the safety devices and moving parts arein proper, efficient working order. Check also thatthere are no damaged elements on the machine andthat all components are installed correctly and workproperly. Any damaged safety devices or parts areto be repaired or replaced entirely by skilledtechnicians or at a service centre authorised by<strong>SAOMAD</strong>.PRELIMINARY OPERATIONSBefore starting normal productionprocedures, check that the machine is inperfect working order.Check the efficiency of all componentssubject to wear and deterioration.All adjustement and preparatory operations forproduction procedures are to be carried out withutmost care.Do not make modifications or adaptations on motorsor on electric device. These interventions can causea no-good work of the machine and bedangerous for the worker.9

TENONING MACHINE ST-3AAll tamperings in the electric system will free<strong>SAOMAD</strong> from all responsabilities.Should you need any further information, do nothesitate to contact the company.When carrying out tool insertion and replacementoperations, use special gloves capable of protectingthe hands against accidental cuts. When choosingtools to be mounted on the machine, it is best to usethose of high quality and bearing indications of thespeed of rotation and the diameter of the tool. toolsof lower grade will, in fact, not be able to providethe expected machine performance rating.CIRCULAR SAWDeplacement of the saw can be pneumatic orelectronic (by a work program pre-setted in thecontrol panel).Adjustment is made by a piston or by a revolver,To mount or dismantle the circular saw:- wear protective gloves- open the external protective gate- up the saw protective coffer- switch off the 4 fixed screwes.- take off the screw cap- insert the Allen spanner, in the central shaft- with the other hand, fit the spanner onto the nutthat fastens the blade to the shaft and loosen the nutand its washer.TOOLSThe machine is equipped with a (one) tenoning shaft.To mount tools is necessary:- wear protective gloves- open the external protective gate- up the tenoning shaft coffer- switch off the 4 fixed screwes.- take off the screwes upon the shaft- take away tools- clean with a ventilator- insert the new tool or substit the oldUSE OF THE MACHINEDANGERThe machine and the area where is located must bealways oversee by the operator.ADJUSTING WORK TABLE AND ITSWORKINGFor the adjusting of the work table , release the stopblocks and- loosen the brake lever- put the wooden piece on the table- settle stop blocks 0,5 mm from the piece- fix the lever. Blocks must be fixed 0.5 cm heightthan wooden piece to avoid crushing fingers.- settle the pedal clavier to make easier operator’swork - at the first stroke of the pedal machine willstart working..- it is possible to active blocks also manually, usingswitch in the control panel.- in the same moment will be on also the 2 ventilatorsto kept cleaning the work table- to realize different tilted tenons is necessary:- switch off the peg (plug)- unscrews- adjust the control square as wish- fix the square with screwsWORKING OPERATION- connect the power supply to the machineby turning on the main power switch onthe control panel- run the machine through a few preliminary idle workcycles (i.e. without work pieces) before startingproduction procedures.- While performing these preliminary operations andduring normal production procedures, the operator10

TENONING MACHINE ST-3AMUST ALWAYS stand alondside the machine, asthis is the only position that will allow workoperations to be carried out correctly.AUTOMATIC OR MANUAL MACHINEConsult the use manual about different works forboth machines.MAINTENANCE OPERATIONSOrdinary maintenance operations can be carried outby the operator. for operations requiring specialcaution, it is best to call a skilled technician. Everyday:· check the general conditions of the machine· lubricating machine· clean tools and their site· oiling the machine· check good screw state· check good working of protections.USING MACHINE· On general switch· Make sure that switch is placed in manual orautomatic position· Check that start light on the control panel is OK· Place wooden pieces on working table· Fix them by the 2 pneumatic blocks· Select program on the control panel and push“ENTER”· Machine places tools following shares settled inthe program.· Machine is ready to work.· On working table by the pedal· Piece are cutted by the circular saw· Tools in the tenoning spindle make their work.· Turn wooden piece and work on the other side.ORDINARY MAINTENANCEDue to its particular configuration, this tenoningmachine does not require any special maintenanceoperations.Operations involving maintenance, adjustement andpreparations for the production process must beperformed only after having disconnected the electricpowe supply.11

TENONING MACHINE ST-3AOVERALL DIMENSIONS ST-3AHEIGHT MACHINE H=1745 mm (1.745 mt.)12

TENONING MACHINE ST-3AGROUND FIXING DEVICEGROUND FIXING DEVICELIFTING POINTSTRANSPORT AND PLACE OF THE MACHINE13

TENONING MACHINE ST-3ACE SAFETY GUARDS14

TENONING MACHINE ST-3ACE SAFETY GUARDSLATERAL VIEWEAR VIEW15

TENONING MACHINE ST-3A16AXE CONTINUED 320 MM SHAFT

TENONING MACHINE ST-3ALATERAL VIEW CARRIAGE17

TENONING MACHINE ST-3APNEUMATIC CIRCULAR SAW BLADE18

TENONING MACHINE ST-3AVSASHING WHEELS1215166345789141011131219