Turning Insert - korloy

Turning Insert - korloy

Turning Insert - korloy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

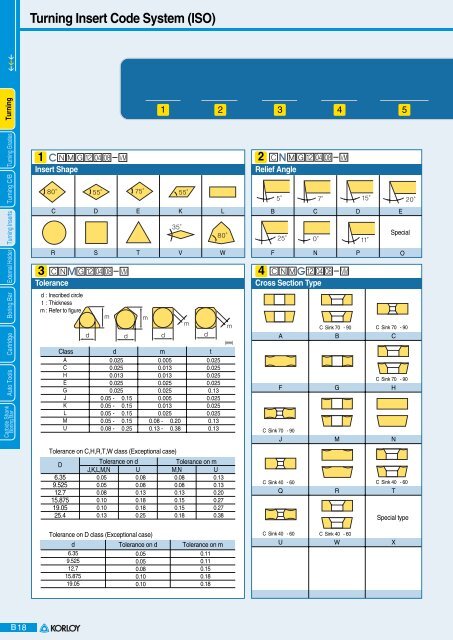

<strong>Turning</strong> <strong>Insert</strong> Code System (ISO)>>> Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong>Carbide ShankBoring Bar1<strong>Insert</strong> Shape3C D E KR S T V WToleranced : Inscribed circlet : Thicknessm : Refer to figure Class d m tACHE0.0250.0250.0130.0250.0050.0130.0130.0250.0250.0250.0250.025G0.0250.0250.13JKL0.05 -0.05 -0.05 -0.150.150.150.0050.0130.0250.0250.0250.025MU0.05 -0.08 -0.150.250.08 -0.13 -0.200.380.130.13Tolerance on C,H,R,T,W class (Exceptional case)D6.359.52512.715.87519.0525.4J,K,L,M,N 0.05 0.05 0.08 0.10 0.10 0.13Tolerance on dU 0.08 0.08 0.13 0.18 0.18 0.251 2 3 4 5Tolerance on mM,N 0.08 0.08 0.13 0.15 0.15 0.18LU 0.13 0.13 0.20 0.27 0.27 0.38(mm)2Relief Angle4B C D EFC Sink 70 - 90C Sink 70 - 90A B CFC Sink 70 - 90JC Sink 40 - 60QNCross Section TypeGMRPSpecialC Sink 70 - 90HNOC Sink 40 - 60TSpecial typeTolerance on D class (Exceptional case)d6.359.52512.715.87519.05Tolerance on d 0.05 0.05 0.08 0.10 0.10Tolerance on m 0.11 0.11 0.15 0.18 0.18C Sink 40 - 60C Sink 40 - 60U W XB18

<strong>Turning</strong> <strong>Insert</strong> Code System (ISO) >>>6 7 8<strong>Turning</strong>5Cutting Edge Length, Diameter of Inscribed Circle030405-0608-09-11-121416-1719-22-2532-040506-0709-11-13-151719-2123-27-3138-030405-0607-09-11-121415-1719-22-2531-SymbolNose Radius (Nose R)Metric Inch d(mm)060809-1113-16-19-222427-3033-38-4454-0304050606070809101112121415161719202225253132-0809-1113-16-19-222427-3033-38-4454-02S303-0405-06-07-080910-1113-15-1721-1.2(5)1.5(6)1.8(7)-22.5-3-3.5-44.55-5.56-7-810-3.974.765.566.006.357.948.009.52510.0011.1112.0012.7014.2915.87516.0017.4619.0520.0022.22525.0025.4031.7532.007 8IC6Height of Cutting EdgeSymbolMetric-T001T10203T304050607091112Inch0.5(1)0.61(2)1.21.5(3)22.533.545678Chip Breaker for <strong>Turning</strong>Height of Cutting Edge(t)mmInch0.791/321.000.0401.591/161.985.642.383/323.181/83.975/324.763/165.567/326.351/47.945/169.523/811.117/1612.701/2( ) Symbol for small size insert<strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarSymbolCorner RadiusMetric Inch Metric Inch0102040812162024283200.5123456780.10.20.40.81.21.62.02.42.83.20.0040.0081/641/323/641/165/643/327/641/800M0--Round insert(Inch)Round insert(Metric)VGVF VQ VW VM VHVT HU HC HA HS HRGSGMGRGHHFP HMP C25 AKB25ARB19

Negative<strong>Turning</strong> <strong>Insert</strong>KNWorkpiece<strong>Insert</strong>sKNUX-11For medium to roughingKNUX-12For medium to roughingRNRNMG-B25For medium to roughingPMKNSHKNUX 160405-R11160410-R11160405-L11160410-L11KNUX 160405-R12160410-R12160405-L12160410-L12PMKNSHRNMG 090300-B25120400-B25150600-B25190600-B25250600-B25250900-B25310900-B25NC3010NC3020NC3120NC3030Parallelogram55¡£NegativeNC500HNC9020PC9030NC6110NC6010CT10CN2000CN20 RoundNegativeNC3010NC3120NC3030NC500HPC8010NC9020PC9030NC305KCT10CN2000CN20ST10H01G10U20H01G10I19.218.819.218.819.218.819.218.8d9.5259.5259.5259.5259.5259.5259.5259.525Cutting edge geometry A06 A09 Recommended chip breaker B12 B17 Code system B18 B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Workpiece<strong>Insert</strong>sSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationCoatedCoatedNC6110NC315KCermetUncoatedCermet UncoatedMachining typesContinuous cuttingGeneral cuttingInterrupted cuttingd9.52512.715.87519.0525.425.431.75Dimensionst4.764.764.764.764.764.764.764.76r0.51.00.51.00.51.00.51.0Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingDimensionst3.184.766.46.356.359.529.52Cutting edge geometry A06 A09 Recommended chip breaker B12 B17 Code system B18 B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = b2.22.23.23.22.22.23.23.2(mm) Cutting Condition Availablefn ap toolholders0.20~0.35 1.00~6.000.30~0.60 1.50~6.000.20~0.35 1.00~6.000.30~0.60 1.50~6.000.25~0.35 1.50~6.000.40~0.70 1.50~6.000.25~0.35 1.50~6.000.40~0.70 1.50~6.00CKJNR/LCKNNR/LCKUNR/LCKJNR/LCKNNR/LCKUNR/LPageB67B96B67B96 : Stock item : Under preparing for stock(mm) Cutting Condition Availabled1 fn ap toolholdersPage3.81 0.90~4.50 0.09~0.905.16 1.20~4.80 0.12~1.206.35 1.15~1.50 1.50~7.507.93 1.90~7.60 0.19~1.90 - -9.12 2.50~10.00 0.25~2.509.12 2.50~10.00 0.25~2.5012.7 3.50~13.00 0.30~2.50 : Stock item : Under preparing for stock>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarB25

Carbide ShankBoring Bar Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong><strong>Turning</strong> <strong>Insert</strong>SNWorkpiece<strong>Insert</strong>sSNGAFor roughingSNGGFor medium cuttingSNGG-HUFor ultra finishingSNGNFor roughingSNGXSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationPMKNSHSNGA 090304090308120404120408120412150608150616190608190612SNGG 090304R090308R120404R120408R120412R090304L090308L120404L120408L120412LSNGG 120408-HUSNGN 090302090304090308120304120308120312120402120404120408120412120424150402150408150412150416190402190412190416250604250616SNGX 120408RNegativeNC3010NC3030NC3120Square90¡£NegativeNC500HCoatedPC8010NC9020PC9030NC305KNC6110NC315KCermet UncoatedCT10CN2000CN20ST30AH01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI9.18.712.311.911.515.014.218.217.89.18.712.311.911.59.18.712.311.911.511.99.39.18.712.311.911.512.512.311.911.510.315.715.014.614.218.917.417.525.023.811.9Dimensionsd t r3.18 0.43.18 0.84.76 0.44.76 0.84.76 1.26.35 0.86.35 1.66.35 0.86.35 1.23.18 0.43.18 0.84.76 0.44.76 0.84.76 1.23.18 0.43.18 0.84.76 0.44.76 0.84.76 1.24.76 0.89.5259.52512.712.712.715.87515.87519.0519.059.5259.52512.712.712.79.5259.52512.712.712.712.79.5259.5259.52512.712.712.712.712.712.712.712.715.87515.87515.87515.87519.0519.0519.0525.425.412.7 For roughingCutting edge geometry A06 A09 Recommended chip breaker B12 B17 Code system B18 B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) =3.183.183.183.183.183.184.764.764.764.764.764.764.764.764.764.764.764.766.356.354.760.20.40.80.40.81.20.20.40.81.22.40.20.81.21.60.21.21.60.41.60.8(mm)d13.813.815.165.165.166.356.357.937.933.813.815.165.165.163.813.815.165.165.165.163.813.813.815.165.165.165.165.165.165.165.166.356.356.356.357.937.937.939.129.125.16Cutting Conditionfn ap0.17~0.50 0.50~4.500.17~0.50 0.50~4.500.15~0.60 1.50~8.000.15~0.60 1.50~8.000.20~0.80 1.50~8.000.20~0.80 2.00~10.000.20~0.90 2.00~10.000.15~0.60 3.00~12.000.20~0.80 3.00~12.000.12~0.35 1.00~3.000.15~0.35 1.00~3.000.15~0.35 1.00~4.000.15~0.35 1.00~4.000.15~0.35 1.00~4.000.12~0.35 1.00~3.000.15~0.35 1.00~3.000.15~0.35 1.00~4.000.15~0.35 1.00~4.000.15~0.35 1.00~4.000.10~0.30 0.20~1.500.05~0.30 0.50~4.000.10~0.35 0.50~4.000.10~0.40 1.00~4.000.13~0.50 1.30~5.000.15~0.60 1.50~6.000.17~0.60 1.70~6.000.10~0.45 1.00~5.000.13~0.50 1.30~5.000.15~0.60 1.50~6.000.17~0.60 1.70~6.000.20~0.65 2.00~6.000.10~0.50 0.50~6.000.15~0.60 1.50~8.000.17~0.60 2.00~8.000.20~0.65 2.50~8.500.10~0.60 2.00~8.500.17~0.70 2.50~10.000.20~0.75 2.50~10.000.30~0.80 3.00~12.000.35~1.00 4.00~12.001.00~4.00 0.15~0.35AvailabletoolholdersMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LCSDNNCSKNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LPageB71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100B90B91B71B72B78B79B80B97B100 : Stock item : Under preparing for stockB26

SNWorkpiece<strong>Insert</strong>sSNMAFor medium to roughingSNMG-B25For medium to roughingSNMG-GMFor medium cuttingSNMG-GRFor roughingSNMG-GSFor medium to finishingSNMG-HASteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelPMKNSHSNMA 090304090308090312120402120404120408120412120416120430150612150616190608190612190616190624250724250924SNMG 090308-B25120404-B25120408-B25120412-B25120416-B25120420-B25150608-B25150612-B25150616-B25190608-B25190612-B25190616-B25250716-B25250724-B25SNMGSNMGSNMGSNMGDesignation120404-GM120408-GM120412-GM120404-GR120408-GR120412-GR150608-GR150612-GR190608-GR190612-GR190616-GR250724-GR250924-GR120404-GS120408-GS120412-GS120416-GS120404-HA120408-HA120412-HANC3010NC3020NC3120Square90¡£NegativeNC3030CoatedNC500HPC8010NC9020PC9030NC305KNC6110NC6010NC315KCN1000Cermet UncoatedCN2000CN20U20H01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingDimensionsI d t r9.1 9.525 3.18 0.48.7 9.525 3.18 0.88.3 9.525 3.18 1.212.5 12.7 4.76 0.212.3 12.7 4.76 0.411.9 12.7 4.76 0.811.5 12.7 4.76 1.211.1 12.7 4.76 1.69.7 12.7 4.76 3.014.6 15.875 6.35 1.214.2 15.875 6.35 1.618.2 19.05 6.35 0.817.8 19.05 6.35 1.217.4 19.05 6.35 1.616.6 19.05 6.35 2.423.0 25.4 7.94 2.423.0 25.4 9.52 2.48.7 9.525 3.18 0.812.3 12.7 4.76 0.411.9 12.7 4.76 0.811.5 12.7 4.76 1.211.1 12.7 4.76 1.610.7 12.7 4.76 2.015.0 15.875 6.35 0.814.6 15.875 6.35 1.214.2 15.875 6.35 1.618.2 19.05 6.35 0.817.8 19.05 6.35 1.217.4 19.05 6.35 1.623.8 25.4 7.94 1.623.0 25.4 7.94 2.412.3 12.7 4.76 0.411.9 12.7 4.76 0.811.5 12.7 4.76 1.212.311.911.515.014.618.217.817.423.023.012.311.911.511.112.311.911.512.712.712.715.87515.87519.0519.0519.0525.425.412.712.712.712.7 For medium to finishingCutting edge geometry A06 A09 Recommended chip breaker B12 B17 Code system B18 B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) =Note)SNMG-HA(H01) has smooth chip control due to buffed on top surface12.712.712.74.764.764.766.356.356.356.356.357.949.524.764.764.764.764.764.764.76Negative0.40.81.20.81.20.81.21.62.42.40.40.81.21.60.40.81.2(mm)d13.813.813.815.165.165.165.165.165.166.356.357.937.937.937.939.129.123.815.165.165.165.165.166.356.356.357.937.937.939.129.125.165.165.165.165.165.166.356.357.937.937.939.129.125.165.165.165.165.165.165.16<strong>Turning</strong> <strong>Insert</strong>Cutting Conditionfn ap0.10~0.45 0.50~4.500.15~0.50 0.50~4.500.20~0.50 0.50~4.500.10~0.50 1.00~4.500.15~0.60 1.00~5.000.15~0.70 1.00~6.000.20~0.80 1.50~6.000.30~1.00 2.00~6.000.30~0.70 2.50~5.000.20~0.80 2.00~8.000.25~0.85 2.50~10.000.20~0.80 2.00~10.000.20~0.80 2.00~10.000.25~0.85 2.50~10.000.35~0.90 3.00~10.000.40~1.00 3.00~13.000.40~1.00 3.00~13.000.17~0.45 0.80~3.500.17~0.45 1.00~3.500.23~0.60 1.50~5.000.25~0.60 2.00~5.000.35~0.70 2.50~5.000.40~0.70 3.00~5.000.25~0.60 1.50~6.000.25~0.60 2.00~6.000.35~0.70 2.00~6.000.25~0.60 3.00~8.000.30~0.60 3.00~8.000.35~0.70 3.00~8.000.35~0.70 4.00~12.000.50 ~1.00 5.00~12.000.05~0.30 0.90~5.000.10~0.50 1.00~5.000.13~0.60 1.30~5.000.15~0.45 0.08~6.000.20~0.50 1.00~7.000.20~0.50 1.00~7.000.25~0.60 1.00~7.000.29~0.75 1.40~7.000.30~0.80 1.70~9.000.30~0.80 1.70~9.000.31~0.82 1.90~12.300.45~1.20 2.60~14.000.50~1.20 2.60~14.000.10~0.45 0.80~4.500.10~0.50 1.00~5.000.13~0.65 1.00~5.000.15~0.70 1.00~5.000.10~0.35 0.80~3.500.10~0.40 0.80~3.500.13~0.55 0.80~3.50AvailabletoolholdersMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LPageB71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100 : Stock item : Under preparing for stock>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarB27

Carbide ShankBoring Bar Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong><strong>Turning</strong> <strong>Insert</strong>SNWorkpiece<strong>Insert</strong>sSNMG-HCFor medium to finishingSNMG-HRFor roughingSNMG-HSFor medium to finishingSNMG-HUFor ultra finishingSNMG-VFFor finishingSNMG-VGFor finishingSNMG-VMFor medium cuttingSNMG-VQFor medium to finishingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelSNMGSNMGSNMGSNMGSNMGSNMGSNMGSNMGDesignationPMKNSH120404-HC120408-HC120408-HR120412-HR120416-HR150608-HR150612-HR150616-HR150624-HR190608-HR190612-HR190616-HR190624-HR250724-HR250924-HR090304-HS090308-HS120404-HS120408-HS120412-HS150612-HS150616-HS190612-HS190616-HS120404-HU120408-HU120412-HU090304-VF120404-VF120408-VF090304-VG090308-VG120404-VG120408-VG090304-VM090308-VM120404-VM120408-VM120412-VM190612-VM090304-VQ090308-VQ120404-VQ120408-VQNegativeNC3010NC3020Square90¡£NegativeNC3120NC3030CoatedNC500HPC8010NC9020PC9030NC6110Cermet UncoatedCN1000CN2000U20H01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI12.311.911.911.511.11514.614.213.418.217.817.416.623239.18.712.311.911.514.614.217.817.412.311.911.59.112.311.99.18.712.311.99.18.712.311.911.517.89.18.712.311.9Dimensionsd t r12.7 4.76 0.412.7 4.76 0.812.712.712.715.87515.87515.87515.87519.0519.0519.0519.0525.425.49.5259.52512.712.712.715.87515.87519.0519.0512.712.712.79.52512.712.79.5259.52512.712.79.5259.52512.712.712.719.059.5259.52512.712.7Cutting edge geometry A06 A09 Recommended chip breaker B12 B17 Code system B18 B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = 4.764.764.766.356.356.356.356.356.356.356.357.949.523.183.184.764.764.766.356.356.356.354.764.764.763.184.764.763.183.184.764.763.183.184.764.764.766.353.183.184.764.760.81.21.60.81.21.62.40.81.21.62.42.42.40.40.80.40.81.21.21.61.21.60.40.81.20.40.40.80.40.80.40.80.40.80.40.81.21.20.40.80.40.8(mm)d15.165.165.165.165.166.356.356.356.357.937.937.937.939.129.123.813.815.165.165.166.356.357.937.935.165.165.163.815.165.163.813.815.165.163.813.815.165.165.167.933.813.815.165.16Cutting Conditionfn ap0.05~0.35 0.80~4.000.08~0.40 0.80~4.000.20~0.50 1.00~7.000.25~0.70 1.30~7.000.32~0.75 1.80~7.000.20~0.50 1.80~8.000.20~0.70 1.30~8.000.30~0.80 1.80~8.000.32~0.90 2.20~8.000.20~0.50 1.00~10.000.25~0.70 1.30~10.000.30~0.80 1.80~10.000.32~0.90 2.30~10.000.40~1.20 2.30~15.000.40~1.20 2.30~15.000.05~0.25 1.00~2.500.10~0.30 1.00~2.500.05~0.30 1.00~4.500.10~0.40 1.00~4.500.13~0.55 1.00~4.500.13~0.55 1.00~6.100.15~0.60 1.00~4.500.13~0.55 1.00~7.600.15~0.60 1.00~7.600.05~0.25 0.10~1.000.10~0.35 0.20~1.500.12~0.35 0.30~1.500.07~0.30 0.50~1.500.07~0.30 0.50~1.500.10~0.40 0.50~1.500.07~0.30 0.50~1.500.10~0.30 0.50~1.500.07~0.30 0.50~1.500.10~0.40 0.50~1.500.05~0.30 0.90~3.500.10~5.00 1.00~3.500.05~0.30 0.90~5.000.10~0.50 1.00~5.000.13~0.60 1.30~5.000.25~0.60 2.50~7.500.05~0.30 0.05~3.500.08~0.30 0.08~4.000.05~0.30 0.80~4.000.08~0.40 0.80~4.00AvailabletoolholdersMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LPageB71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100 : Stock item : Under preparing for stockB28

SNWorkpiece<strong>Insert</strong>sSNMM-GHFor heavySNMM-GMFor medium cuttingSNMM-GRFor roughingSNMNFor medium to roughingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelSNMMSNMMSNMMDesignationPMKNSH120408-GH120412-GH150612-GH190612-GH190616-GH190624-GH250724-GH250924-GH250932-GH120408-GM120412-GM120408-GR120412-GR190612-GR190616-GRSNMN 120304120308120312120404120408120412150404150408150412190416NC3010NC3020NC3120Square90¡£NegativeCoatedNC3030NC500HPC8010NC9020PC9030NC6110CN1000CermetCN2000CN20UncoatedST30AH01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingDimensionsI d t r11.9 12.7 4.76 0.811.5 12.7 4.76 1.214.6 15.875 6.35 1.217.8 19.05 6.35 1.217.4 19.05 6.35 1.616.6 19.05 6.35 2.423 25.4 7.94 2.423 25.4 9.52 2.422.2 25.4 9.52 3.211.911.511.911.517.817.412.311.911.512.311.911.515.515.011.517.412.712.712.712.719.0519.0512.712.712.712.712.712.715.87515.87512.719.054.764.764.764.766.356.353.183.183.184.764.764.764.764.764.764.76Negative0.81.20.81.21.21.60.40.81.20.40.81.20.40.81.21.6(mm)d15.165.166.357.937.937.939.129.129.125.165.165.165.167.937.935.165.165.165.165.165.166.356.356.357.93<strong>Turning</strong> <strong>Insert</strong>Cutting Conditionfn ap0.30~0.60 2.50~8.000.30~0.70 2.50~8.000.30~0.70 2.50~8.000.30~0.70 3.00~8.000.45~1.00 4.00~9.000.55~1.20 4.00~9.000.55~1.20 5.00~12.000.55~1.20 5.00~12.000.55~1.20 5.00~12.000.10~0.50 1.00~5.000.13~0.60 1.30~5.000.20~0.50 1.00~7.000.25~0.65 1.30~7.000.25~0.65 1.30~11.500.32~0.85 1.80~11.500.17~0.45 1.00~3.500.23~0.60 1.50~6.000.25~0.60 2.00~5.000.17~0.45 1.00~3.500.23~0.60 1.50~5.000.25~0.60 2.00~5.000.20~0.50 1.50~6.000.25~0.60 1.50~6.000.25~0.60 2.00~6.000.35~0.70 2.00~6.00AvailabletoolholdersMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LPageB71B72B78B79B80B97B100B71B72B78B79B80B97B100B71B72B78B79B80B97B100B90B91>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsSNMXFor roughingSNUNFor medium to roughingSNMX120408RSNUN 120408120412190412120412TN250724TN11.911.911.517.411.52312.712.712.719.0512.725.44.764.764.764.764.767.940.80.81.21.21.22.45.165.165.165.165.169.120.15~0.35 1.00~4.000.23~0.60 1.50~5.000.25~0.60 2.00~5.000.30~1.00 3.00~10.000.25~0.60 2.00~5.000.30~1.20 3.00~12.00MSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LMSBNR/LMSDNNMSKNR/LMSRNR/LMSSNR/LPSBNR/LPSDNNPSKNR/LPSSNR/LB71B72B78B79B80B97B100B90B91Carbide ShankBoring BarCutting edge geometry A06 A09 Recommended chip breaker B12 B17 Code system B18 B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = : Stock item : Under preparing for stockB29

Carbide ShankBoring Bar Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong>B30<strong>Turning</strong> <strong>Insert</strong>TNWorkpiece<strong>Insert</strong>sTNGAFor roughingTNGGFor medium cuttingTNGG-HUFor ultra finishingTNGG-SCFor finishingTNGNFor medium cuttingTNMAFor roughingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelPMKNSHTNGA 110302110304160304160402160404160408220304220402220404220408220412270612270624TNGG 110304R160402R160404R160408R220404R220408R220412R110304L160402L160404L160408L220404L220408L220412LTNGG 160404-HU160408-HUTNGGDesignation160402R-SC160404R-SC160402L-SC160404L-SCTNGN 110302110304110308160302160304160308160404160408160412220404220408220412220416220424270630TNMA 110308160404160408160412160416220404220408220412220416220420220432270608270612270616330924NegativeNC3010NC3020NC3030Triangular60¡£NegativeNC500HCoatedPC8010PC9030NC305KNC6110NC6010NC315KCermet UncoatedCT10CN20U20H01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI10.510.015.516.015.514.521.021.721.020.019.024.521.310.016.015.514.521.020.019.010.016.015.514.521.020.019.015.514.516.015.516.015.510.510.09.016.015.514.515.514.513.521.020.019.018.217.419.79.015.514.513.512.521.020.019.018.216.816.525.424.423.327.1Dimensionsd t r6.356.359.5259.5259.5259.52512.712.712.712.712.715.87515.8756.359.5259.52512.712.712.712.76.359.5259.52512.712.712.712.79.5259.5259.5259.5259.5259.5256.356.356.359.5259.5259.5259.5259.5259.52512.712.712.712.712.715.8756.359.5259.5259.5259.52512.712.712.712.712.712.715.87515.87515.87519.05Cutting edge geometry A06 A09 Recommended chip breaker B12 B17 Code system B18 B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = 3.183.183.184.764.764.763.184.764.764.764.766.356.353.184.764.764.764.764.764.764.764.763.184.764.764.764.764.764.764.764.764.764.763.183.183.183.183.183.184.764.764.764.764.764.764.764.766.353.184.764.764.764.764.764.764.764.764.764.766.356.356.359.520.20.40.40.20.40.80.40.20.40.81.21.22.40.40.20.40.80.40.81.20.40.20.40.80.40.81.20.40.80.20.40.20.40.20.40.80.20.40.80.40.81.20.40.81.21.62.43.00.80.40.81.21.60.40.81.21.62.03.20.81.21.62.4(mm)d12.42.43.813.813.813.815.165.165.165.165.166.356.352.43.813.813.815.165.165.162.43.813.813.815.165.165.163.813.813.813.813.813.812.42.42.43.813.813.813.813.813.815.165.165.165.165.166.352.43.813.813.813.815.165.165.165.165.165.166.356.356.357.93Cutting Conditionfn ap0.05~0.30 0.20~3.000.05~0.30 0.40~3.000.10~0.35 0.40~4.000.10~0.30 0.20~4.000.10~0.35 0.40~5.000.12~0.40 0.50~5.000.10~0.35 0.50~5.000.05~0.30 0.20~3.000.10~0.35 0.40~5.000.10~0.40 0.50~5.000.12~0.45 1.00~5.500.12~0.45 1.00~7.000.20~0.55 2.00~7.000.05~0.30 0.05~0.250.08~0.30 0.50~3.500.12~0.30 1.00~3.500.15~0.35 1.30~3.500.12~0.30 1.00~5.000.15~0.35 1.30~5.000.17~0.40 1.50~5.000.05~0.30 0.05~0.250.08~0.30 0.50~3.500.12~0.30 1.00~3.500.15~0.35 1.30~3.500.12~0.30 1.00~5.000.15~0.35 1.30~5.000.17~0.40 1.50~5.000.05~0.25 0.10~1.500.10~0.30 0.20~1.500.03~0.20 0.10~1.500.05~0.25 0.30~2.000.03~0.20 0.10~1.500.05~0.25 0.30~2.000.05~0.25 0.20~2.500.10~0.30 0.50~2.500.10~0.30 0.80~2.500.05~0.30 0.20~3.000.10~0.30 0.50~4.000.10~0.40 0.80~4.000.10~0.40 0.50~4.000.10~0.40 1.00~4.000.10~0.50 1.50~4.500.10~0.35 1.00~4.000.15~0.40 1.50~5.000.20~0.50 1.50~5.000.25~0.55 1.50~5.000.30~0.65 2.00~5.000.35~0.70 2.00~5.000.05~0.30 0.50~3.000.10~0.30 1.00~4.000.10~0.40 1.00~4.000.10~0.50 1.50~4.500.15~0.55 1.50~4.500.10~0.35 1.00~4.000.15~0.40 1.50~5.000.20~0.50 1.50~5.000.25~0.55 1.50~5.000.30~0.65 2.00~5.000.35~0.70 2.00~5.000.20~0.45 2.00~7.000.25~0.55 3.00~7.000.30~0.65 3.00~7.000.35~0.75 3.00~9.00AvailabletoolholdersMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNS, MTFNR/LMTGNR/L, MTJNR/LPTFNR/L, PTGNR/LPTTNR/L, WTENNWTJNR/L, WTXNR/LMTENNS, MTFNR/LMTGNR/L, MTJNR/LPTFNR/L, PTGNR/LPTTNR/L, WTENNWTJNR/L, WTXNR/LCTFNR/LCTGNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LPageB73B74B80B81B89B98B100B73B74B80B81B89B98B100B73B74B80B81B89B98B100B73B74B80B81B89B98B100B91B73B74B80B81B89B98B100 : Stock item : Under preparing for stock

TNWorkpiece<strong>Insert</strong>sTNMG-B25For medium to roughingTNMG-GMFor medium cuttingTNMG-GRFor roughingTNMG-GSFor medium to finishingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationPMKNSHTNMG 110308-B25160304-B25160308-B25160312-B25160316-B25160404-B25160408-B25160412-B25160416-B25220404-B25220408-B25220412-B25220416-B25220424-B25220432-B25270608-B25270612-B25270616-B25330716-B25330924-B25TNMG 160304-GM160404-GM160408-GM160412-GM220404-GM220408-GM220412-GMTNMG 160408-GR160412-GR220408-GR220412-GR220416-GR270608-GR270612-GR270616-GR330924-GRTNMG 160404-GS160408-GS160412-GS220408-GSNC3010NC3020NC3120NC3030Triangular60¡£NegativeCoatedNC500HPC8010NC9020PC9030NC6110NC6010NC315KCN1000CN2000CN20Cermet UncoatedH01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI9.015.514.513.512.515.514.513.512.521.020.019.018.217.216.525.524.523.529.027.115.515.514.513.521.020.019.014.513.520.019.018.225.524.523.527.115.514.513.520.0Dimensionst r3.18 0.83.18 0.43.18 0.83.18 1.23.18 1.64.76 0.44.76 0.84.76 1.24.76 1.64.76 0.44.76 0.84.76 1.24.76 1.64.76 2.44.76 3.26.35 0.86.35 1.26.35 1.67.94 1.69.52 2.43.18 0.44.76 0.44.76 0.84.76 1.24.76 0.44.76 0.84.76 1.24.76 0.84.76 1.24.76 0.84.76 1.24.76 1.66.35 0.86.35 1.26.35 1.69.52 2.44.76 0.44.76 0.84.76 1.24.76 0.8d6.359.5259.5259.5259.5259.5259.5259.5259.52512.712.712.712.712.712.715.87515.87515.87519.0519.059.5259.5259.5259.52512.712.712.79.5259.52512.712.712.715.87515.87515.87519.059.5259.5259.52512.7Negative(mm)d12.43.813.813.813.813.813.813.813.815.165.165.165.165.165.166.356.356.357.937.933.813.813.813.815.165.165.163.813.815.165.165.166.356.356.357.933.813.813.815.16<strong>Turning</strong> <strong>Insert</strong>Cutting Conditionfn ap0.17~0.40 1.50~3.000.17~0.45 2.00~3.500.17~0.55 2.00~3.500.25~0.55 2.00~3.500.30~0.60 2.50~3.000.17~0.45 2.00~3.500.17~0.55 2.00~3.500.25~0.55 2.00~3.500.30~0.60 2.50~3.000.17~0.45 1.50~5.000.17~0.55 2.00~5.000.25~0.55 2.00~5.000.30~0.60 2.00~5.000.35~0.70 3.00~7.000.40~0.75 3.50~7.000.17~0.55 2.00~5.000.25~0.55 3.00~7.000.30~0.60 3.00~7.000.35~0.70 3.00~9.000.40~0.80 3.00~9.000.05~0.30 0.80~5.000.05~0.30 0.80~5.000.10~0.50 1.00~5.000.13~0.60 1.30~5.000.05~0.30 0.90~6.300.10~0.50 1.00~6.600.13~0.60 1.30~6.600.20~0.50 1.00~7.000.23~0.54 1.20~8.000.22~0.61 1.10~7.800.28~0.78 1.20~7.800.31~0.75 1.50~7.800.31~0.75 1.50~7.800.31~0.75 1.50~7.800.36~1.00 1.60~7.800.40~1.00 2.00~9.000.05~0.35 1.00~4.500.10~0.50 1.00~5.000.13~0.65 1.00~5.000.10~0.50 1.00~6.80AvailabletoolholdersMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LPageB73B74B80B81B89B98B100B73B74B80B81B89B98B100B73B74B80B81B89B98B100B73B74B80B81B89B98B100>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarTNMG-HAFor medium to finishingTNMG160404-HA160408-HA160412-HA220408-HA15.514.513.520.09.5259.5259.52512.74.764.764.764.760.40.81.20.83.813.813.815.160.05~0.30 0.80~3.500.10~0.40 0.80~3.500.13~0.55 0.80~3.500.10~0.40 0.80~5.30MTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LB73B74B80B81B89B98B100TNMG-HCFor medium to finishingTNMG160404-HC160408-HC160412-HC220408-HC15.514.513.520.09.5259.5259.52512.74.764.764.764.760.40.81.20.83.813.813.815.160.05~0.35 0.50~3.500.08~0.40 0.80~4.000.13~0.50 0.90~4.000.08~0.40 0.80~4.00MTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LB73B74B80B81B89B98B100Cutting edge geometry A06 A09 Recommended chip breaker : B12 B17 Code system B18 B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Note)TNMG-HA(H01) has smooth chip control due to buffed on top surface : Stock item : Under preparing for stockB31

<strong>Turning</strong> <strong>Insert</strong>Negative>>>Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong>TNWorkpiece<strong>Insert</strong>sTNMG-HRFor roughingTNMG-HSFor medium to finishingTNMG-HUFor ultra finishingTNMG-LWFor wiper medium cuttingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelTNMGTNMGTNMGTNMGDesignationPMKNSH160408-HR160412-HR220404-HR220408-HR220412-HR220416-HR270608-HR270612-HR270632-HR330716-HR330924-HR160404-HS160408-HS160412-HS220408-HS220412-HS160404-HU160408-HU160408-LW160412-LWNC3010NC3020NC3120NC3030 Triangular60NegativeCoated CermetNC500HPC8010NC9020PC9030NC6110CN1000CN2000CN20UncoatedH01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI14.513.521.020.019.018.225.524.519.229.027.115.514.513.520.019.015.514.514.513.5Dimensionst r4.76 0.84.76 1.24.76 0.44.76 0.84.76 1.24.76 1.66.35 0.86.35 1.26.35 3.27.94 1.69.52 2.4d9.5259.52512.712.712.712.715.87515.87515.87519.0519.059.5259.5259.52512.712.79.5259.5259.5259.5254.764.764.764.764.764.764.764.764.760.40.81.20.81.20.40.80.81.2(mm)d13.813.815.165.165.165.166.356.356.357.937.933.813.813.815.165.163.813.813.813.81Cutting Conditionfn ap0.20~0.50 1.00~7.000.25~0.60 1.30~7.000.20~0.45 1.00~7.500.20~0.50 1.00~8.000.25~0.60 1.30~8.000.32~0.70 1.80~8.000.35~0.50 1.80~13.000.35~0.70 2.30~13.000.40~0.90 3.00~13.000.40~0.70 1.80~9.000.45~0.90 3.30~16.000.08~0.35 0.50~4.000.10~0.40 1.00~4.500.13~0.55 1.00~4.500.10~0.40 1.00~6.300.13~0.55 1.00~6.300.05~0.25 0.10~1.500.10~0.30 0.20~1.500.15~0.50 0.70~4.500.20~0.60 1.00~5.00AvailabletoolholdersMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LPageB73B74B80B81B89B98B100B73B74B80B81B89B98B100B73B74B80B81B89B98B100B73B74B80B81B89B98B100Carbide ShankBoring BarTNMG-VFFor finishingTNMG110304-VF160404-VF160408-VF160412-VF220404-VF220408-VF10.015.514.513.521.020.06.359.5259.5259.52512.712.73.184.764.764.764.764.760.40.40.81.20.40.82.43.813.813.815.165.160.05~0.20 0.20~1.000.07~0.30 0.50~1.500.10~0.40 0.50~1.500.15~0.50 0.50~1.500.10~0.40 0.50~1.500.10~0.40 0.50~1.50MTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LB73B74B80B81B89B98B100TNMG-VGFor finishingTNMG110304-VG160404-VG160408-VG220404-VG 10.015.514.521.06.359.5259.52512.73.184.764.764.760.40.40.80.42.43.813.815.160.05~0.20 0.20~1.000.07~0.30 0.50~1.500.10~0.40 0.50~1.500.10~0.40 0.50~1.50MTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LB73B74B80B81B89B98B100TNMG-VMFor medium cuttingTNMG110308-VM160404-VM160408-VM160412-VM220404-VM220408-VM220412-VM9.015.514.513.521.020.019.06.359.5259.5259.52512.712.712.73.184.764.764.764.764.764.760.80.40.81.20.40.81.22.43.813.813.815.165.165.160.05~0.30 0.80~4.000.05~0.30 0.90~5.000.10~0.50 1.00~5.000.13~0.60 1.30~5.000.05~0.30 0.90~6.600.10~0.50 1.00~6.600.13~0.60 1.30~6.60MTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LB73B74B80B81B89B98B100Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = : Stock item : Under preparing for stockB32

Negative<strong>Turning</strong> <strong>Insert</strong>TNWorkpiece<strong>Insert</strong>sTNMG-VQFor medium to finishingTNMG-VWFor wiper finishingTNMM-GHFor heavyTNMM-GMFor medium cuttingTNMM-GRFor roughingTNMNFor medium to roughingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelTNMGTNMGTNMMTNMMTNMMDesignationPMKNSH110304-VQ160404-VQ160408-VQ220404-VQ160404-VW160408-VW160408-GH220408-GH220412-GH220416-GH270616-GH270624-GH330924-GH160412-GM220408-GM220412-GM220416-GM220408-GR220412-GR220416-GRTNMN 160408220408220412NC3010NC3020NC3120NC3030Triangular60Negative CoatedPC8010NC9020PC9030NC6110NC315KCN1000CN2000CermetCN20CC115UncoatedH01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI10.015.514.521.015.514.514.520.019.018.223.421.327.113.520.019.018.220.019.018.214.520.019.0Dimensionst r3.18 0.44.76 0.44.76 0.84.76 0.4d6.359.5259.52512.79.5259.5259.52512.712.712.715.87515.87519.059.52512.712.712.712.712.712.79.52512.712.74.764.764.764.764.764.766.356.359.524.764.764.764.764.764.764.764.764.764.760.40.80.80.81.21.61.62.42.41.20.81.21.60.81.21.60.80.81.2(mm)d12.43.813.815.163.813.813.815.165.165.166.356.357.933.815.165.165.165.165.165.163.815.165.16Cutting Conditionfn ap0.05~0.30 0.50~3.500.05~0.35 0.50~3.500.08~0.40 0.80~4.000.05~0.35 0.50~4.000.10~0.35 0.30~3.000.10~0.40 0.30~3.000.20~0.50 1.00~7.000.25~0.60 1.30~7.000.20~0.50 1.00~8.000.25~0.60 1.30~8.000.32~0.70 1.80~8.000.35~0.50 1.80~13.000.35~0.70 2.30~13.000.13~0.60 1.30~5.000.10~0.50 1.00~6.600.13~0.60 1.30~6.600.15~0.65 1.50~7.000.22~0.61 1.10~7.800.28~0.78 1.20~7.800.31~0.75 1.50~7.800.10~0.30 1.00~4.000.15~0.40 1.50~5.000.20~0.50 1.50~5.00AvailabletoolholdersMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LMTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LPageB73B74B80B81B89B98B100B73B74B80B81B89B98B100B73B74B80B81B89B98B100B73B74B80B81B89B98B100B73B74B80B81B89B98B100B91>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarTNMXFor medium to roughingTNMX160402R160404R160408R220404R220408R160404L160408L 16.515.514.521.020.015.514.59.5259.5259.52512.712.79.5259.5254.764.764.764.764.764.764.760.20.40.80.40.80.40.83.813.813.815.165.163.813.810.10~0.30 0.50~3.000.12~0.30 1.00~3.500.15~0.35 1.30~3.400.12~0.30 1.00~5.000.15~0.35 1.30~5.000.12~0.30 1.00~3.500.15~0.35 1.30~3.40MTENNSMTFNR/LMTGNR/LMTJNR/LPTFNR/LPTGNR/LPTTNR/LWTENNWTJNR/LWTXNR/LB73B74B80B81B89B98B100Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = : Stock item : Under preparing for stockB33

<strong>Turning</strong> <strong>Insert</strong>Negative>>>Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong>VNWorkpiece<strong>Insert</strong>sVNGG-HAFor medium to finishingVNMG-GMFor medium cuttingVNMG-HAFor medium to finishingVNMG-HRFor roughingVNMG-HSFor medium to finishingVNMG-VFFor finishingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelVNGGVNMGVNMGVNMGVNMGVNMGDesignationPMKNSH160408-HA160404-GM160408-GM160404-HA160408-HA160408-HR160404-HS160408-HS160402-VF160404-VF160408-VFNC3010NC3120NC3020NC3030 Rhombic35NegativeCoated Cermet UncoatedNC500HPC8010NC9020PC9030 NC305KNC6110NC315KCN1000CT10CN2000CC115H01G10EMachining typesContinuous cuttingGeneral cuttingInterrupted cuttingI14.615.614.615.614.614.615.614.616.115.614.6Dimensionsd9.525t4.76r0.89.5259.5259.5259.5259.5259.5259.5259.5259.5259.5254.764.764.764.764.764.764.764.764.764.760.40.80.40.80.80.40.80.20.40.8(mm) Cutting Conditiond1 fn ap3.81 0.10~0.40 0.80~3.503.813.813.813.813.813.813.813.813.813.810.08~0.45 0.50~3.500.10~0.50 1.00~4.000.08~0.35 0.50~3.000.10~0.40 0.80~3.500.10~0.50 1.00~4.000.08~0.35 0.50~4.000.10~0.40 1.00~4.500.06~0.20 0.30~1.000.08~0.30 0.50~1.500.10~0.40 0.50~1.50AvailabletoolholdersMVJNR/LMVQNR/LMVVNNMVUNR/LMVJNR/LMVQNR/LMVVNNMVUNR/LMVJNR/LMVQNR/LMVVNNMVUNR/LMVJNR/LMVQNR/LMVVNNMVUNR/LMVJNR/LMVQNR/LMVVNNMVUNR/LMVJNR/LMVQNR/LMVVNNMVUNR/LPageB74B75B98B74B75B98B74B75B98B74B75B98B74B75B98B74B75B98Carbide ShankBoring BarVNMG-VGFor finishingVNMG160404-VG160408-VG15.614.69.5259.5254.764.760.40.83.813.810.08~0.30 0.50~1.500.10~0.40 0.50~1.50MVJNR/LMVQNR/LMVVNNMVUNR/LB74B75B98VNMG-VMFor medium cuttingVNMG160404-VM160408-VM160412-VM220404-VM220408-VM 15.614.613.621.120.09.5259.5259.52512.712.74.764.764.764.764.760.40.81.20.40.83.813.813.815.165.160.08~0.45 0.50~3.500.10~0.50 1.00~4.000.20~0.50 1.50~4.000.08~0.45 1.00~5.000.10~0.50 1.50~5.00MVJNR/LMVQNR/LMVVNNMVUNR/LB74B75B98VNMG-VQVNMG160404-VQ160408-VQ 15.614.69.5259.5254.764.760.40.83.813.810.10~0.40 0.50~3.500.12~0.45 0.50~3.50MVJNR/LMVQNR/LMVVNNMVUNR/LB74B75B98For medium to finishingVNMPVNMP 16040416040815.614.69.5259.5254.764.760.40.83.813.810.08~0.30 0.50~1.500.10~0.40 0.50~1.50MVJNR/LMVQNR/LMVVNNMVUNR/LB74B75B98For roughingCutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Note)VNMG-HA(H01) has smooth chip control due to buffed on top surface : Stock item : Under preparing for stockB34

Negative<strong>Turning</strong> <strong>Insert</strong>WNWorkpiece<strong>Insert</strong>sWNMAFor roughingWNMG-B25For medium to roughingWNMG-GMFor medium cuttingWNMG-GRFor roughingWNMG-GSFor medium to finishingWNMG-HAFor medium to finishingWNMG-HCFor medium to finishingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationPMKNSHWNMA 060404060408060412080404080408080412WNMG 080404-B25080408-B25080412-B25WNMG 060404-GM060408-GM080404-GM080408-GM080412-GMWNMG 080404-GR080408-GR080412-GR080416-GRWNMG 060404-GS060408-GS080404-GS080408-GS080412-GSWNMG 060404-HA060408-HA080404-HA080408-HA080412-HAWNMG 060404-HC080404-HC080408-HCNC3010NC3020NC3120 Trigon80NegativeCoatedNC3030PC8010NC9020PC9030 NC305KNC6110 NC6010Cermet UncoatedNC315KCT10CN20H01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI6.26.16.08.48.38.28.48.38.26.26.18.48.38.28.48.38.28.16.26.18.48.38.26.26.18.48.38.26.28.48.3Dimensionsd t r9.5259.5259.52512.712.712.712.712.712.79.5259.52512.712.712.712.712.712.712.79.5259.52512.712.712.79.5259.52512.712.712.79.52512.712.74.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.760.40.81.20.40.81.20.40.81.20.40.80.40.81.20.40.81.21.60.40.80.40.81.20.40.80.40.81.20.40.40.8(mm)d13.813.813.815.165.165.165.165.165.163.813.815.165.165.165.165.165.165.163.813.815.165.165.163.813.815.165.165.163.815.165.16Cutting Conditionfn ap0.10~0.30 0.50~3.000.10~0.30 0.50~3.000.10~0.40 1.00~3.000.15~0.60 1.00~5.000.15~0.60 1.00~6.000.15~0.70 1.50~6.000.17~0.45 1.00~5.000.23~0.60 1.50~5.000.25~0.60 2.00~5.000.05~0.30 0.90~3.500.10~0.45 1.00~3.500.05~0.30 0.90~5.000.10~0.50 1.00~5.000.18~0.60 0.30~5.000.15~0.50 0.08~6.000.20~0.50 1.00~7.000.25~0.50 1.30~7.000.25~0.60 1.80~6.000.05~0.25 0.10~3.000.10~0.50 1.00~4.000.05~0.25 0.10~3.000.10~0.50 1.00~5.000.13~0.65 1.00~5.000.05~0.30 0.10~3.000.10~0.40 0.80~3.500.05~0.30 0.80~3.500.10~0.40 0.80~3.500.13~0.55 0.80~3.500.05~0.30 0.80~4.000.05~0.30 0.80~4.000.08~0.40 0.80~4.00AvailabletoolholdersMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LPageB75B81B89B98B100B75B81B89B98B100B75B81B89B98B100B75B81B89B98B100B75B81B89B98B100B75B81B89B98B100B75B81B89B98B100>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarWNMG-HRWNMG 060408-HR060412-HR080408-HR080412-HR080416-HR6.16.08.38.28.19.5259.52512.712.712.74.764.764.764.764.760.81.20.81.21.63.813.815.165.165.160.20~0.40 1.00~5.500.25~0.50 1.10~5.500.20~0.50 1.00~7.000.25~0.65 1.30~7.000.32~0.70 1.80~7.00MWLNR/LPWLNR/LWWLNR/LB75B81B89B98B100For roughingWNMG-HSFor medium to finishingWNMG 060404-HS060408-HS060412-HS080404-HS080408-HS080412-HS6.26.16.08.48.38.29.5259.5259.52512.712.712.74.764.764.764.764.764.760.40.81.20.40.81.23.813.813.815.165.165.160.05~0.20 1.00~2.500.10~0.20 1.00~2.500.10~0.30 1.00~3.500.05~0.30 1.00~4.500.10~0.40 1.00~4.500.13~0.55 1.00~4.50MWLNR/LPWLNR/LWWLNR/LB75B81B89B98B100Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Note)WNMG-HA(H01) has smooth chip control due to buffed on top surface : Stock item : Under preparing for stockB35

Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong>Carbide ShankBoring Bar<strong>Turning</strong> <strong>Insert</strong>WNWorkpiece<strong>Insert</strong>sWNMG-HUFor ultra finishingWNMG-LWFor Wiper medium cuttingWNMG-VFFor finishingWNMG-VGFor finishingWNMG-VMFor medium cuttingWNMG-VQFor medium to finishingWNMG-VWSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationPMKNSHWNMG 080404-HU080408-HU080412-HUWNMG 060408-LW060412-LW080408-LW080412-LWWNMG 060404-VF060408-VF080404-VF080408-VFWNMG 060404-VG060408-VG080404-VG080408-VGWNMG 060402-VM060404-VM060408-VM060412-VM080404-VM080408-VM080412-VMWNMG 060404-VQ060408-VQ080404-VQ080408-VQWNMG 080404-VW080408-VWNegativeNC3010NC3120NC3030 Trigon80NegativeCoatedNC500HPC8010NC9020PC9030 NC305KNC6110NC315KCermet UncoatedCN1000CN2000 U20H01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI8.48.38.26.16.08.38.26.16.18.48.36.26.18.48.36.56.26.16.08.48.38.26.26.18.48.38.48.3Dimensionsd12.712.712.7t4.764.764.76r0.40.81.29.5259.52512.712.79.5259.52512.712.79.5259.52512.712.79.5259.5259.5259.52512.712.712.79.5259.52512.712.712.712.74.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.760.81.20.81.20.40.80.40.80.40.80.40.80.20.40.81.20.40.81.20.40.80.40.80.40.8(mm)d15.165.165.163.813.815.165.163.813.815.165.163.813.815.165.163.813.813.813.815.165.165.163.813.815.165.165.165.16Cutting Conditionfn ap0.10~0.30 0.20~1.500.10~0.30 0.50~1.500.10~0.35 0.80~1.500.15~0.60 0.50~3.500.20~0.70 0.80~3.500.15~0.60 1.00~5.000.20~0.70 1.00~6.000.07~0.30 0.50~1.500.10~0.40 0.50~1.500.07~0.30 0.50~1.500.10~0.40 0.50~1.500.07~0.30 0.50~1.500.10~0.40 0.50~1.500.07~0.30 0.50~1.500.10~0.40 0.50~1.500.05~0.30 0.90~3.500.10~0.45 1.00~3.500.10~0.50 1.00~4.000.13~0.60 1.30~4.000.05~0.30 0.90~5.000.10~0.50 1.00~5.000.10~0.50 1.00~5.000.05~0.30 0.50~4.000.08~0.30 0.80~4.000.05~0.30 0.50~4.000.08~0.40 0.80~4.000.10~0.30 0.50~3.000.15~0.50 0.50~4.00AvailabletoolholdersMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LMWLNR/LPWLNR/LWWLNR/LPageB75B81B89B98B100B75B81B89B98B100B75B81B89B98B100B75B81B89B98B100B75B81B89B98B100B75B81B89B98B100B75B81B89B98B100For finishingWNMM-B25WNMM 100608-B25130612-B2510.012.015.87519.056.356.350.81.26.357.930.30~0.80 3.00~8.000.40~0.90 4.00~10.00MWLNR/LPWLNR/LWWLNR/LB75B81B89B98B100For medium to roughingCutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = : Stock item : Under preparing for stockB36

CCWorkpiece<strong>Insert</strong>sCCETFor finishingCCGT-C05For finishingCCGT-HFPFor finishingCCGT-KFFor finishing(Auto Tool)CCGT-KMFor medium to finishing(Auto Tool)SteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelCCETDesignationPMKNSH0301005R030101R030102R030104R0401005R040101R040102R040104R0301005L030101L030102L030104L0401005L040101L040102L040104LCCGT 060202-C05060204-C0509T304-C0509T308-C05120404-C05120408-C05CCGT 060202-HFP060204-HFP060208-HFP09T302-HFP09T304-HFP09T308-HFP120404-HFP120408-HFPCCGT 0602003R-KF060201R-KF060202R-KF09T3003R-KF09T301R-KF09T302R-KF0602003L-KF060201L-KF060202L-KF09T3003L-KF09T301L-KF09T302L-KFCCGT 0602003R-KM060201R-KM060202R-KM09T3003R-KM09T301R-KM09T302R-KM0602003L-KM060201L-KM060202L-KM09T3003L-KM09T301L-KM09T302L-KMNC3010NC3020NC3120NC3030 Rhombic80PositiveCoatedPC8010NC9020PC9030NC305KNC6110NC315KCT10Cermet UncoatedCN2000CN20U20H01G10Relief Angle : 7I3.63.53.33.14.34.24.13.93.63.53.33.14.34.24.13.96.26.09.28.812.412.06.26.05.69.49.28.812.412.06.56.56.59.79.79.76.56.56.59.79.79.76.56.56.59.79.79.76.56.56.59.79.79.7Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingDimensionsd t r3.53.53.53.54.34.34.34.33.53.53.53.54.34.34.34.36.356.359.5259.52512.712.76.356.356.359.5259.5259.52512.712.76.356.356.359.5259.5259.5256.356.356.359.5259.5259.5256.356.356.359.5259.5259.5256.356.356.359.5259.5259.5251.391.391.391.391.791.791.791.791.391.391.391.391.791.791.791.792.382.383.973.974.764.762.382.382.383.973.973.974.764.762.382.382.383.973.973.972.382.382.383.973.973.972.382.382.383.973.973.972.382.382.383.973.973.97Positive0.050.10.20.40.050.10.20.40.050.10.20.40.050.10.20.40.20.40.40.80.40.80.20.40.80.20.40.80.40.80.030.10.20.030.10.20.030.10.20.030.10.20.030.10.20.030.10.20.030.10.20.030.10.2(mm)d11.91.91.91.92.32.32.32.31.91.91.91.92.32.32.32.32.82.84.44.45.55.52.82.82.84.44.44.45.55.52.82.82.84.44.44.42.82.82.84.44.44.42.82.82.84.44.44.42.82.82.84.44.44.4<strong>Turning</strong> <strong>Insert</strong>Cutting Conditionfn ap0.01~0.05 0.10~0.300.01~0.05 0.10~0.300.01~0.05 0.10~0.300.01~0.05 0.10~0.300.01~0.10 0.10~0.500.01~0.10 0.10~0.500.01~0.10 0.10~0.500.01~0.10 0.10~0.500.01~0.05 0.10~0.300.01~0.05 0.10~0.300.01~0.05 0.10~0.300.01~0.05 0.10~0.300.01~0.10 0.10~0.500.01~0.10 0.10~0.500.01~0.10 0.10~0.500.01~0.10 0.10~0.500.06~0.11 0.06~1.700.08~0.17 0.10~1.700.11~0.23 0.10~2.000.08~0.30 0.20~2.000.07~0.27 0.10~2.700.08~0.30 0.20~2.700.03~0.06 0.06~1.200.05~0.12 0.10~1.200.05~0.12 0.12~1.400.04~0.16 0.08~1.500.06~0.18 0.10~1.500.08~0.25 0.20~1.500.06~0.20 0.10~2.000.10~0.25 0.20~2.000.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.11 0.06~1.700.02~0.08 0.05~1.500.03~0.11 0.06~1.700.04~0.15 0.08~2.000.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.11 0.06~1.700.02~0.08 0.05~1.500.03~0.11 0.06~1.700.04~0.15 0.08~2.000.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.11 0.06~1.700.02~0.08 0.06~1.500.03~0.11 0.06~1.700.04~0.15 0.08~2.000.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.11 0.06~1.700.02~0.08 0.06~1.500.03~0.11 0.06~1.700.04~0.15 0.08~2.00AvailabletoolholdersSCLCR/L(Boring bar)SCLCR/L(Boring bar)SCACR/LSCLCR/LSCACR/LSCLCR/LSCACR/LSCLCR/LSCACR/LSCLCR/LSCACR/LSCLCR/LSCACR/LSCLCR/LPageB107B107B82B101B82B101B117B117B117B117 : Stock item : Under preparing for stock>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarB37

Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong>Carbide ShankBoring Bar<strong>Turning</strong> <strong>Insert</strong> PositiveCCWorkpiece<strong>Insert</strong>sCCMT-C25For medium cuttingCCMT-HFPFor finishingCCMT-HMPFor medium cuttingCPCPGTCPGT-C05PMKNSHCCMT 060202-C25060204-C25060208-C25080308-C2509T304-C2509T308-C25120404-C25120408-C25120412-C25CCMTCCMT060202-HFP060204-HFP060208-HFP09T302-HFP09T304-HFP09T308-HFP120404-HFP120408-HFP060202-HMP060204-HMP060208-HMP09T302-HMP09T304-HMP09T308-HMP120404-HMP120408-HMP120412-HMPPMKNSHCPGT 080202080204080208090302090304090308CPGT 080204-C05080208-C05090304-C05090308-C05NC3010NC3020NC3120NC3030 NC3020NC3120NC3030Rhombic80PositivePC8010NC9020PC9030 Rhombic80PositiveNC500HPC8010NC9020PC9030NC305KNC6110 NC6010NC315KCN1000CT10CN2000CN20NC305KNC6110NC315KCT10CN2000 U20H01G10Relief Angle : 7H01G10I6.26.05.67.29.28.812.412.011.66.26.05.69.49.20.82.412.06.26.05.69.49.28.812.412.011.6Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Workpiece<strong>Insert</strong>sFor finishingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationCoatedCoatedCermetUncoatedCermet UncoatedMachining typesContinuous cuttingGeneral cuttingInterrupted cuttingRelief Angle : 11I7.87.67.29.49.28.87.67.29.28.8d6.356.356.357.949.5259.52512.712.712.76.356.356.359.5259.5259.52512.712.76.356.356.359.5259.5259.52512.712.712.7Dimensionsd t r7.947.947.949.5259.5259.5257.947.949.5259.525Dimensionst2.382.382.383.183.973.973.974.764.762.382.382.383.973.973.974.764.762.382.382.383.973.973.974.764.764.76Machining typesContinuous cuttingGeneral cuttingInterrupted cutting2.382.382.383.183.183.182.382.383.183.18r0.20.40.80.80.40.80.40.81.20.20.40.80.20.40.80.40.80.20.40.80.20.40.40.40.81.20.20.40.80.20.40.80.40.80.40.8(mm)d12.82.82.83.44.44.45.55.55.52.82.82.84.44.44.45.55.52.82.82.84.44.44.45.55.55.53.43.43.44.44.44.43.43.44.44.4Cutting Conditionfn ap0.03~0.12 0.40~2.000.05~0.15 0.60~2.300.07~0.20 0.80~2.300.08~0.25 0.80~2.300.08~0.25 0.80~3.000.10~0.30 1.00~3.000.10~0.32 0.80~3.000.12~0.36 1.20~3.500.15~0.40 1.40~3.500.03~0.06 0.08~1.200.05~0.12 0.10~1.200.05~0.12 0.10~1.400.04~0.16 0.08~1.500.06~0.18 0.10~1.500.08~0.25 0.20~1.500.07~0.22 0.10~2.000.08~0.30 0.12~2.200.03~0.12 0.10~1.500.06~0.17 0.20~2.400.08~0.23 0.40~2.400.07~0.22 0.10~2.000.08~0.23 0.30~3.000.10~0.30 0.50~3.000.09~0.27 0.30~3.600.24~0.36 1.00~3.600.14~0.43 0.70~3.600.06~0.20 0.10~2.000.08~0.20 0.30~2.000.10~0.25 0.50~2.000.04~0.20 0.30~1.500.06~0.25 0.50~2.000.08~0.30 0.70~2.500.02~0.15 0.50~1.700.04~0.18 0.50~1.700.03~0.20 0.70~2.000.05~0.20 0.70~2.00AvailabletoolholdersSCACR/LSCLCR/LSCACR/LSCLCR/LSCACR/LSCLCR/LSCLPR/L(Boring bar)SCLPR/L(Boring bar)PageB82B101B82B101B82B101 : Stock item : Under preparing for stock(mm) Cutting Condition Availabled1 fn ap toolholdersPageB102B102For finishingCPGT-HMPCPGT090308-HMP8.89.5253.180.84.40.05~0.20 0.70~2.00SCLPR/L(Boring bar)B102For medium cuttingCutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = : Stock item : Under preparing for stockB38

DCWorkpiece<strong>Insert</strong>sDCGT-C05For finishingDCGT-HFPFor finishingDCGT-KFFor finishing(Auto Tool)DCGT-KMFor medium to finishing(Auto Tool)DCMT-C25For medium cuttingDCMT-HFPFor finishingDCMT-HMPFor medium cuttingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelPMKNSHDCGT 070202-C05070204-C0511T302-C0511T304-C0511T308-C05DCGTDCGTDCGT070202-HFP070204-HFP070208-HFP11T301-HFP11T302-HFP11T304-HFP11T308-HFP0702003R-KF070201R-KF070202R-KF11T3003R-KF11T301R-KF11T302R-KF0702003L-KF070201L-KF070202L-KF11T3003L-KF11T301L-KF11T302L-KF0702003R-KM070201R-KM070202R-KM11T3003R-KM11T301R-KM11T302R-KM0702003L-KM070201L-KM070202L-KM11T3003L-KM11T301L-KM11T302L-KMDCMT 070202-C25070204-C25070208-C2511T302-C2511T304-C2511T308-C25DCMT 070202-HFP070204-HFP070208-HFP11T301-HFP11T302-HFP11T304-HFP11T308-HFPDCMTDesignation070202-HMP070204-HMP070208-HMP11T302-HMP11T304-HMP11T308-HMPNC3010NC3020NC3120 Rhombic55PositiveCoatedNC3030PC8010NC9020PC9030 NC305KNC6110NC6010 NC315KCN1000CT10CN2000CN20Cermet Relief Angle : 7UncoatedH01G10I7.57.311.411.210.87.57.36.811.511.411.210.87.87.87.811.611.611.67.87.87.811.611.611.67.87.87.811.611.611.67.87.87.811.611.611.67.57.36.811.311.210.87.57.36.811.511.411.210.87.57.36.811.411.210.8Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingd6.356.359.5259.5259.5256.356.356.359.5259.5259.5259.5256.356.356.359.5259.5259.5256.356.356.359.5259.5259.5256.356.356.359.5259.5259.5256.356.356.359.5259.5259.5256.356.356.359.5259.5259.5256.356.356.359.5259.5259.5259.5256.356.356.359.5259.5259.525Dimensionst2.382.383.973.973.972.382.382.383.973.973.973.972.382.382.383.973.973.972.382.382.383.973.973.972.382.382.383.973.973.972.382.382.383.973.973.972.382.382.383.973.973.972.382.382.383.973.973.973.972.382.382.383.973.973.97Positiver0.20.40.20.40.80.20.40.80.10.20.40.80.030.10.20.030.10.20.030.10.20.030.10.20.030.10.20.030.10.20.030.10.20.030.10.20.20.40.80.20.40.80.20.40.80.10.20.40.80.20.40.80.20.40.8(mm)d12.82.84.44.44.42.82.82.84.44.44.44.42.82.82.84.44.44.42.82.82.84.44.44.42.82.82.84.44.44.42.82.82.84.44.44.42.82.82.84.44.44.42.82.82.84.44.44.44.42.82.82.84.44.44.4<strong>Turning</strong> <strong>Insert</strong>Cutting Conditionfn ap0.06~0.11 0.06~1.500.05~0.17 0.08~1.500.04~0.15 0.08~2.000.06~0.23 0.10~2.000.08~0.30 0.20~2.000.03~0.10 0.06~1.000.05~0.12 0.08~1.000.06~0.12 0.10~1.000.03~0.13 0.06~1.000.04~0.15 0.08~1.500.06~0.20 0.10~1.500.08~0.25 0.20~1.500.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.11 0.06~1.500.02~0.08 0.05~1.500.03~0.11 0.06~1.700.04~0.15 0.08~2.000.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.11 0.06~1.500.02~0.08 0.05~1.500.03~0.11 0.06~1.700.04~0.15 0.08~2.000.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.11 0.06~1.500.02~0.08 0.05~1.500.03~0.11 0.06~1.700.04~0.15 0.08~2.000.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.11 0.06~1.500.02~0.08 0.05~1.500.03~0.11 0.06~1.700.04~0.15 0.08~2.000.03~0.15 0.30~2.000.05~0.20 0.50~2.500.06~0.25 0.80~2.500.04~0.25 0.50~2.500.08~0.30 0.80~3.000.10~0.30 1.00~3.000.03~0.10 0.06~1.000.05~0.12 0.08~1.000.06~0.12 0.10~1.000.03~0.13 0.06~1.000.04~0.15 0.08~1.500.06~0.20 0.10~1.500.08~0.25 0.20~1.500.03~0.12 0.10~1.500.06~0.17 0.20~2.300.08~0.23 0.40~2.300.04~0.22 0.10~2.000.08~0.23 0.30~3.000.10~0.30 0.50~3.00AvailabletoolholdersSDACR/LSDJCR/LSDNCNSDQCR/LSDUCR/LSDZCR/LSDACR/LSDJCR/LSDNCNSDQCR/LSDUCR/LSDZCR/LSDJCR/LSDNCNSDJCR/LSDNCNSDJCR/LSDNCNSDJCR/LSDNCNSDACR/LSDJCR/LSDNCNSDQCR/LSDUCRSDZCR/LSDACR/LSDJCR/LSDNCNSDQCR/LSDUCRSDZCR/LSDACR/LSDJCR/LSDNCNSDQCR/LSDUCRSDZCR/LPageB82B83B102B103B82B83B102B103B117B118B117B118B117B118B117B118B82B83B102B103B82B83B102B103B82B83B102B103 : Stock item : Under preparing for stock>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarB39

Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong>Carbide ShankBoring Bar<strong>Turning</strong> <strong>Insert</strong> PositiveRCWorkpiece<strong>Insert</strong>sRCMXFor medium to roughingSCSCGT-HFPFor finishingSCMT-C25SCMT-HFPRCMXSCGTSCGT1003M01204M01606M02006M02507M03209M0PMKNSHPMKNSH09T304-C0509T308-C05120408-C0509T304-HFPSCMT 060204-C2509T304-C2509T308-C25120404-C25120408-C25SCMT09T304-HFPNC3010NC3020NC3120NC3030 RoundRPositiveNC500HNC9020NC6110NC6010NC315KPC3545CT10CN2000CN20Square90Positive U20H01G10Relief Angle : 7d10.012.016.020.025.032.0Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Workpiece<strong>Insert</strong>sSCGT-C05For finishingFor medium cuttingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationNC3010NC3020NC3120NC3030CoatedCoatedNC9020PC9030NC6110NC6010NC315KCN1000Cermet UncoatedCermetCN2000CN20Dimensionst3.184.766.356.357.949.52Relief Angle : 7UncoatedH01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingMachining typesContinuous cuttingGeneral cuttingInterrupted cuttingI9.18.711.99.15.99.18.712.311.99.1Dimensionsd t r9.525 3.97 0.49.525 3.97 0.812.7 4.76 0.89.5256.359.5259.52512.712.79.5253.972.383.973.974.764.763.970.40.40.40.80.40.80.4(mm)d13.64.25.26.57.259.55d14.44.45.54.44.44.44.45.55.54.4Cutting Conditionfn ap0.25~0.50 1.50~4.000.30~0.60 2.50~5.000.40~0.70 3.00~7.000.48~0.90 3.50~9.000.55~1.20 4.00~12.000.65~1.50 5.00~15.000.11~0.23 0.10~2.000.08~0.30 0.20~2.000.08~0.33 0.20~2.000.05~0.25 0.10~1.500.08~0.25 0.40~2.500.08~0.25 0.60~3.000.10~0.30 1.00~3.000.10~0.30 0.80~3.800.12~0.38 1.20~3.800.05~0.25 0.10~1.50PRDCNPRGCR/LSSBCR/LSSDCNSSKCR/LSSSCR/LSSBCR/LSSDCNSSKCR/LSSSCR/LSSBCR/LSSDCNSSKCR/LSSSCR/LSSBCR/LSSDCNSSKCR/LSSSCR/LB77B78 : Stock item : Under preparing for stock(mm) Cutting Conditionfn apAvailabletoolholdersAvailabletoolholdersPagePageB84B85B103B84B85B103B84B85B103B84B85B103For finishingSCMT-HMPSCMT09T304-HMP09T308-HMP120404-HMP120408-HMP 9.18.712.311.99.5259.52512.712.73.973.974.764.760.40.80.40.84.44.45.55.50.08~0.23 0.30~3.000.10~0.30 0.50~3.000.09~0.27 0.30~3.600.12~0.36 0.60~3.60SSBCR/LSSDCNSSKCR/LSSSCR/LB84B85B103For medium cuttingCutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = : Stock item : Under preparing for stockB40

SPWorkpiece<strong>Insert</strong>sSPGAFor medium to finishingSPGNFor medium to finishingSPGR-FFor finishingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationPMKNSHSPGA 060204090308T090308T-ZSPGN 070202070208090302090304090308120302120304120308120312120316120402120404120408120416120430120440150404150408150412150416150420190404190408190412190416190424SPGR 090304-F120304-FNC3010NC3030NC3120Square90PositiveCoatedNC500HPC6510PC8010NC9020PC9030NC305KNC6110NC315KCermetCT10CN2000UncoatedH01ST30AST30NST20G10Relief Angle : 11Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI5.98.78.77.77.89.39.18.712.512.311.910.510.112.512.311.911.19.78.715.515.014.814.213.918.718.317.817.416.79.112.3Dimensionsd t r6.35 2.38 0.49.525 3.18 0.89.525 3.18 0.87.947.949.5259.5259.52512.712.712.712.712.712.712.712.712.712.712.715.87515.87515.87515.87515.87519.0519.0519.0519.0519.059.52512.72.382.383.183.183.183.183.183.183.183.184.764.764.764.764.764.764.764.764.764.764.764.764.764.764.764.763.183.18Positive0.20.80.20.40.80.20.40.81.21.60.20.40.81.63.04.00.40.81.21.62.00.40.81.21.62.40.40.4(mm)d12.84.43.4--------------------------<strong>Turning</strong> <strong>Insert</strong>Cutting Condition Availablefn ap toolholders0.50~0.25 0.50~2.000.10~0.25 0.70~3.000.10~0.25 0.70~3.00-0.03~0.10 0.50~2.000.10~0.25 0.70~3.000.03~0.10 0.50~3.000.08~0.20 0.70~3.500.10~0.25 0.70~3.500.03~0.20 0.50~3.000.08~0.20 1.00~5.000.10~0.25 1.00~5.000.15~0.30 1.00~5.000.18~0.33 1.00~5.000.03~0.20 0.50~3.000.08~0.20 1.00~5.000.10~0.25 1.00~5.000.18~0.33 1.00~5.000.20~0.60 2.00~5.000.25~0.70 3.00~5.000.08~0.20 1.50~7.000.10~0.25 1.50~7.000.15~0.30 1.50~7.000.18~0.33 1.50~7.000.20~0.45 1.50~7.000.08~0.20 1.50~9.000.10~0.25 1.50~9.000.15~0.45 1.50~9.000.18~0.60 1.50~9.000.25~0.70 2.50~9.000.05~0.20 0.30~2.000.10~0.25 0.50~2.00-CSDPNCSKPR/LPage--B67B68B96>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarSPGR-MSPGR 090308-M120308-M8.711.99.52512.73.183.180.80.8--0.10~0.40 1.00~3.500.20~0.40 1.50~4.00CSDPNCSKPR/LB67B68B96For medium cuttingSPGTSPGT090304R090308R090304L090308L9.18.79.18.79.5259.5259.5259.5253.183.183.183.180.40.80.40.83.43.43.43.40.08~0.23 0.30~3.000.10~0.30 0.50~3.000.08~0.23 0.30~3.000.10~0.30 0.50~3.00SSKPR/L(Boring bar)B104For medium to finishingSPGT-C05SPGT 090304-C05090308-C059.18.79.5259.5253.183.180.40.84.44.40.11~0.23 0.10~2.000.08~0.30 0.20~2.00SSKPR/L(Boring bar)B104For finishingCutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = : Stock item : Under preparing for stockB41

Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong>Carbide ShankBoring Bar<strong>Turning</strong> <strong>Insert</strong> PositiveSPWorkpiece<strong>Insert</strong>sSPMR-FFor finishingSPMR-MFor medium cuttingSPUNFor medium to finishingTBSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationSPMR 090304-F120304-FPMKNSHSPMR 090308-M120308-M120312-MSPUN 120304120308150412190412190416250620120308SNNC3010NC3020NC3120NC3030NC3010 NC3030NC3120Square90PositiveCoatedPC8010NC9020PC9030NC6110CT10CN2000CN20Triangular60PositiveNC500HPC8010NC9020PC9030NC305KNC6110NC315KCermetCT10CN2000UncoatedST30AH01G10Relief Angle : 11U20H01G10I9.112.38.711.910.512.311.914.617.817.523.411.9Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingDimensionsd t9.525 3.1812.7 3.189.52512.712.712.712.715.87519.0519.0525.412.7Relief Angle : 53.183.183.183.183.184.764.764.766.353.18(mm) Cutting Conditionfn apr0.40.40.80.81.20.40.81.21.21.62.00.80.05~0.20 0.30~2.000.10~0.25 0.50~2.000.10~0.40 1.00~3.500.10~0.40 1.50~4.000.20~0.40 1.50~4.000.10~0.30 1.00~5.000.15~0.40 1.00~5.000.20~0.50 1.00~5.000.20~0.50 1.50~7.000.25~0.60 2.00~7.000.30~0.80 3.00~10.000.15~0.40 1.00~5.00AvailabletoolholdersCSDPNCSKPR/L(Boring bar)CSDPNCSKPR/L(Boring bar)-STUBR/L(Compact mini)PageB67B68B96B67B68B96 : Stock item : Under preparing for stockSteel PMachining typesStainless steel MCast iron KContinuous cuttingWorkpieceNon-ferrous metal NGeneral cuttingHeat resistant alloy, Titanium alloyHardened steelSHInterrupted cuttingCoatedCermet Uncoated<strong>Insert</strong>sDesignationDimensions (mm) Cutting ConditionI d t r d1 fn apTBGTTBGT 060102L 6.4 3.97 1.59 0.2 2.16 0.05~0.20 0.10~1.30060104L 5.8 3.97 1.59 0.4 2.16 0.08~0.20 0.10~1.30Availabletoolholders-PageB107For finishingCutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = : Stock item : Under preparing for stockB42

TCWorkpiece<strong>Insert</strong>sTCGT-C05For finishingTCGT-HFPFor finishingTCGT-KFFor finishing(Auto Tool)TCMT-C25For medium cuttingTCMT-HFPFor finishingTCMT-HMPFor medium cuttingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelPMKNSHTCGT 090204-C05110208-C05TCGT090204-HFP110202-HFP110204-HFP16T304-HFPTCGT 0802003R-KF080201R-KF080202R-KF0802003L-KF080201L-KF080202L-KFTCMT 090204-C25090208-C25110202-C25110204-C25110208-C2516T304-C2516T308-C25TCMT 090204-HFP110202-HFP110204-HFP16T302-HFP16T304-HFPTCMTDesignation090204-HMP090208-HMP110202-HMP110204-HMP110208-HMP16T304-HMP16T308-HMPNC3010NC3020NC3120 Triangular60PositiveCoatedNC3030NC9020PC9030NC6110 NC6010NC315KCN1000CT10CermetCN2000CN20 Relief Angle : 7H01G10I8.69.08.610.510.015.58.28.07.78.28.07.78.67.610.510.09.015.514.58.67.610.015.515.58.67.610.510.09.015.514.5Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = UncoatedMachining typesContinuous cuttingGeneral cuttingInterrupted cuttingd5.566.355.566.356.359.5254.764.764.764.764.764.765.565.566.356.356.359.5259.5255.566.356.359.5259.5255.565.566.356.356.359.5259.525Dimensionst2.382.382.382.382.382.382.382.382.382.382.382.382.382.382.382.382.383.973.972.382.382.383.973.972.382.382.382.382.383.973.97Positiver0.40.80.40.20.40.40.030.10.20.030.10.20.40.80.20.40.80.40.80.40.20.40.20.40.40.80.20.40.80.40.8(mm)d12.52.82.52.82.84.42.32.32.32.32.32.32.52.52.82.82.84.44.42.52.82.84.44.42.52.52.82.82.84.44.4<strong>Turning</strong> <strong>Insert</strong>Cutting Conditionfn ap0.05~0.19 0.10~1.700.08~0.22 0.10~1.700.05~0.19 0.10~1.700.03~0.13 0.06~1.700.05~0.19 0.10~1.700.07~0.26 0.10~1.700.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.11 0.06~1.700.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.11 0.06~1.700.06~0.18 0.40~2.500.08~0.25 0.80~2.500.04~0.12 0.40~2.000.06~0.20 0.60~2.500.08~0.25 0.80~2.500.08~0.28 0.80~3.000.10~0.30 1.00~3.000.05~0.19 0.10~1.700.03~0.13 0.06~1.700.05~0.19 0.10~1.700.03~0.13 0.06~1.700.07~0.26 0.10~1.700.06~0.17 0.20~2.300.08~0.23 0.40~2.300.03~0.15 0.10~1.500.06~0.19 0.20~2.500.09~0.26 0.40~2.500.08~0.23 0.30~3.00AvailabletoolholdersSTACR/LSTFCR/LSTGCR/LSTTCR/LSTACR/LSTFCR/LSTGCR/LSTTCR/LSTACR/LSTACR/LSTACR/LSTFCR/LSTGCR/LSTTCR/LSTACR/LSTFCR/LSTGCR/LSTTCR/LSTACR/LSTFCR/LSTGCR/LSTTCR/LPageB85B86B104B85B86B104B118B118B85B86B104B85B86B104B85B86B1040.10~0.30 0.50~3.00 : Stock item : Under preparing for stock>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarTOTriangular60PositiveRelief Angle : 8Workpiece<strong>Insert</strong>sTOEHSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelTOEHDesignation060102L090204L140304LPMKNSHNC3010NC3030NC3120CoatedNC500HPC8010NC9020PC9030NC305KNC6110NC315KCT10Cermet UncoatedCN2000CN20ST10H01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI6.48.613.1d3.975.568.2Dimensionst1.592.383.0r0.20.40.4(mm)d12.152.83.8Cutting Condition Availablefn ap toolholders0.05~0.17 0.10~1.50 FZ unit0.05~0.20 0.30~2.500.05~0.25 0.30~2.50Page-For medium to finishingCutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = : Stock item : Under preparing for stockB43

Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong><strong>Turning</strong> <strong>Insert</strong> PositiveTPWorkpiece<strong>Insert</strong>sTPGHFor medium to finishingTPGNFor medium to finishingTPGR-FFor finishingTPGR-MSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelTPGHDesignation080202L080204LTPGN 090204110302110304110308160302160304160308160310160312160316160404220404220408220412220430220440270408270608TPGR 110302-F110304-F160304-FPMKNSHTPGR 110308-M160308-MNC3010NC3020 NC3120NC3030Triangular60PositiveCoatedPC8010NC9020PC9030NC6110CT10CermetCN2000CN20CN30UncoatedST20EST30A Relief Angle : 11H01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI7.77.28.610.510.09.016.015.514.513.413.512.515.521.020.019.014.211.625.425.410.510.015.59.014.5d4.764.765.566.356.356.359.5259.5259.5259.5259.5259.5259.52512.712.712.712.712.715.87515.8756.356.359.5256.359.525Dimensionst2.382.382.383.183.183.183.183.183.183.183.183.184.764.764.764.764.764.764.766.353.183.183.183.183.18r0.20.40.40.20.40.80.20.41.01.21.21.60.40.40.81.23.04.00.80.80.20.40.40.80.8(mm) Cutting Condition Availabled1 fn ap toolholders2.32.3---------------------0.01~0.12 0.06~1.700.01~0.15 0.08~1.700.07~0.20 0.70~2.000.05~0.15 0.50~2.000.07~0.20 0.70~3.000.10~0.25 1.00~3.000.05~0.18 1.00~5.000.07~0.20 1.00~5.000.10~0.25 1.00~5.000.10~0.25 1.00~5.000.15~0.30 1.00~5.000.15~0.30 1.00~5.000.07~0.20 1.00~5.000.07~0.20 1.50~7.000.10~0.25 1.50~7.000.15~0.30 1.50~7.000.30~0.45 1.50~7.000.30~0.50 1.50~7.000.15~0.25 3.00~8.000.15~0.25 3.00~8.000.05~0.15 0.10~1.500.05~0.20 0.30~1.500.08~0.25 0.50~2.000.13~0.30 1.00~3.000.13~0.30 1.00~5.00--CTFPR/LCTGPR/LCTFPR/LCTGPR/LPage--B68B96B68B96For medium cuttingCarbide ShankBoring BarTPGTFor medium to finishingTPGT-C05TPGT 080202R110302R110304R110308R160404R160408R080202L110302L110304L110308L160404L160408LTPGT 110304-C05160404-C057.710.510.09.015.514.57.710.510.09.015.514.510.015.54.766.356.356.359.5259.5254.766.356.356.359.5259.5256.359.5252.383.183.183.184.764.762.383.183.183.184.764.763.184.760.20.20.40.80.40.80.20.20.40.80.40.80.40.42.33.43.43.44.44.42.33.43.43.44.44.43.44.40.05~0.20 0.30~1.500.05~0.20 0.30~1.500.05~0.20 0.50~2.000.07~0.25 0.50~2.000.05~0.20 0.70~3.000.05~0.20 0.70~3.000.05~0.20 0.30~1.500.05~0.20 0.30~1.500.05~0.20 0.50~2.000.07~0.25 0.50~2.000.05~0.20 0.70~3.000.05~0.20 0.70~3.000.05~0.30 0.50~2.000.05~0.30 0.80~2.00STFPR/L(Boring bar)STUPR/L(Compact mini)STFPR/L(Boring bar)B105B107B105For finishingTPGT-HFPTPGT110304-HFP160308-HFP10.014.56.359.5253.183.180.40.83.44.40.05~0.25 0.30~1.500.05~0.25 0.30~1.50STFPR/L(Boring bar)B105For finishingCutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = : Stock item : Under preparing for stockB44

TPWorkpiece<strong>Insert</strong>sTPGXFor medium to finishingTPMR-FFor finishingTPMR-MFor medium cuttingTPUNFor medium to finishingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelTPGXDesignation090202L090204L090208L110304LTPMR 090202-F090204-F110302-F110304-F110308-F160304-F160308-FPMKNSHTPMR 110304-M110308-M160304-M160308-M160312-M220408-MTPUN 090308110208110304110308160304160308160312220404220408220412330620160308TN160312TN220412TNNC3010NC3020NC3120 Triangular60PositiveCoatedNC3030PC8010NC9020PC9030NC6110 NC6010CermetCT10CN20ST30AUncoatedST20ST30NRelief Angle : 11I9.18.67.610.09.18.610.510.09.015.514.510.09.015.514.513.520.07.69.010.09.015.514.513.521.020.019.027.814.513.519.0Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingd5.565.565.566.355.565.566.356.356.359.5259.5256.356.359.5259.5259.52512.75.566.356.356.359.5259.5259.52512.712.712.719.059.5259.52512.7Dimensionst2.382.382.383.182.382.383.183.183.183.183.183.183.183.183.183.184.763.182.383.183.183.183.183.184.764.764.766.353.183.184.76Positiver0.20.40.80.40.20.40.20.40.80.40.80.40.80.40.81.20.80.80.80.40.80.40.81.20.40.81.22.00.81.21.2(mm)d1-------------------------------<strong>Turning</strong> <strong>Insert</strong>Cutting Conditionfn ap0.10~0.20 0.30~1.000.10~0.25 0.50~1.000.10~0.30 1.00~1.000.10~0.25 0.50~1.200.05~0.15 0.10~1.000.05~0.15 0.10~1.000.05~0.15 0.10~1.500.05~0.20 0.30~1.500.05~0.25 0.30~1.500.08~0.25 0.50~2.000.08~0.25 0.50~3.000.10~0.25 0.70~3.000.13~0.30 1.00~3.000.10~0.25 1.00~5.000.13~0.30 1.00~5.000.15~0.35 1.00~5.000.13~0.30 1.50~7.00Availabletoolholders-CTFPR/LCTGPR/LCTFPR/LCTGPR/LPage-B68B96B68B960.10~0.30 0.50~2.000.15~0.40 1.00~3.000.10~0.30 1.00~3.000.15~0.40 1.00~3.000.10~0.30 1.00~5.000.15~0.40 1.00~5.000.20~0.50 1.50~5.000.10~0.30 1.50~7.00- -0.15~0.40 1.50~7.000.20~0.50 1.50~7.000.30~0.70 3.00~10.000.15~0.40 1.00~5.000.20~0.50 1.50~5.000.20~0.50 1.50~7.00 : Stock item : Under preparing for stock>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarB45

Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong><strong>Turning</strong> <strong>Insert</strong> PositiveVBWorkpiece<strong>Insert</strong>sVBGTFor medium to finishingVBGT-HFPFor finishingVBGT-KFFor finishing(Auto Tool)VBGT-KMFor medium to finishing(Auto Tool)VBMTFor medium to finishingSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelVBGT 160404160408VBGTVBGTVBGTDesignationPMKNSH110301-HFP160408-HFP1103003R-KF110301R-KF110302R-KF1103003L-KF110301L-KF110302L-KF1103003R-KM110301R-KM110302R-KM1103003L-KM110301L-KM110302L-KMVBMT 160404160408NC3010NC3020NC3120NC3030Rhombic35PositiveCoatedPC8010NC9020PC9030NC6110NC6010NC315KCN1000CermetCT10CN2000 Relief Angle : 5UncoatedH01G10Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingI15.614.611.014.611.011.011.011.011.011.011.011.011.011.011.011.015.614.6Dimensionsd t r9.5259.5256.359.5256.356.356.356.356.356.356.356.356.356.356.356.359.5259.5254.764.763.184.763.183.183.183.183.183.183.183.183.183.183.183.184.764.760.40.80.10.80.030.10.20.030.10.20.030.10.20.030.10.20.40.8(mm)d14.44.42.84.42.82.82.82.82.82.82.82.82.82.82.82.84.44.4Cutting Conditionfn ap0.07~0.20 0.50~1.500.15~0.25 0.70~2.000.07~0.20 0.50~1.500.15~0.25 0.70~2.000.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.13 0.06~1.700.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.13 0.06~1.700.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.13 0.06~1.700.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.13 0.06~1.700.07~0.20 0.50~1.500.15~0.25 0.70~2.00AvailabletoolholdersSVABR/LSVHBR/LSVJBR/LSVVBNSVQBR/LSVUBR/LSVABR/LSVHBR/LSVJBR/LSVVBNSVQBR/LSVUBR/LSVJBR/LSVJBR/LSVJBR/LSVJBR/LSVABR/LSVHBR/LSVJBR/LSVVBNSVQBR/LSVUBR/LPageB86B87B105B106B86B87B105B106B118B118B118B118B86B87B105B106Carbide ShankBoring BarVBMT-HMPFor medium cuttingVBMT110204-HMP110208-HMP110304-HMP110308-HMP160404-HMP160408-HMP160412-HMP 10.09.010.09.015.614.613.5Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = 6.356.356.356.359.5259.5259.5252.382.383.183.184.764.764.760.40.80.40.80.40.81.22.82.83.43.44.44.44.40.03~0.20 0.15~2.500.03~0.25 0.15~2.500.03~0.20 0.15~2.700.05~0.25 0.40~2.700.07~0.20 0.20~2.700.09~0.27 0.50~2.700.11~0.32 0.50~2.70SVABR/LSVHBR/LSVJBR/LSVVBNSVQBR/LSVUBR/LB86B87B105B106 : Stock item : Under preparing for stockB46

VCWorkpiece<strong>Insert</strong>sVCGT-HFPFor finishingVCGT-KFFor finishing(Auto Tool)VCGT-KMFor medium to finishing(Auto Tool)VCMT-HFPFor finishingVCMT-HMPFor medium cuttingWBVCGTVCGTVCGTVCMTVCMTPMKNSH110302-HFP110304-HFP110308-HFP160404-HFP160408-HFP1103003R-KF110301R-KF110302R-KF1103003L-KF110301L-KF110302L-KF1103003R-KM110301R-KM110302R-KM1103003L-KM110301L-KM110302L-KM110302-HFP110304-HFP110308-HFP160404-HFP160408-HFP160404-HMP160408-HMPPMKNSHNC3010NC3020 NC3120NC3030Trigon80PositiveRelief Angle : 5CoatedCermet Uncoated<strong>Insert</strong>sDesignationDimensions (mm) Cutting ConditionI d t r d1 fn apWBGT WBGT 020102R2.6 3.97 1.59 0.2 2.2 0.01~0.05 0.10~0.30020102LS30202LS30204L2.63.13.03.974.764.761.592.382.380.20.20.42.22.42.40.01~0.08 0.10~0.400.01~0.08 0.10~0.400.01~0.10 0.10~0.50NC3010NC3020NC3120Rhombic35PositivePC8010NC9020PC9030NC3030PC8010NC6110NC6010NC9020PC9030NC6110CT10NC6010CN2000CN20CT10CN2000U20H01G10U2H01G10Relief Angle : 7I10.510.09.015.614.611.011.011.011.011.011.011.011.011.011.011.011.010.510.09.015.614.615.614.3Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = WorkpieceSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelDesignationSteelStainless steelCast ironNon-ferrous metalHeat resistant alloy, Titanium alloyHardened steelCoatedCermetUncoatedMachining typesContinuous cuttingGeneral cuttingInterrupted cuttingd6.356.356.359.5259.5256.356.356.356.356.356.356.356.356.356.356.356.356.356.356.359.5259.5259.5259.525Dimensionst3.183.183.184.764.763.183.183.183.183.183.183.183.183.183.183.183.183.183.183.184.764.764.764.76Machining typesContinuous cuttingGeneral cuttingInterrupted cuttingPositiver0.20.40.80.40.80.030.10.20.030.10.20.030.10.20.030.10.20.20.40.80.40.80.40.8(mm)d13.43.43.44.44.42.82.82.82.82.82.82.82.82.82.82.82.83.43.43.44.44.44.44.4<strong>Turning</strong> <strong>Insert</strong>Cutting Conditionfn ap0.02~0.18 0.10~1.000.03~0.18 0.15~1.200.04~0.23 0.20~1.200.04~0.20 0.15~1.500.05~0.25 0.20~1.500.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.13 0.06~1.700.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.13 0.06~1.700.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03~0.13 0.06~1.700.01~0.06 0.04~1.300.02~0.08 0.05~1.500.03 ~0.13 0.06~1.700.02~0.18 0.10~1.000.03~0.18 0.15~1.200.04~0.23 0.20~1.200.04~0.20 0.15~1.500.05~0.25 0.20~1.500.10~0.25 0.30~2.600.13~0.33 0.60~2.60AvailabletoolholdersSVJCR/LSVVCNSVQCR/LSVUCR/LSVJCR/LSVJCR/LSVJCR/LSVJCR/LSVJCR/LSVVCNSVQCR/LSVUCR/LSVJCR/LSVVCNSVQCR/LSVUCR/LSWUBR/L(Compact mini)PageB87B88B105B106B118B118B118B118B87B88B105B106B87B88B105B106 : Stock item : Under preparing for stockAvailabletoolholdersPageB108>>><strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarFor medium to finishingCutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Note)WBGTDesignation comparision : WBGT020100 WBGT060100WBGTS30200 WBGT080200 : Stock item : Under preparing for stockB47

Auto Tools Cartridge Boring Bar External Holder <strong>Turning</strong> <strong>Insert</strong>s <strong>Turning</strong> C/B <strong>Turning</strong> Grades <strong>Turning</strong><strong>Turning</strong> <strong>Insert</strong> PositiveWCFor finishingTrigon80PositiveRelief Angle : 7Steel PWorkpieceStainless steel MContinuous cuttingCast iron KNon-ferrous metal NGeneral cuttingHeat resistant alloy, Titanium alloy SInterrupted cuttingHardened steel HCoatedCermet Uncoated<strong>Insert</strong>sDesignationDimensions (mm) Cutting Condition AvailableI d t r d1 fn ap toolholdersPageWCGT-C05 WCGT 080408-C05 8.3 12.7 4.76 0.8 5.5 0.08~0.30 0.20~2.70 SWACR/L B88SWLCR/L B106NC3010NC3020NC3120Carbide ShankBoring BarNC3030PC8010NC9020PC9030NC6110NC6010CT10CN2000CN20U20H01G10Cutting edge geometry : A06 ~ A09 Recommended chip breaker : B12 ~ B17 Code system : B18 ~ B19Note)Unit : Feed(fn) = /rev Depth of cut(ap) = Machining types : Stock item : Under preparing for stockB48

Technical Information for AluminumTechnical Information for Aluminum AK special chip breaker for aluminum AR special chip breaker for aluminum>>>FeaturesUnique and 3-dimensional rake anglecontrols chip breaking and chip flowensuring longer tool life and reducingcutting load.High rake angle at cutting edge partreduces cutting load to increase tool life.Buffed on top face controls chip flowreducing built-up edge. High rake angle & tabby pattern chip pocket - Low cutting load Unique rake angle design - Effective chip breaking and good chip flow Unique and 3-dimensional top face- Longer tool life & Excellent surface roughness Tabby pattern & Sharp cutting edge - Distributing cutting load, long tool life Buffed on top face- Excellent machining, Reducing built-up edge, Excellent chip flowFeaturesAR chip breaker ensuresreliability and good cuttingperformance at high feed,speed and interruptedmachining. AK and AR chip breaker specially developed for aluminumRecommendation rangeGradesCCGTSCGT Flat corner cutting edge improved productivity at high feed machining andensures good surface roughness and reliability owing to strong cutting edge Specially buffed on top face controls chip flow reducing built-up edge KORLOYs own technology applied for cutting edge and corner shapecontrolling chip flow ensures longer tool life KORLOY special chip breaker design controls chip flow at high speedmachining.DCGTRCGTVCGT, VBGTRCGT<strong>Turning</strong><strong>Turning</strong> Grades <strong>Turning</strong> C/B <strong>Turning</strong> <strong>Insert</strong>s External Holder Boring Bar Cartridge Auto ToolsCarbide ShankBoring BarAKap= 0.1~5.0fn= 0.03~0.5/revH01(Uncoated cementedcarbides K10~K20)ND1000(Diamond coating)RCGTARap= 0.1~6.0fn= 0.05~0.6/revH01(Uncoated cementedcarbides K10~K20)ND1000(Diamond coating)PD1000(DLC coating)TCGTRCGT Features of H01 Useful for aluminum and alloyedsteel machining Buffed on top face reducedbuilt-up edge 3-dimensional design reducedcutting load and shows goodperformance at high feed andspeed machining.Workpiecebefore heat treatmentAluminum alloy(forged)after heat treatmentbefore heat treatmentAluminum alloy (cast)after heat treatmentCopper alloy-Non-ferrous metal, etc-Hardness(HB) kc(Mpa) vc(m/min) fn(mm/rev)50 ~ 7090 ~ 11070 ~ 8080 ~ 10090 ~ 110100500 ~ 600700 ~ 900700 ~ 800800 ~ 95070017001000 ~ 2500300 ~ 1000300 ~ 1000200 ~ 600250 ~ 600150 ~ 3000.1 ~ 0.60.1 ~ 0.50.1 ~ 0.60.1 ~ 0.40.1 ~ 0.50.1 ~ 0.6B49