DISA CORE MP-TP-LP - Meta-Mak

DISA CORE MP-TP-LP - Meta-Mak

DISA CORE MP-TP-LP - Meta-Mak

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>DISA</strong> Gro upF o u nded in 1 9 0 0 , <strong>DISA</strong> is th e w o rld’s leadingsu p p lier o f fo u ndry eq u ip ment and metalsu rfac e finish ing systems.W ith fac to ries, sales and serv ic e o ffic es inth ree c o ntinents and an ex tensiv e agentnetw o rk, <strong>DISA</strong> serv es internatio nal indu strialmanu factu rers, fo u ndries and metalw o rkingindu stries w ith leading edge tech no lo gy andserv ic e so lu tio ns tailo red to th eir sp ec ificneeds.Fo r mo re info rmatio n p lease visitw w w .disagro u p .co m<strong>DISA</strong> Industrieanlagen GmbHG erh ard-E llro dt-Strasse 2 6D-0 4 2 4 9 L eip z igG ermanyT el +4 9 3 4 1 4 8 3 4 2 1 0F ax +4 9 3 4 1 4 8 3 4 2 2 0w w w .disagro u p .c o m<strong>DISA</strong>® and <strong>DISA</strong>MATIC® are registered trademarks by <strong>DISA</strong>Indu stries A/S.F o r illu strativ e p u rp o ses th e <strong>DISA</strong> eq u ip ment may be sh o w nw ith o u t any w arning labels and w ith so me o f th e p ro tec tiv egu ards remo v ed. Th e w arning labels and gu ards mu st alw aysbe in p lac e w h en th e eq u ip ment is in u se.Th e tec h nic al data are no t binding. Th ey are no t w arrantedc h arac teristic s and are su bjec t to c h ange.P lease c o nsu lt o u r G eneral Co nditio ns o f Su p p ly.0 6 .2 0 0 7 · <strong>DISA</strong>

06.2007 · <strong>DISA</strong><strong>DISA</strong> <strong>CORE</strong> SOLUTIONS

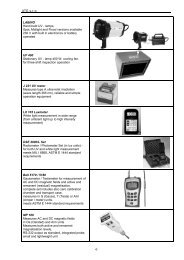

<strong>DISA</strong> <strong>CORE</strong>M P SERIESThe multi-purpose core shooterAdaptability :All core boxes with multiple partinglinesAdjustable to existing core boxesSuitable for all core processesFeatures:R ugged design suited for foundriesN o pits requiredM ulti-purpose use:Multiple core box parting linesControl of movements by measuringsystems integrated in the hydrauliccylindersAutomatic adjustment of the machineto the new tooling and cycleAutomatic clamping of all tools withuniform clamping systems

TECHNICALDATA1 0 <strong>MP</strong> 2 0 <strong>MP</strong> 4 0 <strong>MP</strong> 8 0 <strong>MP</strong> 1 2 0 <strong>MP</strong> 2 0 0 <strong>MP</strong>Machine dimensionsWidth (m m ) 2 8 0 0 34 0 0 4 0 0 0 4 4 0 0 4 8 0 0 4 8 0 0D e p th (m m ) 2 8 0 0 34 0 0 36 0 0 36 0 0 5 2 0 0 5 2 0 0H e ig ht (m m ) 2 7 0 0 35 0 0 36 0 0 36 0 0 4 2 0 0 4 5 0 0Core box dimensionsH e ig ht m in /m a x (m m ) 2 9 0 /5 7 5 38 5 /7 7 0 5 30 /9 1 5 6 1 5 /1 0 0 0 8 7 0 /1 34 0 8 7 0 /1 34 0Width m a x (m m ) 7 4 0 9 9 0 1 1 9 0 1 39 0 1 5 0 0 1 5 0 0D e p th m a x (m m ) 6 0 0 8 0 0 1 0 0 0 1 4 0 0 1 5 0 0 1 5 0 0Shooting and gassing areaWidth x D e p th (m m ) 4 0 0 x4 5 0 6 0 0 x5 0 0 7 0 0 x6 0 0 9 0 0 x9 0 0 dm r 8 0 0 dm r 8 0 0C y lin de r stro k e m a x rig ht/le ft (m m ) 30 0 4 0 0 4 5 0 4 5 0 5 0 0 5 0 0T a b le stro k e m a x (m m ) 30 0 4 0 0 4 0 0 4 0 0 6 0 0 6 0 0V ertical clamping platesWidth x D e p th (m m ) 5 0 0 x2 30 6 0 0 x30 0 7 0 0 x4 7 0 8 5 0 x5 5 0 1 0 0 0 x6 0 0 1 0 0 0 x6 0 0S p a cin g b e tw e e n cla m p in g p la te s (m m ) 7 5 0 1 0 0 0 1 2 0 0 1 4 0 0 1 4 0 0 1 5 2 0Sand req uirementsE ffe c tiv e sho o tin g v o lu m e (dm 3) 1 0 2 0 4 0 8 0 1 2 0 2 0 0S a n d ho p p e r v o lu m e (dm 3) 8 0 1 6 0 2 6 0 30 0 30 0 30 0B asic cycle timeo f the m a c hin e sy ste m (w itho u tsho o tin g , e xha u st a n d g a ssin g tim e s)H o riz o n ta l/4 -p a rt c o re b o xe s (s) 1 3/1 5 1 8 /2 2 2 2 /2 6 2 6 /32 32 /38 32 /38Compressed air 0 .6 <strong>MP</strong>aC o n n e c tio n (" ) 1 1 1 .5 1 .5 1 .5 2Exhaust air v olume(m 3/h) 2 0 0 0 2 6 0 0 32 0 0 4 6 0 0 6 0 0 0 8 0 0 0

<strong>DISA</strong> <strong>CORE</strong><strong>TP</strong> SERIESThe core shooter for highspeed and precisionHigh capacity by means of:Movements are controlled by a hydraulicallydriven rotary activator and specialproportional control techniquesQ uick tooling change and automaticsetting of the core making cycleLow maintenance requirementsU niform clamping system for all core boxpartsPrecision by:H igh closing pressure and continuousclamping of the core box throughoutthe core making processPermanent parameter control duringthe whole core making process bymeans of position sensor systemsComplete data processing system withlarge memory and consequent dataavailability for reuse

TECHNICALDATA20 <strong>TP</strong> 40 <strong>TP</strong> 60/80 <strong>TP</strong>Machine dimensionsWidth (mm) 4500 4900 5800Depth (mm) 3500 3650 4200Height (mm) 4300 4600 5000/5200Core box dimensionsHeight min/max (mm) 500/600 600/700 600/800Width max (mm) 750 1000 1250Depth max (mm) 750 850 1100Shooting and gassing areaWidth x Depth (mm) 650x650 900x750 1150x1000Table stroke max (mm) 270 270 370Sand requirementsEffective shooting volume (dm 3 ) 20 40 60/80Sand hopper volume (dm 3 ) 260 260 260Basic cycle timeof machine system (withoutshooting, exhaust and gassingtimes (s) 16 17 20Compressed air 0.6 <strong>MP</strong>aConnection (") 1.5 1.5 2Exhaust air volume(m 3 /h) 3200 3800 4600/5500

<strong>DISA</strong> <strong>CORE</strong><strong>LP</strong> SERIESThe core shooter for the manufactureof big cores15 0 <strong>LP</strong> 25 0 <strong>LP</strong>Machine dimensionsWidth (mm) 4500 4500Depth (mm) 4000 4500Height (mm) 4800 5100Core box dimensionsHeight min/max (mm) 470/750 600/900Width max (mm) 2600 2600Depth max (mm) 1100 1600Shooting and gassing areaWidth x Depth (mm) 2200x800 2200x1100Table stroke max (mm) 750 750Customer specific requirements and standardsolutions are the basis for these large coreshooters.This series is designed so that no pits arenecessary.Through innovative design we offer thecustomer tailor-made solutions for highproductivity.Sand requirementsEffective shooting volume (dm 3 ) 150 250Sand hopper volume (dm 3 ) 600 600Basic cycle timeof the machine system (withoutshooting, exhaust and gassingtimes (s) 33 36Compressed air 0.6 <strong>MP</strong>aConnection (") 2 2Exhaust air volume(m 3 /h) 6000 6000Customer advantages:A design, which makes the avoidanceof pits possible for these large coreshooters, even for big strokes.The requirement for cleaning of themachine is reduced to a minimumHigh efficient shooting system.

<strong>DISA</strong><strong>CORE</strong>Installation, Training and ServicePrior to leaving the factory your new coreshooter has been through a comprehensivetest run.After the final test in our works the machineis shipped to the destination and installed.Y our maintenance personnel and machineoperators will be thoroughly trained.An easy-to-learn operator training programme,together with an operator panelwith a clear overview, gives a short learningtime.For core manufacture <strong>DISA</strong> can makequotations for services and equipment,from core shooting to core setting in themould, from simple units to fully automaticcore logistics.<strong>DISA</strong> has comprehensive know-how frommany plants installed all over the worldcovering very different requirements.The solution spectrum includes coretechnology for jobbing foundries withvaried demands as well as systems withhigh output for the biggest demands, corecomplexity and core quality.