Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

Operating instructions - EWM Hightec Welding GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

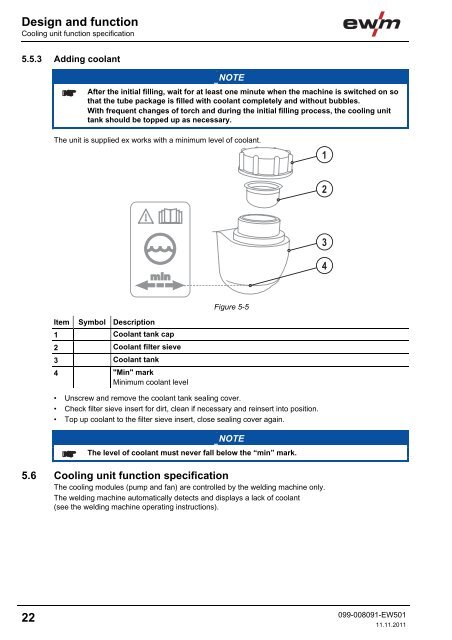

Design and functionCooling unit function specification5.5.3 Adding coolantNOTEAfter the initial filling, wait for at least one minute when the machine is switched on sothat the tube package is filled with coolant completely and without bubbles.With frequent changes of torch and during the initial filling process, the cooling unittank should be topped up as necessary.The unit is supplied ex works with a minimum level of coolant.Item Symbol Description 01 Coolant tank cap2 Coolant filter sieve3 Coolant tank4 "Min" markMinimum coolant levelFigure 5-5• Unscrew and remove the coolant tank sealing cover.• Check filter sieve insert for dirt, clean if necessary and reinsert into position.• Top up coolant to the filter sieve insert, close sealing cover again.NOTEThe level of coolant must never fall below the “min” mark.5.6 Cooling unit function specificationThe cooling modules (pump and fan) are controlled by the welding machine only.The welding machine automatically detects and displays a lack of coolant(see the welding machine operating <strong>instructions</strong>).22099-008091-EW50111.11.2011