Joining - The Welding Alloys group

Joining - The Welding Alloys group

Joining - The Welding Alloys group

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

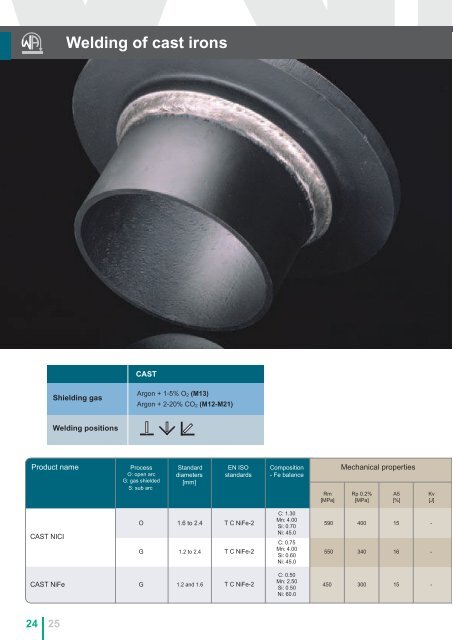

Our <strong>Welding</strong> commitment of cast irons to qualityISO 9001BUREAU VERITASCertification<strong>The</strong> <strong>Welding</strong> <strong>Alloys</strong> Group orientates all its economicand strategic choices with an eye to the future. Ourresponsibilities are towards our customers, ourpersonnel, and our environment.<strong>The</strong> <strong>Welding</strong> <strong>Alloys</strong> Group mission is:“To supply our customers with the mostadvanced technology, to ensure them longterm profit and satisfaction, thanks to ourexpertise in the field of welding applications.”<strong>The</strong> ISO-approved quality assurance system hasbeen in place for the Group wire production unitssince 1993, and is a fundamental ingredient inachieving our quality objectives.<strong>The</strong> daily commitment from all of our employeesguarantees the utmost respect for the qualityrequirements and values that are consistentwith this dedication:- Production according to strict procedures, conformingto current standards and customer specifications- Customer service by specialists, allowing the besttechnical and economic choices to be made- Permanent commitment to customer satisfaction- Team spirit driven by the pride of belonging to adynamic and innovative <strong>group</strong>Research and Development programmes<strong>The</strong> real value of <strong>Welding</strong> <strong>Alloys</strong> Cored WiresPackagingPurchase cost is not the only consideration when deciding upon a welding consumable, though it is astrong Metal factor. basket <strong>The</strong> choice reel must include the critical WA Pack factors - of production time, re-working, finishing costs,not shownand associated consumable costs. <strong>Welding</strong> <strong>Alloys</strong> manufactures cored welding wires of the highestStandard net weight : 25kgWire Capacity: 400kgtechnological standards, offering constant quality and high productivity, a combinationExternal Ø: 410mm DimensionsDrumthat gives thebest overall value and cost control.Internal Ø: 300mm Diameter: 800mm Standard net weight : 330kg: 105mm Height: 950mm External Ø: 595mmQualityEN ISO 544 standard : B 450Fully recyclable cardboard packaging Height: 680mm• Very clean fusion and very good bead appearance• Virtually no spatter• Deposit soundness comparable to that of electrodes• Low welding energy which limits deformation, while guaranteeing excellent mechanicaland metallurgical propertiesFlexibilityMetal basket spool• Various arc welding processes: open-arc, gas shielded, submerged arcStandard net weight• Usable with all types of power sources and with low cost standard gas mixturesExternal Ø• Wide range of welding parameters – all-position welding is much easier than with solid wiresInternal Ø• Possibility of purchasing small quantities adapted to particular technical specificationsWidthPerformanceEN ISO 544 standard• High deposit rates (kg/h), around three times greater than with coated electrodes• Optimised arc time• High welding speed• <strong>The</strong> penetration characteristics allow for work with narrower chamfers, thus reducing thequantity of the weld metalPlastic spool *Standard net weightIn view of their technological and economic advantages, cored wires represent a growing External Øshare ofthe welding market. <strong>The</strong>y are specified and approved by constructors and engineers Internal in leading-edgeØindustries, which impose the strictest requirements in terms of quality and productivity. WidthEN ISO 544 standard: 15kg: 300mm: 51.5mm: 103mm: BS 300: 15kg: 300mm: 51.5mm: 103mm: S 300OPERATING 24/7CASTArgon + 1-5% O Shielding gas2 (M13)Argon + 2-20% CO 2 (M12-M21)<strong>Welding</strong> positions<strong>The</strong> success of <strong>Welding</strong> <strong>Alloys</strong> cored welding wiresis due to their quality and performance. This is closelylinked to our commitment to continuous improvementand to our substantial investment in R and D. As atrue partner in progress, <strong>Welding</strong> <strong>Alloys</strong> collaboratesclosely with customers on their own specific projects.We maintain technological awareness, allowing us toanticipate future needs by proposing welding productssuited to new construction steels.Plastic reel *Standard net weightExternal ØInternal ØWidthEN ISO 544 standard: 15kg: 390mm: 305mm: 90mm: R 435Small plastic spool *Standard net weightExternal ØInternal ØWidthEN ISO 544 standard: 5kg: 200mm: 51.5mm: 55mm: S 200Small metal basket spoolStandard net weight : 5kgExternal Ø: 200mmInternal Ø: 51.5mmWidth: 55mm* Manufactured to order onclient’s requestProduct name Mechanical propertiesDescription and applications Base materialCAST NICICAST NiFeProcessO: open arcG: gas shieldedS: sub arcStandarddiameters[mm]EN ISOstandardsComposition- Fe balanceRmRp 0.2%A5 KCV Kv[MPa][MPa][%][J]C: 1.30Mn: 4.00O1.6 to 2.4T C NiFe-2Si: 0.70590 400 15-• FeNi deposit for rebuilding ductile or spheroidal cast ironNi: 45.0and for joining cast irons to each otherC: 0.75• Reduced heat affected zone (HAZ)Mn: 4.00G1.2 to 2.4T C NiFe-2Si: 0.60550 340 16-• Dissimilar joints between cast irons and steelsNi: 45.0G1.2 and 1.6T C NiFe-2C: 0.50• NiFe deposit for joining heavy thicknesses of ductile andMn: 2.50spheroidal cast iron and for restrained joints450 300 15-Si: 0.50• Reduced heat affected zone (HAZ)Ni: 60.0• Easily machined deposit<strong>The</strong>winningtechnologyGG10 to GG40, GTS35 to GTS 70, GTW35 to GTW 70,GGG40 to GGG80GG10 to GG40, GTS35 to GTS 70, GTW35 to GTW 70,GGG40 to GGG80244 525 <strong>Joining</strong>