Download - Mega-UK - Mega Electronics

Download - Mega-UK - Mega Electronics

Download - Mega-UK - Mega Electronics

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

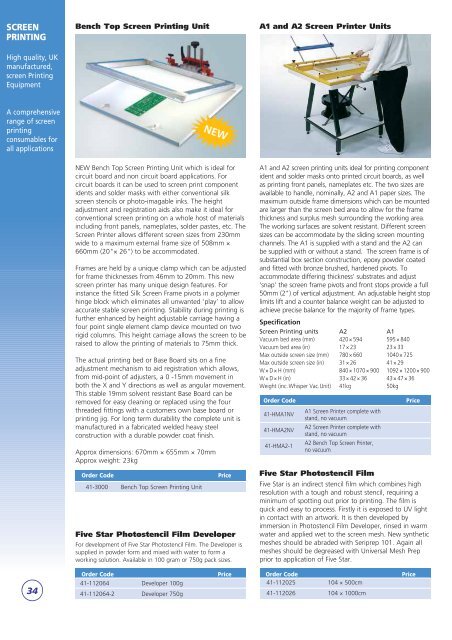

SCREENPRINTINGHigh quality, <strong>UK</strong>manufactured,screen PrintingEquipmentBench Top Screen Printing UnitA1 and A2 Screen Printer UnitsA comprehensiverange of screenprintingconsumables forall applicationsNEWNEW Bench Top Screen Printing Unit which is ideal forcircuit board and non circuit board applications. Forcircuit boards it can be used to screen print componentidents and solder masks with either conventional silkscreen stencils or photo-imagable inks. The heightadjustment and registration aids also make it ideal forconventional screen printing on a whole host of materialsincluding front panels, nameplates, solder pastes, etc. TheScreen Printer allows different screen sizes from 230mmwide to a maximum external frame size of 508mm ×660mm (20"× 26") to be accommodated.Frames are held by a unique clamp which can be adjustedfor frame thicknesses from 46mm to 20mm. This newscreen printer has many unique design features. Forinstance the fitted Silk Screen Frame pivots in a polymerhinge block which eliminates all unwanted ‘play’ to allowaccurate stable screen printing. Stability during printing isfurther enhanced by height adjustable carriage having afour point single element clamp device mounted on tworigid columns. This height carriage allows the screen to beraised to allow the printing of materials to 75mm thick.The actual printing bed or Base Board sits on a fineadjustment mechanism to aid registration which allows,from mid-point of adjusters, a 0 -15mm movement inboth the X and Y directions as well as angular movement.This stable 19mm solvent resistant Base Board can beremoved for easy cleaning or replaced using the fourthreaded fittings with a customers own base board orprinting jig. For long term durability the complete unit ismanufactured in a fabricated welded heavy steelconstruction with a durable powder coat finish.Approx dimensions: 670mm × 655mm × 70mmApprox weight: 23kgOrder Code41-3000 Bench Top Screen Printing UnitPriceFive Star Photostencil Film DeveloperFor development of Five Star Photostencil Film. The Developer issupplied in powder form and mixed with water to form aworking solution. Available in 100 gram or 750g pack sizes.A1 and A2 screen printing units ideal for printing componentident and solder masks onto printed circuit boards, as wellas printing front panels, nameplates etc. The two sizes areavailable to handle, nominally, A2 and A1 paper sizes. Themaximum outside frame dimensions which can be mountedare larger than the screen bed area to allow for the framethickness and surplus mesh surrounding the working area.The working surfaces are solvent resistant. Different screensizes can be accommodate by the sliding screen mountingchannels. The A1 is supplied with a stand and the A2 canbe supplied with or without a stand. The screen frame is ofsubstantial box section construction, epoxy powder coatedand fitted with bronze brushed, hardened pivots. Toaccommodate differing thickness' substrates and adjust'snap' the screen frame pivots and front stops provide a full50mm (2") of vertical adjustment. An adjustable height stoplimits lift and a counter balance weight can be adjusted toachieve precise balance for the majority of frame types.SpecificationScreen Printing units A2 A1Vacuum bed area (mm) 420 × 594 595 × 840Vacuum bed area (in) 17 × 23 23 × 33Max outside screen size (mm) 780 × 660 1040 × 725Max outside screen size (in) 31 × 26 41 × 29W × D × H (mm) 840 × 1070 × 900 1092 × 1200 × 900W × D × H (in) 33 × 42 × 36 43 × 47 × 36Weight (inc. Whisper Vac.Unit) 41kg 50kgOrder Code41-HMA1NV41-HMA2NV41-HMA2-1A1 Screen Printer complete withstand, no vacuumA2 Screen Printer complete withstand, no vacuumA2 Bench Top Screen Printer,no vacuumPriceFive Star Photostencil FilmFive Star is an indirect stencil film which combines highresolution with a tough and robust stencil, requiring aminimum of spotting out prior to printing. The film isquick and easy to process. Firstly it is exposed to UV lightin contact with an artwork. It is then developed byimmersion in Photostencil Film Developer, rinsed in warmwater and applied wet to the screen mesh. New syntheticmeshes should be abraded with Seriprep 101. Again allmeshes should be degreased with Universal Mesh Prepprior to application of Five Star.34Order Code41-112064 Developer 100g41-112064-2 Developer 750gPriceOrder Code41-112025 104 × 500cm41-112026 104 × 1000cmPrice