Cuban Mortar Tiles - infogram.co.uk > Home

Cuban Mortar Tiles - infogram.co.uk > Home

Cuban Mortar Tiles - infogram.co.uk > Home

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Cuban</strong> <strong>Mortar</strong> <strong>Tiles</strong> Chapter 8 Production of Mosai<strong>co</strong>s Hidrauli<strong>co</strong>s after 1959<br />

Havana Vieja Factory<br />

The Habana Vieja factory is owned by the Empresa de Restauracion de Monumentos,<br />

a <strong>co</strong>nstruction <strong>co</strong>mpany which carries out work for the Offi ce of the<br />

City Historian of Havana. The factory was founded in July 2009 to producing<br />

200x200mm tiles, and currently has a limited range of designs matching traditional<br />

tiles (10 patterns). They plan to expand the range in due <strong>co</strong>urse. The factory<br />

currently has one press (i.e 2 workstations) and the two operatives estimate<br />

between them they produce between 60 to 80 tiles a day of a fairly <strong>co</strong>mplicated<br />

pattern. (It is interesting to <strong>co</strong>mpare this to the rate of production of a one-press<br />

private workshop in Santa Clara which produces badly made jaspeado tiles under<br />

<strong>co</strong>ntract to the local State building products <strong>co</strong>mpany – at a rate of 800 tiles<br />

per day!) The Italian-made presses are new and the result of lengthy research<br />

by the Empresa de Restauracion de Monumentos. The new presses have<br />

automatic lifting of mould lids, which slightly reduces the manual <strong>co</strong>mponent of<br />

the process. The factory sells to the Offi ce of the City Historian of Havana They<br />

do not sell to individuals. There is no in-house moldero so they have to buy in<br />

new moulds.<br />

In interview, the technical director for the Empresa de Restauracion de Monumentos<br />

reported that the factory at Las Guasimas currently produces plain<br />

tiles at 250 x 250 mm size. The factory produced tiles for the Saratoga hotel in<br />

Havana. Production suffered from “diffi culties with the presses and with<br />

de<strong>co</strong>rative technique”. An architect working in the architecture section of the<br />

OHC also tried to obtain tiles from the Las Guasimas factory, but the quality was<br />

so poor the tiles were taken up and thrown away after they had been installed.<br />

Another factory at Limonar was trying to produce 200 x 200 mm tiles, but were<br />

using polymer bases for the moulds which scratched easily, producing faults in<br />

the tiles.<br />

Small scale artisan production<br />

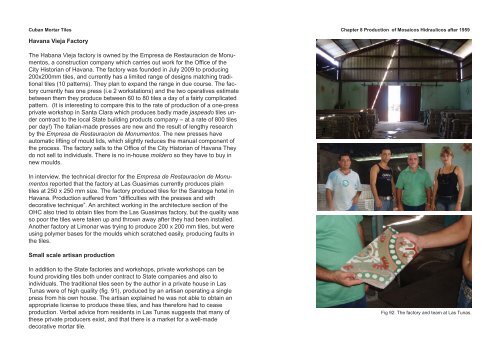

In addition to the State factories and workshops, private workshops can be<br />

found providing tiles both under <strong>co</strong>ntract to State <strong>co</strong>mpanies and also to<br />

individuals. The traditional tiles seen by the author in a private house in Las<br />

Tunas were of high quality (fi g. 91), produced by an artisan operating a single<br />

press from his own house. The artisan explained he was not able to obtain an<br />

appropriate license to produce these tiles, and has therefore had to cease<br />

production. Verbal advice from residents in Las Tunas suggests that many of<br />

these private producers exist, and that there is a market for a well-made<br />

de<strong>co</strong>rative mortar tile.<br />

Fig 92: The factory and team at Las Tunas.