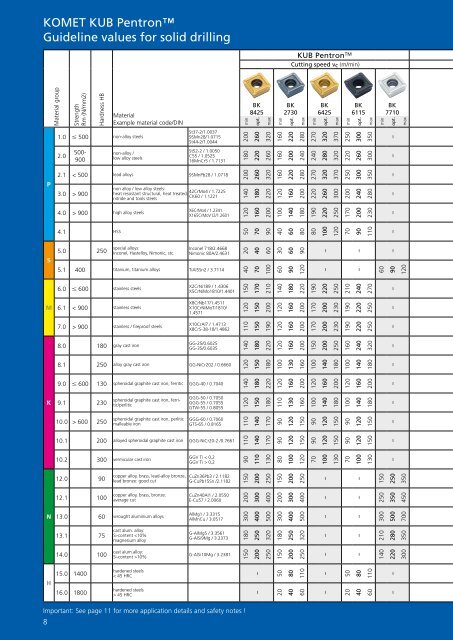

<strong>KOMET</strong> <strong>KUB</strong> PentronGuideline values for solid <strong>drilling</strong><strong>KUB</strong> Pentron TMCutting speed vc (m/min)Material groupStrengthRm (N/mm2)Hardness HBMaterialExample material code/DINminBK8425opt.maxminBK2730opt.maxminBK6425opt.maxminBK6115opt.maxminBK7710opt.max1.0 # 500non-alloy steelsSt37-2/1.00379SMn28/1.0715St44-2/1.0044200260320160220280270320370250300350–2.0500-900non-alloy /low alloy steelsSt52-2 / 1.0050C55 / 1.052516MnCr5 / 1.7131180220260160200240240280320220260300–P2.1 < 500 lead alloys9SMnPb28 / 1.07183.0 > 900non alloy / low alloy steels:heat resostant structural, heat treated,42CrMo4 / 1.7225nitride and <strong>to</strong>ols steelsCK60 / 1.1221200140260180320220160120220160280200270220320260370300250200300240350280––4.0 > 900high alloy steelsX6CrMo4 / 1.2341X165CrMoV12/1.2601120160200100140180190220250170200230–4.1HSS507090406080801001207090110–S5.0 250special alloys:Inconel, Hastelloy, Nimonic, stc.Inconel 718/2.4668Nimonic 80A/2.4631204060306090–––5.1 400 titanium, titanium alloysTiAl5Sn2 / 3.711440701006090120––60901206.0 # 600stainless steelsX2CrNi189 / 1.4306X5CrNiMo1810/1.4401150170210140180220190220250210240270–M6.1 < 900stainless steelsX8CrNb17/1.4511X10CrNiMoTi1810/1.4571120150200120160200170200230190220250–7.0 > 900stainless / fireproof steelsX10CrAl7 / 1.4713X8CrS-38-18/1.4862110150190120160200170200230190220250–8.0 180gray cast ironGG-25/0.6025GG-35/0.6035140180220120160200150200250160240320–8.1 250 alloy gray cast ironGG-NiCr202 / 0.6660120150180100130160100140180100140180–9.0 # 600 130 spheroidal graphite cast iron, ferritic GGG-40 / 0.7040140180220120160200120160200120160200–K9.1 230spheroidal graphite cast iron, ferritic/perliticGGG-50 / 0.7050GGG-55 / 0.7055GTW-55 / 0.8055120150180110130160100140180100140180–10.0 > 600 250spheroidal graphite cast iron, perliticmalleable ironGGG-60 / 0.7060GTS-65 / 0.8165110140170901201509012015090120150–10.1 200 alloyed spheroidal graphite cast iron GGG-NiCr20-2 /0.7661110140170901201509012015090120150–10.2 300vermicular cast ironGGV Ti < 0,2GGV Ti > 0,290110130801001207010013070100130–12.0 90copper alloy, brass, lead-alloy bronze,lead bronze: good cutCuZn36Pb3 / 2.1182G-CuPb15Sn /2.1182150200250150200250––15025035012.1 100copper alloy, brass, bronze:average cutCuZn40Al1 / 2.0550E-Cu57 / 2.0060200300400200300400––250350450N13.0 60wrought aluminium alloysAlMg1 / 3.3315AlMnCu / 3.0517300400500300400500––30050070013.1 75cast alum. alloy:Si-content 10%G-AlSi10Mg / 3.2381150200250150200250––140220300H15.0 140016.0 1800hardened steels< 45 HRChardened steels> 45 HRC––5020804011060––5020804011060––Important: See page 11 for more application details and safety notes !

4×D 5×Dx18,5–19,0x19,1–20,0x20,1–22,0x22,1–23,0x23,1–24,0x24,1–25,0x25,1–26,0x18,5–19,0x19,1–20,0x20,1–22,0x22,1–23,0x23,1–24,0x24,1–25,0x25,1–26,00,050,070,100,050,070,100,060,090,120,060,090,120,060,090,120,060,090,120,060,090,120,050,070,100,050,070,100,060,090,120,060,090,120,060,090,120,060,090,120,060,090,121.0P0,100,120,150,100,120,150,110,130,160,110,130,160,110,130,160,110,130,160,110,130,160,080,100,130,080,100,130,090,110,140,090,110,140,090,110,140,090,110,140,090,110,142.00,110,130,160,110,130,160,130,150,180,130,150,180,130,150,180,130,150,180,130,150,180,090,110,140,090,110,140,110,130,160,110,130,160,110,130,160,110,130,160,110,130,162.10,110,140,160,110,140,160,130,150,180,120,160,200,140,180,220,140,180,220,140,180,220,080,100,130,080,100,130,130,150,180,140,180,200,140,180,220,140,180,220,140,180,223.00,090,120,150,090,120,150,130,150,180,120,160,200,140,180,220,140,180,220,140,180,220,090,120,150,090,120,150,130,150,180,120,160,200,140,180,220,140,180,220,140,180,224.0––––––––––––––4.15.0S5.10,080,100,120,080,100,120,100,130,150,120,150,180,120,150,180,120,150,180,120,150,180,060,080,100,060,080,100,090,110,130,090,110,130,100,140,160,100,140,160,100,140,166.0M0,080,100,120,080,100,120,100,130,150,120,150,180,120,150,180,120,150,180,120,150,180,060,080,100,060,080,100,090,110,130,090,110,130,120,140,160,120,140,160,120,140,166.10,060,080,100,060,080,100,090,110,130,090,110,130,100,140,160,100,140,160,100,140,160,060,080,100,060,080,100,070,090,110,070,090,110,100,120,140,100,120,140,100,120,147.00,120,150,180,120,150,180,140,180,220,140,180,220,160,200,250,180,220,270,200,250,300,100,130,160,100,130,160,120,160,200,120,160,200,140,180,230,160,200,250,180,230,288.0K0,100,130,160,100,130,160,120,160,200,120,160,200,140,180,230,160,200,240,180,230,280,080,110,140,080,110,140,100,140,180,100,140,180,120,160,210,140,180,220,160,210,268.10,120,150,180,120,150,180,140,180,220,140,180,220,160,200,250,180,220,270,200,250,300,100,130,160,100,130,160,120,160,200,120,160,200,140,180,230,160,200,250,180,230,289.00,120,150,180,120,150,180,140,180,220,140,180,220,160,200,250,180,220,270,200,250,300,100,130,160,100,130,160,120,160,200,120,160,200,140,180,230,160,200,250,180,230,289.10,120,150,180,120,150,180,140,180,220,140,180,220,160,200,250,180,220,270,200,250,300,100,130,160,100,130,160,120,160,200,120,160,200,140,180,230,160,200,250,180,230,2810.00,100,130,160,100,130,160,120,160,200,120,160,200,140,180,230,160,200,240,180,230,280,080,110,140,080,110,140,100,120,180,100,140,180,120,160,210,140,180,230,160,210,2610.10,090,120,150,090,120,150,110,150,190,110,150,190,130,170,220,150,190,230,170,220,270,070,1014,000,070,100,140,090,110,170,090,130,170,110,150,200,130,170,220,150,200,2510.20,100,130,150,100,130,150,100,130,150,120,150,180,120,150,180,120,150,180,120,150,180,100,130,150,100,130,150,100,130,150,120,150,180,120,150,180,120,150,180,120,150,1812.0N0,080,110,130,080,110,150,080,110,130,100,130,160,100,130,160,100,130,160,100,130,160,080,110,130,080,110,150,080,110,130,100,130,160,100,130,160,100,130,160,100,130,1612.10,080,110,130,080,110,150,080,110,130,100,130,160,100,130,160,100,130,160,100,130,160,080,110,130,080,110,150,080,110,130,100,130,160,100,130,160,100,130,160,100,130,1613.00,100,130,150,100,130,150,100,130,150,120,150,180,120,150,180,120,150,180,120,150,180,100,130,150,100,130,150,100,130,150,120,150,180,120,150,180,120,150,180,120,150,1813.10,130,160,180,130,160,180,130,160,180,150,180,210,150,180,210,150,180,210,150,180,210,130,160,180,130,160,180,130,160,180,150,180,210,150,180,210,150,180,210,150,180,2114.0––––––––––––––15.0H––––––––––––––16.0Material groupFeed f (mm/rev)Feed f (mm/rev)minopt.maxminopt.maxminopt.maxminopt.maxminopt.maxminopt.maxminopt.maxminopt.maxminopt.maxminopt.maxminopt.maxminopt.maxminopt.maxminopt.maxon reques<strong>to</strong>n reques<strong>to</strong>n reques<strong>to</strong>n request