Code Approval of Composite Propane Cylinders for Indoor Use ...

Code Approval of Composite Propane Cylinders for Indoor Use ...

Code Approval of Composite Propane Cylinders for Indoor Use ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

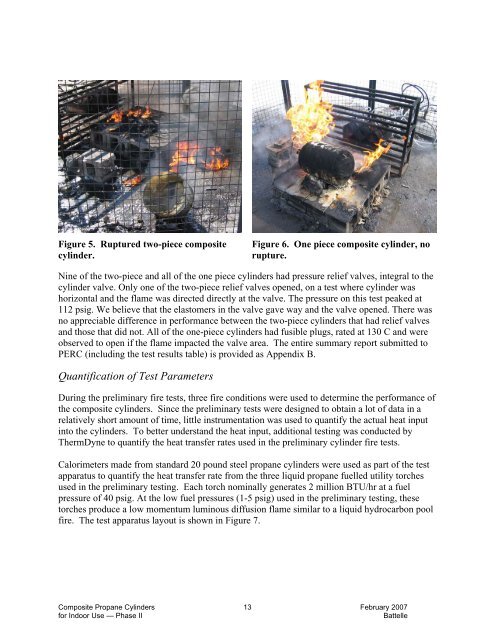

Figure 5. Ruptured two-piece compositecylinder.Figure 6. One piece composite cylinder, norupture.Nine <strong>of</strong> the two-piece and all <strong>of</strong> the one piece cylinders had pressure relief valves, integral to thecylinder valve. Only one <strong>of</strong> the two-piece relief valves opened, on a test where cylinder washorizontal and the flame was directed directly at the valve. The pressure on this test peaked at112 psig. We believe that the elastomers in the valve gave way and the valve opened. There wasno appreciable difference in per<strong>for</strong>mance between the two-piece cylinders that had relief valvesand those that did not. All <strong>of</strong> the one-piece cylinders had fusible plugs, rated at 130 C and wereobserved to open if the flame impacted the valve area. The entire summary report submitted toPERC (including the test results table) is provided as Appendix B.Quantification <strong>of</strong> Test ParametersDuring the preliminary fire tests, three fire conditions were used to determine the per<strong>for</strong>mance <strong>of</strong>the composite cylinders. Since the preliminary tests were designed to obtain a lot <strong>of</strong> data in arelatively short amount <strong>of</strong> time, little instrumentation was used to quantify the actual heat inputinto the cylinders. To better understand the heat input, additional testing was conducted byThermDyne to quantify the heat transfer rates used in the preliminary cylinder fire tests.Calorimeters made from standard 20 pound steel propane cylinders were used as part <strong>of</strong> the testapparatus to quantify the heat transfer rate from the three liquid propane fuelled utility torchesused in the preliminary testing. Each torch nominally generates 2 million BTU/hr at a fuelpressure <strong>of</strong> 40 psig. At the low fuel pressures (1-5 psig) used in the preliminary testing, thesetorches produce a low momentum luminous diffusion flame similar to a liquid hydrocarbon poolfire. The test apparatus layout is shown in Figure 7.<strong>Composite</strong> <strong>Propane</strong> <strong>Cylinders</strong> 13 February 2007<strong>for</strong> <strong>Indoor</strong> <strong>Use</strong> — Phase IIBattelle