tunnel thrusters - Scana Industrier ASA

tunnel thrusters - Scana Industrier ASA

tunnel thrusters - Scana Industrier ASA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

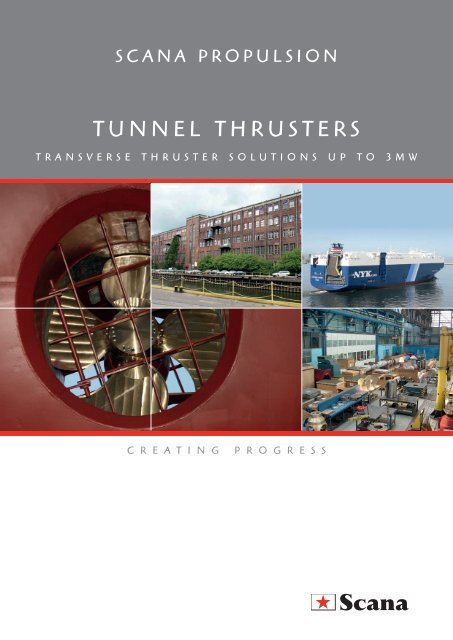

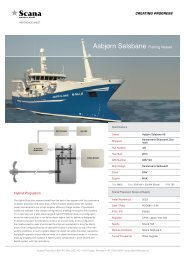

S c a n a p r O P u l s I O nt u n n e l t h r u s t e r st r a n s v e r s e t h r u s t e r s o l u t I O n s u p t o 3 m wc r e a t i n g p r O G r e s s

<strong>tunnel</strong> thruster systems<strong>Scana</strong> <strong>Industrier</strong> <strong>ASA</strong> (<strong>Scana</strong>) is a Nordic industrial group operating in three business areas:Steel, Marine and Oil & Gas. The group provides a complete range of propelled propulsionsolutions for all sizes of sea-going vessels. Products and systems are based on <strong>Scana</strong>’s technology,unique material knowledge and extensive production experience.For over 40 years our factory in Elblag has also been known as a manufacturer of <strong>tunnel</strong> <strong>thrusters</strong>.During that time more than a thousand transverse <strong>thrusters</strong> with a power range from 100 kW to3000 kW have been produced for different types of ships.DesIGNThe family of <strong>thrusters</strong> CPT and FPThas been designed in order to achievemaximum thrust for a specific propellerdiameter and guarantee maximumefficiency.CPT <strong>tunnel</strong> <strong>thrusters</strong> are equipped withcontrollable pitch propellers. The torqueof the propulsion motor is transmitted byan elastic coupling and bevel-gear to theshaft on which the hub of the propelleris mounted. The direction of the thrust iscontrolled by means of a change of thepitch propeller. The change of pitch iscontrolled by a hydraulic method.FPT <strong>tunnel</strong> <strong>thrusters</strong> are equipped withfixed pitch propellers. The direction of thethrust is obtained by means of a change ofrotation direction in the propulsion motor.The thrust is controlled by a changein the number of motor revolutions. Thesize of the pitch propeller and the shapeof blades are designed according to thepower and revolutions of the motor.The main advantages of our <strong>thrusters</strong>:• a special blade design to avoidcavitation phenomena;• the thruster shaft and thruster pinionare seated on high quality rollerbearings for a long lifetime;• the application of high qualityCyclo-Palloid bevel gears which aremade using the HPG method;• the application of high quality shaftseals which are environ mentallyfriendly and guarantee protection forthe thruster’s internal mechanisms.teChnIC AL BeneFItsThe thruster design is compact. Thereduced length of <strong>thrusters</strong> allows themounting of <strong>thrusters</strong> in narrow areas ofthe vessel’s hull.The hub design facilitates easy bladedisassembly in a horizontal position. Inthis solution it is not necessary to applydisassembly covers in the <strong>tunnel</strong>.In the emergency replacement of a bladeunderwater or a trimmed vessel withoutthe necessity to empty oil from thethruster is possible.It is possible also to disassemble the pinionunit in order to inspect or replace bearingswithout the necessity of dismounting thethruster or dock a vessel.The application of skew back blades minimisesnoise and vibrations.In all thruster units the same type of oilis used.hyDRAulIC/luBRIC ATIONsystemsThe system of gravity lubrication is appliedin <strong>thrusters</strong> of the types CPT and FPT.The main function of the system is tosupply oil to the thruster casing andretain overpressure inside the thruster inrelation to water outside. In CPT <strong>thrusters</strong>the pitch is controlled hydraulically bymeans of oil from the system. Sub-unitsassembled on an integrated hydraulicpower pack (HPP) prepare and distributeoil inside the thruster. On the HPP tankthere are built in pump aggregates, oilfilters, block valves, flow and safety valvesand controlling tools.remOte COntrOL systemThrusters are remotely controlled fromthe bridge or from additional locations.The <strong>Scana</strong> Zamech <strong>tunnel</strong> <strong>thrusters</strong> areequipped with a remote control systemintegrated with a driving system.The system is based on programmablecontrollers. It consists of a central unit,which is assembled in the <strong>tunnel</strong> thrustercontrol box and a remote unit in thewheelhouse. Both units are workingtogether via serial communication.The PLC unit is responsible for all remotecontrol functions such as: s etting of <strong>tunnel</strong>thruster propeller pitch, supervision ofstarting procedure of hydraulic and drivingmotor and monitoring. Thruster controlscan be integrated with other ships’ controlsystems, dynamic positioning systems andvoyage data recorder.

DRIVE systemThe drive systems of the <strong>thrusters</strong> FPTconsist of frequency converters andsquirrel cage motors of variable rotationspeeds. The frequency c onverter controlsthe motor start-up as well as the motorrotation speed.The drive systems of <strong>thrusters</strong> CPTinclude squirrel cage motors of a fixedrotation speed. These motors fulfil marineexecution requirements. The followingparameters, among others, are adaptedto the Customer’s requirements: voltage,frequency, duty class, protection degree,insulation class. Motor windings areequipped with temperature sensors andanticondensation heaters.The standard starting system of CPTthruster consists of:• the <strong>tunnel</strong> thruster Control Boxfor remote control, driving motorand the hydraulic pump aggregatecontrol;• compact starting autotransformerwhich limits the starting current;• voltage step-up transformeraccording to the Customer’sspecifications.<strong>tunnel</strong> OF thrusterThe <strong>tunnel</strong> of a thruster is made ofthe steel plate grade required by theClassifi cation Society. The coat is madeby welding and the anti-cavitation ringmade of Stainless Steel is mounted insidethe <strong>tunnel</strong> in the propeller blade area.The <strong>tunnel</strong> is equipped with radial andhorizontal ribs for welding to the ship’shull structure.The bracket for the electric motoris made as a separate part andscrewed to the <strong>tunnel</strong>. The <strong>tunnel</strong>Is delivered in standard length.OPTIONWe offer a wide range of <strong>tunnel</strong> <strong>thrusters</strong>olutions. Each delivery is individualand optimized to meet our Customers’requirements.As a total supplier we take responsi bilityfor all elements in the installation.Standard range of delivery includes:• thruster unit• hydraulic/lubrication systems• remote control system (3 posts)• interface to ship control systems,dynamic positioning systems andvoyage data recorderAs an option we offer:• <strong>tunnel</strong> of thruster (standard or extralength)• drive system• additional control system postSPAre PArts & ONBOARDserVICesAfter-sales service and support is anintegral part of our total delivery andgreatly influences the lifetime cost andprofitability of a ship’s operations.Our service engineers guarantee thehighest product skills to meet onboardservice requirements. They ensure24-hour telephone technical supportand guarantee global service in anydestination.Spare Parts are handled by our localMmarine Service Centres, providingcommunication in local languages.

technIC Al DAtaThruster Motor Current Motor Propeller Main dimensionstype power* frequency rotation rotation A B Cmax (kW) (Hz) (rpm) max.(rpm) (mrn)FPT 0.8 200 50 1480 800 800 811 82560 1750CPT/ FPT 1.0 340 50 1480 660 978 988 1000280 60 1750CPT/ FPT 1.25 500 50 1480 530 1225 1238 1250450 60 1750CPT/ FPT 1.5 780 50 1480 440 1468 1484 1500660 60 1750CPT /FPT 1.75 880 50 1480 380 1714 1730 17501080 60 1190CPT/ FPT 2.0 1050 50 14801300 50 980 333 1950 1970 20001300 60 1190CPT/ FPT 2.25 1450 50 980 290 2200 2220 22501740 60 1190CPT/ FPT 2.5 1800 50 980 265 2440 2470 25002050 60 1190CPT/ FPT 2.75 2400 50 980 240 2700 2730 27502540 60 880CPT/ FPT 3.0 2700 50 730 220 2940 2970 30003000 60 880ØCØA ØB* Max. power dependent on sailing profile and classification society requirements.<strong>Scana</strong> PropulsionNO-6101 Volda, NorwayTel.: +47 7005 9000propulsion@scana.no<strong>Scana</strong> Volda ASNO-6101 Volda, NorwayTel.: +47 7005 9000volda@scana.no<strong>Scana</strong> Zamech82-300 Elblag, PolandTel.: +48 55 23 64 82024/365 hour servicetel.: +48 601 888 019zamech@scana.no<strong>Scana</strong> Mar-El ASNO-3880 Dalen, NorwayTel.: +47 35 07 58 00mar-el@scana.no<strong>Scana</strong> do Brasil Industrias LtdaBotafogo 22290-160Rio de Janeiro, BrazilTel.: +55 (21) 35440010johnar.olsen@scana.no<strong>Scana</strong> Shanghai Rep. OfficeTel.: +86 21 6288 8881jack.zhu@scana.no<strong>Scana</strong> Singapore Pte Ltd.Tel.: +65 68 72 27 02terry.choo@scana.no<strong>Scana</strong> VoldaKorea Rep. OfficeTel.: +82 51 731 2081khan@scanavolda.co.kr<strong>Scana</strong> IndustriesUSA, Inc.Tel.: +1 985 249-9425dan.gaiennie@scana.no<strong>Scana</strong> Marine ServiceNO-6101 Volda, NorwayTel.: +47 7005 9000volda@scana.no<strong>Scana</strong> Zamech Sp. z o.o.Stoczniowa 2, 82-300 Elblag, PolandTel. +48 55 236 4820 Fax +48 55 239 205024/365 hour service tel.: +48 601 888 019e-mail : zamech@scana.nowww.scana.no24/365 hour service tel.Mech.: +47 47 8 24 365Elec.: +47 957 24 365