Vibration Tube Mill ENG - Grenzebach Maschinenbau GmbH

Vibration Tube Mill ENG - Grenzebach Maschinenbau GmbH

Vibration Tube Mill ENG - Grenzebach Maschinenbau GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Mechanical Process<br />

<strong>Vibration</strong> <strong>Tube</strong> <strong>Mill</strong><br />

Function<br />

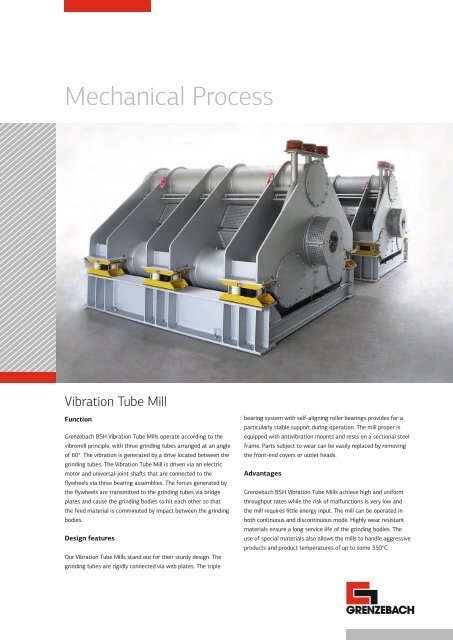

<strong>Grenzebach</strong> BSH <strong>Vibration</strong> <strong>Tube</strong> <strong>Mill</strong>s operate according to the<br />

vibromill principle, with three grinding tubes arranged at an angle<br />

of 60°. The vibration is generated by a drive located between the<br />

grinding tubes. The <strong>Vibration</strong> <strong>Tube</strong> <strong>Mill</strong> is driven via an electric<br />

motor and universal-joint shafts that are connected to the<br />

flywheels via three bearing assemblies. The forces generated by<br />

the flywheels are transmitted to the grinding tubes via bridge<br />

plates and cause the grinding bodies to hit each other so that<br />

the feed material is comminuted by impact between the grinding<br />

bodies.<br />

Design features<br />

Our <strong>Vibration</strong> <strong>Tube</strong> <strong>Mill</strong>s stand out for their sturdy design. The<br />

grinding tubes are rigidly connected via web plates. The triple<br />

bearing system with self-aligning roller bearings provides for a<br />

particularly stable support during operation. The mill proper is<br />

equipped with antivibration mounts and rests on a sectional steel<br />

frame. Parts subject to wear can be easily replaced by removing<br />

the front-end covers or outlet heads.<br />

Advantages<br />

<strong>Grenzebach</strong> BSH <strong>Vibration</strong> <strong>Tube</strong> <strong>Mill</strong>s achieve high and uniform<br />

throughput rates while the risk of malfunctions is very low and<br />

the mill requires little energy input. The mill can be operated in<br />

both continuous and discontinuous mode. Highly wear resistant<br />

materials ensure a long service life of the grinding bodies. The<br />

use of special materials also allows the mills to handle aggressive<br />

products and product temperatures of up to some 350°C.

Typical Applications<br />

Our <strong>Vibration</strong> <strong>Tube</strong> <strong>Mill</strong>s are used in the<br />

building materials, ceramics and chemical<br />

industries. They are suitable in particular<br />

for dry and wet grinding of medium-hard to<br />

hard, abrasive products, such as slag, ash,<br />

fireclay etc.<br />

Limits of Application<br />

<strong>Grenzebach</strong> BSH <strong>Vibration</strong> <strong>Tube</strong> <strong>Mill</strong>s<br />

achieve throughput rates of up to 20 t/h,<br />

depending on the feed material. Product<br />

feed temperatures up to 350°C are<br />

possible. At a feed particle size < 10 mm,<br />

an end fineness of d90 = 50 µm can be<br />

achieved, depending on the product quality.<br />

GRENZEBACH BSH <strong>GmbH</strong><br />

Rudolf-<strong>Grenzebach</strong>-Straße 1<br />

36251 Bad Hersfeld, Germany<br />

Phone: +49 6621 81-3000<br />

Fax: +49 6621 81-93613<br />

e-mail: process@grenzebach.com<br />

www.grenzebach.com