TDW Tapping Fittings - ASME B31.4 - T.D. Williamson, Inc.

TDW Tapping Fittings - ASME B31.4 - T.D. Williamson, Inc.

TDW Tapping Fittings - ASME B31.4 - T.D. Williamson, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

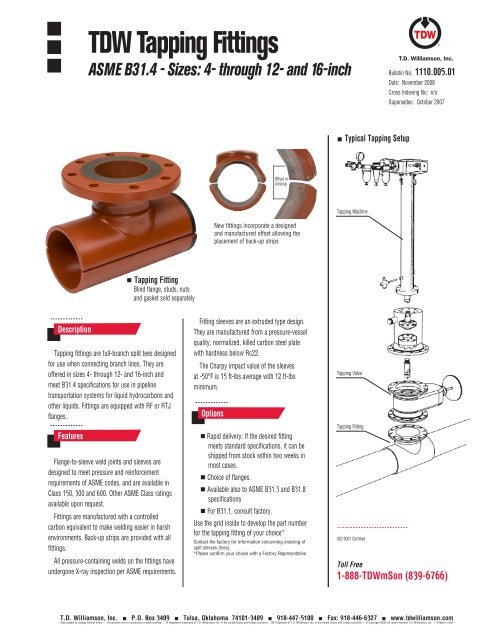

<strong>TDW</strong> <strong>Tapping</strong> <strong>Fittings</strong><strong>ASME</strong> <strong>B31.4</strong> - Sizes: 4- through 12- and 16-inchBulletin No: 1110.005.01Date: November 2008Cross Indexing No: n/aSupersedes: October 2007Typical <strong>Tapping</strong> SetupOffset incloseup<strong>Tapping</strong> MachineNew fittings incorporate a designedand manufactured offset allowing theplacement of back-up strips<strong>Tapping</strong> FittingBlind flange, studs, nutsand gasket sold separatelyDescription<strong>Tapping</strong> fittings are full-branch split tees designedfor use when connecting branch lines. They areoffered in sizes 4- through 12- and 16-inch andmeet <strong>B31.4</strong> specifications for use in pipelinetransportation systems for liquid hydrocarbons andother liquids. <strong>Fittings</strong> are equipped with RF or RTJflanges.Flange-to-sleeve weld joints and sleeves aredesigned to meet pressure and reinforcementrequirements of <strong>ASME</strong> codes, and are available inClass 150, 300 and 600. Other <strong>ASME</strong> Class ratingsavailable upon request.<strong>Fittings</strong> are manufactured with a controlledcarbon equivalent to make welding easier in harshenvironments. Back-up strips are provided with allfittings.All pressure-containing welds on the fittings haveundergone X-ray inspection per <strong>ASME</strong> requirements.Fitting sleeves are an extruded type design.They are manufactured from a pressure-vesselquality, normalized, killed carbon steel platewith hardness below Rc22.The Charpy impact value of the sleevesat -50°F is 15 ft-lbs average with 12 ft-lbsminimum.OptionsFeatures Rapid delivery: If the desired fittingmeets standard specifications, it can beshipped from stock within two weeks inmost cases.Choice of flanges.Available also to <strong>ASME</strong> B31.3 and B31.8specificationsFor B31.1, consult factory.Use the grid inside to develop the part numberfor the tapping fitting of your choice*Contact the factory for information concerning ordering ofsplit sleeves (tees).*Please confirm your choice with a Factory Representative<strong>Tapping</strong> Valve<strong>Tapping</strong> FittingISO 9001 CertifiedToll Free1-888-<strong>TDW</strong>mSon (839-6766)T.D. <strong>Williamson</strong>, <strong>Inc</strong>. P.O. Box 3409 Tulsa, Oklahoma 74101-3409 918-447-5100 Fax: 918-446-6327 www.tdwilliamson.comData subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. <strong>Williamson</strong>, <strong>Inc</strong>. in the United States and foreign countries / TM Trademark of T.D. <strong>Williamson</strong>, <strong>Inc</strong>. in the United States and foreign countries / © Copyright 2008. All rights reserved T.D. <strong>Williamson</strong>, <strong>Inc</strong>. / Printed in USA

Order Information<strong>TDW</strong> <strong>Tapping</strong> <strong>Fittings</strong> - <strong>ASME</strong> <strong>B31.4</strong>Example36-1103-0606-11 is a <strong>Tapping</strong> Fitting 6” (run) x 6” (branch), with an RTJ standard weight, A105material flange, class 150, and A 537 CL. 1 <strong>TDW</strong> Std. sleeve material with back-up strips.1110.005.01- p236-XXXX-SIZE-XXFlange Type & Sleeve MaterialPart Number Option36-1103-XXXX-XX 150 LB36-1104-XXXX-XX 300 LB36-1105-XXXX-XX 600 LBRun / Branch<strong>Inc</strong>hes (Nom.)04 0406 0608 0810 1012 1216 16Flange Type & Sleeve MaterialOption Size Flange Material Flange Type Sleeve Material01 4 - 12 & 16-<strong>Inc</strong>h A105N RF A537 CL 103 4 - 12 & 16-<strong>Inc</strong>h A105N RF A516 GR 70N11 4 - 12 & 16-<strong>Inc</strong>h A105N RTJ A537 CL 113 4 - 12 & 16-<strong>Inc</strong>h A105N RTJ A516 GR 70NHDLFitting DimensionsSize Dim. H (in.) RF Dim. H (in.) RTJ Dim. D Dim L<strong>Inc</strong>hes (Nom.) Class 150 Class 300 Class 600 Class 150 Class 300 Class 600 <strong>Inc</strong>hes <strong>Inc</strong>hes04 6.188 6.516 7.718 6.438 6.766 7.500 4.656 10.7506 7.750 8.156 9.125 8.000 8.406 9.188 6.781 14.0008 9.438 9.781 10.906 9.688 10.031 10.968 8.812 16.5010 10.718 11.344 12.968 10.968 11.656 13.031 10.938 20.0012 12.422 13.046 14.296 12.672 13.359 14.359 12.968 22.0016 13.546 14.546 16.046 13.796 14.796 16.046 16.218 30.00Fitting Weights and Pressure RatingsSize Weight (lbs.) Weight (lbs.) Weight (lbs.) Maximum Allowable Operating Pressure (in psi) @ -20 to 250°F with .72 design factor<strong>Inc</strong>hes (Nom.) Class 150 Class 300 Class 600 Class 150 Class 300 Class 60004 40 45 60 285 740 148006 60 80 115 285 740 148008 90 120 165 285 740 148010 160 200 290 285 740 96512 250 300 390 285 740 93016 460 570 690 285 740 965Consult factory for other pressure and temperature requirementsT.D. <strong>Williamson</strong>, <strong>Inc</strong>. P.O. Box 3409 Tulsa, Oklahoma 74101-3409 918-447-5100 Fax: 918-446-6327 www.tdwilliamson.comData subject to change without notice. / Dimensions not for construction unless certified. / ® Registered trademark of T.D. <strong>Williamson</strong>, <strong>Inc</strong>. in the United States and foreign countries / TM Trademark of T.D. <strong>Williamson</strong>, <strong>Inc</strong>. in the United States and foreign countries / © Copyright 2008. All rights reserved T.D. <strong>Williamson</strong>, <strong>Inc</strong>. / Printed in USA