Spirit 43 - Volvo Construction Equipment

Spirit 43 - Volvo Construction Equipment

Spirit 43 - Volvo Construction Equipment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

180 Years offorward thinkingCentaur 110524Sfinx 110500This year, <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> is 180 years old. Though we are proud of ourlong history, we are already looking to the future by modelling the Sfinx, Gryphinand Centaur. They are a vision of <strong>Volvo</strong>’s efforts to meet your future business needs.And to celebrate our 180th anniversary, we are offering these concept modelsfor a special price. Invest in the forward thinking of your business:purchase an idea from our <strong>Volvo</strong> Concept Scale Model Range.*Contact your local dealer or log on to the website.Gryphin 110523www.volvomerchandise.comwww.volvobrandshop.com (North America)*Not available in all markets<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> concept SCALE model range

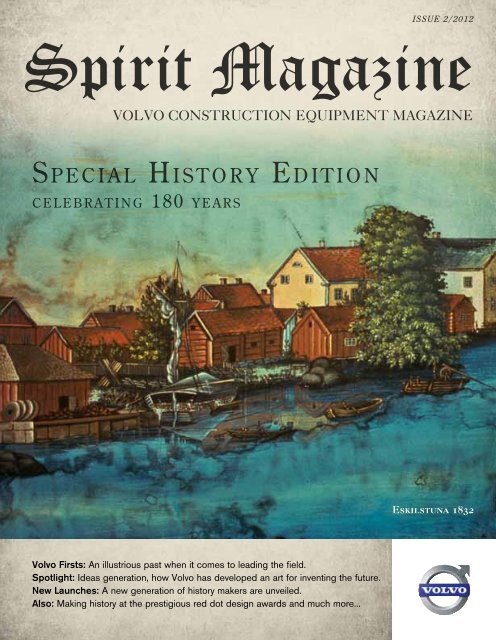

<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> MagazineIssue 02 / 2012contents9 GlobetrottingAs Miami hosts the <strong>Volvo</strong> Ocean Race, we visitone of <strong>Volvo</strong> CE’s customers with an interestingbusiness in the Sunshine State.21 A New Generation of History Makers<strong>Volvo</strong> CE expands its portfolio of productsto a record new level in its 180th year.25 <strong>Volvo</strong> FirstsWe plot how <strong>Volvo</strong> CE’s innovation has ledto many industry firsts over time.33 Life Through a LensWe talk to the people who bring <strong>Volvo</strong> CE’sillustrious past to life and preserve its historyat the Munktell Museum in Eskilstuna, Sweden.37 Simply the Best<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> makes historyby winning the coveted red dot design award -for a second year in a row.Join us on:<strong>Volvo</strong> <strong>Spirit</strong> Magazine App is nowavailable from the Apple itunes store.Proud to be firstOver the years <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> has been fairly modestabout its achievements. But as we turn 180 this year, making us the oldestconstruction equipment manufacturer in the world, we think it’s time toemphasize just how much we have achieved in almost two centuries.In this special anniversary edition we chart our history from 1832 to thepresent day and celebrate the innovations that have made world andindustry-firsts. From producing the world’s first wheel loader with parallellinkage in 1954, to putting the world’s first truly low-emission engines forconstruction equipment into production in 1978, to becoming the firstforeign company to invest in Korea in 1998…and the list goes on.Our 180th year sees us continuing this history of innovation with a recordbreaking number of product launches – over 60 this year alone. And thenews that we’re winning more awards than ever before – as we celebratereceiving the prestigious red dot design award for the second year running– another industry first for <strong>Volvo</strong> CE.Lastly, it wouldn’t be a special anniversary edition of <strong>Spirit</strong> without someinnovations to this very magazine. So we bring you the latest <strong>Spirit</strong> iPadapp with even more exclusive material and behind the scenes footage.(download free at: www.volvospiritmagazine.com).You may also notice several QR Codes throughout themagazine. Scan the one on this page with your mobiledevice and watch our (also award-winning) history filmThe Master Builder to see why wereally do have so much to be proudof in our 180th year.Best wishes,Clare Gittins Editor in ChiefPUBLISHED BY <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> (<strong>43</strong>rd edition)EDITOR IN CHIEF Clare Gittins Assistant EDITOR Steven LefebvreEDITORIAL PRODUCTION AND DESIGN EMG Communications LtdCONTRIBUTORS Niall Edworthy, Tony Lawrence, Dan WaddellPHOTOGRAPHY Julian Cornish TrestrailPlease send your editorial correspondence to <strong>Volvo</strong> <strong>Spirit</strong>, <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>,Hunderenveld 10 – 1082 Brussels, Belgium or by e-mail to volvo.spirit@volvo.com.All rights reserved. No part of this publication (text, data or graphic) may be reproduced, stored in adata retrieval system or transmitted, in any form whatsoever or by any means, without obtaining <strong>Volvo</strong> CE’sprior written consent. <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> does not necessarily endorse the views or factualaccuracy of the articles in this issue. Four issues per year – printed on environmentally friendly paper.www.volvoce.com/global

<strong>Volvo</strong><strong>Construction</strong><strong>Equipment</strong>:Göran LindgrenPresident, Sales Region AmericasNEW LOOK,NEW CHALLENGES,SAME COMMITMENTVincent TanPresident, Sales Region APACGöran Lindgren, Vincent Tan, Lawrence Luoand Tomas Kuta have a lot in common.As <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’s new regionalSales and Marketing Presidents, they carry the samejob title. They have similar high levels of expertise.All four are relishing their new responsibilities.And all share the same commitment, as well as theconviction that the company’s sales and marketingre-organization will become a source of strengthin the years to come. Yet while their aspirations ofdriving the <strong>Volvo</strong> CE brand forwards are the same,the challenges they face vary markedly.Lawrence LuoPresident, Sales Region ChinaAs Tomas Kuta, President of Sales Region EMEA(Europe, Middle East and Africa) points out, eachnew sales area has its own particular characteristics.‘‘Take EMEA,’’ he says. ‘‘It is a very diverse region.It consists of some 120 countries differing in size,economics, culture, history and politics.’’Tomas KutaPresident, Sales Region EMEASPIRIT5

BIG AMBITIONS‘‘On the one hand you have dormant economies likeGreece and Portugal, on the other booming commodityrichcountries like Russia, Saudi Arabia and the Gulfarea and African nations like Nigeria, Algeria and SouthAfrica.’’‘‘The main regional strategy is to protect our core, maturemarkets in Europe while strengthening our positionfurther. We have big ambitions in upcoming markets,expanding our market share and our distribution andafter-sales networks, while Africa is another big andimportant part of the jigsaw.’’The Asia Pacific (APAC) markets, meanwhile, are bothsimilar and diverse at the same time, according toPresident of Sales Region APAC, Vincent Tan.‘‘Many of the APAC markets are commodity-based,producing coal, minerals or metals for export to largereconomies like China,” he says. “So we’re focussedon industries such as mining, construction, quarrying,road construction. There are lots of heavy infrastructureprojects, with some forestry.’’DIFFERENT CHALLENGES‘‘In other respects, though, there’s great diversity. India,the largest market, is very different from, say, Australia.Each presents different challenges. But, with our teamand distribution network, we’re well placed to furtherimprove our position in the region.’’For Goran Lindgren, President of the new AmericasSales Region, combining North and South Americamakes a natural fit.‘‘Mixing the mature, recovering North American marketwith the rapidly developing economies of Central andSouth America may seem an awkward fit but it makesperfect business sense.’’‘‘There are differences – Latin America is a rapidlydeveloping market with different customer demands aswell as trade, cultural and linguistic differences, whereasNorth America is largely a mature market and singlehomogeneous trading block. Though there are a lotmore things that bind us together. The idea is to mergetogether all of the good aspects and practices from thetwo hubs. Communication, co-operation and the creationof a unified culture is the name of the game.’’SPIRIT6

“We’ve grown globallyover the last fewyears and Asia hasbeen a substantialand dramatic partof that growth.”CHINA’S MARKET LEADER“Together with our joint venture partner in China, SDLG(Shangdong Lingong <strong>Construction</strong> Machinery Co. Ltd)we’re number one in the Chinese market for excavatorsand wheel loaders and we see this growing further stillin the next three to five years.”“China is looking to move away from an export andinvestment-driven economic model to one fuelled bydomestic consumption. That means greater urbanisation,bringing huge opportunities to construction equipmentmanufacturers.”“Our dual brand strategy in China with SDLG gives us apowerful presence to all customers.”“There are specific challenges, of course. We have to beable to react quickly to changes in demand by developingand bringing new models to market.”“But <strong>Volvo</strong>’s quality, durability and fuel efficiency is highlyappreciated here. We’re strong in industries such asmining, heavy infrastructure, quarry and aggregates androad building. We’re perfectly placed to fulfil our strategyof growth and of outperforming the market.”GROWTH POTENTIALLuo’s excitement about growth potential is shared by Tan.“For me, the most exciting thing is how far the region hascome in such a short space of time – and how far it hasto go.”“We’ve grown globally over the last few years and Asia hasbeen a substantial and dramatic part of that growth. Thattrend is continuing as the center of economic gravity shiftseastwards.”Equally, concludes Tomas Kuta, President of sales regionEMEA, <strong>Volvo</strong> CE’s sales and marketing re-organization, byre-aligning areas and work teams in response to changingmarket situations right across the globe, will itself presentnew operational efficiencies and opportunities.“It’s fascinating to build up our new regional organizationfrom scratch and drive our brand and sales to new heights.Despite short-term economic uncertainties, we have greatpotential across some very exciting markets.’’’iPad exclusiveDownload the app formore in-depth informationSPIRIT8

GLOBETROTTINGFlorida, USAFlorida, the Sunshine State, produces one fifth of the world’s supply of phosphate.We meet one such supplier who’s found the perfect partner in <strong>Volvo</strong> CE.SPIRIT9

“Our operators tell me that the <strong>Volvo</strong> equipment, particularly the articulated haulers,are going TO places the competitors’ machines can’t in certain situations.”Mike Williams, General Superintendent at JVSThink of Florida andyou’ll probably think oforanges, of the world-famousEverglades national park, DisneyWorld and the Kennedy SpaceCenter. Perhaps you’ll think of theUS state’s sandy beaches – Floridahas 1,350 miles (2,170 km) of coastlinebordering the Gulf of Mexico andthe Atlantic Ocean – or ofTallahassee, its capital.Or perhaps you’ll even think of the hurricanes thatregularly lash the south eastern state and its 19 million inhabitants(in 2004, four Florida hurricanes caused an estimated $45 billion ofdamage).It’s unlikely, though, that many people link Florida withphosphate. Yet the mining of this chemical, a major componentin fertilizer, represents the region’s third-largest industry. Florida,the ‘Sunshine State’, indeed, produces nearly half of US farmers’requirements – and almost one fifth of the world’s supply. And withthe world’s population estimated to grow to more than 8 billionby 2030, it’s clear how important crop nutrients will be in feedingfuture generations.It’s something Mosaic is certainly aware of. The company,the world’s leading producer of fertilizer made from phosphate, hasmining rights to 300,000 acres of land in Florida, including FourCorners - the world’s largest phosphate mine - just outside Tampa.Phosphate is generally found between 3-15 meters(10-50 ft.) below the surface, and usually on land which wasonce an ancient sea bed, where nutrient-rich coral, shellfish and fish skeletons havebeen deposited over thousands of years. The chemical is mined with a dragline andthe material fed into pipes and pumped to processing areas where the phosphate isseparated from the sand and clay.SPIRIT10

<strong>Construction</strong> <strong>Equipment</strong> has a tremendous opportunity to maketheir mark and increase their market share in Florida.“Phosphate extraction represents the large miningactivity in the state,” says McDonell. “We are making inroads intothe segment. Our equipment is on the high-profile Four Cornersmine site and we are producing great results. They have highproductivity and are fuel efficient while reducing emissions dueto <strong>Volvo</strong>’s Tier 4 interim engine technology.”The <strong>Volvo</strong>s not only help in the mining process butalso in restoring the land, once the mining is completed, byhauling sand and fill during the reclamation process. The land isthus restored to a useable state for wildlife, agriculture and people.Reclaiming a mine site is required by law in Florida. For Mosaic,though, it’s more than a requirement. The company sees it as aresponsibility. Last year alone, Mosaic reclaimed more than 5,000acres and planted 1.3 million trees. The land is often turned backinto wetlands, pasture and agricultural sites, as well as parks andrecreation areas. Reclamation happens concurrently with themining process. Every acre mined at The Four Corners mine willbe reclaimed.ENVIRONMENTAL COMMITMENTThis commitment fits well with <strong>Volvo</strong> <strong>Construction</strong><strong>Equipment</strong> and its core values of quality, safety and environmentalcare. <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’s reputation for producingmachines that are not only highly efficient but which also have alow impact on the environment is certainly not lost on Mosaic.“Mosaic chooses to do business with companies that share ourvalues - those that honestly deliver on their promises whiletreating their employees fairly and showing excellence in safetyand environmental stewardship,” says Chris Lambe, Director SocialResponsibility at Mosaic.<strong>Volvo</strong> launched its first Environmental Policy in 1972.The company’s global environmental footprint is continuouslyimproved through the development of pioneering productimprovements and services and by improvements within theindustrial infrastructure. <strong>Volvo</strong> proved this recently by signingan agreement with the World Wide Fund for Nature (WWF)Climate Savers program, agreeing to reduce its CO 2emissionsby 30 million tonnes together with the <strong>Volvo</strong> Group, becomingthe first construction equipment company in the industry tojoin the program.As the world’s population increases, the need for foodis also increasing. If it takes a village to raise a child, so the sayinggoes, it takes everyone - from individuals to major corporations -to care for the future of the environment.Text & photography: Diana Henry*Learn more about <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> and its newWWF agreement at: www.volvoce.com/wwf*Find out how <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> is committed toits core values: www.volvoce.com/globaliPad exclusiveDownload the app formore in-depth informationALL EYES ON MIAMI FORTHE VOLVO OCEAN RACEIt won’t take a mind reader to tell you what the <strong>Volvo</strong>Ocean Race crews are thinking as Miami comes into view overthe horizon in May. Their delight will be matched by the cheeringcrowds who turn out to greet them as the fleet completes the4,800-nautical-mile sixth leg of sailing’s most exciting andchallenging offshore event.The crews, battle-hardened by six months of cutthroatcompetition, then get a couple of weeks to recuperateand repair their yachts before an in-port race and the start of thenext test - across the Atlantic, destination Lisbon. The premiernine-leg event ends in Galway in Ireland on July 7.Mark McDonell, President of Flagler <strong>Construction</strong><strong>Equipment</strong>, <strong>Volvo</strong> CE’s dealership in Florida, is equallydelighted to host the 39,270-nautical-mile (72,000 km)sailing extravaganza. For McDonell, it is “a global event whichallows the dealers to show customers who is behind not onlythe construction equipment products, but all the services andproducts that the <strong>Volvo</strong> Group provides.”“It builds credibility. It shows the level of commitmentthat the <strong>Volvo</strong> Group has to each of its business areas.” Inshort, the race – the sport’s homage to the best, most durableand safety-conscious sailors on the planet – will provide amagnificent backdrop for the company to profile its productsand its commitment to sustainability.The Miami Race Village will be open from 6th – 20th MayThe Miami Race Weekend will take place from 18th – 20th MayFor more information visit:www.volvoce.com/oceanraceSPIRIT12

<strong>Volvo</strong> Financial Services –Supporting customers through theyears makes real business senseSPIRIT13

Take Cemex, for instance. The company was born asa small local concern in 1906 in northern Mexico.Three years later, it had doubled its production.Today, it is a multi-national organization, the world’sleading supplier of ready-mix concrete and a prominentcement and aggregates producer... with annual salestopping $15 billion.Somehow, though, the company survived theturmoil, to the point that today Cemex is a multi-nationalorganization, the world’s leading supplier of ready-mix concreteand a prominent cement and aggregates producer. RegionCentral West Sales Director Michael Ksionzek would arguethat <strong>Volvo</strong> Financial Services belongs to the same category ofideas too good to be ignored. “The <strong>Volvo</strong> Group first movedinto financing around 25 years ago,” says Ksionzek. “It beganwith the truck business – that’s when it was founded. It’s beensupporting <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> for more than 10years now. Why? Simple - people wanted it. People needed it.”and it finances the growth and renewal of its fleet through <strong>Volvo</strong>Financial Services.“From both the <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> and<strong>Volvo</strong> Financial Services perspective, Cemex represents one ofour biggest customers,” says Ksionzek, who is responsible for anarea covering Germany, Austria and Switzerland. “But it’s morethan that - Cemex also takes advantage of our whole portfolioof machines and services. In all, they acquire hundreds of <strong>Volvo</strong>machines each year all over the world, either through purchasing,leasing or renting, depending on their needs.”<strong>Volvo</strong> Financial Services and Cemex make a good fit.Cemex operates in 50 countries across the globe, whether in theAmericas, Europe, Africa or Asia, while <strong>Volvo</strong> Financial Services,with its headquarters in Greensboro, North Carolina, has moreTOTAL SOLUTIONSCemex is a perfect example of a company whichhas bought into <strong>Volvo</strong>’s vision of offering a ‘total solution’ toits customers made up of products and services. Across theworld, Cemex buys <strong>Volvo</strong> trucks and <strong>Volvo</strong> <strong>Construction</strong><strong>Equipment</strong>. It has them serviced by expert <strong>Volvo</strong> technicians,SPIRIT14

“Cemex also takes advantage ofour whole portfolio of machinesand services.”than 1,300 employees in more than 40 countries. And, as partof the $46 billion <strong>Volvo</strong> Group, <strong>Volvo</strong> Financial Services canjustifiably claim that it - like Cemex - is here to stay.INDUSTRY EXPERTISEPerhaps the greatest attraction of all, however, is that<strong>Volvo</strong> Financial Services understands the construction industryand its customers’ businesses.“The value of that expertise is highlighted when thingsget tough,” explains Ksionzek. “When the global financial crisisstruck, we were able to take the long-term view. We understandthis industry’s business cycles. Our priority was to supportcustomers and do everything to ensure they survived. More than90 per cent of the companies that needed to restructure duringthat period are still in business today.”“We also know all about the <strong>Volvo</strong> machines thatthese companies own. We know their true asset value, whethernew or second-hand. Non-specialist finance companies often focussolely on the balance sheet while overlooking the hidden reservesof value in such machines.”NUMBER ONE CHOICEFor Ksionzek, it’s a no-brainer. “Very few people can,or would, choose to buy construction equipment with cash. It“The value of thatexpertise is highlightedwhen things get tough.”SPIRIT15

would have a big effect on cash flow. In Europe, barely five percent of customers choose to do so. So 95 per cent are relyingon some form of financing to make their purchase. We’re theirnumber one choice.”“Across Europe, our penetration rate is 30 per cent -that means that 30 out of every 100 of our machines bought aredone so through <strong>Volvo</strong> Financial Services.”There are other, equally practical reasons for using<strong>Volvo</strong> Financial Services, as Cemex’s Michael Neumann explains.“I’m the procurement cap-ex (capital expenditure)manager for Germany,” says Neumann. “That means I’mresponsible for purchases ranging from a concrete plant orcrusher on the one hand to articulated haulers, wheel loaders andexcavators on the other.”“Why use <strong>Volvo</strong> Financial Services? Simple. It’s easier.When I make a deal with <strong>Volvo</strong>, I only have one contact personthat I need to talk to. When we decide to order a <strong>Volvo</strong> wheelloader, for example, we negotiate over the leasing rate per month,I calculate the total cost of ownership and that’s it.”“When a customer visits adealership the salesman canprovide everything, from themachine to the financing, theservice contracts and insurance.everything comes together.”ONE-STOP SHOPPING“You could call it one-stop shopping,” adds Ksionzek.“When a customer visits a dealership the salesman can provideeverything, from the machine to the financing, the servicecontracts and insurance. Everything comes together.”Neumann, though, makes it clear that it remains ahard-nosed business agreement. The VFS figures must add up andmust business make sense. <strong>Volvo</strong> CE and <strong>Volvo</strong> Financial Serviceshas been making business sense together right across the world formore than a decade.<strong>Volvo</strong> Financial Services’ appeal continues to grow innew markets like Russia, China and Asia. And in Europe’s moremature markets, too, there are opportunities. In Germany, forinstance, 50 per cent of customers use <strong>Volvo</strong> financing.In Denmark, meanwhile, it’s as high as 60 per cent.The conversation turns back to industry expertise.Take Neumann and Ksionzek themselves. On the face of it, saysKsionzek, “we are just ‘number crunchers’ sitting in an office.”SPEAKING THE SAME LANGUAGEBut Neumann has a background in electricalengineering. “When you get out and visit one of the companyplants to discuss what is needed, it’s a big advantage when youknow the language of your colleagues. It really helps that youknow how a concrete plant works,” he says.Ksionzek agrees. “It’s about understanding thebusinesses of the people we serve, at the most basic level. It’sabout insight. And yes, it’s about speaking the same language.”“At <strong>Volvo</strong> Financial Services we even get a chanceevery year to take off our suits and get into <strong>Volvo</strong> <strong>Construction</strong><strong>Equipment</strong>’s new machines and do a bit of digging and driving.That doesn’t happen in many finance companies. And it makesa big difference.”Text: Tony LawrenceSPIRIT16

SPOT LIGHTIDEAS GENERATIONThe art of inventing the future.SPIRIT17

Groundbreaking innovation and the shape of things to come.“It is very important for <strong>Volvo</strong><strong>Construction</strong> <strong>Equipment</strong> to work closelywith academia in order to help secure newskill sets.”How Mäki’s department forecasts the market needs ofthe future is a complex business which involves close examinationof political, economic, social and market trends and conditions.Fuel prices, new legislation, labor costs, environmental issues,regional political developments…every area that has a bearingon future markets is scrutinized in an effort to build a picture ofupcoming scenarios.CREATING BUSINESSThe Advanced Engineering department looks at everyaspect of <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’s operations and markettrends. “There’s a little bit of everything: new vehicle concepts,different subsystems that can be improved,” explains Mäki. “Itmight be a new type of drive train, or a hybrid technology or oneof a human /machine interface. There’s no end to the possibilities.For instance, if a particular product is creating a lot of business wewill be encouraged to look at how that product can be developed.Now more than ever, it is important to stay competitive andinvest in the right products and areas.”The future as forecast by Mäki’s department isenshrined in a confidential document known as the <strong>Volvo</strong><strong>Construction</strong> <strong>Equipment</strong> Technology Plan, which has to beapproved by the Executive Management Team (EMT) every year.It is the guiding document that shapes and defines the projectSPIRIT19

portfolio and pinpoints areas where the company builds researchprojects with academia to secure external skills and funds.“The document contains the changes we see comingin the market - all the emerging scenarios and technology trendshifts that we believe we should be looking at developing in 2015,2020, 2025 and so on,” adds Mäki. “We also have a long-termtrajectory in the plan, looking at where the technology will takeus in the 2040 timeframe to drive innovative ideas past today’slimitations and guide key technology areas to develop further.”“For the twelve plus year timeframe, we create theplans and the project descriptions, get them budgeted beforehanding them over to the relevant parts of the organization toexecute. As you can imagine, there is a lot of co-operation withother departments, every separate area of <strong>Volvo</strong> <strong>Construction</strong><strong>Equipment</strong> is represented.”INVESTING IN THE FUTUREThe department’s other important area of responsibilityis the acquisition of external funding to support academic researchprojects.“It is very important for <strong>Volvo</strong> <strong>Construction</strong><strong>Equipment</strong> to work closely with academia in order to help securenew skill sets, new technologies and discover other areas we mightnot gain knowledge of internally,” explains Mäki. “Typically, wework with university departments in areas where there are mutualbenefits. All the collaborative projects are practical initiatives witha wider public interest in making improvements for the future.”The Gryphin, <strong>Volvo</strong>’s futuristic wheel loader concept machine.“We also have a long-term trajectory inthe plan, looking at where the technologywill take us in 2040.”It has been said that ‘If you don’t think about thefuture, you cannot have one.’ It must be reassuring for <strong>Volvo</strong><strong>Construction</strong> <strong>Equipment</strong> and its customers to know that, behindthe scenes, their future needs are being so expertly shaped anddefined by Mäki and his colleagues in Advanced Engineering.Text: Niall EdworthySPIRIT20

VOLVO USHERS IN ANEW GENERATION OFHISTORY-MAKERS2012 will see <strong>Volvo</strong> <strong>Construction</strong><strong>Equipment</strong> make history.SPIRIT21

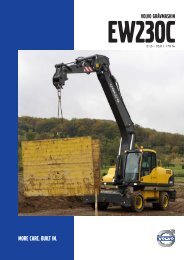

In adding more than 60 state-of-the-art products toits range – on top of the 55 launched in 2011 – <strong>Volvo</strong><strong>Construction</strong> <strong>Equipment</strong> will overhaul its portfolio to anextent never previously seen in its 180-year existence.It’s a fundamental, record-breaking project rather thana face-lift. As <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> President Pat Olneyemphasized at Intermat 2012, this new generation of machineswill deliver unmatched levels of performance, feeding through to“quantifiable benefits to customers around the world.”Put another way, they will be more productive andefficient than ever before – and deliver those improvementsstraight to the customers’ bottom line.NO COMPROMISE IN PERFORMANCETake the new ECR145D and ECR235D short swingradius excavators, which not only meet the latest Stage IIIB/Tier4 Interim emissions legislation but also boast digging performance,balance and stability to match many traditional-format excavators.There is no compromise in performance despite theadded maneuverability. With their narrow-body design and centralboom (mono or two-piece), the rear of these machines swingonly fractionally outside the track width. During highway projects,that means operating safely within the width of a road lane andminimizing traffic disruption.For those seeking a wheeled excavator, meanwhile,there’s the new four-model D-Series; the EW140D, EW160D,EW180D and EW210D, ranging from 14-21 tonnes and ideallysuited for jobs ranging from trench digging, concrete breaking andgrading to craning and hole-boring. They are also able to movebetween job sites, at speeds of up to 35km/h (22mp/h).The improvements begin with new four and sixcylinderengines and a new cab and extend to improvedhydraulics, substructure, boom/arm and controls.The stable of crawler excavators, meanwhile, has beenstrengthened in the middleweight range, with the EC140D,EC160D and EC220D targeted at customers in Europe andNorth America and boasting fuel efficiency improvements ofup to 14%. The EC180D and EC235D will also be available inEurope.The three smallest excavators of the range feature anew rear access, while the EC235D boasts an oversized heavydutyundercarriage.INDUSTRY-LEADING FUEL EFFICIENCYThere are <strong>Volvo</strong> wheel loaders, reinforced by the newL45G and L50G in the 9-10 tonne class and by the mid-sizedL60G, L70G and L90G.The L45G and L50G feature the latest emissionscompliantD4 engines, industry leaders in fuel efficiency, and<strong>Volvo</strong> patented Torque Parallel Linkage, ensuring high breakoutforce and parallel movement during lifting. Smaller and moremaneuverable than many rivals, their compactness is dueto a shorter frame and the engine being sited conversely.SPIRIT22

“Put another way, theywill be more productiveand efficient than everbefore – and deliver thoseimprovements straight tothe customers’ bottom line.”The L60G, L70G and L90G offer a combination ofpower, parallel movement and long reach, while also featuringthe G-Series’ new electrically operated sloping engine hooddesign for improved rear visibility and better access to theengine compartment. Those engines are meticulously matchedto drivetrain, hydraulics and lifting systems, all designed andproduced by <strong>Volvo</strong>.During 2012, <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> is alsointroducing its C-Series wheeled and tracked skid steer loadersto European customers for the first time.Their unique single loader arm design deliverssuperb loading performance and durability while ensuringimproved visibility, safety and enhanced cab access.The C-Series are ideal for truck loading and a wide rangeof material handling applications.SPIRIT23

ROAD MACHINERY THAT DELIVERSFinally, there’s the new road machinery recruits, starting with theG900B-Series motor graders, launched in North America and now availablein the EU and selected international markets. Ranging from the G930B to theG960B, they boast the highest blade-down pressure in each weight class.They are followed by the P7820C ABG and P8820C ABGtracked pavers, paving widths of up to 11m (36ft) and 13m (42.7ft)respectively and delivering perfectly smooth mats, even on steep hills andthrough tight turns.For small compaction jobs, look no further than the double drumDD25 and DD25W. Members of the 2.5 tonne weight class, they offer highfrequency and exceptional all-round visibility thanks to a commanding seatingposition and an unobtrusive engine cover, ensuring the drum edgesare always visible.And behind this new generation ofmachines, of course, lies an ever-expanding andincreasingly sophisticated menu of customersupport products and services, tailored tomaximize machine performanceand uptime.DISCOVER A NEW WAY...<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’s biggestproblem at Intermat 2012? How to squeeze allthe good news - and all the latest innovations- within its stand space at the Parc desExpositions in Paris!Under the theme ‘Discover A New Way’,the company showcased a range of newmachines from the new ECR145D reducedradius excavator to the revolutionary L250Gwheel loader, while a Service and Support unitpromoted the company’s high-tech diagnosticsand monitoring systems, maintenance packagesand financing solutions.<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> President PatOlney highlighted a 21% increase in annualsales, a record 84,000 machines and majorsuccesses and expansion plans in key marketssuch as China and Russia.AWARD WINNING SYSTEM<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>beat off more than 100 rivalentries to win Gold at the 2012Intermat Innovation Awards for itsrevolutionary On Board WeighingSystem for its F-Series fullsuspension articulated haulers.The system relies on pressure sensors to relaythe weight of each load into the machine’selectronics. The information appears on theoperator’s display and can also be accessedremotely via the CareTrack telematics system.A red light warns of overloading, thus ensuringsafety and overall machine efficiency. A nominalload can be preset to suit local requirements.Combined with fuel consumption data, OnBoard Weighing highlights true machineproductivity as never before.SPIRIT24

<strong>Volvo</strong>FirstsThe modern world movesat bewildering speed. Intimes of such momentouschange, having a richand illustrious past issomething to celebrate.SPIRIT25

1853Munktell manufactures Sweden’sfirst steam locomotive1832Munktell founds companyin Eskilstuna, Sweden1893The first internal combustionengine was built. This was the startof the company’s success as one ofthe world’s leading manufacturersof crude oil enginesAt 180 years old this year, <strong>Volvo</strong> CE is the oldest constructionequipment manufacturer in the industry. The company boasts aculture and tradition of excellence that is ingrained into everythingit does, not least when it comes to innovation and leading the field.That all began in 1832 when Johan Theofron Munktell, then only27, founded what became <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> in Eskilstuna,Sweden. Not only was he among the first industrialists to manufacture earlyconstruction machinery, he was also the pioneer of Sweden’s first printing press.Munktell’s values and ethos of quality, innovation and technical expertise were,like the company he founded and the machines he made, extremely durable:the company would cleave to them for the next 180 years.InventionMunktell followed up the printing press with Sweden’s firstmechanical loom and then its first mowing machine. He followed this explosionof invention by giving the nation its first threshing machine. Yet he truly brokethe mould in 1853 when he produced the country’s first steam locomotive,‘Forstlingen’.The machine was delivered to a mine railway and did not proveimmediately popular – the locals referred to it as ‘the pig’ for the way it gruntedand squealed as it made its way around the narrow, often steep track. However,Munktell and his team were able to build on the experience and their secondlocomotive proved far more popular. During the next 70 years the companywould produce another 6,500 steam locomotives until the arrival of thecombustion engine. When the age of steam came to a close, Munktell was readyto prosper and not wither. In 1913 they produced Sweden’s first tractor, with30 to 40 horsepower, achieved with a two-cylinder combustion engine. Themachine weighed a gigantic eight tonnes, but, along with the production of itsown crude oil, it ushered in a new age for Munktell. More tractors followed, aswell as the first motor roller, with a 24 hp engine, and a motor grader with atop speed of 9.1 km/h in 1914.Meanwhile, elsewhere in Sweden, other visionaries and entrepreneurswere making progress. J & C.G Bolinder of Stockholm had been thriving since1844 manufacturing steam engines and, later, crude engine oil.1913Munktell produces Sweden’sfirst tractor1932Munktell and Bolinder merge toform Bolinder Munktell1934Bolinder Munktell produce thelegendary BM 25 tractor1950Bolinder Munktellis bought by <strong>Volvo</strong>SPIRIT26

1978<strong>Volvo</strong> puts the world’s firsttruly low-emission enginesfor construction equipment inproduction with intercoolertechnology for higherperformance, lower fuelconsumption and cleaneremissions1981Making award winning history<strong>Volvo</strong> has even won awardsfor its history. ‘The Master Builder’, ashort film created by <strong>Volvo</strong> telling itshistory from 1832 to the modern erain a dynamic and accessible way, wontwo awards in 2011. It won a silver‘Dolphin’ trophy in the 2011 CannesCorporate Media & TV Awards and itwon the European Excellence Awardsin the Corporate Film category.The film featured Hollywoodactor Phil Barantini as a storytellerstriding through the company’s history,using existing <strong>Volvo</strong> facilities, machinesand employees, who all volunteeredtheir time and energy. It demonstratedthe global reach and rich heritage ofthe company. It fought off fiercecompetition from more than 400corporate films to win the prize. It hasalso received nearly 30,000 hits onYou Tube http://www.youtube.com/watch?v=8eidcQ1BPEA.World Wildlife Fund agreementThe World Wide Fundfor Nature (WWF) is the world’slargest conservation organization witha vision to arrest the degradation ofthe natural environment. Its ClimateSavers Program is a global enterprisethat mobilizes multinational companiesto cut their emissions of CO 2. In2012 <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>became the world’s first construction1991<strong>Volvo</strong> introduces TP linkageon its wheel loaders, a uniqueboom system that combinesparallel movement with greatbreak out force.The company produces AutomaticPower Shift in its wheel loadersequipment company to join the WorldWide Fund for Nature’s Climate SaversProgram committing itself to the mostambitious carbon-reduction agenda everundertaken within the industry. Thishighly challenging initiative will bringsignificant benefits both to customersand the cause of environmental care.For more information about <strong>Volvo</strong> CE’sinvolvement in the WWF Climate Saversprogram, log-on to:www.volvoce.com/wwfChina Partnership2012 marks the 20thanniversary of the <strong>Volvo</strong> Group inChina and the 10th anniversary of<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>.A historic Strategic CooperationMemorandum was signed between<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> andShanghai Municipal Government onMarch 2012 in Shanghai to establish theRegional Headquarters in Shanghai, tofurther strengthen <strong>Volvo</strong> CE’s marketposition in China and better serve theneeds of local customers.1991<strong>Volvo</strong> introduces the <strong>Volvo</strong>Care Cab; the best cabon the market then andnow. Providing a safe andcomfortable environmentthat puts the operator incomplete control1998<strong>Volvo</strong> CE became the first foreigncompany ever to invest in Korea2007<strong>Volvo</strong> CE launches theworld’s first full-suspensionarticulated hauler2010<strong>Volvo</strong> CE’s telematics systemCareTrack became standard fiton most machines, increasingsecurity, productivity andavailability through the useof operation reports, servicereminders and error alerts2011<strong>Volvo</strong> CE wins red dot designaward for its L220G wheelloader, The first in theindustry to do such2012<strong>Volvo</strong> CE, together with its jointventure partner SDLG becomesthe first construction equipmentcompany in the industry to signan agreement with the WWFClimate Savers<strong>Volvo</strong> wins the red dot awardagain, this time the ‘best of thebest’, an even higher accolade forits A40F articulated hauler. Thecompany also wins Gold at theIntermat Innovation awards for itsOn Board Weighing system for itsF-Series, full suspension, haulersFor more information about the historyof <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>, log onto www.volvoce.com/history or scanthe QR code for direct viewing on yourmobile device.SPIRIT28

Waves ofProgressCirca 1974: ‘Sayula II’ skippered by Ramon Carlin, returning to Portsmouth to win the first Whitbread Round the World Yacht Race.SPIRIT29

The <strong>Volvo</strong> Ocean Race is the mostgruelling sailing competition on theplanet, a monumental test of humanspirit and strength and a physical andmental challenge that pits man againsthis wiliest foe – nature.Yet, for all the mountainouswaves and howling galesits many participants haveendured over the years, therace was devised over a glass ofbeer in a cozy unassuming Englishpub in 1971. While single-mannedraces existed at that time, therewas none for crewed yachts, sowhen Colonel Bill Whitbread, of thebrewers of that name, met AdmiralOtto Steiner of Britain’s Royal NavalSailing Association for a pint inPortsmouth to discuss such an ideamany thought it was overdue.The result was the firstOcean Race in 1973, involving 17boats and 167 sailors, which started andfinished in Portsmouth via Cape Town,Sydney and Rio de Janeiro.AdvancedMost of the crews, theirskippers aside, consisted of amateursailors and those seeking adventure.Their navigation was done by use ofdead reckoning and the stars (whichmight be why one of the skippersadmitted afterwards his boat was lostmost of the time). Meanwhile, thevessels themselves were no furtheradvanced than the flotilla of yachts thataccompanied them out of the Solent atthe start of the race.Now, four decades on fromthat meeting in Portsmouth, the racehas been transformed, not least by manyof the innovations introduced by <strong>Volvo</strong>when they took over sponsorship of therace in 1998. The competing yachts arevastly different to what you might see inyour local marina. They are built fromthe same hi-tech materials that are usedto construct space shuttles and travelat speeds that the sailors of 1973 couldonly dream of. The fastest 24-hourrun in 1973 was 305 nautical miles.In 2008, Torben Grael’s Ericsson 4managed a staggering 596 nautical miles.Sextants and dead reckoninghave been replaced by advancedtechnologies and onboard computerswhich means at every second of the racethe crew knows where they are, wherethey are heading, at what speed, and theweather and types of sea they will beencountering.VividWhile fans in 1973 had torely on newspaper reports, or accountsfrom the participants written after therace was ended, now they can be asclose to the action as possible, able toaccess video footage and live link-upsfrom embedded crew members whichshow in vivid detail what could only bepreviously imagined. Meanwhile, a globaltelevision audience of 1.3 billion nowtune into pictures that yachting fans of1973 could only dream of.Two factors haven’t changedthough – firstly, the comfort of those onboard. If anything, it has become worse.In those early years, there are stories ofcrews setting sail laden with fine wineand meat, with comfortable berths andon-board cooks. Now the pursuit ofKings Legend, finishing the 1973 WhitbreadRound the World Race.1989/90 Whitbread Round the World Yacht Race: Onboard‘Merit’ skippered by Pierre Fehlmann in heavy weather.SPIRIT301981/2 Cornelis van Rietschoten receives the Whitbread Roundthe World Race Trophy from Prince Philip.

‘Flyer’ skippered by Cornelis van Rietschoten returning up the Solent in a force 10 gale to win the 1977/8 Whitbread Round the World Race.“They are built from the samehi-tech materials that are usedto construct space shuttles andtravel at speeds that the sailorsof 1973 could only dream of.”1981/2: Ceramco New Zealand skippered by Peter Blake sailingunder jury rig after being dismasted during first leg.1977/8 ‘Flyer’ skippered by Cornelis van Rietschoten (centre with spinnaker) leadsthe fleet out of Auckland Harbour at the start of the 3rd leg of the WhitbreadRound the World Race.SPIRIT31

“With our online presence and embedded videoreporters, we are able to bring the action directly topeople in a way we couldn’t 20 years ago.”the lightest, fastest boat possible meansthat crews exist, like those on theaforementioned space shuttle, on energydrinks, powdered foods and protein bars.What little sleep they get is in sharedbunks and grabbed on the go.Then there is the secondunchanging feature – nature. Theboats might be faster, the crews moreprofessional, fitter and better prepared,but the challenge of coping with lifeat the extreme remains the same – itrequires courage and co-operationthat any sailor from any time wouldrecognize. The race has also widened itsreach, visiting new regions, drawing inmillions more viewers and fans than itmight otherwise have done.GlobalKnut Frostad is CEO of the<strong>Volvo</strong> Ocean Race and someone whohas experienced the event from bothon and off shore, having competedfour times before switching to anorganizational role, and has seen howfar it has evolved, particularly over thepast two decades. “Many of the majorchanges were brought in by <strong>Volvo</strong> whenthey became involved in 1998,” he says.“Before then the race went to traditionalsailing ports, but now we have made itmore ‘global’. We have taken the raceto new regions like India and China andincreased its appeal and its audience.”“It’s also become much moreof a communication event. The globalmarketplace is very competitive andthere are hundreds of events competingfor people’s attention, and a race thattakes place hundreds of miles out atsea where people can’t see isn’t wellpositioned.”“But with our onlinepresence, and embedded video reporters,we are able to bring the action directlyto people in a way we couldn’t 20 yearsago. We are also involving people farmore off shore. Before, when the racestopped somewhere, little happened. Butnow we have race villages of 35000square meters (377000ft²), lots of publicevents and entertainment, and thousandsof people come to experience the raceand also to experience <strong>Volvo</strong> and <strong>Volvo</strong>products.”Text: Dan WaddellFor more information about <strong>Volvo</strong> CEand the <strong>Volvo</strong> Ocean Race, log on to:www.volvoce.com/oceanraceAs the <strong>Volvo</strong> Ocean Race technology and design hasevolved, so too has <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>.To celebrate this, <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> haslaunched a new limited edition excavator complete withthe <strong>Volvo</strong> Ocean Race livery. Available for the models:EC200B, EC210B, EC240B, EC290BLC. The excavatorshave been decorated with a distinctive stripe designdown the side of the machine to symbolize waves, whileinside the cab there is a striking <strong>Volvo</strong> Ocean Raceemblem to complement the unique <strong>Volvo</strong> Ocean Racebranded seat embroidery. For more information contactyour local <strong>Volvo</strong> dealer or visit www.volvoce.comSPIRIT32

LIFE THROUGH A LENSLeif AnvägBringing the past to life.SPIRIT33

“This is a little bit different to other jobs, It becomes a part of your life.”Håkan Ripell, Bo Liljestrand - cataloguing the paper document archive.Running the Munktell Museumin Eskilstuna is not just a job,according to its manager Leif Anväg –it’s a way of life.The museum tells the remarkable storyof <strong>Volvo</strong> CE’s history since its humble beginningsas Munktell in 1832 through exhibits, machines,photographs, films and all kinds of other documents.It also doubles as a venue for a variety of events,conferences and celebrations, which keeps Leif asbusy as he’s ever been during a long, successfulcareer with <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>.“This is a little bit different to other jobs,”he explains. “It becomes a part of your life. I have less spare time now than I did whenI was travelling all the time, but I’m not complaining.”Leif, 55, began his <strong>Volvo</strong> career in 1974 as a mechanic with a local dealer.Other than an interruption for military service, he has been with the company eversince, working in a variety of training roles, including a stint in Dubai, and thenreturning to Sweden to manage the service department.IllustriousWhile in the latter role he worked with Ralph Angestam, his predecessoras curator. In 2006, nearing retirement, Ralph earmarked Leif for the role. However,Leif didn’t feel quite ready. “I wanted the job but I was 49, and I think that youshould have the position for only 8 or 9 years, and then you need someone withnew ideas to come in and help the development, so I thought it might be a little bittoo early.”SPIRIT34

Munktell Museum.“It’s one of <strong>Volvo</strong>’s strengths that we havebeen in the business for so many years.”“Ralph said, ‘Well I can wait!’ He stayed on and in thebeginning of 2009, he asked me again. This time I didn’t wantto take the risk of delaying again, so I agreed to it.” Since 2009the museum has grown in popularity and last year entertainedmore than 25000 visitors – 7000 more than in 2010 – many ofwhom are pleasantly surprised to discover just how illustrious andextensive the company’s history is.Experience“I once took a visitor around from New Zealand,” Leifsays. “He couldn’t believe the history went right back to 1832. Hesaid, ‘This company is older than our country!’”“When we run our ‘<strong>Volvo</strong> Days’ and host customersfrom all over the world, we always start with a welcome drinkand then after 45 minutes the guests are meant to be seatedfor a show. But every evening we struggle to get people to sitdown because they become so absorbed in the machines and theexhibits. It’s one of <strong>Volvo</strong>’s strengths that we have been in thebusiness for so many years, we have this expertise and inventionto demonstrate and people can see how far the company hasdeveloped.”The museum has 89 people involved, the vast majorityof whom are volunteers, most former <strong>Volvo</strong> employees whoseSPIRIT35

vast experience is put to use maintaining and repairing machines,or checking and archiving documents. Some spend only a few daysa year at the museum, while others give up their time five daysa week. There is also a ‘Veterans’ team that travels the country,running machines and engines, promoting the museum. Last yearthey hosted 60,000 people at various events.The documents archive has a copy of nearly everymanual ever printed. How does the museum source suchmaterials?“The company departments now know they arenot allowed to scrap anything until we have had a chance tocheck it to see if it would be of interest. But it’s not just <strong>Volvo</strong><strong>Construction</strong> <strong>Equipment</strong> that contacts us. For example, there wasa museum in the south of Sweden which had lot of old blueprintsfor engines we have produced. They had to close their operationso they sent all these drawings to us.”Unique“We are also contacted by other places that havematerials and machines that might otherwise be scrapped.Unfortunately we have limited space and we can’t take care ofeverything, but we make sure we check it as closely as we can sowe have the best exhibits possible.”Does he have a wish list of machines that he wantsto put in the museum? “We have a list of machines that weare looking for. We also have a policy that we should have anexample on show of every unique product we have launched.”Nader Saati, Lars Uno Karlsson - working on a tractor together.“We also have a policy that we shouldhave an example on show of every uniqueproduct we have launched.”iPad exclusive*Want to see what goes on behind the scenes at the MunktellMuseum? Check out our exclusive reportage in the latest <strong>Spirit</strong>iPad app, available for download at:www.volvospiritmagazine.com“For example, in 1991 we introduced a new range ofwheel loader with TP linkage. In the future we should have oneof these machines in the museum. But our policy says that it mustbe 20 years since the machine went out of production before weexhibit it in the museum, so we must consider that too.”Despite the calls on his time, Leif, who grew up nearEskilstuna and still lives in the area, manages to find time tounwind either fishing, or relaxing at his family’s summer house,with his wife Lillemor and son David.Text: Dan WaddellPhotography: Julian Cornish TrestrailFor more informationabout <strong>Volvo</strong> CE’shistory, scan theQR code for directviewing on yourmobile device.SPIRIT36

SIMPLYTHE BEST–AND THAT’SOFFICIAL!<strong>Volvo</strong> <strong>Construction</strong><strong>Equipment</strong> has madehistory after its flagshipA40F articulated haulerbeat off thousands ofcompetitors to scoop the‘best of the best’ 2012 reddot design award.SPIRIT37

No other constructionequipment manufacturer hasever won the category before,let alone won it two years ina row. Last year <strong>Volvo</strong> CE won ared dot design award for itsL220G wheel loader.“I speak on behalf of the whole company when I saywe are extremely proud to win such a highly respected awardfrom the largest, most distinguished design competition in theworld,” says Anders Larsson, Executive Vice President of <strong>Volvo</strong><strong>Construction</strong> <strong>Equipment</strong>’s Technology function.“This award symbolizes the creativity, hard work andinnovative spirit we have at <strong>Volvo</strong>. It is fantastic that the A40Fhas received this globally-recognized mark of industrial designquality and we are delighted that it’s getting the recognition itdeserves.”COVETED AWARDThe red dot product design awards are covetedworldwide. They honor outstanding industrial design and havebeen running since 1955.The ‘best of the best’ award is the very top prize andhanded out by a panel of experts. In all, 4,515 products wereentered in 2012 by designers and companies from 58 countriesall over the world. The A40F triumphed in category 16, includingautomobiles, transportation, commercial and water vehicles. “Theexpert jury thoroughly examined, tested and evaluated eachindividual entry, applying the highest standards,” says ProfessorDr. Peter Zec, the initiator and CEO of the red dot design award.The A40F articulated hauler, Red dot ‘Best of the Best’ winner, 2012SPIRIT38

“With their performances, the laureates not onlydemonstrated extraordinary design quality but they also showedthat design is an integral part of innovative product solutions.”INNOVATIVE LEADERS“This accolade shows that we are delivering world classmachine designs,” says Stina Nilimaa Wickström, Design Directorat <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>. “We are proud to continuethe <strong>Volvo</strong> tradition of being innovative leaders in the constructiondesign arena.”As Stina Nilimaa Wickström explains, there’s more towinning a red dot award than meets the eye.“The jurors base their selection on 12 criteria. Thedesign must, of course, look awesome. But they also consider otherfactors, such as whether it’s intuitive and easy to use. There’s theergonomics. They even look at how environmental the machine is.”The groundbreaking F-Series, improved in terms ofdesign, functionality and maintenance, is also more efficient thanthe preceding E-Series which, until now, has led the industry interms of fuel consumption.“it’s not just about looking good. It’s aboutthe whole picture, and whether a machinedelivers what it is designed to do.”The L220G wheel loader, red dot design award winner, 2011.Remarkably, <strong>Volvo</strong> has continued to dominatearticulated hauler markets worldwide in terms of quality,efficiency, power and safety ever since first introducing theconcept almost half a century ago.The F-Series also stands out from the crowd because ofits combination of unique self-compensating articulated steering,its differential locks and its industry leading cab.Automatic Traction Control (ATC) detects the rightdrive combination as required, for reduced tire wear and improvedfuel consumption, while the drive train, all designed and built by<strong>Volvo</strong>, provides industry-leading fuel efficiency.WHY FULL SUSPENSION SPELLS PERFORMANCEThere is also an all-wheel hydraulic full suspensionversion of the A40F, thus permitting higher speeds on the mostdemanding of terrains while independent wheel movement alsoserves up greater comfort for the operator, reducing fatigue andthus increasing performance and safety in equal measure.An A40F is due to be integrated in a permanentexhibition at the red dot design museum in Essen, Germany,later this year.The unprecedented success of the articulated haulerfollowed the L220G grabbing headlines of its own in 2011, thewheel loader seeing off all comers before being declared thewinner of the vehicle category.THE WHOLE PICTURE“So it’s not just about looking good. It’s about the wholepicture, and whether a machine delivers what it is designed to do.”“It was so satisfying to see the L220G wheel loaderprogress from paper, to machine and then to an internationaldesign award. It was only possible thanks to great teamwork.”The L220G, like the A40F, certainly delivers rightacross the board.It boasts a 20% increase in lifting force and a 10%improvement in breakout force, thanks in large measure to <strong>Volvo</strong><strong>Construction</strong> <strong>Equipment</strong>’s ability to design, produce and perfectlymatch its own components.Its patented Torque Parallel linkage design offers highbreakout torque throughout the range while the newly-designed,electronically-opening engine hood – as the red dot experts clearlynoted – does not just look ultra-stylish but also provides improvedventilation and easier maintenance.More than 1,000 guests from the world of design,industry, society and media will celebrate the red dot awardwinners on July 2nd in Essen’s opera house, the Aalto Theater,Germany. The <strong>Volvo</strong> A40F articulated hauler will then bedisplayed during a four-week special exhibition in the red dotdesign museum, together with the other prize-winning products,from July 3rd – 29th 2012.SPIRIT39

AWARD-WINNING VOLVOMACHINES MASTERTHE ART OF BEING SEENBUT NOT HEARDWhen Joe Charles visits one ofNew Zealand’s ports, the last thinghe expects – or wants - to hear isa <strong>Volvo</strong> engine.That, after all, is one of the key reasons why C3’s Fleet TechnicalManager started buying <strong>Volvo</strong> wheel loaders in the first place.He wanted them to be seen, but not heard.“Over the last few years, <strong>Volvo</strong> has become our priority pick,” hesays. “There’s a whole lot of reasons for that, but one of them isundoubtedly their low operating noise levels.”LOW NOISE LEVELS“Here in New Zealand, noise pollution legislation isstrict. That’s because we have a lot of ports which are surroundedby housing. Sometimes there are homes virtually straight acrossthe street.”“The <strong>Volvo</strong> machines are so quiet that we can usethem at certain ports where we wouldn’t get away with othermachines. That’s a really big difference for us.”C3 is the country’s leading port product handlingcompany. It operates in 15 ports across New Zealand and inAustralia, handling more than 14.5 million tonnes of cargoannually. That includes 23 million logs, 3.5 million tonnes offorest products and 300,000 tonnes of steel.The company has just taken delivery of seven awardwinningL220G <strong>Volvo</strong> wheel loaders to bolster its total fleet ofaround 200 machines.Noise level, of course, was not the only criteria foradopting <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> machines as C3’s firstchoice, says Charles.“About four years ago we studied the market and thefirst thing that stood out was the <strong>Volvo</strong> power-to-weight ratio,” hesays. “Take a look at the L220s. You can be sure that there aren’ttoo many other machines on the market that weigh 38 tonnes andcan lift 17 tonnes of logs.”“Then there’s the fuel economy, the safety record andthe operator comfort – of course you look at all these things.”TAKING THINGS TO A NEW LEVELThe L220G, Charles adds, has just taken thestandard to a new level. “The F Series was already an excellentmachine. This one is simply better. We’re very, very pleasedwith them.”SPIRIT40

Wellington harbour.“You can be sure that there aren’t too many othermachines on the market that weigh 38 tonnes and canlift 17 tonnes of logs.”SPIRIT41

The L220G boasts a 20% increase in lifting force and10% improvement in breakout force. Charles himself says he hasbeen impressed in particular by <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’sOptiShift technology, providing improved productivity and fuelsavings in short cycle loading work, by the new bonnet design forease of maintenance and by the improvements to the CareCab.“Safety is a primary focus at our ports,” he says. “Weget lots of people walking around the wharfs and you have tobe aware of them all the time. It’s a confined area and you can’tmake mistakes when you’ve got machines weighing up to 40tonnes.”“So really good cab visibility and ergonomics are veryimportant. The <strong>Volvo</strong> cab design and controls mean operatorssimply don’t get tired like they used to. That makes them moreproductive and safer.”HOW TO FEEL FRESH AFTER A 12-HOUR SHIFT“You can put a 65-year-old person in one – that’s myage – and they can do a 12-hour shift and go home still feelingfresh. Drive them the way they’re designed to be driven and youcan sit there all day.”Talking to Charles, you get the impression that that’sexactly what he would like to do – sit in an L220G all day. Hislong-lasting love of machines, he acknowledges, means he’d swaphis Christchurch office for a <strong>Volvo</strong> cab any day.Most of his time is spent flying up and down NewZealand, monitoring C3’s fleet of loaders, excavators and forklifts.“I love getting out to our branches and talking to ourguys. It’s a lot better than paperwork! I like getting the overallsback on and getting in a machine or helping out in a workshop.”The company’s history goes back 50 years. Charles- known as ‘Pop’ by his colleagues - has been on board for thelast 30 of them, working his way up the ranks after joining as amachine operator.“do a 12-hour shift and gohome still feeling fresh –Drive them the way they’redesigned to be driven and youcan sit there all day.”He has no plans to retire in the foreseeable future. If itwere suggested that it was time for him to stand down from hiscurrent position, he says, he knows exactly what he would do.“Simple. I’d ask them to re-hire me as an operator.These new <strong>Volvo</strong>s are so easy to operate, they’re a retirementperson’s dream.”Text: Tony LawrenceSPIRIT42

INSIDE TRACKSWECONThe longest-serving <strong>Volvo</strong> dealer in the world.SPIRIT<strong>43</strong>

“A lot of our customers certainly think of us as <strong>Volvo</strong>.”A crucial first point of contact for customers.What does 1946 mean to you?Perhaps you remember it as theyear when the United Nations first met?The year when World War II was officiallydeclared over, when Hungary and Italybecame republics, or even as the yearwhen golfer Ben Hogan won the first ofhis nine Majors?For <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>, itmarked the start of its relationship with its first everdealer, Swecon. And that 66-year relationship, thelongest of any <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> dealer, isstill going strong today. Not, of course, that either partyexisted under its current name when the relationshipwas first formed.<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’s rootsactually go back as far as 1832, when entrepreneurialengineer Johan Theofron Munktell moved to Eskilstuna– still home to <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’soperations today – and set up a workshop there.Swecon’s story, meanwhile, goes back almost as far, to1880, when Svenska Lantmännens Riksförbund (SLR),an umbrella group of local farming associations inSweden and today simply known as Lantmännen,was formed.PART OF THE FAMILYToday, though, <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> and Swecon, which wascreated by Lantmännen in 1999 to act as an exclusive ‘mega-dealer’ for <strong>Volvo</strong> inSweden, are closely bonded together. “It’s a very strong link,” says Swecon MarketCommunications Manager Fredrik Rigö, “It is as if we’re part of the family. For onething, our head office is actually located in the <strong>Volvo</strong> Customer Centre in Eskilstuna!”SPIRIT44

Swecon head office in Eskilstuna, Sweden.“That is what we want - to be seen as asingle unit providing a total offering.”“And lots of people working for us have previouslyworked for <strong>Volvo</strong> in some form. When Swecon was launched,many of <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’s sales staff moved acrossto the new organization.“You could say that the two companieshave grown in tandem. A lot of our customers certainly think ofus as <strong>Volvo</strong>.”It’s an easy mistake to make. For most customers inSweden, Swecon, with around 420 employees and 41 serviceoutlets across the country, represents a crucial first point ofcontact. If you want a <strong>Volvo</strong> machine in Sweden, you’ll visitSwecon. If you want help with finance or if you want an after-saleservice agreement, you’ll visit Swecon.SHARED VALUESEven the Swecon logo colors – the original <strong>Volvo</strong>blue and machine yellow - remind you of <strong>Volvo</strong>. Equally, it’sno great surprise to hear that the two companies even have thesame core values.“Yes, we do share <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’score values of quality, safety and environmental care althoughwe’ve added three ‘soft’ core values of our own – service,confidence and care. For us, they go hand-in-hand,”says Rigö.SPIRIT45

“Basically, what we’ve done is build the brand around<strong>Volvo</strong>. When we started out, we tried to differentiate ourselves,adopting a totally different look and feel to things like the styleof our printed brochures or our advertisements. But that’s allchanged. Now we’ve integrated our ways of working as well asthe way we present ourselves. That is what we want - to be seenas a single unit providing a total offering.” It’s clearly beena successful strategy.GROWTH POTENTIALLantmännen, with more than 10,000 employees,operates its core businesses within the agriculture, energy and foodindustries. It is also active within the machinery sector, however.Swecon, as part of this sector, has been highly successful, also nowoperating in Germany and the Baltic countries and continuing toshow the potential to develop and grow further.In Sweden <strong>Volvo</strong> machines account for more than40 per cent of the construction equipment market, almostreaching 50 per cent in recent years as the global financialcrisis took hold.“That is one of Swecon’s internal ambitions – thatevery other machine that is sold in Sweden should be a <strong>Volvo</strong>,”adds Rigö. “We know how the industry works, we’re big and we’vebeen around for ages. We have 22,000 <strong>Volvo</strong> units working acrossthe country, there’s a lot of need for after-market services andthat’s where our strength lies.”“With all our outlets, we’re very close to ourcustomers. When times are good, you get other brands, say fromChina, entering the Swedish market, but when things get tougheconomically businesses need a strong partner to work with.You need security. That is what we offer.”‘IT’S VOLVO OR NOTHING’“When we advertised in 2010, we stressed our jointheritage with <strong>Volvo</strong> while making the point: ‘We were thereyesterday, we are here today and we will be here tomorrow.’ Thatis what it boils down to.” Rigö himself personifies the long-runninglink between Swecon and <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>. Hisgrandfather, he recalls, worked for <strong>Volvo</strong> as a purchaser and usedto give him models of <strong>Volvo</strong> machines to play with as a child.“I’m a Swecon man and proud of it. I joined thecompany when it was formed and I’ve been with it throughoutthe journey. Ours is a small, personal company. We’re proud ofwhat we have achieved through hard work and proud of the waywe look after our customers.”“But we’re also very proud of being associated with<strong>Volvo</strong> – we know we have a premium offering for our customers.”With all our outlets we are very close to our customers.“We have 22,000 <strong>Volvo</strong> units workingacross the country, there’s a lot of needfor after-market services and that’swhere our strength lies.”“For me, everything started with <strong>Volvo</strong>. I was threeyears old when I went to my first ‘<strong>Volvo</strong> Days’ machinedemonstration at Eskilstuna. I drive a <strong>Volvo</strong>, I live <strong>Volvo</strong>. Iwouldn’t trade it for any other brand. If I am going to work in thisindustry, it has to be <strong>Volvo</strong>. Otherwise, I’d have to go and dosomething completely different.”Text: Tony LawrenceToday <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong> has an extensivenetwork of dealers worldwide. To find your closest dealer, orfor more information, log on to: www.volvoce.com*For more information about <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>and Swecon please visit: www.swecon.comSPIRIT46

Driven by passion.Powered by professionals.www.volvoce.comwww.volvoce.comwww.volvoce.comvolvo www.volvoce.comconstruction equipmentvolvo construction equipmentSome people face great challengesfor a living. Find out how atvolvoce.com/volvooceanrace

A Model Customer<strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’s scale models are a musthave collector’s item for many <strong>Volvo</strong> enthusiasts.“I wanted toreach as bigan audienceas possible,and as wide aspossible.”Only available on the official<strong>Volvo</strong> Merchandise website they are soldall over the world, to both consumers and<strong>Volvo</strong> companies.Like many enthusiasts, IanWebb’s fascination with constructionmachines started when he was a boy growingup in Central London, where constructionequipment and cranes are a feature of theskyline and he was surrounded by all kindsof building work.It was a passion he took into hiscareer as a civil engineer, which has seen himwork on many of UK’s high-profile projects,including building the M25 motorway, theextension to the London Underground’sJubilee Line and the Channel Tunnel.It was in the year 2000 that hebought his first scale model of a constructionmachine and liked what he saw. Now, 12years later and he is the proud owner ofa website that reviews models for othercollectors, which attracts more than100,000 visitors a month.He started the website,http://www.CranesEtc.co.uk/, becausethere were few other resources for modelcollectors to research their purchases.Running Cranes Etc also allowsIan to indulge some of his other hobbies,like web design and photography. Eachmodel he receives is tested, inspected andphotographed in painstaking detail and theresults and grades posted to his site. Onaverage he reviews two or three modelsa week.While he attends the NurembergToy Fair as a collector, he doesn’t exhibithis collection. ‘‘I have got my own missionhere. I wanted to spread the word aboutthe models, because I think they’re good,and I wanted to reach as big an audience aspossible, and as wide as possible. These daysthe Internet is the best place and the bestway to do that.’’Detail‘‘The reason behind the websiteis that many of these models aren’t availablein high street shops. You can usually onlyget them from the original equipmentmanufacturers or their dealers.’’‘‘So I decided to set up a websitewhere I reviewed them. It allows peopleto see an independent review of a model,whether it’s good or bad, and make theirdecision whether they want to buy or not.’’SPIRIT48

‘‘I have got my ownmission here. I wanted tospread the word aboutthe models.”SPIRIT49

QualityWhat are he, and his fellowcollectors, looking for in a model? ‘‘I gradethem according to the packaging, the detailon the model, its features, the quality andthe price,’’ he explains.Ian also explains that manycollectors are attracted to models that mimicthe features of the original machines. Forthis knowledge, Ian can draw on his long andsuccessful career as a civil engineer, where hesees many of the original machines in action,as well as conducting a great deal of onlineresearch.“<strong>Volvo</strong> are the onlymanufacturers tohave commissioneda model of afuturistic machinethat doesn’t exist.”FuturisticIan, has over 500 models in hiscollection. Last year he started to producevideo reviews of his new acquisitions, andthey have proved to be extremely populartoo. A review of the <strong>Volvo</strong> Sfinx ConceptExcavator has received 125,000 views onYouTube.‘‘It’s popular because <strong>Volvo</strong> is theonly manufacturer to have commissioned amodel of a futuristic machine that doesn’texist. Most models are of an existingmachine, so this is something different.’’‘‘It was also an interesting model to review,because part of my process is to compareit to the original machine. Is the detailgood, that sort of thing? But here I haveno benchmark to compare it with, so it’s achallenge. But it’s proved very popular.’’As has Ian’s website, whichgets visitors from all over the world. ‘‘I’mextremely big in Vietnam,’’ he says with asmile. ‘‘It’s one of my biggest audiences.’’One of his favourite models isalso one of the first he ever bought, a <strong>Volvo</strong>A40D articulated hauler. What makes it sospecial? ‘‘It was an outstanding model of itstime. The quality was good, the detail wasexcellent and it has some features whichwere unusual for the time. For examplethe hood opens and you can see a detailedengine.’’His website also boasts a shoppingmall, where collectors can track down themodels they wish to buy. As for Ian, hiscollection is growing all the time, but as heworks out of his home in Croydon, SouthEast London, he is rapidly running out ofspace. Only 100 or so of his models are ondisplay – the rest are stored in his loft.Does he enjoy doing it? ‘‘Yesabsolutely. I invest a lot of time in this, it’swhat I enjoy doing.’’ And what do his wifeand two children, who share the house withhim and his models, think about it? Iansmiles. ‘‘The models look good, so my wife’sOK with it, and the fact it only takes up oneroom helps.’’ His smile broadens. ‘‘We havean understanding.’’To see <strong>Volvo</strong> <strong>Construction</strong> <strong>Equipment</strong>’srange of scale models, please visit:www.volvomerchandise.com orwww.volvobrandshop.com(North America).iPad exclusiveDownload the app formore in-depth informationSPIRIT50

OUR PHILOSOPHY:Every drop counts. Save up to 7%* fuel withI-Shift, our thinking transmission.Learn more at volvotrucks.com/everydropcounts* The claimed fuel savings are compared to the same vehicle with a manual gearbox.Actual savings will depend upon the driver and driving conditions.<strong>Volvo</strong> Trucks. Driving Progress

dig a bit deeper with the spirit appLog on to www.volvospiritmagazine.com and download our free <strong>Spirit</strong> iPadapplication for exclusive articles, videos and more...