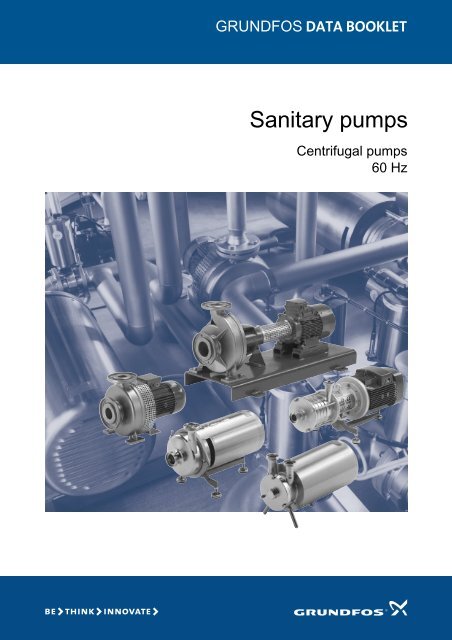

Sanitary pumps

Sanitary pumps

Sanitary pumps

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ContentsIntroductionGrundfos sanitary <strong>pumps</strong> 3Hygienic design 3Performance rangePerformance range, 2-pole 4Performance range, 4-pole 4Euro-HYGIA ®Euro-HYGIA ® 6ContraContra 8SIPLASIPLA 10MAXA and MAXANAMAXA and MAXANA 12IdentificationType keys 14Product dataProduct range, 60 Hz 15ConstructionMotor 16Impeller types 19Surface treatment 19Standard pipe connectionsEuro-HYGIA ® I 27Euro-HYGIA ® II 28Contra I 29Contra II 32MAXA 35MAXANA 36InstallationMechanical installation 37Space requirements 37Foundation and vibration dampening 38Terminal box positions 38Curve chartsHow to read the curve charts 39Curve conditions 40Performance curves/Technical dataEuro-HYGIA ® I 41Euro-HYGIA ® II 47Contra I 56Contra II 63SIPLA 70MAXA 76MAXA L 85MAXA CN 87MAXANA 90Further product documentationWebCAPS 106Shaft sealsMechanical shaft seal 20CertificationApprovals and certificates 21Certificates 21Surface finish of hygienic <strong>pumps</strong> 22Designs and versionsDesign variations 23Housing sealing for Euro-HYGIA ® <strong>pumps</strong> 262

Introduction<strong>Sanitary</strong> <strong>pumps</strong>60 HzGrundfos sanitary <strong>pumps</strong>Stainless steel sanitary <strong>pumps</strong> designed for a widerange of hygienic and sanitary applications such as• breweries• beverage industry• dairies• food industry• pharmaceutical industry• biotechnology industry• cosmetics industry• water treatment systems• semi-conductor industry• textile industry.The Grundfos range of sanitary <strong>pumps</strong> comprises thebelow <strong>pumps</strong> types - each state-of-the-art within itsspecific field of application. The <strong>pumps</strong> can be fittedwith a variety of features to adapt to specific pumpingtasks.In addition, it is possible to customise the <strong>pumps</strong> foroptimum function or performance in relation to the jobat hand.Euro-HYGIA ®Euro-HYGIA ® <strong>pumps</strong> are all single-stage, end-suctioncentrifugal <strong>pumps</strong>. The <strong>pumps</strong> offer heads up to 108metres, flow rates up to 130 m 3 /h and an operatingpressures up to 16 bar. Pipe connections range fromDN 25 to DN 125 and the motor sizes from 0.55 to22.0 kW.For further information, see page 6.ContraContra <strong>pumps</strong> are single-stage or multistage, endsuctioncentrifugal <strong>pumps</strong>. The <strong>pumps</strong> offer heads up to220 metres, flow rates up to 55 m 3 /h and operatingpressures up to 25 bar. Pipe connections range fromDN 25 to DN 80 and motor sizes from 0.55 to 18.5 kW.For further information, see page 8.SIPLASIPLA <strong>pumps</strong> are all single-stage, self-priming sidechannel<strong>pumps</strong>. The <strong>pumps</strong> offer heads up to 78metres, flow rates up to 75 m 3 /h and operating pressuresup to 10 bar. Pipe connections range from DN 32to DN 80 and motor sizes from 0.55 to 15 kW.For further information, see page 10.MAXAMAXA <strong>pumps</strong> are all single-stage, end-suction centrifugal<strong>pumps</strong>. MAXA <strong>pumps</strong> are designed according toDIN EN 733. The <strong>pumps</strong> offer heads up to 97 metres,flow rates up to 800 m 3 /h and operating pressures up to10 bar. Pipe connections range from DN 80 to DN 150and motor sizes from 3 to 90 kW.For further information, see page 12.MAXANAMAXANA <strong>pumps</strong> are all single-stage, end-suctioncentrifugal <strong>pumps</strong>. MAXANA <strong>pumps</strong> are designedaccording to DIN EN 733. The <strong>pumps</strong> offer heads up to97 metres, flow rates up to 140 m 3 /h and operatingpressures up to 10 bar. Pipe connections range fromDN 32 to DN 80 and motor sizes from 0.55 to 55 kW.For further information, see page 12.Hygienic designThe Grundfos sanitary <strong>pumps</strong> have been designed inaccordance with the strictest hygienic design criteria.The surface finish of the materials used is of the utmostimportance - both for physical properties and withregard to preventing possible breeding grounds forbacteria and germs.Fully drainable models are available, and the use ofAISI 316L (DIN EN 1.4404/1.4435) cold-rolled and/orforged stainless steel ensures a homogeneous porefreesurface, in contrast to cast materials.The design requirements and materials used as well asmaterial surface finish are subject to a variety ofnational and international rules and regulations, guidelinesand laws. Among these are the EU machinerydirective, GMP Rules and Regulations, FDA Regulations,3A sanitary standard, EU Foodstuff HygienicGuidelines, DIN EN 12462 Biotechnology, the recommendationsof the EHEDG (European Hygienic EquipmentDesign Group) and QHD (Qualified HygienicDesign).Shaft sealsDepending on the application and pumped liquid, singleor double mechanical shaft seal arrangements areavailable to ensure trouble-free operation.Double seal arrangements are offered as either atandem or back-to-back seal arrangement.The single shaft seals used are inboard mechanicalseals with an optimum position in the pumped liquid inorder to ensure lubrication, cooling as well as CIP(Cleaning-In-Place) and SIP (Sterilisation-In-Place).Standard seals have seal faces of carbon/stainlesssteel and O-rings of EPDM. Other seal face materialcombinations are available on request.ConnectionsA variety of connections are available. These includesterile threads to DIN 11864-1 PN 16 and sterileflanges to DIN 11864-2 PN 16.Other connections such as SMS, RJT, DIN or ISOclamp connections and Tri-Clover are available onrequest.Special sterile threaded fittings and flanges can also besupplied.3

Performance range<strong>Sanitary</strong> <strong>pumps</strong>60 HzPerformance range, 2-polep[kPa]H[m]60 Hz2000200Contra ll150100090080070060050010080706050Contra I Euro-HYGIA II MAXANA MAXA4004030030Euro-HYGIA I200205 6 8 10 15 20 30 40 50 60 80 100 150 200 300 400 500Q[m³/h]Performance range, 4-poleTM03 0979 4405p[kPa]700600H[m]80706060 Hz5004005040SIPLA30030MAXANAMAXA20020Euro-HYGIA II151009080706050108765Euro-HYGIA I5 6 8 10 15 20 30 40 50 60 80 100 150 200 300 400 500600 800 1000Q[m³/h]TM03 0980 44054

Euro-HYGIA ®<strong>Sanitary</strong> <strong>pumps</strong>60 HzEuro-HYGIA ®ConstructionEuro-HYGIA ® <strong>pumps</strong> are single-stage, end-suctioncentrifugal <strong>pumps</strong> designed to meet the hygienicrequirements of sterile process technology. The <strong>pumps</strong>are CIP and SIP capable in compliance with the DINEN 12462 performance criteria.GR8963Fig. 1 Euro-HYGIA ®Technical dataEuro-HYGIA ® I and IIHead:up to 108 mFlow rate: up to 130 m 3 /h(Euro-HYGIA ® III - on request): up to 250 m 3 /hOperating pressure:up to 16 barOperating temperature: 95°C(up to 150°Con request)Sterilisation temperature: 140°C (SIP).ApplicationsThe unique hygienic design and the use of materialsmake the Euro-HYGIA ® pump range suitable for:Food and beverage industry• Liquid transfer in breweries and dairies• Mixing in soft drink applications• Food processing plants.Pharmaceutical industry• Pure water systems (WFI)• Biotechnology• Cosmetics.Other industrial applications• Semi-conductor manufacturing• CIP (Cleaning-In-Place) systems.The design of the wetted parts meets the QualifiedHygienic Design (QHD) standard, EHEDG test certificatefor CIP cleanability (TNO), 3A sanitary standard(USA) and GOST (Russia).The pump housing is made of heavy-duty, rolled anddeep-drawn CrNiMo steel DIN EN 1.4404/1.4435,equivalent to AISI 316L.Three impeller types are available depending on theapplication: Semi-open, closed and free-flow impeller.For further information, see page 19.The <strong>pumps</strong> have a mechanical shaft seal and a fancooledasynchronous motor with enclosure class IP 55.2 3 7Fig. 2 Sectional drawing of Euro-HYGIA ® I Bloc-SUPERon combi-footMaterialsPos. Component Material DIN EN1 Impeller CrNiMo steel2 Pump housing CrNiMo steel1 4 5 6TM02 9607 35041.4404/1.44351.4404/1.44353 Shaft sealSterile applications: SiC/SiC/EPDMHygienic applications: Carbon/stainless steel/EPDM or FKM4 Pump shaft CrNiMo steel 1.45715 Motor6 Shroud Stainless steel7 Support Stainless steel/cast iron6

Contra<strong>Sanitary</strong> <strong>pumps</strong>60 HzContraGR8961ConstructionContra <strong>pumps</strong> are either single-stage or multi-stage,end-suction centrifugal <strong>pumps</strong> designed in accordancewith the Qualified Hygienic Design (QHD) criteria, theEHEDG certification and the 3A sanitary material specification.The <strong>pumps</strong> are CIP and SIP capable in compliance withthe DIN EN 12462 performance criteria. Furthermore,the <strong>pumps</strong> meet the GMP requirements for FDAapprovedmaterials.Fig. 3 Contra pumpTechnical dataContra I and IIHead:up to 220 mFlow rate: up to 55 m 3 /hOperating pressure: up to 25 barOperating temperature: 95°C(up to 150°C on request)Sterilisation temperature: 140°C (SIP).ApplicationsThe unique hygienic design and the use of materialsmakes the Contra pump range suitable for pressureboosting in:Food and beverage industry• Breweries and dairies• Carbonising systems• Food processing plants.Pharmaceutical industry• Purification systems• Pure water systems (WFI).Fig. 4 CertificationThe pump housing is made of rolled and forged stainlesssteel, DIN EN 1.4404/1.4435, equivalent to AISI316L. This guarantees a homogeneous pore-freesurface, in contrast to cast materials.The Contra <strong>pumps</strong> have open diffusers. The O-ring seallocations for the housing and impellers are designed tomeet the criteria of hygienic design with metal-to-metalcontact seal areas and no pump housing dead-ends.Contra <strong>pumps</strong> are fitted with a semi-open impeller asstandard. For further information, see page 19.The vertical versions are fully self-draining through thesuction port of the <strong>pumps</strong>.The <strong>pumps</strong> have a mechanical shaft seal and a fancooledasynchronous motor with enclosure class IP 55.1 4 5 6Other industrial applications• Surface treatment systems• Water processing systems• CIP feeding systems.2 3 7Fig. 5 Sectional drawing of Contra I Bloc-SUPER oncombi-footTM02 9610 35048

Contra<strong>Sanitary</strong> <strong>pumps</strong>60 HzMaterialsPos. Component Material EN/DIN1 Impeller CrNiMo steel2 Pump housing CrNiMo steel3 Shaft seal4 Pump shaft CrNiMo steelDesign variationsSterile applications: SiC/SiC/EPDMHygienic applications: Carbon/stainlesssteel/EPDM orFKM5 Motor6 Shroud Stainless steel7 Support Stainless steel/cast ironGrundfos offers the below design variations for Contra<strong>pumps</strong>:Standard variationContra Adapta ®Contra Adapta ® SUPERContra Adapta ® -VContra BlocContra Bloc-SUPERVariations on requestContra Bloc-VContra CNContra tronicMechanical shaft seal1.4404/1.44351.4404/1.44351.4571/1.4462Short descriptionHorizontal installation, Adapta ® motor stoolHorizontal installation, Adapta® motor stool,motor with stainless steel shroudVertical installation, Adapta ® motor stoolHorizontal installationHorizontal installation, motor with stainlesssteel shroudShort descriptionVertical installationHorizontal installation, long-coupled versionmounted on baseplateHorizontal/vertical installation, motor withbuilt-in frequency converter up to 7.5 kWGrundfos offers the following three seal arrangementsas standard:• single seal• double tandem seal• double back-to-back seal.The mechanical shaft seals used are single inboardmechanical shaft seals with an optimum position in thepumped liquid. This ensures lubrication, cooling as wellas CIP and SIP according to the criteria of hygienicdesign.Standard seals have seal faces of carbon/stainlesssteel and O-rings of EPDM.On request Grundfos offers other seal face materialcombinations.For further information, see page 20.Surface treatmentAs standard all wetted parts are electro-polished toimprove corrosion-resistance and surface finish.ConnectionsDepending on the nominal diameter of the Contrapump, Grundfos offers the below pipe connections asstandard:• Threads to DIN 11851, PN 25-40• Flanges to DIN EN 1092-1, PN 10 (DIN 2642, PN10)(industrial applications only)• Pipe threads to DIN ISO 228, PN 10 (max.)• Sterile threads to DIN 11864-1, PN 16• Sterile flanges to DIN 11864-2, PN 16.Other connections are available on request, e.g. SMS,RJT, clamp connections to DIN, ISO, Tri-Clover,special sterile threaded fittings and flanges.For further information about pipe connections forContra <strong>pumps</strong>, see page 29 to page 34.Product features and benefitsThe Contra <strong>pumps</strong> have the following product featuresand benefits:• A wide range of support possibilities for both motorand pump.• Extremely reliable operation under most workingconditions.• Optimised hydraulics for high efficiency- reduced power consumption.• Contra Adapta ® and CN with explosion- or flameproofmotors are available for ATEX-applications.• Motors with special voltages and frequencies.• Pump with water-cooled motor for clean room applications.• Adapta ® "tronic" versions are fitted with motors forvariable speed drive with built-in frequency converter.Available for motor sizes up to 7.5 kW.• Flush or barrier fluid systems for tandem or back-tobackdouble mechanical seals.• Mobile <strong>pumps</strong> mounted on two-wheel trolley withon/off switch.• Special paint for motor, cast iron and carbon steelparts (except for Adapta ® Bloc).9

SIPLA<strong>Sanitary</strong> <strong>pumps</strong>60 HzSIPLAConstructionSIPLA <strong>pumps</strong> are single-stage, self-priming sidechannel<strong>pumps</strong> designed in accordance with the 3Asanitary standard.Fig. 6 SIPLA pumpTechnical dataSIPLA <strong>pumps</strong>Head:up to 78 mFlow rate: up to 75 m 3 /hOperating pressure: up to 10 barOperating temperature: 95°CSterilisation temperature: 140°C (SIP)ApplicationsThe unique hygienic design, the use of materials andthe exceptional self-priming capability make the SIPLApump range suitable for:GR8965Fig. 7 CertificationThe pump housing and front cover are made of precisioncast stainless steel DIN EN 1.4404 and theimpeller nut of stainless steel DIN EN 1.4435, equivalentto AISI 316L.SIPLA <strong>pumps</strong> are fitted with an open star impeller asstandard.The pump shaft is made of stainless steel DINEN 1.4571 (equal to AISI 316TI).Thanks to its unique side-channel design, the SIPLApump is capable of handling liquids with a high contentof air as in CIP return systems.The <strong>pumps</strong> have a mechanical shaft seal and a fancooledasynchronous motor with enclosure class IP 55.2 4 5 6Food and beverage industry• Transfer of yeast• Transfer of cheese whey.Pharmaceutical industry• Transfer of glycerine.Other industrial applications• CIP returned pumping.1 7 3 7TM02 9608 3504Fig. 8 Sectional drawing of SIPLA Bloc-SUPER on stainlesssteel ball feetMaterialsPos. Component Material EN/DIN1 Impeller CrNiMo steel 1.44042 Pump housing CrNiMo steel 1.44043 Shaft sealHygienic applications: Carbon/stainlesssteel /EPDM orFKM4 Pump shaft CrNiMo steel 1.45715 Motor6 Shroud Stainless steel7 Support Stainless steel/cast iron10

SIPLA<strong>Sanitary</strong> <strong>pumps</strong>60 HzDesign variationsGrundfos offers the below design variations for SIPLA<strong>pumps</strong>:Standard variationSIPLA Adapta ® SUPERSIPLA BlocSIPLA Bloc-SUPERVariations on requestSIPLA CNSIPLA tronicShort descriptionHorizontal installation, Adapta ® motorstool, motor with stainless steel shroudHorizontal installationHorizontal installation, motor with stainlesssteel shroudShort descriptionFor further information, see page 24.Horizontal installation, long-coupled versionmounted on baseplateHorizontal/vertical installation, motor withbuilt-in frequency converter up to 7.5 kWProduct features and benefitsThe SIPLA <strong>pumps</strong> have the following product featuresand benefits:• A wide range of support possibilities for both motorand pump.• Extremely reliable operation under most workingconditions.• Optimised hydraulics for high efficiency- reduced power consumption.• Motors for variable speed drive with built-in frequencyconverter, "tronic". Available for motor sizesup to 7.5 kW.• ATEX-certified <strong>pumps</strong> available on request.Mechanical shaft sealSIPLA <strong>pumps</strong> are fitted with a single inboard mechanicalshaft seal with an optimum position in the pumpedliquid that ensuring efficient CIP, SIP, cooling and lubrication.As standard Grundfos offers a shaft seal with seal facesof carbon/stainless steel and O-rings of either EPDM orFKM.On request Grundfos offers shaft seals with seal facesof silicon carbide/silicon carbide and an O-ring ofEPDM or FKM.For further information, see page 20.Surface treatmentAs standard all wetted parts are electro-polished toimprove corrosion-resistance and surface finish.ConnectionsDepending on the nominal diameter of the SIPLApump, Grundfos offers threaded pipe connectionsaccording to DIN 11851.Optional connections are threaded connections: SMS,RJT, IDF clamp connections to DIN and clamps Tri-Clamp/Tri-Clover.11

MAXA and MAXANA<strong>Sanitary</strong> <strong>pumps</strong>60 HzMAXA and MAXANAApplicationsThe MAXA and MAXANA <strong>pumps</strong> meet the requirements:Fig. 9 MAXANA and MAXA <strong>pumps</strong>Technical dataMAXA <strong>pumps</strong>Head:97 mFlow rate: up to 800 m 3 /hOperating pressure: up to 10 barOperating temperature: 95°C(up to 150°C on request)Sterilisation temperature: 140°C (SIP)MAXANA <strong>pumps</strong>Head:up to 97 mFlow rate: up to 140 m 3 /hOperating pressure: up to 10 barOperating temperature: 95°C(up to 150°C on request)Sterilisation temperature: 140°C (SIP)TM03 0170 4304Pump typeMAXANAMAXAThe MAXA and MAXANA pump ranges are suitable for:Food and beverage industry• Gentle pumping of mash and wort, and beer filtration(hot side)• Dairies• Food processing.Other industrial applications• Water treatment plants• Chemical handling systems• Liquids with a high content of solid particles.ConstructionStandard3A03A0, 3A1 and 3A2The MAXA and MAXANA <strong>pumps</strong> are single-stage, endsuctioncentrifugal <strong>pumps</strong> designed for heavy-dutyoperation in industrial processes.The major dimensions and characteristics of these<strong>pumps</strong> correspond to DIN EN 733 and DIN EN 22858.The pump housing are made of heavy-duty, rolled anddeep-drawn stainless steel in quality DIN EN 1.4404.The back plate is made of rolled stainless steel DIN EN1.4571.The <strong>pumps</strong> feature closed impellers with optimisedblade entry angles made of steel quality DINEN 1.4571.For further information about impeller types, seepage 19.2 5 4 6 71 3 8TM02 9609 3504Fig. 10 Sectional drawing of MAXANA-CN on baseplate12

MAXA and MAXANA<strong>Sanitary</strong> <strong>pumps</strong>60 HzMaterialsPos. Component Material EN/DIN1 Impeller CrNiMo steel2 Pump housing CrNiMo steel3 Shaft seal4 Pump shaft CrNiMo steel5 Bearing bracket Stainless steel6 Coupling7 Motor8 Baseplate Stainless steelDesign variationsSterile applications: SiC/SiC/EPDMHygienic applications: Carbon/stainless steel/EPDM or FKMGrundfos offers the below design variations for MAXAand MAXANA <strong>pumps</strong>:Standard variationMAXA LMAXANA Adapta ®MAXANA BlocVariations on requestMAXA DINMAXA CNMAXA BlocMAXA tronicMAXANA CNMAXANA LMAXANA tronicFor further information, see page 25.Mechanical shaft seal1.4404/1.44351.4404/1.44351.4462/1.4571Short descriptionHorizontal installationHorizontal installation, Adapta ® motor stoolHorizontal installationShort descriptionHorizontal installation, mounted on baseplateHorizontal installation, mounted on baseplateHorizontal installationHorizontal installation, motor with built-infrequency converter up to 7.5 kWHorizontal installation, mounted on baseplateHorizontal installation, mounted on pumpfoot or motor footHorizontal installation, motor with built-infrequency converter up to 7.5 kWGrundfos offers the following three seal arrangementsas standard:• single seal• double tandem seal• double back-to-back seal.As standard MAXA and MAXANA <strong>pumps</strong> are fitted witha single inboard mechanical shaft seal with an optimumposition in the pumped liquid ensuring efficientcleaning, cooling and lubrication.The mechanical shaft seal is in accordance with DINEN 12756.Standard seals have seal faces of carbon/stainlesssteel and O-rings of EPDM.On request Grundfos offers other seal face materialcombinations.For further information, see page 20.Surface treatmentAs standard all wetted parts are made of corrosionresistantchrome-nickel-molybdenum steel.Grundfos offers industrial variants that are electropolished.ConnectionsDepending on the nominal diameter of the MAXA andMAXANA <strong>pumps</strong>, Grundfos offers a standard flangedconnection according to DIN EN 1092-1, PN 10(DIN 2632, PN 10).Optional connections include connections in accordancewith ANSI and JIS standards.Product features and benefitsThe MAXA and MAXANA <strong>pumps</strong> have the followingproduct features and benefits:• A wide range of support possibilities for both motorand pump.• Extremely reliable operation under most workingconditions.• Optimised hydraulics for high efficiency- reduced power consumption.• On request the <strong>pumps</strong> are available with the dischargeport positioned at the top, to the right or tothe left.• Double mechanical seals, depending on model, eitherwith flushing or barrier fluid.• Packed gland as shaft seal, single or flushed with C-bearing support to DIN EN 22858 and shaft sleeve.• Motors with special voltages and frequencies.• Adapta ® and CN available with a flameproof threephasemotor for ATEX-applications.• Motors for variable speed drive with built-in frequencyconverter as "tronic". Available for motorsizes up to 7.5 kW.• Housing drain connection DN 15; other sizes available.• Housing with heating jacket.• Special paint for motor and steel components.• MAXA Adapta ® and MAXANA Adapta ® <strong>pumps</strong>available with trolley.13

Identification<strong>Sanitary</strong> <strong>pumps</strong>60 HzType keysEuro-HYGIA ®ExamplePump rangeSizeDesignNominal diameter of suction port (DN)Nominal diameter of discharge port (DN)Motor power (P 2 )Number of polesContraEuro-HYGIA ® I Bloc 40 32 2.2 4Example Contra I/1 Bloc 32 25 1.5 2Pump rangeSize/StagesDesignNominal diameter of suction port (DN)Nominal diameter of discharge port (DN)Motor power (P 2 )Number of polesMAXAExample MAXA 80-250 CN 100 80 37 2Pump rangeSizeDesignNominal diameter of suction port (DN)Nominal diameter of discharge port (DN)Motor power (P 2 )Number of polesMAXANAExample MAXANA 32-200 Bloc 50 32 5.5 2Pump rangeSizeDesignNominal diameter of suction port (DN)Nominal diameter of discharge port (DN)Motor power (P 2 )Number of polesSIPLAExample SIPLA 3.1 Bloc 32 32 0.75 4Pump rangeSizeDesignNominal diameter of suction port (DN)Nominal diameter of discharge port (DN)Motor power (P 2 )Number of poles14

Product data<strong>Sanitary</strong> <strong>pumps</strong>60 HzProduct range, 60 HzPump rangeHydraulic dataEuro-HYGIA ® IEuro-HYGIA ® IIContra IContra IIMax. head [m] 62 108 150 220 31 46 34 39 50 48 78 97 97Flow rate [m 3 /h] 0-22 0-130 0-23 0-55 0-5.5 0-8 0-14 0-22 0-30 0-55 0-75 20-800 0-140Max. operating temperature [°C] 95 95 95 95 95 95 95 95 95 95 95 95 95Max. temperature [°C]– on request150 150 140 140 140 140 140 140 140 140 140 150 150Max. operating presssure [bar] 16 16 25 25 10 10 10 10 10 10 10 10 10Max. pump efficiency [%] 62 68 55 62 20.5 38 25.5 34 46 39 39 87 72Motor dataMotor power [kW] 0.55-5.5 0.75-22 0.55-5.5Design0.75-18.5SIPLA 3.1SIPLA 6.1SIPLA 12.1SIPLA 18.1SIPLA 28.10.75 1.5-2.2 1.5-2.2 3-4 4-5.5 7.5-11 11-15 3-90 0.55-55Bloc • • • • • • • • • • • •Bloc SUPER • • • • • • • • • • •Bloc-V Adapta ® • • • • •Adapta ® SUPER • • • • • • • • • • •Adapta ® -V • •CN • L • Tronic version MaterialsPump housing:CrNiMo stainless steel 1.4404Pump housing:Stainless steel 1.4404/1.4435Pipe connection• • • • • • • • • • •• •Threads, DIN 11851, PN 25-40 • • • • • • • • • • •Threads, DIN ISO 228, PN 10 Sterile threads, DIN 11864-1, PN 16 Flanges, DIN EN 1092-1(DIN 2632)Flanges, DIN EN 1092-1(DIN 2642) Sterile flanges, DIN 11864-2, PN 16 SMS RJT DIN clamp connection Clamps Tri-Clover/Tri-Clamp Special sterile threaded fittings andflanges Impeller typesSIPLA 52.1SIPLA 65.1MAXAMAXANA• •Semi-open • • • •Closed • • • •Two-channel (closed) Free-flow Star • • • • • • •• Standard. Available on request. Euro-HYGIA ® III <strong>pumps</strong> offer flow rates up to 250 m 3 /h - on request. For information about pipe connection, see page 27. For industrial applications only.15

Construction<strong>Sanitary</strong> <strong>pumps</strong>60 HzMotorThe motor is a totally enclosed, fan-cooled standardmotor with main dimensions to IEC and DIN standards.Electrical tolerances to IEC 34.Mounting designationPump rangeRelative humidity: Max. 95%Enclosure class: IP 55Insulation class: F, to IEC 85Ambient temperature: Max. 40°CIn humid locations, the lowest drain hole in the motormust be opened. In such cases the motor enclosureclass is IP 44.Motor rangesEuro-HYGIA ® IEuro-HYGIA ® I IMounting designation - IEC 34-7Horizontal installation Vertical installationEuro-HYGIA ®ContraIM 1001 (IM B3)SIPLAIM 3001 (IM B5)IM 2001 (IM B35)MAXAMAXANAIM 1011 (IM V5)IM 3011 (IM V1)IM 2011 (IM V15)P 2 kW 2-pole 4-pole0.550.751.11.52.23.04.05.5The grey shaded areas indicate non-available motors.P 2 kW 2-pole 4-pole0.751.11.52.23.04.05.57.511.015.018.522.0The grey shaded areas indicate non-available motors.Contra IContra IISIPLAP 2 kW0.550.751.11.52.23.04.05.52-pole4-pole1-stage2-stage3-stage4-stage5-stage6-stage1-stageThe grey shaded areas indicate non-available motors.P 2 kW0.751.11.52.23.04.05.57.511.015.018.52-pole4-pole1-stage2-stage3-stage4-stage5-stage1-stageThe grey shaded areas indicate non-available motors.4-poleP 2 kWSize3.1 6.1 12.1 18.1 28.1 52.1 65.10.751.11.52.23.04.05.57.511.015.018.5The grey shaded areas indicate non-available motors.16

Construction<strong>Sanitary</strong> <strong>pumps</strong>60 HzMAXA, 2-polekW7.511.015.018.522.030.037.045.055.075.090.0MAXA, 4-pole2-poleSize80-16080-20080-250100-200100-250The grey shaded areas indicate non-available motors.kW3.04.05.57.511.015.018.522.030.037.045.055.075.090.04-poleSize80-16080-20080-25080-315100-200100-250100-315125-250125-315150-250150-315150-400200-400The grey shaded areas indicate non-available motors.MAXANA, 4-polekW0.550.751.11.52.23.04.05.54-poleSize32-16032-20040-16040-20050-12550-16050-20065-12565-16065-20065-250The grey shaded areas indicate non-available motors.Electrical data of standard motorsElectrical data, 2-pole 3 x 440-480 VP2 [kW] I 1/1 [A] cos ϕ η [%] n [min -1 ]0.55 1.36 0.82 71 33600.75 1.73 0.86 73 34261.1 2.40 0.87 77 34141.5 3.25 0.85 79 34322.2 4.55 0.85 82 34563.0 6.1 0.85 84 34684.0 7.8 0.86 86 34865.5 10.3 0.89 86.5 35107.5 13.8 0.89 88 351611.0 20.0 0.88 89.5 352815.0 26.5 0.90 90 352818.5 32.5 0.91 91 352822.0 39.0 0.88 91.7 352830.0 53.0 0.89 92.3 353437.0 65.0 0.89 92.8 353445.0 78.0 0.89 93.6 355255.0 96.0 0.88 93.6 356475.0 130.0 0.88 94.5 357090.0 154.0 0.89 95.1 3570MAXANA, 2-polekW2.23.04.05.57.511.015.018.522.030.037.045.055.02-poleSize32-16032-20040-16040-20050-12550-16050-20065-125The grey shaded areas indicate non-available motors.65-16065-20065-250Electrical data, 4-pole 3 x 440-480 VP2 [kW] I 1/1 [A] cos ϕ η [%] n [min -1 ]0.55 1.45 0.82 67 16740.75 1.86 0.81 72 16741.1 2.55 0.81 77 16981.5 3.40 0.81 79 17042.2 4.70 0.82 82 170417

Construction<strong>Sanitary</strong> <strong>pumps</strong>60 HzElectrical data, 4-pole 3 x 440-480 VP2 [kW] I 1/1 [A] cos ϕ η [%] n [min -1 ]3.0 6.40 0.82 83 17044.0 8.20 0.83 85 17285.5 11.4 0.81 86 17467.5 15.2 0.82 87 174611.0 21.5 0.84 88.5 175215.0 28.5 0.84 90 175218.5 35.0 0.83 90.5 175222.0 41.0 0.84 91.2 175230.0 55.0 0.86 91.8 175837.0 66.0 0.87 92.9 176445.0 80.0 0.87 93.4 176455.0 100.0 0.85 93.5 177675.0 136.0 0.85 94.2 178290.0 160.0 0.86 94.6 1792Electrical data of standard motorswith built-in frequency converterElectrical data, 2-pole 3 x 440-480 VP2 [kW]I 1/1 [A]1.1 2.41.5 3.252.2 4.553.0 6.14.0 7.85.5 10.37.5 13.8Motor protectionThree-phase motors must be connected to a motorstarter.All three-phase standard motors can be connected toan external frequency converter. The connection of afrequency converter will often overload the motor insulationsystem, and the motor will be more noisy thanduring normal operation. In addition, large motors areloaded by bearing currents caused by the frequencyconverter.In the case of frequency converter operation, thefollowing should be considered:• In 2- and 4-pole motors of 75 kW (frame size 250)and upwards, one of the motor bearings should beelectrically isolated to prevent damaging currentsfrom passing through the motor bearings.• In the case of noise-sensitive applications, the motornoise can be reduced by fitting a dU/dt filter betweenthe motor and the frequency converter.In particularly noise-sensitive applications, we recommendto fit a sinusoidal filter.• The length of the cable between motor and frequencyconverter affects the motor load. It shouldtherefore be checked that the cable length meetsthe specifications laid down by the frequency convertersupplier.Electrical data, 4-pole 3 x 440-480 VP2 [kW]I 1/1 [A]1.1 2.551.5 3.42.2 4.73.0 6.44.0 8.25.5 11.47.5 15.218

Construction<strong>Sanitary</strong> <strong>pumps</strong>60 HzImpeller typesFree-flow impellerGrundfos offers four impeller types selected on thebasis of the pumped liquid and application.Not all impeller types are available for the completeproduct range.Semi-open impellerGR9393Fig. 13 Free-flow impellerFig. 11 Semi-open impellerThis electro-polished stainless steel impeller is availablein three versions according to the application.Impeller construction Application Surface finishCast Industrial/hygienic 3A0 to 3A1Sheet metal formed Industrial/hygienic 3A0 to 3A1Milled Industrial/hygienic/sterile 3A2 to 3A3For further information about surface finish requirements,see page 22.The impeller is suitable for both low-viscosity andparticle-containing pumped liquids.Closed impellerGR9394This electro-polished stainless steel impeller is availablein two versions according to the application.Impeller construction Application Surface finishCast Industrial/hygienic 3A0 to 3A1Sheet metal formed Industrial/hygienic 3A0 to 3A1For further information about surface finish requirements,see page 22.The free-flow impeller is a non-clogging impellerdesigned for pumped liquids with a high content of solidparticles or fibres.Star impellerGRA0393pFig. 14 Star impellerTwo-channel, closedFig. 12 Closed impellerClosedThese two electro-polished stainless steel impellers areavailable in two versions according to the application.Impeller construction Application Surface finishCast Industrial/hygienic 3A0 to 3A1Sheet metal formed Industrial/hygienic 3A0 to 3A1For further information about surface finish requirements,see page 22.The two-channel impeller is suitable for pumped liquidscontaining solid particles.The closed impeller is suitable for pumped liquids witha low content of solid particles. This impeller has thehighest efficiency.GR9391 - GR9392This electro-polished stainless steel impeller is availablein the version according to the application.Impeller construction Application Surface finishCast Industrial/hygienic 3A0 to 3A1For further information about surface finish requirements,see page 22.The star impeller is high efficient self priming and suitablefor pumped liquids with a low content of solid particles.Surface treatmentAll non-wetted parts of the <strong>pumps</strong> are given thefollowing surface treatment.1. Priming colour- Epoxy resin (RAL 7032)- Thickness of film: 50 to 70 µm.2. Top coat (standard)- Epoxy resin (RAL 5010)- Thickness of film: 50 to 70 µm.19

Shaft seals<strong>Sanitary</strong> <strong>pumps</strong>60 HzMechanical shaft sealThe operating range of the shaft seal depends on thetype of shaft seal, operating pressure and liquidtemperature.Sterile applicationsAs standard Grundfos offers a closed O-ring seal forsterile applications.Standard shaft seals are mentioned below; other shaftseals are available on request.Hygienic applicationsFig. 15 Single seal for hygienic applications.This shaft seal has seal faces of carbon/stainless steeland O-rings of either EPDM or FKM.p [bar]15105100 -40 -20 0 20 40 60 80 1002t [˚C]Fig. 16 Operating range of shaft seal with metal spring asseal driver for hygienic applications1: Carbon/stainless steel + EPDM2: Carbon/stainless steel + EPDM andcarbon/stainless steel + FKM.TM02 9660 3604TM03 0121 4104Fig. 17 Single seal for sterile applications.The O-ring seal has seal faces of silicon carbide/siliconcarbide (SiC/SiC) and O-rings of EPDM (optionallyFFKM (white) or FKM).p [bar]30252015105SiC/SiC/EPDMSiC/SiC/EPDMSiC/SiC/FFKMSiC/SiC/FKM0 t [˚C]0 -40 -20 0 20 40 60 80 100Fig. 18 Operating range of closed O-ring seal for sterileapplications.Seals for sanitary <strong>pumps</strong>As standard Grundfos offers a single shaft seal fittedwith a metal spring as seal driver for hygienic applications.Pump rangeShaft seal Euro-HYGIA ® Contra SIPLA MAXA MAXANASingle seal • • • • •Tandem Back-to-back • Standard. On request.TM02 9664 3604TM03 0118 410420

Certification<strong>Sanitary</strong> <strong>pumps</strong>60 HzApprovals and certificatesThe design, materials used and surface finish aresubject to a variety of national and international rulesand regulations. Among these are the 3A sanitarystandard, the recommendations of EHEDG (EuropeanHygienic Equipment Design Group) and the QHD(Qualified Hygienic Design).3A sanitary standardFig. 19 3A symbolThe 3A sanitary standard provide material specificationsand determination of surface finish.The goal is to protect consumable products fromcontamination and to ensure that all surfaces can becleaned (CIP).The 3A symbol is used by manufacturers to indicateconformance to 3A standards.For further information about surface finish of hygienic<strong>pumps</strong>, see page 22.EHEDG (European Hygienic Equipment DesignGroup)Fig. 20 EHEDG symbolThe EHEDG is a testing system describing the criteriafor the safe and hygienic design of equipment intendedfor the processing of food.The goal is to ensure the microbiological safety of theend product, e.g. the pumped liquid.The EHEDG symbol is used by manufacturers to indicateconformance to EHEDG recommendations.QHD (Qualified Hygienic Design)Fig. 21 QHD symbolQualified Hygienic Design (QHD) stands for a twophasetesting system for the hygienic design and thecleanability of components, machinery and plant foraseptic or sterile applications.The goal is to ensure that all surfaces can be cleaned(CIP).The QHD symbol is used by manufacturers to indicateconformance to QHD guidelines.CertificatesGeneral informationGrundfos offers a number of certificates and approvalsfor different purposes. The following types are available:• Hygienic design certificates(certificates guaranteeing compliance with the 3Asanitary standard, the EHEDG and the QHD recommendations)• material certificates(certificates stating material specifications)• performance certificates(test reports guaranteeing and certifying test data ofQH, current consumption, speed, curves, etc.)• authorized test by third party(surveyed performance test)• ATEX-approved sanitary <strong>pumps</strong>(according to ATEX-directive 94/9/EC)The certificates must be ordered with the pump.21

Certification<strong>Sanitary</strong> <strong>pumps</strong>60 HzSurface finish of hygienic <strong>pumps</strong>In order to meet the demands of the pharmaceutical,food and the beverage industries Grundfos has developedthe below surface finish requirements:TM03 0091 3904Code Application Material Surface finish3A0.01 Industrial CrNiMo steel3A1.02 Hygienic CrNiMo steel Ra≤3.2µm3A2.03 Sterile1.4404/1.4435(AISI 316L)Ra≤0.8µm3A1.04 Pharmaceutical 1.4435, Fe≤3% Ra≤3.2µm3A2.05 Sterile 1.4435, Fe≤1% Ra≤0.8µm3A3.06 Sterile 1.4435, Fe≤1% Ra≤0.4µm3A3.07 Sterile3A2.33 Sterile3A3.37 Sterile1.4404/1.4435(AISI 316L)1.4404/1.4435Fe≤3%(AISI 316L)1.4404/1.4435Fe≤3%(AISI 316L)Ra≤0.4µmRa≤0.8µmRa≤0.4µmCertificate3A sanitary design certificateEHEDG test reportQHD test reportMaterial specification reportMaterial report with certificateCE declaration of conformityATEX-approved pumpInspection certificateInspection certificate- Lloyds Register of Shipping (LRS),- Det Norske Veritas (DNV),- Germanischer Lloyd (GL),- Bureau Veritas (BV), etc.StandardEN 10.204 3.1.BEN 10.204 3.1.CSurface roughness reportMotor test reportStandard test report ISO 9906Vibration reportCertificate of compliance with theEN 10.204 2.1orderTest report - non-specific inspectionEN 10.204 2.2and testingReportCleaned and dried pumpReportElectro-polished pump22

Designs and versions<strong>Sanitary</strong> <strong>pumps</strong>60 HzDesign variationsGrundfos offers each pump range in different designs.Principal sketches of each design variant are shownbelow.Bloc on motor footAdapta ®TM03 0082 3904TM03 0079 3904Fig. 27 Example: Euro-HYGIA ® Adapta ® on cast iron footAdapta ® -SUPERFig. 22 Example: Euro-HYGIA ® Bloc on motor footBloc on stainless steel footTM03 0083 3904TM03 0080 3904Fig. 28 Example: Euro-HYGIA ® Adapta ® -SUPER onstainless steel combi-footAdapta ® on stainless steel trolleyFig. 23 Example: Euro-HYGIA ® Bloc on stainless steelfootBloc-SUPERFig. 24 Example: Euro-HYGIA ® Bloc-SUPER with shroudand on stainless steel combi-footBloc on stainless steel trolleyTM03 0081 3904Fig. 29 Example: Euro-HYGIA ® Adapta ® on stainlesssteel trolleyAdapta ® -VTM03 0087 3904CNFig. 25 Example: Euro-HYGIA ® Bloc on stainless steeltrolleyTM03 0086 3904TM03 0085 3904Fig. 30 Example: Euro-HYGIA ® Adapta ® -V on pedestaland with suction elbow connectionTM03 0088 3904Fig. 26 Example: Euro-HYGIA ® CN on baseplate23

Designs and versions<strong>Sanitary</strong> <strong>pumps</strong>60 HzThe tables below state possible designs and versionsof each pump range.Each version number is described in the version key onpage 26.Euro-HYGIA ® IDesignVersion numberAdapta ® ★ 1 2 3 18 19 23 24 31 50 51 52 60 61Adapta ® -SUPER ★★ 1 2 3 18 19 23 31 50 52 60 61Adapta ® -V ★ 8 9 10 11 31 50 51 52 60 61Bloc 1 2 3 5 6 7 18 19 23 24 50 60 61Bloc-SUPER ★★ 1 2 3 5 6 7 18 19 23 50 60 61Bloc-V 8 9 10 11 50 60 61CN 25 26 27 28 29 30 31 32 33 34 50 51 52 60 61★ Size I.★★SUPER = motor with stainless steel shroud.Euro-HYGIA ® IIDesignVersion numberAdapta ® ★ 1 2 3 18 19 22 23 24 31 50 51 52 60 61Adapta ® -SUPER ★★ 1 2 3 18 19 22 23 31 50 52 60 61Adapta ® -V ★ 8 9 10 11 31 50 51 52 60 61Bloc 1 2 3 5 6 7 18 19 23 24 50 60 61Bloc-SUPER ★★ 1 2 3 5 6 7 18 19 23 50 60 61Bloc-V 8 9 10 11 50 60 61CN 25 26 27 28 29 30 31 32 33 34 50 51 52 60 61★ Size II up to frame size 160; frame size 180 is size III.★★ SUPER = motor with stainless steel shroud.Contra IDesignVersion numberAdapta ® ★ 1 2 3 18 19 23 24 31 50 51 52Adapta ® -SUPER ★★ 1 2 3 18 19 23 31 50 52Adapta ® -V ★ 8 9 10 11 31 50 51 52Bloc 1 2 3 5 6 7 18 19 23 24 50Bloc-SUPER ★★ 1 2 3 5 6 7 18 19 23 50Bloc-V 8 9 10 11 50CN 25 26 27 28 29 30 31 32 33 34 50 51 52★Size I.★★ SUPER = motor with stainless steel shroud.Contra IIDesignVersion numberAdapta ® ★ 1 2 3 18 19 22 23 24 31 50 51 52Adapta ® -SUPER ★★ 1 2 3 18 19 22 23 31 50 52Adapta ® -V ★ 8 9 10 11 31 50 51 52Bloc 1 2 3 5 6 7 18 19 23 24 50Bloc-SUPER ★★ 1 2 3 5 6 7 18 19 23 50Bloc-V 8 9 10 11 50CN 25 26 27 28 29 30 31 32 33 34 35 50 51 52★Size II up to frame size 160; frame size 180 is size III.★★ SUPER = motor with stainless steel shroud.SIPLA 3.1DesignVersion numberAdapta ® ★ 1 2 3 18 19 23 31 51 52 53Adapta ® -SUPER ★★ 1 2 3 18 19 23 31 52 53Bloc 4 5 18 19 32 33 51 54Bloc-SUPER ★★ 4 18CN 25 26 27 28 30 31 32 33 34 51 52★ Size I.★★ SUPER = motor with stainless steel shroud.SIPLA 6.1DesignVersion numberAdapta ® ★ 1 2 3 18 19 23 31 50 51 52 53Adapta ® -SUPER ★★ 1 2 3 18 19 23 31 50 52 53Bloc 4 5 18 19 32 33 50 51 54Bloc-SUPER ★★ 4 18 50CN 25 26 27 28 30 31 32 33 34 50 51 52★Size I.★★ SUPER = motor with stainless steel shroud.SIPLA 12.1DesignVersion numberAdapta ® ★ 1 2 3 18 19 23 31 50 51 52 53Adapta ® -SUPER ★★ 1 2 3 18 19 23 31 50 52 53Bloc 4 5 18 19 32 33 50 51 54Bloc-SUPER ★★ 4 18 50CN 25 26 27 28 30 31 32 33 34 50 51 52★Size I.★★ SUPER = motor with stainless steel shroud.24

Designs and versions<strong>Sanitary</strong> <strong>pumps</strong>60 HzSIPLA 18.1DesignVersion numberAdapta ® ★ 1 2 3 18 19 23 31 50 51 52 53Adapta ® -SUPER ★★ 1 2 3 18 19 23 31 50 52 53Bloc 4 5 18 19 32 33 50 51 54Bloc-SUPER ★★ 4 18 50CN 25 26 27 28 30 31 32 33 34 50 51 52★Size II.★★ SUPER = motor with stainless steel shroud.SIPLA 28.1DesignVersion numberAdapta ® ★ 1 2 3 18 19 23 31 50 51 52 53Adapta ® -SUPER ★★ 1 2 3 18 19 23 31 50 52 53Bloc 4 5 18 19 32 33 50 51 54Bloc-SUPER ★★ 4 18 50CN 25 26 27 28 30 31 32 33 34 50 51 52★ Size II.★★ SUPER = motor with stainless steel shroud.SIPLA 52.1DesignVersion numberAdapta ® ★ 1 2 3 18 19 23 31 50 51 52 53Adapta ® -SUPER ★★ 1 2 3 18 19 23 31 50 52 53Bloc 4 5 18 19 50 54Bloc-SUPER ★★ 4 18 50 54CN 25 26 27 28 30 31 32 33 34 50 51 52★ Size II.★★ SUPER = motor with stainless steel shroud.MAXADesignVersion numberAdapta ® ★ 1 2 22 31 50 51 52Adapta ® ★★ 22 31 51 52Adapta ® -V ★ 8 10 31 50 51 52Adapta ® -V ★★ 16 31 51 52L 5 6 7 21 31 50 51 52C ★★★ 25 26 27 28 29 30 31 32 33 34 50 51 52CN ★★★★ 25 26 27 28 29 30 31 32 33 34 50 51 52★ Size II.★★ Size III.★★★ CN with shaft sleeve.★★★★ N.MAXANADesignVersion numberAdapta ® ★ 1 2 22 31 50 51 52Adapta ® ★★ 22 31 51 52Adapta ® -SUPER ★★★ 8 10 31 50 51 52Bloc 16 31 51 52L 5 6 7 21 31 50 51 52C ★★★★ 25 26 27 28 29 30 31 32 33 34 50 51 52CN ★★★★★ 25 26 27 28 29 30 31 32 33 34 50 51 52★Size II.★★ Size III.★★★ SUPER = motor with stainless steel shroud.★★★★ CN with shat sleeve.★★★★★ N.SIPLA 65.1DesignVersion numberAdapta ® ★ 22 31 51 52 53Adapta ® -SUPER ★★ 4 22 31 52Bloc 4 5Bloc-SUPER ★★ 4CN 25 26 27 28 30 31 32 33 34 51 52★Size III.★★ SUPER = motor with stainless steel shroud.25

Designs and versions<strong>Sanitary</strong> <strong>pumps</strong>60 HzVersion keyVersion number Description1 On cast iron foot2 On stainless steel foot3 Without foot/stainless steel ball feet4 On stainless steel ball feet5 On motor foot6 On motor foot with carbon steel plinth7 On motor foot with stainless steel plinth8 On stainless steel pedestal without suction elbow9 On stainless steel pedestal with suction elbow10 Without pedestal and suction elbow ★11 Without pedestal but with suction elbow16 On vertical frame without suction elbow ★18 On stainless steel trolley, normal wheels19 On stainless steel trolley, anti-static wheels21 On pump and motor support feet (≤frame size 112)22 On Adapta ® foot (≤45 kW, size III)23 On stainless steel combi-foot24 Wall-mounting (Euro-HYGIA ® : Only available as HPM, Contra; 3 stages are standard)25 Without baseplate ★★26 With coupling (

Standard pipe connections<strong>Sanitary</strong> <strong>pumps</strong>60 HzEuro-HYGIA ® IConnectionsThreadedconnectionDIN 11851(3A0-3A1)AsepticthreadedconnectionDIN 11864-1 ★(3A0-3A3)AsepticflangeDIN 11864-2 ★★(3A0-3A3)Clamp toDIN 32676(3A0-3A2)FlangeDIN EN 1092-1 ★★★(DIN 2633/42)PN 10(3A0)Clamp toTri-CloverITE-Tri-Clamp(3A0-3A2)Weld neckflangeDIN EN 1092-1(DIN 2633)PN 16(3A0)ThreadedconnectionDIN ISO 228(male)(3A0)DIN 32/25 32/32 40/25 40/32 40/40 50/32 50/40 50/50 65/40 65/50OD 1 1/4 / 1 1 1/4 / 1 1/4 1 ½ / 1 1 ½ / 1 1/4 1 ½ / 1 ½ 2 / 1 1/4 2 / 1 ½ 2 / 2 2 ½ / 1 ½ 2 ½ / 2a 1 75 75 75 75 75 75 75 75 75 75e 1 85 85 85 85 85 85 85 75 85 75h 2 170 170 170 170 170 170 170 170 170 170e 5 109 109 120 120 120 135 135 135 145 145h 3 132 132 133 133 133 148 148 148 160 160a 1 86 86 82 82 82 78 78 78 78 78e 1 85 85 85 85 85 85 85 75 85 75h 2 183 187 183 187 188 187 188 188 188 188e 5 105 105 108 108 108 136 136 136 146 146h 3 120 120 131 131 131 144 144 144 156 156a 1 81 81 76 76 76 72 72 72 67 67e 1 85 85 85 85 85 85 85 75 85 75h 2 182 182 182 182 182 182 182 182 182 182e 5 112 112 122 122 122 135 135 135 142 142h 3 115 115 125 125 125 138 138 138 145 145a 1 87 87 77 77 77 73 73 73 75 75e 1 85 85 85 85 85 85 85 75 85 75h 2 178 178 178 178 170 178 170 178 170 178e 5 113 113 123 123 123 136 136 136 150 150h 3 111 111 121 121 121 134 134 134 148 148a 1 75 75 75 75 75 75 75 75 75 75e 1 85 85 85 85 85 85 85 75 85 75h 2 170 170 170 170 170 170 170 170 170 170e 5 105 105 115 115 115 128 128 128 145 145h 3 103 103 113 113 113 126 126 126 143 143a 1 - - 88 - 88 - 86 86 70 70e 1 - - 85 - 85 - 85 75 85 75h 2 - - 185 - 185 - 185 185 185 185e 5 - - 123 - 123 -h 3 - - 121 - 121 -On requesta 1 100(10) 100(10) 100 100 100 97 97 97 97 97e 1 85 85 85 85 85 85 85 75 85 75h 2 170 197 170 197 199 197 199 202 199 202e 5h 3On requesta 1 85 85 81 81 81 80 80 80 - -e 1 85 85 85 85 85 85 85 75 - -h 2 170 170 170 170 170 170 170 170 - -e 5- -h 3On request- -Tolerances to DIN EN 735 connection dimensions for centrifugal <strong>pumps</strong>.★ Aseptic threaded connection for pipes to DIN 11850 row 2/3, Form A.★★ Aseptic grooved flange for pipes to DIN 11850 row 2/3, Form A.★★★ DNs/DNd - fixed/loose flange (DNs 65 as DIN 2642-loose flange).(10) Dimensions for KLM version. For HPM version dimension a 1 is 91mm for DN s 32.Dimensions e 5 and h 3 for vertical version. Discharge branch cannot be completely drained (not eccentric).27

Pipe connections<strong>Sanitary</strong> <strong>pumps</strong>60 HzEuro-HYGIA ® IIConnectionsThreadedconnectionDIN 11851(3A0-3A1)AsepticthreadedconnectionDIN 11864-1 ★(3A0-3A3)AsepticflangeDIN 11864-2 ★★(3A0-3A3)Clamp toDIN 32676(3A0-3A2)FlangeDIN EN 1092-1 ★★★(DIN 2633/42)PN 10(3A0)Clamp toTri-CloverITE-Tri-Clamp(3A0-3A2)Weld neckflangeDIN EN 1092-1(DIN 2633)PN 16(3A0)FlangeAPV FN1/FG1PN 10(3A0-3A1)DIN 50/50 65/50 65/65 80/50 80/65 80/80 100/65 100/80 100/100 125/80 125/100OD 2 / 2 2 ½ / 2 2½ / 2½ 3 / 2 3 / 2½ 3 / 3 4 / 2½ 4 / 3 4 / 4 5 / 3 5 / 4a 1 116 116 116 116 116 116 116 116 116 116 116e 1 98 98 98 98 98 85.5 98 85.5 85.5 85.5 85.5h 2 200 200 200 200 200 200 200 200 200 200 200e 5 135 145 145 175 175 175 190 190 190 - -h 3 148 160 160 190 190 190 209 209 209 - -a 1 112 119 119 125 125 125 133 133 133 - -e 1 98 98 98 98 98 85.5 98 85.5 85.5 - -h 2 206 206 213 206 213 220 213 220 227 - -e 5 136 146 146 175 175 175 191 191 191 - -h 3 144 156 156 187 187 187 205 205 205 - -a 1 106.5 108.5 108.5 110.5 110.5 110.5 110.5 110.5 110.5 - -e 1 98 98 98 98 98 85.5 98 85.5 85.5 - -h 2 200.5 200.5 202.5 200.5 202.5 205.5 202.5 205.5 204.5 - -e 5 135.5 142.5 142.5 169.5 169.5 169.5 179.5 179.5 179.5 - -h 3 138.5 145.5 145.5 172.5 172.5 172.5 182.5 182.5 182.5 - -a 1 102.5 111 111 111 111 111 111 111 111 - -e 1 98 98 98 98 98 85.5 98 85.5 85.5 - -h 2 209 209 228 209 228 206 228 206 205 - -e 5 136.5 150 150 175 175 175 185 185 185 - -h 3 134.5 148 148 173 173 173 183 183 183 - -a 1 116 116 116 116 116 116 116 116 116 116 116e 1 98 98 98 98 98 85.5 98 85.5 85.5 85.5 85.5h 2 200 200 200 200 200 200 200 200 200 200 200e 5 128 145 145 170 170 170 185 185 185 - -h 3 126 143 143 168 168 168 183 183 183 - -a 1 109.6 109.6 109.6 111.6 111.6 111.6 111.6 111.6 111.6 - -e 1 98 98 98 98 98 98 98 98 85.5 - -h 2 215.6 215.6 215.6 215.6 215.6 225 215.6 225 215.6 - -e 5- -h 3On request- -a 1 126 128 128 133 133 133 135 135 135 - -e 1 98 98 98 98 98 85.5 98 85.5 85.5 - -h 2 232 232 234 232 234 228 234 228 229 - -e 5- -h 3On request- -a 1 105 107 107 107 107 107 107 107 107 145 145e 1 98 98 98 98 98 85.5 98 85.5 85.5 85.5 85.5h 2 199 199 224 199 224 200 224 200 200 200 200e 5- -h 3On request- -Tolerances to DIN EN 735 connection dimensions for centrifugal <strong>pumps</strong>.★ Aseptic threaded connection for pipes to DIN 11850 row 2/3, Form A.★★ Aseptic grooved flange for pipes to DIN 11850 row 2/3, Form A.★★★DNs/DNd - fixed/loose flange (DN s 1255 as DIN 2642-loose flange. Attention! This type of connection cannotbe used for Bloc-SUPER with frame size 160. Use weld neck flange to DIN 2633.Dimensions e 5 and h 3 for vertical version. Discharge branch cannot be completely drained (not eccentric).28

Pipe connections<strong>Sanitary</strong> <strong>pumps</strong>60 HzContra IConnectionsThreadedconnectionDIN 11851(3A0-3A1)AsepticthreadedconnectionDIN 11864-1 ★(3A0-3A3)AsepticflangeDIN 11864-2 ★★(3A0-3A3)Clamp toDIN 32676(3A0-3A2)FlangeDIN EN 1092-1 ★★★(DIN 2642)PN 10(3A0)Clamp toTri-CloverITE-Tri-Clamp(3A0-3A2)Weld neckflangeDIN EN 1092-1(DIN 2633)PN 16(3A0)ThreadedconnectionDIN ISO 228(male)(3A0)DIN 25/25 32/25 32/32 40/32 40/40 25/25 32/25 32/32 40/32 40/40OD 1 / 1 1 1/4 / 1 1 1/4 / 1 1/4 1½ / 1 1/4 1½ / 1½ 1 / 1 1 1/4 / 1 1 1/4 / 1 1/4 1½ / 1 1/4 1½ / 1½1-Stage2-Stagea 1 117 120 123 124 127 143 146 149 150 153f 2 1 1 4 4 7 1 1 4 4 7h 2 160 160 160 160 160 160 160 160 160 160e 5 106 109 109 120 120 106 109 109 120 120h 3 119 122 122 133 133 119 122 122 133 133a 1 114 118 121 122 125 140 144 147 149 151f 2 1 1 4 4 7 1 1 4 4 7h 2 157 157 158 158 158 157 157 158 158 158e 5 106 105 105 108 108 106 105 105 108 108h 3 116 120 120 131 131 116 120 120 131 131a 1 113.5 113.6 116.5 116.6 119.5 139.5 139.5 142.5 142.5 145.5f 2 1 1 4 4 7 1 1 4 4 7h 2 156.5 156.5 153.5 153.5 152.5 156.5 156.5 153.5 153.5 152.5e 5 112 112 112 122 122 112 112 112 122 122h 3 115 115 115 125 125 115 115 115 125 125a 1 109.5 109.5 112.5 112.5 115.5 135.5 135.5 138.5 138.5 141.5f 2 1 1 4 4 7 1 1 4 4 7h 2 152.5 152.5 149.5 149.5 148.5 152.5 152.5 149.5 149.5 148.5e 5 113 113 113 123 123 113 113 113 123 123h 3 111 111 111 121 121 111 111 111 121 121a 1 101 101 104 104 107 127 127 130 130 133f 2 1 1 4 4 7 1 1 4 4 7h 2 144 144 141 141 140 144 144 141 141 140e 5 105 105 105 115 115 105 105 105 115 115h 3 103 103 103 113 113 103 103 103 113 113a 1 116.6 - - - 125 142.6 - - - 151f 2 1 - - - 7 1 - - - 7h 2 160 - - - 158 160 - - - 158e 5 95 - - - 123 95 - - - 123h 3 93 - - - 121 93 - - - 121a 1 117 121 124 133 136 143 147 150 159 162f 2 1 1 4 4 7 1 1 4 4 7h 2 160 160 160 160 169 160 160 160 160 169e 5On request On requesth 3a 1 113 113 116 121 124 139 139 142 147 150f 2 1 1 4 4 7 1 1 4 4 7h 2 156 156 153 153 157 156 156 153 153 157e 5On request On requesth 3Tolerances to DIN EN 735 connection dimensions for centrifugal <strong>pumps</strong>.★ Aseptic threaded connection for pipes to DIN 11850 row 2/3, Form A.★★ Aseptic grooved flange for pipes to DIN 11850 row 2/3, Form A.★★★ DN s /DN d - loose flangeDimensions e 5 and h 3 for vertical version. Discharge branch can be completely drained (eccentric).29

Pipe connections<strong>Sanitary</strong> <strong>pumps</strong>60 HzConnectionsThreadedconnectionDIN 11851(3A0-3A1)AsepticthreadedconnectionDIN 11864-1 ★(3A0-3A3)AsepticflangeDIN 11864-2 ★★(3A0-3A3)Clamp toDIN 32676(3A0-3A2)FlangeDIN EN 1092-1 ★★★(DIN 2642)PN 10(3A0)Clamp toTri-CloverITE-Tri-Clamp(3A0-3A2)Weld neckflangeDIN EN 1092-1(DIN 2633)PN 16(3A0)ThreadedconnectionDIN ISO 228(male)(3A0)DIN 25/25 32/25 32/32 40/32 40/40 25/25 32/25 32/32 40/32 40/40OD 1 / 1 1 1/4 / 1 1 1/4 / 1 1/4 1½ / 1 1/4 1½ / 1½ 1 / 1 1 1/4 / 1 1 1/4 / 1 1/4 1½ / 1 1/4 1½ / 1½3-Stage4-Stagea 1 169 172 175 176 179 195 198 201 202 205f 2 1 1 4 4 7 1 1 4 4 7h 2 160 160 160 160 160 160 160 160 160 160e 5 106 109 109 120 120 106 109 109 120 120h 3 119 122 122 133 133 119 122 122 133 133a 1 166 170 173 174 177 192 196 199 201 203f 2 1 1 4 4 7 1 1 4 4 7h 2 157 157 158 158 158 157 157 158 158 158e 5 106 105 105 108 108 106 105 105 108 108h 3 116 120 120 131 131 116 120 120 131 131a 1 165.5 165.5 168.5 168.5 171.5 191.5 191.5 194.5 194.5 197.5f 2 1 1 4 4 7 1 1 4 4 7h 2 156.5 156.5 153.5 153.5 152.5 156.5 156.5 153.5 153.5 152.5e 5 112 112 112 122 122 112 112 112 122 122h 3 115 115 115 125 125 115 115 115 125 125a 1 161.5 161.5 164.5 164.5 167.5 187.5 187.5 190.5 190.5 193.5f 2 1 1 4 4 7 1 1 4 4 7h 2 152.5 152.5 149.5 149.5 148.5 152.5 152.5 149.5 149.5 148.5e 5 113 113 113 123 123 113 113 113 123 123h 3 111 111 111 121 121 111 111 111 121 121a 1 153 153 156 156 159 179 179 182 182 185f 2 1 1 4 4 7 1 1 4 4 7h 2 144 144 141 141 140 144 144 141 141 140e 5 105 105 105 115 115 105 105 105 115 115h 3 103 103 103 113 113 103 103 103 113 113a 1 168.6 - - - 177 194.6 - - - 203f 2 1 - - - 7 1 - - - 7h 2 160 - - - 158 160 - - - 158e 5 95 - - - 123 95 - - - 123h 3 93 - - - 121 93 - - - 121a 1 169 173 176 185 188 195 199 202 211 214f 2 1 1 4 4 7 1 1 4 4 7h 2 160 160 160 160 169 160 160 160 160 169e 5On request On requesth 3a 1 165 165 168 173 176 191 191 194 199 202f 2 1 1 4 4 7 1 1 4 4 7h 2 156 156 153 153 157 156 156 153 153 157e 5On request On requesth 3Tolerances to DIN EN 735 connection dimensions for centrifugal <strong>pumps</strong>.★ Aseptic threaded connection for pipes to DIN 11850 row 2/3, Form A.★★ Aseptic grooved flange for pipes to DIN 11850 row 2/3, Form A.★★★ DN s /DN d - loose flangeDimensions e 5 and h 3 for vertical version. Discharge branch can be completely drained (eccentric).30

Pipe connections<strong>Sanitary</strong> <strong>pumps</strong>60 HzConnectionsThreadedconnectionDIN 11851(3A0-3A1)AsepticthreadedconnectionDIN 11864-1 ★(3A0-3A3)AsepticflangeDIN 11864-2 ★★(3A0-3A3)Clamp toDIN 32676(3A0-3A2)FlangeDIN EN 1092-1 ★★★(DIN 2642)PN 10(3A0)Clamp toTri-CloverITE-Tri-Clamp(3A0-3A2)Weld neckflangeDIN EN 1092-1(DIN 2633)PN 16(3A0)ThreadedconnectionDIN ISO 228(male)(3A0)DIN 25/25 32/25 32/32 40/32 40/40 25/25 32/25 32/32 40/32 40/40OD 1 / 1 1 1/4 / 1 1 1/4 / 1 1/4 1½ / 1 1/4 1½ / 1½ 1 / 1 1 1/4 / 1 1 1/4 / 1 1/4 1½ / 1 1/4 1½ / 1½5-Stage6-Stagea 1 221 224 227 228 231 247 250 253 254 257f 2 1 1 4 4 7 1 1 4 4 7h 2 160 160 160 160 160 160 160 160 160 160e 5 106 109 109 120 120 106 109 109 120 120h 3 119 122 122 133 133 119 122 122 133 133a 1 218 222 225 226 229 244 248 251 253 255f 2 1 1 4 4 7 1 1 4 4 7h 2 157 157 158 158 158 157 157 158 158 158e 5 106 105 105 108 108 106 105 105 108 108h 3 116 120 120 131 131 116 120 120 131 131a 1 217.5 217.5 220.5 220.5 223.5 243.5 243.5 246.5 246.5 249.5f 2 1 1 4 4 7 1 1 4 4 7h 2 156.5 156.5 153.5 153.5 152.5 156.5 156.5 153.5 153.5 152.5e 5 112 112 112 122 122 112 112 112 122 122h 3 115 115 115 125 125 115 115 115 125 125a 1 213.5 213.5 216.5 216.5 219.5 239.5 239.5 242.5 242.5 245.5f 2 1 1 4 4 7 1 1 4 4 7h 2 152.5 152.5 149.5 149.5 148.5 152.5 152.5 149.5 149.5 148.5e 5 113 113 113 123 123 113 113 113 123 123h 3 111 111 111 121 121 111 111 111 121 121a 1 205 205 209 209 211 231 231 234 234 237f 2 1 1 4 4 7 1 1 4 4 7h 2 144 144 141 141 140 144 144 141 141 140e 5 105 105 105 115 115 105 105 105 115 115h 3 103 103 103 113 113 103 103 103 113 113a 1 220.6 - - - 229 246.6 - - - 255f 2 1 - - - 7 1 - - - 7h 2 160 - - - 158 160 - - - 158e 5 95 - - - 123 95 - - - 123h 3 93 - - - 121 93 - - - 121a 1 221 225 228 237 240 247 251 254 263 266f 2 1 1 4 4 7 1 1 4 4 7h 2 160 160 160 160 169 160 160 160 160 169e 5On request On requesth 3a 1 217 217 220 225 228 243 243 246 251 254f 2 1 1 4 4 7 1 1 4 4 7h 2 156 156 153 153 157 156 156 153 153 157e 5On request On requesth 3Tolerances to DIN EN 735 connection dimensions for centrifugal <strong>pumps</strong>.★ Aseptic threaded connection for pipes to DIN 11850 row 2/3, Form A.★★ Aseptic grooved flange for pipes to DIN 11850 row 2/3, Form A.★★★ DN s /DN d - loose flangeDimensions e 5 and h 3 for vertical version. Discharge branch can be completely drained (eccentric).31

Pipe connections<strong>Sanitary</strong> <strong>pumps</strong>60 HzContra IIConnectionsThreadedconnectionDIN 11851(3A0-3A1)AsepticthreadedconnectionDIN 11864-1 ★(3A0-3A3)AsepticflangeDIN 11864-2 ★★(3A0-3A3)Clamp toDIN 32676(3A0-3A2)FlangeDIN EN 1092-1 ★★★(DIN 2642)PN 10(3A0)Clamp toTri-CloverITE-Tri-Clamp(3A0-3A2)DIN 50/40 50/50 65/50 65/65 80/65 50/40 50/50 65/50 65/65 80/65OD 2 / 1½ 2 / 2 2½ / 2 2½ / 2½ 3 / 2½ 2 / 1½ 2 / 2 2½ / 2 2½ / 2½ 3 / 2½1-Stage2-Stagea 1 124 127 132 140 145 156 159 164 172 177f 2 0 3 3 11 11 0 3 3 11 11h 2 205 205 205 205 205 205 205 205 205 205e 5 135 135 145 145 175 135 135 145 145 175h 3 148 148 160 160 190 148 148 160 160 190a 1 120 123 128 136 142 152 155 160 168 174f 2 0 3 3 11 11 0 3 3 11 11h 2 203 201 201 201 201 203 201 201 201 201e 5 136 136 146 146 175 136 136 146 146 175h 3 144 144 156 156 187 144 144 156 156 187a 1 113 116 117 125 127 145 148 149 157 159f 2 0 3 3 11 11 0 3 3 11 11h 2 198 196 196 191 191 198 196 196 191 191e 5 135.5 135.5 142.5 142.5 169.5 135.5 135.5 142.5 142.5 169.5h 3 138.5 138.5 145.5 145.5 172.5 138.5 138.5 145.5 14.5 172.5a 1 110 113 120 128 128 142 145 152 160 160f 2 0 3 3 11 11 0 3 3 11 11h 2 194 192 192 193 193 194 192 192 193 193e 5 136.5 136.5 150 150 175 136.5 136.5 150 150 175h 3 134.5 134.5 148 148 173 134.5 134.5 148 148 173a 1 102 105 115 123 122 134 137 147 155 154f 2 0 3 3 11 11 0 3 3 11 11h 2 185 183 183 188 188 185 183 183 188 188e 5 128 128 145 145 170 128 128 145 145 170h 3 126 126 143 143 168 126 126 143 143 168a 1 146 149 - - - 178 181 - - -f 2 0 3 3 11 11 0 3 3 11 11h 2 201 199 199 194 194 201 199 199 194 194e 5On request On requestWeld neckflangeDIN EN 1092-1(DIN 2633)PN 16(3A0)AVP-FG1ThreadedconnectionDIN ISO 228(male)(3A0)h 3a 1 134 137 137 145 - 166 169 169 177 -f 2 0 3 3 11 - 0 3 3 11 -h 2 214 215 215 210 - 214 215 215 210 -e 5h 3On request On requesta 1 113 116 116 124 - 145 148 148 156 -f 2 0 3 3 11 - 0 3 3 11 -h 2 - 194 194 189 - - 194 194 189 -e 5h 3On request On requestTolerances to DIN EN 735 connection dimensions for centrifugal <strong>pumps</strong>.★ Aseptic threaded connection for pipes to DIN 11850 row 2/3, Form A.★★ Aseptic grooved flange for pipes to DIN 11850 row 2/3, Form A.★★★ DN s /DN d - loose flangeDimensions e 5 and h 3 for vertical version. Discharge branch can be completely drained (eccentric).32

Pipe connections<strong>Sanitary</strong> <strong>pumps</strong>60 HzConnectionsThreadedconnectionDIN 11851(3A0-3A1)AsepticthreadedconnectionDIN 11864-1 ★(3A0-3A3)AsepticflangeDIN 11864-2 ★★(3A0-3A3)Clamp toDIN 32676(3A0-3A2)FlangeDIN EN 1092-1 ★★★(DIN 2642)PN 10(3A0)Clamp toTri-CloverITE-Tri-Clamp(3A0-3A2)DIN 50/40 50/50 65/50 65/65 80/65 50/40 50/50 65/50 65/65 80/65OD 2 / 1½ 2 / 2 2½ / 2 2½ / 2½ 3 / 2½ 2 / 1½ 2 / 2 2½ / 2 2½ / 2½ 3 / 2½3-Stage4-Stagea 1 188 191 196 204 209 220 223 228 236 241f 2 0 3 3 11 11 0 3 3 11 11h 2 205 205 205 205 205 205 205 205 205 205e 5 135 135 145 145 175 135 135 145 145 175h 3 148 148 160 160 190 148 148 160 160 190a 1 184 187 192 200 206 216 219 224 232 238f 2 0 3 3 11 11 0 3 3 11 11h 2 203 201 201 201 201 203 201 201 201 201e 5 136 136 146 146 175 136 136 146 146 175h 3 144 144 156 156 187 144 144 156 156 187a 1 177 180 181 189 191 209 212 213 221 223f 2 0 3 3 11 11 0 3 3 11 11h 2 198 196 196 191 191 198 196 196 191 191e 5 135.5 135.5 142.5 142.5 169.5 135.5 135.5 142.5 142.5 169.5h 3 138.5 138.5 145.5 14.5 172.5 138.5 138.5 145.5 14.5 172.5a 1 174 177 184 192 192 206 209 216 224 224f 2 0 3 3 11 11 0 3 3 11 11h 2 194 192 192 193 193 194 192 192 193 193e 5 136.5 136.5 150 150 175 136.5 136.5 150 150 175h 3 134.5 134.5 148 148 173 134.5 134.5 148 148 173a 1 166 169 179 187 186 198 201 211 219 218f 2 0 3 3 11 11 0 3 3 11 11h 2 185 183 183 188 188 185 183 183 188 188e 5 128 128 145 145 170 128 128 145 145 170h 3 126 126 143 143 168 126 126 143 143 168a 1 210 213 - - - 242 245 - - -f 2 0 3 3 11 11 0 3 3 11 11h 2 201 199 199 194 194 201 199 199 194 194e 5On request On requestWeld neckflangeDIN EN 1092-1(DIN 2633)PN 16(3A0)AVP-FG1ThreadedconnectionDIN ISO 228(male)(3A0)h 3a 1 198 201 201 209 - 230 233 233 241 -f 2 0 3 3 11 - 0 3 3 11 -h 2 214 215 215 210 - 214 215 215 210 -e 5h 3On request On requesta 1 177 180 180 188 - 209 212 212 220 -f 2 0 3 3 11 - 0 3 3 11 -h 2 - 194 194 189 - - 194 194 189 -e 5h 3On request On requestTolerances to DIN EN 735 connection dimensions for centrifugal <strong>pumps</strong>.★ Aseptic threaded connection for pipes to DIN 11850 row 2/3, Form A.★★ Aseptic grooved flange for pipes to DIN 11850 row 2/3, Form A.★★★ DN s /DN d - loose flangeDimensions e 5 and h 3 for vertical version. Discharge branch can be completely drained (eccentric).33

Pipe connections<strong>Sanitary</strong> <strong>pumps</strong>60 HzConnectionsThreadedconnectionDIN 11851(3A0-3A1)AsepticthreadedconnectionDIN 11864-1 ★(3A0-3A3)AsepticflangeDIN 11864-2 ★★(3A0-3A3)Clamp toDIN 32676(3A0-3A2)FlangeDIN EN 1092-1 ★★★(DIN 2642)PN 10(3A0)Clamp toTri-CloverITE-Tri-Clamp(3A0-3A2)Weld neckflangeDIN EN 1092-1(DIN 2633)PN 16(3A0)AVP-FG1ThreadedconnectionDIN ISO 228(male)(3A0)DIN 50/40 50/50 65/50 65/65 80/65OD 2 / 1½ 2 / 2 2½ / 2 2½ / 2½ 3 / 2½5-Stagea 1 252 255 260 268 273f 2 0 3 3 11 11h 2 205 205 205 205 205e 5 135 135 145 145 175h 3 148 148 160 160 190a 1 248 251 256 264 270f 2 0 3 3 11 11h 2 203 201 201 201 201e 5 136 136 146 146 175h 3 144 144 156 156 187a 1 241 244 245 253 255f 2 0 3 3 11 11h 2 198 196 196 191 191e 5 135.5 135.5 142.5 142.5 169.5h 3 138.5 138.5 145.5 14.5 172.5a 1 238 241 248 256 256f 2 0 3 3 11 11h 2 194 192 192 193 193e 5 136.5 136.5 150 150 175h 3 134.5 134.5 148 148 173a 1 230 233 243 251 250f 2 0 3 3 11 11h 2 185 183 183 188 188e 5 128 128 145 145 170h 3 126 126 143 143 168a 1 274 277 - - -f 2 0 3 3 11 11h 2 201 199 199 194 194e 5h 3On requesta 1 262 265 265 273 -f 2 0 3 3 11 -h 2 214 215 215 210 -e 5h 3On requesta 1 241 244 244 252 -f 2 0 3 3 11 -h 2 - 194 194 189 -e 5h 3On requestTolerances to DIN EN 735 connection dimensions for centrifugal <strong>pumps</strong>.★ Aseptic threaded connection for pipes to DIN 11850 row 2/3, Form A.★★ Aseptic grooved flange for pipes to DIN 11850 row 2/3, Form A.★★★ DN s /DN d - loose flangeDimensions e 5 and h 3 for vertical version. Discharge branch can be completely drained (eccentric).34

Pipe connections<strong>Sanitary</strong> <strong>pumps</strong>60 HzMAXAMAXA, frame size 80-160ConnectionsDIN 100/80 125/80 125/100 150/80OD 4 / 3 5 / 3 5 / 4 6 / 3Kremo-flange a 1 125 125 - 125DIN EN 1092-1(DIN 2633)(3A0)h 2 225 225 - 225MAXA, frame size 80-200ConnectionsDIN 100/80 100/100 125/80 125/100 150/80 150/100OD 4 / 3 4 / 4 5 / 3 5 / 4 6 / 3 6 / 4Kremo-flange a 1 125 125 - - - 125DIN EN 1092-1(DIN 2633)(3A0)h 2 250 250 - - - 250MAXA, frame size 80-250ConnectionsDIN 100/80 100/100 125/80 125/100 150/80 150/100OD 4 / 3 4 / 4 5 / 3 5 / 4 6 / 3 6 / 4Kremo-flange a 1 125 - - 125 125 125DIN EN 1092-1(DIN 2633)(3A0)h 2 280 - - 280 280 280MAXA, frame size 80-315ConnectionsDIN 100/80 100/100 125/80 125/100 150/80 150/100OD 4 / 3 4 / 4 5 / 3 5 / 4 6 / 3 6 / 4Kremo-flange a 1 125 125 125 125 125 125DIN EN 1092-1(DIN 2633)(3A0)h 2 315 315 315 315 315 315MAXA, frame size 100-200ConnectionsDIN 125/100 125/125 150/100 150/125OD 5 / 4 5 / 5 6 / 4 6 / 5Kremo-flange a 1 125 125 125 125DIN EN 1092-1(DIN 2633)(3A0)h 2 280 280 280 280MAXA, frame size 100-250ConnectionsDIN 125/100 125/125 150/100 150/125OD 5 / 4 5 / 5 6 / 4 6 / 5Kremo-flange a 1 140 140 - 140DIN EN 1092-1(DIN 2633)(3A0)h 2 280 280 - 280MAXA, frame size 125-250ConnectionsDIN 150/125 150/150 175/125 200/125 200/150OD 6 / 5 6 / 6 7 / 5 8 / 5 8 / 6Flangea 1 - - - 140 -DIN EN 1092-1 ★★★(DIN 2632) h 2 - - - 355 -(3A0)Flangea 1 140 140 140 - 140DIN EN 1092-1 ★★★(DIN 2633)(3A0)h 2 355 355 355 - 355MAXA, frame size 100-315ConnectionsDIN 125/100 125/125 150/100 150/125OD 5 / 4 5 / 5 6 / 4 6 / 5Kremo-flange a 1 140 140 140 140DIN EN 1092-1(DIN 2633)(3A0)h 2 315 315 315 315MAXA, frame size 125-315ConnectionsDIN 150/125 200/150OD 6 / 5 8 / 6Flangea 1 140 140DIN EN 1092-1 ★★★(DIN 2633)(3A0)h 2 355 355MAXA, frame size 150-250ConnectionsDIN 200/150 250/150 250/200OD 8 / 6 10 / 6 10 / 8Flangea 1 160 160 160DIN EN 1092-1 ★★★(DIN 2632) h 2 375 375 375(3A0)Flangea 1 160 160 -DIN EN 1092-1 ★★★(DIN 2633)(3A0)h 2 375 375 -MAXA, frame size 150-315ConnectionsDIN 200/150 250/150 250/200OD 8 / 6 10 / 6 10 / 8Flangea 1 160 160 160DIN EN 1092-1 ★★★(DIN 2632) h 2 400 400 400(3A0)Flangea 1 - 160 -DIN EN 1092-1 ★★★(DIN 2633)(3A0)h 2 - 400 -MAXA, frame size 150-400ConnectionsDIN 200/150 200/200OD 8 / 6 8 / 8Flangea 1 160 160DIN EN 1092-1 ★★★(DIN 2632)(3A0)h 2 450 450MAXA, frame size 200-400ConnectionsDIN 200/200 250/200OD 8 / 8 10 / 8Flangea 1 175 175DIN EN 1092-1 ★★★(DIN 2632)(3A0)h 2 530 53035

Pipe connections<strong>Sanitary</strong> <strong>pumps</strong>60 HzMAXANAMAXANA, frame size 32-160ConnectionsDIN 50/32 50/40 65/32 65/40OD 2 / 1/1/4 2 / 1½ 2½ / 1 1/4 2½ / 1½Kremo-flange a 1 80 80 80 80DIN EN 1092-1(DIN 2633)(3A0)h 2 160 160 160 160MAXANA, frame size 32-200ConnectionsDIN 40/25 50/32 50/40 65/32 65/40 65/50OD 1½ / 1 2 / 1/1/4 2 / 1½ 2½ / 1 1/4 2½ / 1½ 2½ / 2Kremo-flange a 1 - 80 80 80 80 80DIN EN 1092-1(DIN 2633)(3A0)h 2 - 180 180 180 180 180MAXANA, frame size 40-160ConnectionsDIN 65/40 65/50 80/40 80/50OD 2½ / 1½ 2½ / 2 3 / 1½ 3 / 2Kremo-flange a 1 80 80 80 80DIN EN 1092-1(DIN 2633)(3A0)h 2 160 160 160 160MAXANA, frame size 40-200ConnectionsDIN 65/40 65/50 80/40 80/50OD 2½ / 1½ 2½ / 2 3 / 1½ 3 / 2Kremo-flange a 1 100 100 100 100DIN EN 1092-1(DIN 2633)(3A0)h 2 180 180 180 180MAXANA, frame size 65-125ConnectionsDIN 80/65 100/65 80/80 100/80OD 3 / 2½ 3½ / 2½ 3 / 3 3½ / 3Kremo-flange a 1 100 100 100 100DIN EN 1092-1(DIN 2633)(3A0)h 2 180 180 180 180MAXANA, frame size 65-160ConnectionsDIN 80/65 80/80 100/65 100/80OD 3 / 2½ 3 / 3 3½ / 2½ 3½ / 3Kremo-flange a 1 100 100 100 100DIN EN 1092-1(DIN 2633)(3A0)h 2 200 200 200 200MAXANA, frame size 65-200ConnectionsDIN 80/65 80/80 100/65 100/80OD 3 / 2½ 3 / 3 3½ / 2½ 3½ / 3Kremo-flange a 1 100 100 100 100DIN EN 1092-1(DIN 2633)(3A0)h 2 225 225 225 225MAXANA, frame size 65-250ConnectionsDIN 80/65 80/80 100/65 100/80OD 3 / 2½ 3 / 3 3½ / 2½ 3½ / 3Kremo-flange a 1 100 100 100 100DIN EN 1092-1(DIN 2633)(3A0)h 2 250 250 250 250MAXANA, frame size 50-125ConnectionsDIN 65/50 65/65 80/50 80/65OD 2½ / 2 2½ / 2½ 3 / 2 3 / 2½Kremo-flange a 1 100 100 100 100DIN EN 1092-1(DIN 2633)(3A0)h 2 160 160 160 160MAXANA, frame size 50-160ConnectionsDIN 65/50 65/65 80/50 80/65OD 2½ / 2 2½ / 2½ 3 / 2 3 / 2½Kremo-flange a 1 100 100 100 100DIN EN 1092-1(DIN 2633)(3A0)h 2 180 180 180 180MAXANA, frame size 50-200ConnectionsDIN 65/50 65/65 80/50 80/65OD 2½ / 2 2½ / 2½ 3 / 2 3 / 2½Kremo-flange a 1 100 100 100 100DIN EN 1092-1(DIN 2633)(3A0)h 2 200 200 200 20036

Installation<strong>Sanitary</strong> <strong>pumps</strong>60 HzMechanical installationThe pump should never be installed with the motorpointing downwards.Horizontal installation• Pumps fitted with motors up to and including 4 kWrequire a 300 mm clearance behind the motor,please see the figure below.• Pumps fitted with motors of 5.5 kW and up require a300 mm clearance behind and a 1 metre clearanceabove the motor to allow the use of lifting equipment.Fig. 32 InstallationTM03 0113 40040.55-4 kW300mmThe <strong>pumps</strong> must be installed in such a way that strainfrom the pipework is not transferred to the pumphousing.When installed outdoors, the motor must be providedwith a suitable cover to avoid condensation on the electroniccomponents and to protect the pump and motoragainst the direct effects of the elements.Space requirements5.5-30 kW1mVertical installation• Pumps fitted with motors up to and including 4 kWrequire a 300 mm clearance above the motor,please see the figure below.• Pumps fitted with motors of 5.5 kW and up requireat least a 1 metre clearance above the motor to allowthe use of lifting equipment.Fig. 34 Horizontal installation300mm0.55-4 kW 5.5-30 kW300mm1mTM03 0114 4004TM03 0115 4004Fig. 33 Vertical installation37

Installation<strong>Sanitary</strong> <strong>pumps</strong>60 HzFoundation and vibration dampeningIn order to achieve optimum operation and to reducenoise and vibration to a minimum, it may be necessaryto consider vibration dampening of the pump in certaincases. Generally this should always be considered inthe case of <strong>pumps</strong> with motors larger than 11 kW.Smaller motors, however, may also cause undesirablenoise and vibration.Noise and vibration are generated by the rotations inthe motor and pump and by the flow in pipes andfittings. The effect on the environment is subjective anddepends on correct installation and the state of theremaining system.FoundationPumps should be installed on a plane and rigidconcrete foundation which is the optimum solution forvibration dampening.ExpansionjointsConcrete foundationVibration dampersFig. 35 Example of foundation of a Contra II pumpTM03 0116 4004Expansion jointsExpansion joints are installed to• absorb expansions/contractions in the pipeworkcaused by changing liquid temperature• reduce mechanical strains in connection with pressuresurges in the pipework• isolate mechanical structure-borne noise in thepipework (only rubber bellows expansion joints).Note: Expansion joints must not be installed tocompensate for inaccuracies in the pipework such ascentre displacement of flanges.Fit expansion joints at a distance of minimum 1 to 1½ xDN diameter from the pump on the suction as well ason the discharge side. This prevents the developmentof turbulence in the expansion joints, resulting in bettersuction conditions and a minimum pressure loss on thepressure side. At high water velocities (> 5 m/s) it isadvisable to install larger expansion joints correspondingto the pipework.Expansion joints with limit rods can be used to minimizethe forces caused by the expansion joints. Expansionjoints with limit rods are always recommended forflanges larger than DN 100.The pipes should be anchored so that they do notstress the expansion joints and the pump. Follow thesupplier’s instructions and pass them on to advisers orpipe installers.Terminal box positionsThe below terminal box positions are possible for allpump ranges.As a rule of thumb, the weight of a concrete foundationshould be 1.5 x the pump weight.DampeningTo prevent the transmission of vibrations to buildings, itis advisable to isolate the pump foundation frombuilding parts by means of vibration dampers.The selection of the right vibration damper requires thefollowing data:• forces transmitted through the damper• motor speed considering speed control, if any• required dampening in % (suggested value is 70%).Which is the right damper varies from installation toinstallation, and a wrong damper may increase thevibration level. Vibration dampers should therefore besized by the supplier.If the pump is installed on a pedestal with vibrationdampers, expansion joints should always be fitted onthe pump flanges. This is important to prevent the pumpfrom "hanging" in the flanges.12 o’clock 3 o’clock 9 o’clock On fan cover(Bloc-SUPER)Fig. 36 Possible terminal box positionsTM03 0117 400438

Curve charts<strong>Sanitary</strong> <strong>pumps</strong>60 HzHow to read the curve chartsH[m]70MAXA 80-16060 HzPump type and frequency605040QH curve for the individual pump with aspecific impeller diameter302010/180/159 /166 /173/1870P20 40 80 120 160 200 240 Q [m³/h][kW]35/187302520151057065/180/173/166/1590Eta0 40 80 120 160 200 240 Q [m³/h][%]75/187The power curve indicates pumpinput power [P2] for the individualpump with a specific impellerdiameter.The eta curve indicates the pumpefficiency for the individual pumpwith a specific impeller diameter.60/1805550/159 /166 /173450NPSH40 80 120 160 200 240 Q [m³/h][m]86/159/166The NPSH curve indicates the NetPositive Suction Head of the individualpump with a specific impellerdiameter.42/180/187/17300 40 80 120 160 200 240 Q [m³/h]0 20 40 60 Q [l/s]TM03 0939 090539

Curve charts<strong>Sanitary</strong> <strong>pumps</strong>60 HzCurve conditionsThe guidelines below apply to the curves shown on thefollowing pages:1. Tolerances to ISO 9906, Annex A.2. QH curves of the individual <strong>pumps</strong> are shown withexpected speed of a three-phase standard motor.3. Measurements have been made with airless waterat a temperature of +20°C.4. The curves apply to a kinematic viscosity ofυ = 1 mm 2 /s (1 cSt).5. If the pumped liquid density and/or viscosity ishigher than that of water, it may be necessary touse a motor with a higher performance.6. All NPSH curves are based on tests run at 50 Hz.40

Performance curvesEuro-HYGIA ® I60 HzEuro-HYGIA ® I, 2-poleEuro-HYGIA ® I, 4-poleH[m]7065605550454035302520151050/185Euro-HYGIA I60 Hz/120/155H[m]181614121086420Euro-HYGIA I60 Hz/120/185/155P2[kW]760 5 10 15 20 25 30 35 40 Q [m³/h]/185/155P2[kW]1.41.20 2 4 6 8 10 12 14 16 18 20 22 Q [m³/h]/185543/1201.00.80.6/15520.4/12010.20Eta[%]605550454035300 5 10 15 20 25 30 35 40 Q [m³/h]/185/120/155250NPSH5 10 15 20 25 30 35 40 Q [m³/h][m]2.52.01.51.00.50.0/185/120/1550 5 10 15 20 25 30 35 40 Q [m³/h]0 2 4 6 8 10 12Q [l/s]TM02 9744 44050.0Eta[%]605550454035300 2 4 6 8 10 12 14 16 18 20 22 Q [m³/h]/120/185/155250NPSH2 4 6 8 10 12 14 16 18 20 22 Q [m³/h][m]2.52.01.51.00.50.0/120/185/1550 2 4 6 8 10 12 14 16 18 20 22 Q [m³/h]0 1 2 3 4 5 6 Q [l/s]TM02 9743 4405Performance curves/ Technical dataEuro-HYGIA® I41

Technical dataEuro-HYGIA ® I60 HzEuro-HYGIA ® I Adapta ® on cast iron footOptionAnnular housing with clamp ring (KLM)TM03 0039 3804Technical dataOn cast iron footP2 [kW] n [min -1 ] IEC sizeb k (1)3 u (1)0.55 1750 80 0 245 1450.75 1750 80 0 245 1451.1 3500 80 0 245 1451.1 1750 90S 10 285 1501.5 3500 90S 10 285 1501.5 1750 90L 10 285 1502.2 3500 90L 10 285 1502.2 1750 100L 20 320 1753.0 3500 100L 20 320 1754.0 3500 112M 20 340 1855.5 3500 132S 40 390 205Dimensions depend on housing size (DN s , DN d , a 1 , h 2 , e 1 ), see table of connections on page 27.(1) Motor dimensions depend on make; maximum size for basic design given.(2) Other sizes and special connections are available on request.(4) Largest diameter of pump without motor.(7) N-Eupex coupling.(8) Option: Drain-Gemü membrane valve DN 15. Drain-clamp connection to DIN 32 676 DN 15 (45° angle).42

Technical dataEuro-HYGIA ® I60 HzEuro-HYGIA ® I Adapta ® SUPER on stainless steel combi-foot(frame size 80-90)OptionAnnular housing with clamp ring (KLM)TM03 0040 3804Technical dataOn stainless steel combi-footP2 [kW] n [min -1 ] IEC sizel H h H ø d H0.55 1750 80 370 180 3200.75 1750 80 370 180 3201.1 3500 80 370 180 3201.1 1750 90S 370 180 3201.5 3500 90S 370 180 3201.5 1750 90L 370 180 3202.2 3500 90L 370 180 320Dimensions depend on housing size (DN s , DN d , a 1 , h 2 , e 1 ), see table of connections on page 27.(2) Other sizes and special connections are available on request.(4) Largest diameter of pump without motor.(7) N-Eupex coupling.(8) Option: Drain-Gemü membrane valve DN 15. Drain-clamp connection to DIN 32 676 DN 15 (45° angle).43

Technical dataEuro-HYGIA ® I60 HzEuro-HYGIA ® I Adapta ® SUPER on stainless steel combi-foot(frame size 100-132)OptionAnnular housing with clamp ring (KLM)TM03 0041 3804Technical dataOn stainless steel combi-footP2 [kW] n [min -1 ] IEC sizel H h H ø d H2.2 1750 100L 460 210 3703.0 3500 100L 460 210 3704.0 3500 112M 460 210 3705.5 3500 132S 510 240 420Dimensions depend on housing size (DN s , DN d , a 1 , h 2 , e 1 ), see table of connections on page 27.(2) Other sizes and special connections are available on request.(4) Largest diameter of pump without motor.(7) N-Eupex coupling.(8) Option: Drain-Gemü membrane valve DN 15. Drain-clamp connection to DIN 32 676 DN 15 (45° angle).44

Technical dataEuro-HYGIA ® I60 HzEuro-HYGIA ® I Bloc on cast iron footOptionAnnular housing with clamp ring (KLM)TM03 0042 3804Technical dataCast iron footP2 [kW] n [min -1 ] IEC size(1)k 3 u (1)0.55 1750 80 258 1240.75 1750 80 258 1241.1 3500 80 258 1241.1 1750 90S 282 1301.5 3500 90S 282 1301.5 1750 90L 282 1302.2 3500 90L 282 1302.2 1750 100L 327 1583.0 3500 100L 327 1584.0 3500 112M 355 1715.5 3500 112M 391 171Dimensions depend on housing size (DN s , DN d , a 1 , h 2 , e 1 ), see table of connections on page 27.(1) Motor dimensions depend on make; maximum size for basic design given.(2) Other sizes and special connections are available on request.(4) Largest diameter of pump without motor.(8) Option: Drain-Gemü membrane valve DN 15. Drain-clamp connection to DIN 32 676 DN 15 (45° angle).45

Technical dataEuro-HYGIA ® I60 HzEuro-HYGIA ® I Bloc-SUPER on stainless steel combi-footOptionAnnular housing with clamp ring (KLM)TM03 0043 3804Technical dataOn stainless steel combi-footP2 [kW] n [min -1 ] IEC sizel l H ø d H0.55 1750 80 470 410 2200.75 1750 80 470 410 2201.1 3500 80 470 410 2201.1 1750 90S 470 410 2201.5 3500 90S 470 410 2201.5 1750 90L 470 410 2202.2 3500 90L 470 410 2202.2 1750 100L 540 480 2703.0 3500 100L 540 480 2704.0 3500 112M 540 480 2705.5 3500 112M 580 520 270Dimensions depend on housing size (DN s , DN d , a 1 , h 2 , e 1 ), see table of connections on page 27.(2) Other sizes and special connections are available on request.(4) Largest diameter of pump without motor.(8) Option: Drain-Gemü membrane valve DN 15. Drain-clamp connection to DIN 32 676 DN 15 (45° angle).46

Performance curvesEuro-HYGIA ® II60 HzEuro-HYGIA ® II, 2-poleEuro-HYGIA ® II, 4-poleH[m]110100Euro-HYGIA II60 HzH[m]2826Euro-HYGIA II60 Hz9024/230807060/230/210/19022201816/2105014/190401230P2[kW]2520151050Eta[%]706560555045400 10 20 30 40 50 60 70 80 Q [m³/h]/230/210/1900 10 20 30 40 50 60 70 80 Q [m³/h]/230/210/190350NPSH10 20 30 40 50 60 70 80 Q [m³/h][m]510P20 10 20 30 40 50 60 Q [m³/h][kW]6/2305/2104/1903210Eta[%]706560555045400 10 20 30 40 50 60 Q [m³/h]/230/190/210350NPSH10 20 30 40 50 60 Q [m³/h][m]54/19043210/210/2300 10 20 30 40 50 60 70 80 Q [m³/h]0 5 10 15 20 Q [l/s]TM02 9748 44053210/230/210/1900 10 20 30 40 50 60 Q [m³/h]0 5 10 15 Q [l/s]TM02 9747 4405Euro-HYGIA ® II47

Technical dataEuro-HYGIA ® II60 HzEuro-HYGIA ® II Adapta ® on Adapta ® foot (frame size 180M)OptionAnnular housing with clamp ring (KLM)TM03 0056 3804Technical dataOn cast iron footP2 [kW] n [min -1 ] IEC size(1)k 3 u (1)22.0 3500 180M 605 265Dimensions depend on housing size (DN s , DN d , a 1 , h 2 , e 1 ), see table of connections on page 28.(1) Motor dimensions depend on make; maximum size for basic design given.(2) Other sizes and special connections are available on request.(4) Largest diameter of pump without motor.(7) N-Eupex coupling.(8) Option: Drain-Gemü membrane valve DN 15. Drain-clamp connection to DIN 32 676 DN 15 (45° angle).48

Technical dataEuro-HYGIA ® II60 HzEuro-HYGIA ® II Adapta ® on cast iron foot (frame size 100-160)OptionAnnular housing with clamp ring (KLM)TM03 0057 3804Technical dataOn cast iron footP2 [kW] n [min -1 ] IEC sizeb (1)k 3 u (1)2.2 1750 100L 0 320 1753.0 1750 100L 0 320 1753.0 3500 100L 0 320 1754.0 1750 112M 0 340 1854.0 3500 112M 0 340 1855.5 1750 132S 20 390 2055.5 3500 132S 20 390 2057.5 3500 132S 20 390 2057.5 1750 132M 20 420 20511.0 3500 160M 51 490 24015.0 3500 160M 51 490 24018.5 3500 160L 51 530 240Dimensions depend on housing size (DN s , DN d , a 1 , h 2 , e 1 ), see table of connections on page 28.(1) Motor dimensions depend on make; maximum size for basic design given.(2) Other sizes and special connections are available on request.(4) Largest diameter of pump without motor.(7) N-Eupex coupling.(8) Option: Drain-Gemü membrane valve DN 15. Drain-clamp connection to DIN 32 676 DN 15 (45° angle).49