Metal working machines - Optimum Maschinen

Metal working machines - Optimum Maschinen

Metal working machines - Optimum Maschinen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

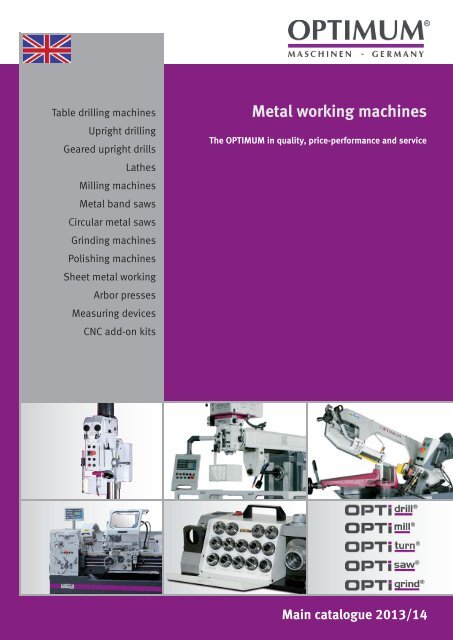

Table drilling <strong>machines</strong>Upright drillingGeared upright drillsLathesMilling <strong>machines</strong><strong>Metal</strong> band sawsCircular metal sawsGrinding <strong>machines</strong>Polishing <strong>machines</strong>Sheet metal <strong>working</strong>Arbor pressesMeasuring devicesCNC add-on kits<strong>Metal</strong> <strong>working</strong> <strong>machines</strong>The OPTIMUM in quality, price-performance and serviceMain catalogue 2013/14

<strong>Optimum</strong> factory, Yangzhou ChinaThe OPTIMUM guarantee of quality:All OPTIMUM products are produced with highquality requirements.QualityOPTIMUM products are produced with high quality standards. There are same or similar products on themarket, however, this products do not meet the OPTIMUM quality standards: OPTIMUM products are oftenimitated.DistributionOPTIMUM <strong>machines</strong> can be purchased from your competent specialized dealers on site. An area-wide networkof specialized dealers and sales partners - who are supported by the employees of OPTIMUM - are atyour disposal to help you with words and deeds.After-Sales-ServiceShould you require our after-sales service, we as well as your locally specialized dealer will be at your disposalwith an experienced service team. A comprehensive stock of spare parts is available at our headofficeso that we are able to supply spare parts at short notice, if necessary. Our service guarantees the best useof your machine for many years.Please use our free of charge phone hotline for any further questions: s: 0951 - 96 555 74Worldwide representationsAs a German company, OPTIMUM is <strong>working</strong> togetherwith competent partners in lots of countries worldwidefrom its company headquarters at Hallstadt/Bamberg.The international distribution network of OPTIMUM extendsworldwide over many countries.Kilian StürmerExecutive Direktor3 3

PlanningAlready during the planning phase our technical department intervenes in the development of new products which are manufacturedat our facility as well as at the facilities of our partners. In this way, all marketing influences and customer requirementsare immediately added where the future direction for a successful product design is set.Our technical department has a well-established team of technically highly qualified specialists.Their well-founded expertise allows flexible and creative implementation of all requirements whichare demanded for our product and services.DevelopmentThe development work is performed by creating a virtualmachine model using most modern 3D CAD software. In doingso, beside the optimum functionality of the machine we alsopay attention to the re-usability of the data which are createdduring the development phase. Such data do not only serve toelaborate manufacturing documents and documentations, butalso to establish calculations as well as for computer-aidedmanufacturing and to visualize and simulate the product.Testing in practiceOur engineers are combining theory and practice. Regardingproduct satisfaction we do not leave anything to chance;application-specific tests are performed on all <strong>machines</strong> andselected customers are consequently involved in this testing.In this way, any new product first has to prove itself during everydaywork before it is included in our range of products as aninherent part.. The technical analysis helps us to recognize andresolve any remaining weak points.4

Technical customer supportOur customers may rightly expect that our specialists are using theirknowledge and experience to their utmost satisfaction. Our productconsultants support the user with technical information. A free of chargephone hotline as well as an info mail account are available which ourcustomers may use in order to receive qualified informations or problemsolutions short term.PrefaceDrillingProtecting the copyrightIn order to continuously protect our technical development work for us aswell as for our customers, a patent and protection of registered designsis indispensable. In this way, we continuously maintain the technicaladvance of OPTIMUM products.TurningMillTechnical documentation and Risk analysisSawingOur technical authors are able to achieve a high standardized level whichcomplies with all legal requirements or even exceeds them. These enormousefforts only serve to easily introduce the machine to our customersas well as to guarantee the continuous and safe operation.In order to compensate the identified safety gaps, measures are takento minimize the risk in the frame of the analysis. Then an evaluation ofthe remaining residual risk is performed after having implemented thesemeasures.GrindingIndexLampsMeasuringPolishingSupply of replacement partsWe know that the rapid availability of spare parts is one of the basicrequirements for a satisfying, customer-focused service concept.At <strong>Optimum</strong> Machines Germany GmbH the planning, coordination andavailability of replacement parts are harmonized in a way to ensure maximumbenefit regarding economic efficiency and speed.Siemens cooperation partner for CNC trainingCNCSince many years Siemens is system supplier of the controland drive technology for the CNC controlled lathes and milling<strong>machines</strong> of <strong>Optimum</strong> Machines. For the CNC controlled lathesand milling <strong>machines</strong> of <strong>Optimum</strong> Machines Germany GmbH.Due to the long-term and successful cooperation a cooperationpartnership for the CNC training was agreed in June 20125

Supplier supportRegular meetings with our engineers contribute to transfer our new developments and enhancements aimed to serial production.This direct care at our manufacturing facilities is indispensable in order to produce the quality products in which ourcustomers trust since more than 20 years.We see the basis for a constantly high customer satisfaction and our current and futuremarket success in the clear technical orientation of our employees.Sales supportThe requirements in OPTIMUM <strong>machines</strong> are not less versatilethan the workpieces and manufacturing requirements of ourend customers. Our representatives and specialized dealersare at your disposal for any further questions with the wholeapplication-specific knowledge of our technicians.The customers are obtaining the support which is necessary toadapt the selected product to the corresponding requirementsin a qualified and informative sales conversation.Sales training and training of staff / customer trainingThe success in handling our products is mainly determined bypassing the technical knowledge on to the sales and serviceemployees by consequent internal training measures. Thisqualification forms the basis so that we are able to guaranteea skilled, qualified consultation and troubleshooting at anytime when a customer contacts us. This qualification alsoincludes our customers; we are providing workshops at ourfacility or training courses at the customer's premises.6

Production supportA team of employees directly influences the production process on site byregular training courses and tests. Only due to this intensive care at theproduction site we are able to achieve literally the OPTIMUM.PrefaceTurningPolishingDrillingQuality management incoming goods inspectionOur well trained quality manager from Germany is the first contact foradhering to quality on site.He is responsible for the dimensional accuracy of the components as wellas their control and the quality of the manufacturing process. He is closely<strong>working</strong> together with our technical department in the headquarters inGermany and thus forming an optimum symbiosis.MillQuality management outgoing goods inspectionBeside delivery reliability and service the quality of our products is ofhighest importance for us. Our quality is ensured by continuous internaland external monitoring on site by our well-trained and motivated qualitymanager.Our comprehensive outgoing goods inspection is performed according tothe general technical guidelines.SawingGrindingService support...because good service is important for us!Our OPTIMUM technicians are at your disposal to you at any time in caseof service in order to support the shop in performing a rapid and targetedrepair.Weak points are analysed and customer wishes noted in close cooperationwith the service centre and its internal and external employees. Thesepoints are evaluated under technical points of view and noted down inspecific requirement or measure catalogues.LampsMeasuringTwo-stage price-performance ratioWe subdivide our metal <strong>working</strong> <strong>machines</strong> into two categories with an"OPTIMUM" in quality and price-performance.CNCStandard linePremium line- <strong>Metal</strong> <strong>working</strong> <strong>machines</strong> for professionalcraftsmen and the industry.- Made in EURefer to the pages 8 to 9Index7

Premium <strong>machines</strong>Our Premium products are manufactured by our ISO certified subcontracted manufacturers in Europe. Beside a qualitatively high productionwe can also provide a considerably more rapid and flexible order processing.Beside a considerable gain in quality we can also provide technically and optically high quality products of high functional safety.This also includes the use of high quality components which are manufactured in Europe.With our premium <strong>machines</strong> “Made in EU” we offerin all areas OPTIMUM performance and reliability.Productionwith modern devices using high quality materials. The technicalknow-how in the stated manufacturing quality alreadyachieved big successes.All production steps are performed at one production site. Thisvertical integration ensures a very high quality standard.Quality testQuality production in the mechanical engineering is based ontarget-oriented development, production with most modernmachine technique and a high quality workforce.8

Final assemblyThe final assembly and commissioning of our PREMIUM<strong>machines</strong> provides added value and allows perfect long-term<strong>working</strong> with the machine.MeasuringPolishingPrefaceTurningSawingMillDrillingProduction<strong>Optimum</strong> Machines has very intensively examined the questionof quality. Therefore, we have chosen a production site for ourPREMIUM product line which is certified according to DIN EN ISO.FinishThe PREMIUM <strong>machines</strong> are manufactured for us with in this finish.These are the significant differentiating factors to a pretended "morecost-efficient" offer of our competitors.GrindingQuality assuranceCoordinate measurement on a 3-D measuring machine.With these comprehensive components of the measuring techniquethe 3-D scanning of 3-D materials not only provides a completepicture of complex surface geometries but also correlates themmeaningfully.LampsSupplier supportThe best precondition to deliver safe and high quality is a thoroughselection of suppliers as well as inspection of all usedproduction materials.The value of sound relations with our suppliers can generallybe measured in a good cooperation and by a high degree ofsatisfaction.CNCIndex9

Table of contentsDrilling <strong>machines</strong>Overview drilling <strong>machines</strong> ............... 12V-belt-<strong>machines</strong>B - SeriesB 13 - B 32 ............................ ............ 14Radial drilling <strong>machines</strong>RB 6T / RB 8S .................................... 16Pro-SeriesB 17Pro - B 33 Pro .............................. 18H-SeriesB 16H - B 34 H ................................... 20Vario-<strong>machines</strong>Pro Vario-SeriesB 23Pro Vario - B 33Pro Vario ............. 22H Vario-SeriesB 16HV - B 34HV ............................... 24DH-SeriesDH 24BV - DH 34BV ............................ . ... 26B 30BS Vario ........... .......................... 28Gear <strong>machines</strong>B 30VGM....... .................................... 30DH-SeriesDH 26GT - DH 32GS............................ . 32B 40E / B 40PTE............... .................. 34B 40GSP / B 40GSM .......................... 36B 50GSM .......................................... 38TU 2404 / TU 2404V / TU 2406V ........ 60TU 2506 / TU 2506VTU 2807 / TU 2807V .......................... 62D 320 x 630 / D 320 x 920 / DPA ........ 64TU 3209V ........................................... 66D 330 x 1000 / DPA ........................... 68D 360 x 1000 / DPA ........................... 70TU 3610V .......................................... .. 72D 420 x 1000 / D 420 x 1500..............74TU 4210V ........................................... . 76D 460 x 1000 bis 2000 DPA.................78TU 4615V .......................................... .. . 80D 560 x 1500 bis 3000 DPA.................82TU 5620V .......................................... .. . 84D 660 x 2000 / D 660 x 3000 DPA .......86TU 8020 / TU 8030............................. . 88Premium-<strong>machines</strong>TZ 4012 PREMIUM ............................. .. . 90TZ 5216 / TZ 6222 PREMIUM...............92. Accessories turnAccessories turn ................................ 95Milling <strong>machines</strong>Overview milling <strong>machines</strong> ............. 108PREMIUMPremium-<strong>machines</strong>DZ 25 / DZ 35 PREMIUM............... . . .... ....... 40DZ 40 / DZ 50 PREMIUM ..................... . 42Radial drilling <strong>machines</strong>DR-SeriesDR 4 - DR 6......................................... 44Accessories drillingAccessories drilling .. ......................... 46LathesOverview lathes ................................. 54Vario and conventionalTU 1503V ........................................... .55TU 2004V .......................................... 56TU 2304/TU 2304V ........................... . 58PREMIUMBF 16Vario ....................................... 110BF 20Vario / BF 20LVario .................. 112MH 28V ........................................... .. 114MB 4 ................................................ 116MB 4P ............................................. ..118F 40E ............................................... 120BF 30Vario ...................................... 122BF 46Vario / BF 46TC ....................... 124MF 1 Vario ....................................... 126MF 2 Vario /MF 4 Vario .................... 128MT 50 ............................................. . .. 130MT 100 / MT 200 ............................. . .. . 132MT 8 ................................................ .134MX-SeriesMX 2 - MX 4 ..................................... .. 13610 10

Accessories milAccessories mil ............................... 139<strong>Metal</strong> band sawsOverview of metal band saws ........... 150S 92G / S 122G ............................... 152S 100G ........................................... 153S 131GH .......................................... 154S 150G Vario ................................... 155S 181 .............................................. 156S 181G ........................................... 157S 210G / S 275G / Vario................... 158S 285DG ......................................... 160S 300DG / S 300DG Vario .................161S 310DG Vario ................................. 162S 350DG .......................................... 164SD 350AV ....................................... 166CS 275 / CS 315 .............................. 168Accessories sawMaterial stand MSR .......................... 170Grinding <strong>machines</strong>Drill bit grinderGH 10T / GH 15T ................ ..............176...Drill bit grinderGH 20T / GH 20TB ................ ............177.Drill bit grinderDG 20 ............................................. 178Belt and disc grinding machineDBS 75 ............................................ 179Double grindersQSM 150 - QSM 200 ........................ 180Double grindersSM 175 - SM 300 ............................. 181Grinding machineSM 200SL / SM 250SL ..................... 182Disc grinderTS 305 ............................................ 183Belt grinding <strong>machines</strong>BSM75/BSM 150 ............................. 184Polishing <strong>machines</strong>Polishing <strong>machines</strong>PSM 200 / PSM 250 ......................... 186Folding machineFP 30 .............................................. 1883-cylinder roundBM 3 ............................................... 188Steel sheet processing machineSAR 1000 ........................................ 189Alligator shearsPS 125 - PS 300 ............................... 190ViceWBS 135 ......................................... 191Arbor pressesDDP10 - DDP 5 ................................. 192LampsLED-and Halogenlamps ................... 194Measuring devicesMeasuring devices ........................... 196Digital magnetic measuringMPA - 4 ........................................... 197Digital position displayDPA 2000 ........................................ 198DPA 2000 S ...................................... 199NEWALL - DPA 700 ........................... 200CNCCNC-ControllerController III / VI ............................... 204CNC-Controller IV.............................. 206Complete and add-on kitfor BF 20 (L)Vario ............................. 208for BF 30 Vario / F40 E .. ................... 210for BF 46 Vario ................................ 212for TU2506 / TU2807 ...................... 214for D 320 x 630 / 920 / TU 3209V..... 216HousingsSHC 1 - SHC 7 .................................. 218Step motor controlPower Drive 1................................... 219CNC add-on kitMK F20X / MK RT1/MK RT2 ............... 219Software recommendationNCdrive ............................................ 222IndexCNCMeasuringLampsPolishingGrindingSawingMillTurningDrilling Preface11

Accessories for drilling <strong>machines</strong>Technical datas ofdrilling <strong>machines</strong> for general orientationConvincing arguments: quality, efficiency and priceV-beltMotor power kwDrilling capacity insteel max. Ø in mmSpindle seatThroat in mmSpeed ranges1/minB13 0,3 Ø 13 fixed B16 104 520-2620Infinitely variableSpeed controlCoolant equipment(Series)Tread cutting(Series)Autom. feedWorking lamp(Series)Quick-action drill chuck230V versionavailable400V versionavailableBench drillUpright drillingmachineGear drilling machineRadial drilling machineB14 0,35 Ø 14 fixed B16 104 520-2620B16 0,45 Ø 16 MT2 125 660 - 2500B20 0,55 Ø 20 MT2 170 210- 2220B25 0,55 Ø 20 MT3 170 210- 2220B 32 1,1 Ø 32 MT4 225 140-2020RB 6T 0,75 Ø 16 MT2 115-430 390-3000RB 8S 0,75 Ø 16 MT2 115-430 390-3000B 17 Pro 0,5 Ø 16 MT2 180 500-2520B 23 Pro 0,75 Ø 25 MT2 180 200-2440B 26 Pro 0,75 Ø 25 MT3 10 200-2440B 33 Pro 1,1 Ø 30 MT4 254 120-1810B 23 Pro Vario 0,75 Ø 25 MT2 180 30-3500B 26 Pro Vario 0,75 Ø 25 MT3 210 30-3500B 33 Pro Vario 1,5 Ø 30 MT4 254 20-3500B16H 0,55 Ø 13 MT2 130 450-3500B24 H 0,85 Ø 24 MT2 165 350-4000B28 H 0,85 Ø 28 MT3 200 120-4000B34 H 1,5/2,2 Ø 34 MT4 285 145-4800B16 HV 0,55 Ø 16 MT2 130 100-7500B24 HV 0,85 Ø 24 MT2 165 100-5950B28 HV 0,85 Ø 28 MT3 200 35-5600B34 HV 1,5/2,2 Ø 34 MT4 285 40-5000B30 BS 2,2 Ø 30 MT3 285 30-3900B 30 VGM 2,5 Ø 30 MT3 285 80 - 3000DH 26 GT 0,65 Ø 26 MT3 255 105 -2900autoDH 28 GS 0,65 Ø 26 MT3 255 105 -2900DH 32 GS 1,1/1,5 Ø 32 MT4 285 75 -2000B40 E 1,1/1,5 Ø 28 MT4 285 95 - 3200B40 PTE 1,1/1,5 Ø 32 MT4 285 95 - 3200mechan.B40 GSP 1,5 Ø 35 MT4 350 64 - 3060 mechan.B40 GSM 1,5 Ø 35 MT4 350 64 - 3060 elec magDZ 25 0,8 / 1,2 Ø 25 MT3 250 64 - 3060DZ 35 0,8 / 1,2 Ø 35 MT4 300 75 - 2100DZ 40 1,5 Ø 40 MT4 350 93 - 1420DZ 50 3 Ø 50 MT4 400 45 - 685B50 GSM 3/2,4 Ø 50 MT4 375 54 -2090 elec mag12

MillTurningDrilling13Drilling <strong>machines</strong>PrefacePlease find further information on „Accessories for drilling <strong>machines</strong>“ on page 4713IndexCNCMeasuringLampsPolishing GrindingSawing

B 13 / B 14 / B 16 / B 20 / B 25 / B 32Cost-efficient bench drills and upright drilling <strong>machines</strong> with V-beltConvincing arguments: quality, efficiency and price· Precisely machined <strong>working</strong> table, can be inclined by ± 45° and turnable by 360°· Solid, largely dimensioned base plate with slots, heavily ribbed at the rear side· 400 volt types equipped with cam switch for right-handed/left-handed rotation· Millionfold proven quality· Fully equipped machine, the user can immediately start to work productivelyfrom OPTI drill B 14 on· Smooth running and powerful quality aluminium electrical motor· Serial T-slots for vice fixtureV-beltFig.: B 13 Fig.: B 14 Fig.: B 16 Fig.: B 20Type B 13 B 14 B 16 B 20Item No 300 8131 300 8141 300 8161 300 8201(230V) 300 8203 (400V)€ plus VAT 149.00 199.00 289.00 379.00 419.00Machine datasElectrical connection 230 V / 1 Ph ~50 Hz 230 V / 1 Ph ~50 Hz 230 V / 1 Ph ~50 Hz 230 V / 1 Ph or 400 V / 3 PhMotor power 300 W 350 W 450 W 0.55 kWDrilling capacityDrilling capacity in steel (S235JR) Ø 13 mm Ø 14 mm Ø 16 mm Ø 20 mmContinuous drilling capacity in steel Ø 12 mm Ø 12 mm Ø 15 mm Ø 18 mmSpindle seatThroat 104 mm 104 mm 125 mm 170 mmSpindle seat fixed/B16 fixed/B16 MT 2 MT 2Spindle stroke 50 mm 50 mm 65 mm 80 mmSpeedsSpindle speeds 520 - 2'620 min -1 520 - 2'620 min -1 660 - 2'500 min -1 210 - 2'220 min -1Number of steps 5 steps 5 steps 5 steps 12 stepsDrilling tableTable size length x width 160 x 160 mm 160 x 160 mm 200 x 200 mm 275 x 275 mmT-slot size (slot width) 14 mm 14 mm 14 mm 14 mmDrilling table slewable/turnable ± 45° / 360° ± 45° / 360° ± 45° / 360° ± 45° / 360°Distance spindle - table (max.) 240 mm 330 mm 390 mm 465 mmWorking surface pedestal (L x W) 135 x 175 mm 140 x 180 mm 160 x 170 mm 205 x 200 mmDistance spindle - stand (max.) 325 mm 440 mm 525 mm 645 mmDimensionsColumn diameter 46 mm 46 mm 60 mm 70 mmLength x width x height 420 x 220 x 580 mm 420 x 230 x 700 mm 510 x 270 x 820 mm 600 x 350 x 990 mmNet weight 19 kg 21 kg 36 kg 53 kgStandard equipment14Gear rim drill chuck(1 - 13 mm)Quick-action drillchuck (0 - 13 mm)2 T-slotsQuick-action drill chuck (0 - 16 mm)Morse taper MT2, 2 T-slots

Convincing arguments...SawingMillDrillingPreface· High running smoothness thanks toground multi-toothed follower· Best power transmission due to aluminiumbelt pulleys in connection withtoothed GATES quality V-belt· V-belt cover with safety switchTurningFig.: B 25 Fig.: B 32Type B 25 B 32Item No 300 8253 300 8323€ plus VAT 479.00 799.00Machine datasElectrical connection 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 HzMotor power 0.55 kW 1.1 kWDrilling capacityDrilling capacity in steel (S235JR) Ø 20 mm Ø 32 mmContinuous drilling capacity in steel Ø 18 mm Ø 28 mmSpindle seatThroat 170 mm 225 mmSpindle seat MT 3 MT 4Spindle stroke 80 mm 125 mmSpeedsSpindle speeds 210 - 2'220 min -1 140 - 2'020 min -1Number of steps 12 steps 9 stepsDrilling tableTable size length x width 275 x 275 mm 360 x 360 mmT-slot size 14 mm 14 mmDrilling table slewable/turnable ± 45°/360° ± 45° /360°Distance spindle - table (max.) 760 mm 600 mmWorking surface pedestal 235 x 220 mm 260 x 270 mmDistance spindle - stand (max.) 1'210 mm 1'170 mmDimensionsColumn diameter Ø 70 mm Ø 92 mmLength x width x height 690 x 390 x 1'570 mm 790 x 400 x 1'730 mmNet weight 60 kg 135 kgQuick-action drill chuck (0 - 16 mm), 2 T-slotsStandard equipmentMorse taper MT 3 Morse taper MT 4· Guaranteed true running accuracyof better than 0.03 mm measured inthe drilling spindle· Drilling spindle with precision ballbearing· OPTIMUM quick-action drill chuckincluded in the standard scope ofdelivery· Long, ergonomic sleeve lever withSoftgrip handles for safe <strong>working</strong>· Drilling depth stop· User-friendly switch for IP 54 withundervoltage release,· Separate EMERGENCY-STOP pushbutton„Accessories for drilling <strong>machines</strong>“ on page 47IndexCNCMeasuringLampsPolishing Grinding15

RB 6T / RB 8SLight-weighted radial drilling machine with large throat to manufacture wood, plastic materialand aluminiumConvincing arguments: quality, efficiency and price· High running smoothness thanks to ground multi-toothed follower· Best power transmission due to aluminium belt pulleys in connectionwith toothed GATES quality V-belt· Drilling spindle with precision ball bearings· OPTIMUM sprocket wheel drill chuck included in the standard scope ofdelivery· <strong>Optimum</strong> price/performance ratio· Stable value· Fully equipped machine, the user can immediately start towork productivelyV-beltSafety switch· Easy-to-operate·Protection class IP 54· Undervoltage release· Separate EMERGENCY-STOPpush buttonElectric motor· Smooth running· Powerful· Aluminium housingDrilling depth stopDrilling spindle· Guaranteed true running accuracybetter than 0.03 mm measured inthe drilling spindle· Precision ball bearingsDrill chuck protection· Best possible protection of theuser· Height-adjustable· micro switchSpindle sleeve lever· Long, ergonomicallydesigned· Softgrip handles for safe<strong>working</strong>Drilling table· Precisely worked· RB 6T: Mounting holes forenlarged table support)· RB 8S: Transversally runningT-slotsSteel column· High smooth running andstabilityBase plate· Solid and largely dimensioned· Slots for T-slots· Heavily ribbed at the rear sideFig.: OPTI drill RB 6TFig.: OPTI drill RB 8S16

Technical data and accessoriesType RB 6T RB 8SItem No 300 9161 300 9181€ plus VAT 349.00 409.00PrefaceMachine datasElectrical connection230 V / 1 Ph ~50 HzMotor power750 WDrilling capacityDrilling capacity in steel (S235JR)Ø 16 mmContinuous drilling capacity in steel (S235JR)Ø 12 mmSpindle seatSpindle seat MT 2Throat115 - 430 mmSpindle stroke80 mmSpeedsSpindle speeds 390 - 3'000 min -1Number of steps5 stepsDrilling tableTable size length x width 225 x 230 mm 262 x 262 mmSlot size14 mmDrilling table inclinable ± 45 0Distance spindle - table (max.) 380 mm 740 mmDistance spindle - stand (max.) 550 mm 1,250 mmDimensionsColumn diameter Ø 60 mm Ø 70 mmLength x width x height 820 x 290 x 930 mm 820 x 290 x 1'640 mmTotal weight 40 kg 63 kgSawingMillTurning DrillingStandard equipmentAccessories Item No € plus VATClamping tool kit SPW12 335 2017 79.00· T-slots 14 mm . Draw bar thread M 12· Metric threadsCone drill drift MSP 1 305 0636 22.50Twist drill HSS MT 2 305 1002 139.00· Right hand cutting . 9-piecesGear rim drill chuck (1-16 mm) B 16Morse taper MT 2 - B 16Accessories Item No € plus VATTwist drill Kit coated with titanium 305 1010 41.00· 25 pcs; drill bit sizes 1 -13 mmMachine vice MSO 100 300 0100 23.90Machine vice MSO 75 300 0075 21.90· Many assembly options on the drilling table by oblong holes· Exact jaw guidingGrindingPolishingIndexCNCLampsConvincing arguments...Please find further information on „Accessories for drilling <strong>machines</strong>“ on page 47Measuring· The drill head can be inclinedby ± 45°· Variable throat by shifting the drilling head· The <strong>working</strong> table can be inclinedby ± 45°17

B 17Pro / B 23Pro / B 26Pro / B 33ProRobust bench drills and upright drilling <strong>machines</strong> with V-belt driveConvincing arguments: quality, efficiency and price· Smooth running and powerful electrical motor· Easy-to-operate safety switch according to IP 54 with undervoltage releaseand separate EMERGENCY-STOP push button· 400 volt types with right-handed/left-handed rotation· Drilling depth stop· Precisely worked <strong>working</strong> table with diagonally running T-slots· Height adjustment of the drilling table via toothed rack· The <strong>working</strong> table can be inclined by ± 45° and turned by 360°· V-belt cover with safety switch· Aluminium die-cast sleeve lever made of one piece with Softgrip handles· Solid, largely dimensioned base plate with slots, heavily ribbed at the rearside (for OPTI drill B 33Pro T-slots)· Heavy type of the whole machineV-beltFig.: B 17ProFig.: B 23ProFig.: B 26ProFig.: B 33ProBelt drive· High running smoothness thanks to groundmulti-toothed follower· Best power transmission due to aluminium beltpulleys in connection with toothed GATES qualityV-belt· Guaranteed true running accuracy 0.02 mmmeasured in the drilling spindle· Drilling spindle with precision ball bearings· High-quality quick-action drill chuck as· Largely dimensioned, height adjustable protectivescreen with safety switch18

Technical data and accessoriesType B 17Pro B 23Pro B 26Pro B 33ProItem No (230 V) 300 3171 300 3231 (230 V) - -€ plus VAT 349.00 539.00 - -Item No (400 V) - 300 3233 (400 V) 300 3263 300 3333€ plus VAT - 549.00 619.00 959.00Machine datasElectrical connection 230 V / 1 Ph ~50 Hz 230 V/1 Ph or 400 V/3 Ph 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 HzMotor power 500 W 750 W 750 W 1.1 kWDrilling capacityDrilling capacity in steel (S235JR) Ø 16 mm Ø 25 mm Ø 25 mm Ø 30 mmContinuous drilling capacity in steel Ø 12 mm Ø 20 mm Ø 20 mm Ø 25 mmSpindle seatSpindle stroke 65 mm 80 mm 85 mm 120 mmSpindle seat MT 2 MT 2 MT 3 MT 4Throat 152 mm 180 mm 210 mm 254 mmSpeedsSpindle speeds 500 - 2'520 min -1 200 - 2'440 min -1 200 - 2'440 min -1 120 - 1'810 min -1Number of steps 5 steps 12 steps 12 steps 9 stepsDrilling tableWork surface table length x width 235 x 220 mm 280 x 245 mm 330 x 290 mm 475 x 425 mmT-slot size 12 mm 12 mm 14 mm 14 mmDrilling table slewable/turnable ± 45° / 360° ± 45° / 360° ± 45° / 360° ± 45° / 360°Distance spindle - table (max.) 325 mm 425 mm 720 mm 695 mmWork surface stand length x width 220 x 230 mm 240 x 250 mm 385 x 260 mm 410 x 270 mmDistance spindle - stand (max.) 530 mm 618 mm 1'230 mm 1'180 mmDimensionsColumn diameter Ø 60 mm Ø 73 mm Ø 80 mm Ø 92 mmLength x width x height 600 x 260 x 860 mm 654 x 330 x 1'012 mm 700 x 350 x 1'670 mm 860 x 480 x 1'720 mmTotal weight 39 kg 66 kg 82 kg 135 kgStandard equipment Morse taper MT 2 - B 16 Morse taper MT 3 - B 16 Morse taper MT 4 - B 16Quick-action drill chuck (3 - 16 mm) B16T-slotsGrindingSawingMillTurning DrillingPrefaceAccessories OPTI drill B 17Pro / B 23Pro Item No € plus VATDirect quick-action drill chuck:MT 2 / 1 - 16 mm 305 0571 76.00MT 2 / 1 - 13 mm 305 0572 66.50Morse taper MT 2 - B16 305 0659 5.00Twist drill kit coated with titanium 13mm 305 1010 41.00Twist drill HSS / MT 2 305 1002 139.00Clamping tool kit SPW 10 335 2016 69.00Cone drill drift MSP1 305 0636 22.50Universal coolant equipment 230 V 335 2002 189.00Machine vices Item No € plus VATBMS 100 300 0010 39.90BMS 120 300 0012 49.90BSI 100 300 0210 125.00BSI 140 300 0214 179.00BSI-Q 100 300 0230 139.00BSI-Q 140 300 0240 259.00Fig.: BMS Fig.: BSI Fig.: BSI-QAccessories OPTI drill B 26Pro Item No € plus VATDirect quick-action drill chuck MT3 305 0573 76.50Reducing bushes MT 3 - MT 2 305 0663 7.70Morse taper MT 3 - B16 305 0660 8.10Twist drill kit coated with titanium 13mm 305 1010 41.00Twist drill HSS / MT 3 305 1003 139.00Clamping tool kit SPW 12 335 2017 79.00Cone drill drift MSP1 305 0636 27.50Tapping chuck M5-M12 335 2042 349.00Universal coolant equipment 400 V 335 2001 189.00Accessories OPTI drill B 33Pro Item No € plus VATDirect quick-action drill chuck MT4 305 0574 76.50Reducing bushes MT 4 - MT 3 305 0664 12.30Morse taper MT 4 - B16 305 0661 13.20Twist drill kit coated with titanium 13mm 305 1010 41.00Twist drill HSS / MT 3 305 1003 139.00Clamping tool kit SPW 12 335 2017 79.00Cone drill drift MSP2 305 0637 27.50Tapping chuck M5-M12 335 2042 349.00Universal coolant equipment 400 V 335 2001 189.00Please find further information on „Accessories for drilling <strong>machines</strong>“ on page 4719IndexCNCMeasuringLampsPolishing

B 16H / B 24H / B 28H / B 34HRobust bench drills and upright drilling <strong>machines</strong> with V-belt driveConvincing arguments: quality, efficiency and price· Smooth running and powerful electrical motor· Separate EMERGENCY-STOP push button· 400 volt types with right-handed/left-handed rotation· Drilling depth stop· Precisely worked <strong>working</strong> table with diagonally running T-slots· The <strong>working</strong> table can be turned by 360°· V-belt cover with safety switch· V-belt tensioning device· Long, ergonomic aluminium die-cast sleeve lever made of one piecewith Softgrip handles (OPTI drill B 16H / B 24H)· Sleeve lever made of steel (OPTI drill B 28H / B 34H )· Solid, largely dimensioned base plate with slots, heavily ribbed at therear side· Usable as a <strong>working</strong> surface for extra high workpieces due to therotatable drill tablefrom OPTI drill B 24H on:· Machine lampfrom OPTI drill B 28H on:· Easy tool change due to integrated drill driftOPTI drill B 34 H:· Digital depth gauge· Digital speed displayV-beltFig.: B 16 HFig.: B 24 HFig.: B 28 HFig.: B 34 HBelt drive· High running smoothness thanks to groundmulti-toothed follower· Best power transmission due to aluminium beltpulleys in connection with toothed GATES qualityV-belt· Guaranteed true running accuracy of better than0.015 mm measured in the drilling spindle· Drilling spindle with precision ball bearings· High-quality <strong>Optimum</strong> quick-action drill chuck as· Largely dimensioned, height adjustable protectivescreen with safety switch20

Technical data and accessoriesType B 16H B 24H B 28H B 34HItem No (230 V) 302 0217 302 0241 - -Item No (400 V) - 302 0243 302 0283 302 0333€ plus VAT 599.00 1'099.00 1'319.00 2'090.00PrefaceMachine datasElectrical connection 400V / 3Ph ~50 Hz 230 V/1 Ph or 400 V/3 Ph 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 HzMotor power 550 W 850 W 850 W 1.5/2.2 kWDrilling capacityDrilling capacity in steel (S235JR) Ø 13 mm Ø 24 mm Ø 28 mm Ø 34 mmCont. drilling capacity in steel (S235JR) Ø 11 mm Ø 20 mm Ø 24 mm Ø 26 mmSpindle seatSpindle stroke 65 mm 85 mm 105 mm 160 mmSpindle seat MT 2 MT 2 MT 3 MT 4Throat 130 mm 165 mm 200 mm 285 mmSpeedsSpindle speeds 450 - 3'500 min -1 350 - 4'000 min -1 120 - 4'000 min -1 145 - 4'800 min -1Number of steps 5 steps 7 steps 16 steps 2 x 9 stepsDrilling tableWork surface table length x width 230 x 245 mm 280 x 300 mm 340 x 360 mm 420 x 400 mmT-slot size 12 mm 14 mm 14 mm 14 mmDrilling table turnable 360° 360° 360° 360°Distance spindle - table (max.) 370 mm 515 mm 860 mm 790 mmWork surface stand length x width 200 x 240 mm 280 x 260 mm 320 x 320 mm 390 x 390 mmDistance spindle - stand (max.) 495 mm 681 mm 1'275 mm 1'275 mmDimensionsColumn diameter Ø 60 mm Ø 80 mm Ø 92 mm Ø 115 mmLength x width x height 549 x 300 x 848 mm 665 x 434 x 998 mm 698 x 449 x 1'721 mm 918 x 585 x 1'895Total weight 65 kg 84 kg 140 kg 274 kgStandard equipmentQuick-action drill chuck(1 - 13 mm)Quick-action drill chuck(1 - 16 mm)Quick-action drill chuck(1 - 16 mm)Quick-action drill chuck(1 - 16 mm)Morse taper MT 2 Morse taper MT 2 Morse taper MT 3 Morse taper MT 4T-slots T-slots T-slots T-slotsGrindingSawingMillTurning DrillingTransportation packaging flat rateplus VAT- - TPFR 1 = € 19.00 TPFR 1 = € 19.00PolishingAccessories OPTI drill B 16H / B 24H Item No € plus VATDirect quick-action drill chuck:MT2/ 1 - 16 mm 305 0571 76.00MT2/ 1 - 13 mm 305 0572 66.50Morse taper MT 2 - B16 305 0659 5.00Twist drill kit coated with titanium 305 1010 41.00Twist drill HSS / MT 2 305 1002 139.00Clamping tool kit SPW 10 335 2016 69.00Universal coolant equipment 230 V 335 2002 189.00Universal coolant equipment 400 V 335 2001 189.00Accessories OPTI drill B 28H Item No € plus VATDirect quick-action drill chuck305 0573 76.50MT3/0.3-16 mmReducing bushes MT 3 - MT 2 305 0663 7.70Morse taper MT 3 - B16 305 0660 8.10Twist drill kit coated with titanium 305 1010 41.00Twist drill HSS / MT 3 305 1003 139.00Clamping tool kit SPW 12 335 2017 79.00Universal coolant equipment 400 V 335 2001 189.00Tapping chuck M5-M12 335 2042 349.00LampsMeasuringMachine vices Item No € plus VATBSI 100 300 0210 125,00BSI 140 300 0214 179,00BSI-Q 100 300 0230 139,00BSI-Q 140 300 0234 199,00Accessories OPTI drill B 34H Item No € plus VATDirect quick-action drill chuck.305 0574 76.50MT4/1-16 mmReducing bushes MT 4 - MT 3 305 0664 12.30Morse taper MT 4 - B16 305 0661 13.20Twist drill kit coated with titanium 305 1010 41.00Clamping tool kit SPW 12 335 2017 79.00Universal coolant equipment 400 V 335 2001 189.00Tapping chuck M5-M12 335 2042 349.00CNCIndexFig.: BSIFig.: BSI-QPlease find further information on „Accessories for drilling <strong>machines</strong>“ on page 4721

B 23Pro Vario / B 26Pro Vario / B 33Pro VarioRobust bench drills and upright drilling <strong>machines</strong> with V-belt drive, electrically adjustablespeed for continuous useConvincing arguments: quality, efficiency and price· 12 steps, speed electronically variable on B 23Pro Vario and B 26Pro Vario· 9 steps, electronically adjustable speed on B 33Pro Vario· High torque for all speed settings· Heavy type of the whole machine· Fully equipped machine, the user can immediately start to work productivelyVarioV-belt covering· with safety switchBelt drive· Best power transmission due toaluminium belt pulleys in connectionwith toothed GATES qualityV-belt· High running smoothness thanksto ground multi-toothed followerAluminium die-cast sleeve lever· Long and ergonomically· One-piece casting· Softgrip handles for safe <strong>working</strong>Speed control· by means of apotentiometerTrue running accuracy· Guaranteed 0.02 mm measuredin the drilling spindleDrilling spindle· Precision ball bearing· High-quality - quickactiondrill chuck as standardIndustrial motor withfrequency converterMade in Germany· Smooth running· Durable· Extreme high-torqueDrilling depth stopChuck guard· Best possible protection ofthe user· Height-adjustable· micro switchDrilling table· Precisely worked· Transversally running T-slots· Inclined by ± 45° / turnable by 360°Drilling table support· Robust and thick-walledSteel column· Thick-walled· High power absorption andstability· 5 times screwed togetherBase plate· Solid· Largely dimensioned· Heavily ribbed at the rear sideFig.: OPTI drill B 23Pro VarioFig.: OPTI drill B 33Pro Vario22

Technical data and accessoriesType B 23Pro Vario B 26Pro Vario B 33Pro VarioItem No 301 1233 301 1263 301 1333€ plus VAT 1'299.00 1'419.00 1'749.00PrefaceMachine datasElectrical connection 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 HzMotor power 750 W 750 W 1.5 kWDrilling capacityDrilling capacity in steel (S235JR) Ø 25 mm Ø 25 mm Ø 30 mmContinuous drilling capacity in steel Ø 20 mm Ø 20 mm Ø 25 mmSpindle seatSpindle stroke 80 mm 85 mm 120 mmSpindle seat MT 2 MT 3 MT 4Throat 180 mm 210 mm 254 mmSpeedsSpindle speeds 60 - 3'500 min -1 60 - 3'500 min -1 20 - 3'500 min -112 steps,electrically adjustable speed12 steps,electrically adjustable speed9 steps,electrically adjustable speedNumber of stepsDrilling tableWork surface table length x width 280 x 245 mm 330 x 290 mm 475 x 425 mmT-slot size 12 mm 14 mm 14 mmDrilling table slewable ± 45° ± 45° ± 45°Drilling table turnable 360° 360° 360°Distance spindle - table (max.) 425 mm 720 mm 695 mmWork surface stand length x width 240 x 250 mm 385 x 260 mm 410 x 270 mmDistance spindle - stand (max.) 610 mm 1'230 mm 1'180 mmDimensionsColumn diameter Ø 73 mm Ø 80 mm Ø 92 mmLength x width x height 660 x 320 x 1'010 mm 710 x 350 x 1'670 mm 870 x 480 x 1'720 mmTotal weight 75 kg 90 kg 140 kgStandard equipment Morse taper MT 2 - B 16 Morse taper MT 3 - B 16 Morse taper MT 4 - B 16Quick-action drill chuck (3 - 16 mm) B16T-slotsGrindingSawingMillTurning DrillingAccessories OPTI drill B 23Pro Vario Item No € plus VATDirect quick-action drill chuck:MT2/ 1 - 16 mm 305 0571 76.00MT2/ 1 - 13 mm 305 0572 66.50Morse taper MT 2 - B16 305 0659 5.00Twist drill kit coated with titanium 13mm 305 1010 41.00Twist drill HSS / MT 2 305 1002 139.00Clamping tool kit SPW 10 335 2016 69.00Cone drill drift MSP1 305 0636 22.50Universal coolant equipment 400 V 335 2001 189.00Machine vices Item No € plus VATBMS 100 300 0010 39.90BMS 120 300 0012 49.90BSI 100 300 0210 125.00BSI 140 300 0214 179.00BSI-Q 100 300 0230 139.00BSI-Q 140 300 0240 259.00Accessories OPTI drill B 26Pro Vario Item No € plus VATDirect quick-action drill chuck. MT3 305 0573 76.50Reducing bushes MT 3 - MT 2 305 0663 7.70Morse taper MT 3 - B16 305 0660 8.10Twist drill kit coated with titanium 13mm 305 1010 41.00Twist drill HSS / MT 3 305 1003 139.00Clamping tool kit SPW 12 335 2017 79.00Cone drill drift MSP1 305 0636 27.50Tapping chuck M5-M12 335 2042 349.00Universal coolant equipment 400 V 335 2001 189.00Accessories OPTI drill B 33Pro Vario Item No € plus VATDirect quick-action drill chuck. MT4 305 0574 76.50Reducing bushes MT 4 - MT 3 305 0664 12.30Morse taper MT 4 - B16 305 0661 13.20Twist drill kit coated with titanium 13mm 305 1010 41.00Twist drill HSS / MT 3 305 1003 139.00Clamping tool kit SPW 12 335 2017 79.00Cone drill drift MSP2 305 0637 27.50Tapping chuck M5-M12 335 2042 349.00Universal coolant equipment 400 V 335 2001 189.00IndexCNCMeasuringLampsPolishingFig.: BMS Fig.: BSI Fig.: BSI-QPlease find further information on „Accessories for drilling <strong>machines</strong>“ on page 4723

B 16HV / B 24HV / B 28HV / B 34HVBench drills and upright drilling <strong>machines</strong> with powerful OPTIMUM Brushless drive,electronically adjustable speedConvincing arguments: quality, efficiency and price· Smooth running and powerful electrical motor· Easy-to-operate safety switch according to IP 54 with undervoltage releaseand separate EMERGENCY-STOP push button· Largely dimensioned, height-adjustable screening grid with safety switchfor best possible protection of the user· Long, ergonomic aluminium die-cast sleeve lever made of onepiece with Softgrip handles (OPTI drill B 16HV / B 24HV)· Sleeve lever made of steel (OPTI drill B 28HV/ B 34HV)· Drilling depth stop· V-belt cover with safety switchVarioPowerful Brushless drive· Particularly smooth running· High power output· Nearly constant torque overthe entire speed rangefrom OPTI drill B 24HV on:· Right-/left handed rotationfrom OPTI drill B 28HV on:· Coolant equipment· New chips filter according to machinery directive· Easy tool change due to integrated drill driftOPTI drill B 34HV :· Spindle stroke 160 mm· Threading functionOPTI drill B 34 HVOperating mode "auto"· Motor is starting up automatically after moving the lever· Stops again in the initial positionauto · It is not necessary to actuate the push button startand stop repeatedly for repeated drilling tasksOperating mode "Threading"· The engine is being activated by moving the gripdownward· The direction of rotation is changed by pressing thelimit switch on the adjustable drilling depth stopBelt drive· Best power transmission due toaluminium belt pulleys in connectionwith toothed GATES qualityV-belt· High running smoothness thanksto ground multi-toothed followerDigital speed display· Easy-to-read· Integrated in the housingSpeed control· by means of a potentiometerTrue running accuracy· Guaranteed 0.015 mmmeasured in the drillingspindleDrilling spindle· Precision ball bearing· High-quality OPTIMUMquick-action drill chuck asstandardDrilling depth gauge· Digital· Accuracy of the display0.01 mm (B 34HV)V-belt tensioning deviceMachine lamp· Integrated in the drillhead· Halogen lampDrilling table· Precisely worked· Transversally runningT-slots· turnable by 360°Casting column· Thick-walled· High power absorptionand stabilityBase plate· Solid· Largely dimensioned· Heavily ribbed at the rear sideFig.: OPTI drill B 24HV24

Technical data and accessoriesType B 16HV B 24HV B 28HV B 34HVItem No 302 0218 302 0245 302 0285 302 0335€ plus VAT 1'399.00 1'999.00 2'400.00 2'890.00PrefaceMachine datasElectrical connection 230 V / 1 Ph ~50 Hz 230 V / 1 Ph ~50 Hz 230 V / 1 Ph ~50 Hz 230 V / 1 Ph ~50 HzMotor power 1.5 kW 1.5 kW 1.5 kW 2.2 kWDrilling capacityDrilling capacity in steel (S235JR) Ø 16 mm Ø 24 mm Ø 28 mm Ø 34 mmContinuous drilling capacity in steel Ø 13 mm Ø 20 mm Ø 24 mm Ø 26 mmSpindle seatSpindle stroke 65 mm 85 mm 105 mm 160 mmSpindle seat MT 2 MT 2 MT 3 MT 4Throat 130 mm 165 mm 200 mm 285 mmSpeedsSpindle speeds 100 - 6'000 min -1 100 - 5'950 min -1 35 - 5'600 min -1 40 - 5'000 min -1No of speeds, electrically adjustable speed 5 steps 4 steps 12 steps 9 stepsDrilling tableWork surface table length x width 230 x 245 mm 280 x 300 mm 340 x 360 mm 420 x 400 mmT-slot size 12 mm 14 mm 14 mm 14 mmDrilling table turnable 360° 360° 360° 360°Distance spindle - table (max.) 370 mm 515 mm 860 mm 790 mmWork surface stand length x width 200 x 240 mm 280 x 260 mm 320 x 320 mm 390 x 390 mmDistance spindle - stand (max.) 495 mm 681 mm 1'275 mm 1'275 mmDimensionsColumn diameter Ø 60 mm Ø 80 mm Ø 92 mm Ø 115 mmLength x width x height 540 x 370 x 850 mm 665 x 434 x 998 mm 701 x 474 x 1'755 mm 918 x 595 x 1'930 mmTotal weight 65 kg 85 kg 141 kg 290 kgSawingMillTurning DrillingStandard equipmentOPTIMUM quality quickactiondrill chuck(1 - 13 mm)OPTIMUM quality quickactiondrill chuck(1 - 16 mm)OPTIMUM qualityquick-action drill chuck(1 - 16 mm)OPTIMUM qualityquick-action drill chuck(1 - 16 mm)Morse taper MT 2 Morse taper MT 2 Morse taper MT 3 Morse taper MT 4T-slots T-slots T-slots T-slotsGrindingTransportation packaging flat rate plus VAT - - TPFR 1 = € 19.00 TPFR 1 = € 19.00PolishingAccessories OPTI drill B 16HV / B 24HV Item No € plus VATDirect quick-action drill chuck:MT2/ 1 - 16 mm 305 0571 76.00MT2/ 1 - 13 mm 305 0572 66.50Morse taper MT 2 - B16 305 0659 5.00Twist drill kit coated with titanium 13mm 305 1010 41.00Twist drill HSS / MT 2 305 1002 139.00Clamping tool kit SPW 10 335 2016 69.00Accessories OPTI drill B 28HV Item No € plus VATDirect quick-action drill chuck. MT3 305 0573 76.50Reducing bushes MT 3 - MT 2 305 0663 7.70Morse taper MT 3 - B16 305 0660 8.10Twist drill kit coated with titanium 13mm 305 1010 41.00Twist drill HSS / MT 3 305 1003 139.00Clamping tool kit SPW 12 335 2017 79.00Tapping chuck M5-M12 335 2042 349.00LampsMeasuringMachine vices Item No € plus VATBSI 100 300 0210 125,00BSI 140 300 0214 179,00BSI-Q 100 300 0230 139,00BSI-Q 140 300 0234 199,00Accessories OPTI drill B 34HV Item No € plus VATDirect quick-action drill chuck. MT4 305 0574 76.50Reducing bushes MT 4 - MT 3 305 0664 12.30Morse taper MT 4 - B16 305 0661 13.20Twist drill kit coated with titanium 305 1010 41.00Clamping tool kit SPW 12 335 2017 79.00Tapping chuck M5-M12 335 2042 349.00IndexCNCFig.: BSIFig.: BSI-QPlease find further information on „Accessories for drilling <strong>machines</strong>“ on page 4725

DH 24 BV / DH 28 BV / DH 34 BVBench drills and upright drilling <strong>machines</strong> with infinitely variable mechanical gearboxConvincing arguments: quality, efficiency and price· Smooth running and powerful electrical motor· Easy-to-operate safety switch according to IP 54 with undervoltage releaseand separate EMERGENCY-STOP push button· Long, ergonomic aluminium die-cast sleeve lever made of one piecewith Softgrip handles (DH 24BV)· Sleeve lever made of steel (DH 28BV/ DH 34BV)· Usable as a <strong>working</strong> surface for extra high workpieces due to the rotatabledrill table· Right-/left handed rotation· 2 speed stages· V-belt cover with safety switchVarioVARIO DRIVEmadeinGermany· Fully equipped machine, the user canimmediately start to work productivelyfrom OPTI drill DH 28BV on· Easy tool change due to integrated drill driftOPTI drill DH 34BV· Digital depth gaugeInfinitely variable mechanical gearbox· Extremely reliable due to manualspeed regulation· Powerful smooth running· Durable V-belt· Speed modification while the motoris running· Permanently optimum efficiencydegree of the motorDigital speed display· Easy-to-read· Integrated in the housingTrue running accuracy· Guaranteed 0.015 mmmeasured in the drillingspindleChuck guard· Best possible protection ofthe user· Height-adjustable· micro switchMachine lamp· Integrated in the drill head· Halogen lampDrilling spindle· Precision ball bearing· High-quality quick-actiondrill chuck as standardDrilling table· Precisely worked· Transversally runningT-slots· turnable by 360°Casting column· Thick-walled· High power absorptionand stabilityBase plate· Solid· Largely dimensioned· Heavily ribbed at the rear sideFig.: OPTI drill DH 24BVFig.: OPTI drill DH 34BV26

Technical data and accessoriesType DH 24BV DH 28BV DH 34BVItem No 302 0420 302 0430 302 0440€ plus VAT 1'890.00 2'100.00 2'690.00PrefaceMachine datasElectrical connection 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 HzMotor power 1.5 / 0.85 kW 1.5 / 0.85 kW 1.5 / 2.2 kWDrilling capacityDrilling capacity in steel (S235JR) Ø 24 mm Ø 28 mm Ø 34 mmContinuous drilling capacity in steel Ø 20 mm Ø 24 mm Ø 26 mmSpindle seatSpindle stroke 85 mm 105 mm 160 mmSpindle seat MT 2 MT 3 MT 4Throat 165 mm 200 mm 285 mmSpeedsSpindle speeds 300 - 4'000 min -1 300 - 4'000 min -1 300 - 4'000 min -12 steps 2 steps 2 stepsDrilling tableWork surface table length x width 280 x 300 mm 340 x 360 mm 420 x 400 mmT-slot size 14 mm 14 mm 14 mmDrilling table turnable 360° 360° 360°Distance spindle - table (max.) 515 mm 860 mm 790 mmWork surface stand length x width 280 x 260 mm 320 x 320 mm 390 x 390 mmDistance spindle - stand (max.) 681 mm 1'275 mm 1'025 mmDimensionsColumn diameter Ø 80 mm Ø 92 mm Ø 115 mmLength x width x height 665 x 434 x 1,000 mm 701 x 474 x 1'780 mm 918 x 595 x 1'960 mmTotal weight 80 kg 160 kg 270 kgStandard equipmentOPTIMUM quality quick-action drillchuck (1 - 16 mm)OPTIMUM quality quick-action drillchuck (1 - 16 mm)Morse taper MT 2 Morse taper MT 3 Morse taper MT 4T-slots T-slots T-slotsOPTIMUM quality quick-action drillchuck (1 - 16 mm)GrindingSawingMillTurning DrillingTransportation packaging flat rate - TPFR 1 = € 19.00 plus VAT TPFR 1 = € 19.00 plus VATAccessories DH 24BV Item No € plus VATDirect quick-action drill chuck:MT2/ 1 - 16 mm 305 0571 76.00MT2/ 1 - 13 mm 305 0572 66.50Morse taper MT 2 - B16 305 0659 5.00Twist drill kit coated with titanium 305 1010 41.00Twist drill HSS / MT 2 305 1002 139.00Clamping tool kit SPW 10 335 2016 69.00Universal coolant equipment 230 V 335 2002 189.00Machine vices Item No € plus VATBSI 100 300 0210 125,00BSI 140 300 0214 179,00BSI-Q 100 300 0230 139,00BSI-Q 140 300 0234 199,00Accessories DH 28BV Item No € plus VATDirect quick-action drill chuck. MT3 305 0573 76.50Reducing bushes MT 3 - MT 2 305 0663 7.70Morse taper MT 3 - B16 305 0660 8.10Twist drill kit coated with titanium 305 1010 41.00Twist drill HSS / MT 3 305 1003 139.00Clamping tool kit SPW 12 335 2017 79.00Universal coolant equipment 400 V 335 2001 189.00Tapping chuck M5-M12 335 2042 349.00Accessories DH 34BV Item No € plus VATDirect quick-action drill chuck. MT4 305 0574 76.50Reducing bushes MT 4 - MT 3 305 0664 12.30Morse taper MT 4 - B16 305 0661 13.20Twist drill kit coated with titanium 305 1010 41.00Clamping tool kit SPW 12 335 2017 79.00Tapping chuck M5-M12 335 2042 349.00IndexCNCMeasuringLampsPolishingFig.: BSIFig.: BSI-QPlease find further information on „Accessories for drilling <strong>machines</strong>“ on page 4727

B 30BS VarioUpright drilling machine with powerful OPTIMUM Brushless drive, electronically adjustable speedConvincing arguments: quality, efficiency and price· Smooth running and powerful DC drive with excellent controlcharacteristics· High running smoothness thanks to ground multi-toothed follower· Vario Speed (4 belt stages with electronically adjustable speed)· Best power transmission due to aluminium belt pulleys in connectionwith GATES 7 M industrial V-belts· Emergency-stop push button· Drilling spindle with precision ball bearings· Right-/left handed rotation· Triple sleeve lever made of steel· Adjustable drilling depth stopPowerful Brushless driveVarioV-belt covering· with safety switch· Particularly smooth running· High power output· Nearly constant torque over the entirespeed rangeQuick-action belt clamping of the belt· Quick-action belt clamping of the beltvia eccentricSpindle locking withintegrated drill drift:· for a simple tool changeControl panel· Digital speed display· Emergency-stop push button· Selector switch operating mode/rotatingdirection· Digital depth gauge accuracy of the display0.01 mmMachine lamp· Integrated in the drill head· Halogen lampCasting column· Thick-walled· For high power absorption andstabilityChuck guard· Best possible protection of the user· Height-adjustable· micro switchDrilling table· Largely dimensioned· Solid· Precisely worked· Transversally running T-slots· Heavily ribbed at the rear side· Double clampedBase plate· Usable as a <strong>working</strong> surface for extrahigh workpieces due to the rotatabledrill table· Solid· Precisely machined at the surfaceChip filter· cleans the coolant fromrough components· according to the machinedirectiveCoolant equipment· Coolant tank integrated inthe base plate· Tank capacity of coolant tank4.5 litresFig.: OPTI drill B 30BS Vario28

Technical data and dimensionsTypeB 30BS VarioItem No 302 1303€ plus VAT 3'350.00DimensionsPrefaceMachine datasElectrical connection230 V / 1 Ph ~50 HzTotal connected value2.2 kWMotor coolant pump40 WDrilling capacityDrilling capacity in steel (S235JR)Ø 30 mmContinuous drilling capacity in steel (S235JR)Ø 28 mmThread cutting in steel (S235JR)M16Spindle seatSpindle stroke125 mmSpindle seatMT3Throat285 mmSpeedsSpindle speeds 30 - 3'900 min -1Number of steps4 steps, electrically adjustable speedDrilling tableWork surface table length x width400 x 500 mmT-slot size14 mmDrilling table turnable 360°Distance spindle - table (max.)780 mmWork surface stand length x width270 x 390 mmDistance spindle - stand (max.)1'230 mmDimensionsColumn diameterØ 115 mmLength x width x height715 x 560 x 1'850 mmTotal weight280 kgStandard equipmentQuick-action drill chuck 0 - 16 mm B16Morse taper MT 3 - B16T-slotsGrindingSawingMillTurning DrillingTransportation packaging flat rateTPFR 1 = € 19.00 plus VATCNCLampsPolishingOperating mode "Threading"· Motor is starting up automaticallyafter moving the lever and· stops again in theinitial position· It is not necessary to actuatethe push button start and stop repeatedly for repeated drilling tasksOperating mode "auto"auto· The engine is being activated by movingthe grip downward· The direction of rotation is changed bypressing the limit switch on theadjustable drilling depth stopMeasuring· In order to optimize the drillingcapacity - additional speed levelStageSpeedTorque130 - 300 min -1100 Nm2120 - 1'200 min -125 Nm3240 - 2'400 min -113 Nm4390 - 3'900 min -16 NmIndex„Accessories for drilling <strong>machines</strong>“ on page 4729

B 30VGMGear drilling machine with OPTIMUM Brushless drive and automatic spindle sleeve feedConvincing arguments: quality, efficiency and price· High running smoothness thanks to ground multi-toothed follower· High true running accuracy due to hardened and ground main spindle· Vario Speed (3 gear stages with electronically adjustable speed)· Best power transmission due to aluminium belt pulleys in connectionwith GATES 7 M industrial V-belts· Electromagnetic coupling for the automatic spindle sleeve feed· Right-/left handed rotation· Quadruple steel gripGearDigital speed display· Easy-to-read· Integrated in the housingV-belts· with pre transmissiongear· Adjustable drilling depth stop· Digital depth gauge· Thread cutting modePowerful Brushless drive· New Brushless controller· Optimized running performance· Higher power output (2.5 kW)· Signals are digitally processed· Particularly smooth running· Nearly constant torque over the entirespeed rangeAutomatic spindle sleeve feed· For deep drillings or pocket holedrillings, the coupler of the automaticspindle sleeve feed canbe opened or closed at any time byactuating the spindle feed switch· Spindle locking with integrateddrill drift for a simpletool change (monitored)Machine lamp· integrated· 12 V halogen lampChuck guard· for best possible protection ofthe user· Height-adjustable· Micro switchCasting column· Thick-walled and stable· for high power absorptionDrilling table· Largely dimensioned, solid andprecisely worked· Transversally running T-slots· Heavily ribbed at the rear side· Rotation of 360° about thecolumnChip filter· cleans the coolant from roughcomponents· according to the machinedirectiveBase plate· Robust with T-slots· Precisely machined at the surface· Usable as a <strong>working</strong> surface forextra high workpieces due to therotatable drill tableCoolant equipment· Coolant tank integrated inthe base plateFig: OPTI drill B30VGM30

Technical data, accessories and dimensionsTypeB 30VGMItem No 303 4303€ plus VAT 3'950.00DimensionsPrefaceMachine datasElectrical connectionTotal connected valueMotor coolant pumpDrilling capacityDrilling capacity in steel (S235JR)Continuous drilling capacity in steel (S235JR)Spindle seatSpindle strokeSpindle seatThroatAutom. spindle sleeve feed230 V / 1 Ph ~50 Hz2.5 kW40 WØ 30 mmØ 24 mm125 mmMT3285 mm1. Step - 0.1 mm/rev up to Ø 30 mm2. Step - 0.15 mm/rev up to Ø 24 mm3. Step - 0.2 mm/rev up to Ø 20 mmSpeedsSpindle speeds 80 - 3'000 min -1Number of steps3 steps, electrically adjustable speedDrilling tableWork surface table length x width400 x 500 mmT-slot size14 mmDrilling table turnable 360°Distance spindle - table (max.)780 mmWork surface stand length x width385 x 385 mmDistance spindle - stand (max.)1'320 mmDimensionsColumn diameterØ 115 mmLength x width x height600 x 735 x 1'915 mmTotal weight305 kgStandard equipmentQuick-action drill chuck 0 - 16 mmMorse taper MT 3GrindingSawingMillTurning DrillingTransportation packaging flat rateTPFR 1 = € 19.00 plus VATPolishingAccessories Item No € plus VATDirect quick-action drill chuck MT3/0.3-16 mm 305 0573 76.50Reducing bushes MT 3 - MT 2 305 0663 7.70Morse taper MT 3 - B16 305 0660 8.10Twist drill kit coated with titanium ø 1-13 mm 305 1010 41.00Twist drill HSS / MT 3 305 1003 139.00Clamping tool kit SPW 12 335 2017 79.00Tapping chuck M5-M12 335 2042 349.00Please find further information on „Accessories for drilling <strong>machines</strong>“ on page 47LampsMeasuringCombination Belt Drive / GearVery smooth and low noise runningGear stage L M HSpindlespeeds80-700Easy tool changedue to integrated drill drift170-1500400-3000Torque 28 Nm 14 Nm 7 NmCNCIndex31

DH 26GT / DH 28GS / DH 32GSBench drills and upright drilling <strong>machines</strong> with gearConvincing arguments: quality, efficiency and price· High running smoothness thanks to ground multi-toothed follower· High true running accuracy due to hardened and ground main spindle· Wide speed range· Heavy, solid cast iron construction· Adjustable drilling depth stop with millimetre scale· Low maintenance gear with grease lubricationOPTI drill DH 32 GS:· Threading function· Threading function with <strong>Optimum</strong> foot switch· Automatic spindle sleeve feed· Coolant pumpGearGear· 8 stepsOPTI drill DH 32GSAutomatic spindle sleeve feed75 - 2'900 min -1 Casting columnIntegrated drill drift· Easy tool change due toejection mechanism· For deep drilling or pocket holedrilling, the coupler of the automaticspindle sleeve feed can beopened or closed at any time byactuating the spindle feed switchRight-/left handed rotationMachine lamp· Integrated in the drill head· Halogen lampChuck guard· Best possible protection of the user· Height-adjustable· micro switch· Thick-walled· For high power absorptionand stabilityDrilling table· Largely dimensioned· Solid· Precisely worked· Transversally running T-slots· Heavily ribbed at the rear sideCoolant equipmentChip filter· according to the machine directiveBase plate· Usable as a <strong>working</strong> surface forextra high workpieces due to therotatable drill table· Solid· Precisely machined at the surfaceFig.: OPTI drill DH 26GT withoptional drill chuckFig.: OPTI drill DH 32GSwith optional drill chuck32

Technical data and dimensionsType DH 26GT DH 28GS DH 32GSItem No 303 4220 303 4230 303 4240€ plus VAT 1'650.00 2'150.00 2'750.00PrefaceMachine datasElectrical connection 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 HzTotal connected value 1.1 / 1.5 kW 1.1 / 1.5 kW 1.5 / 2.2 kWDrilling capacityDrilling capacity in steel (S235JR) Ø 26 mm Ø 28 mm Ø 32 mmContinuous drilling capacity in steel (S235JR) Ø 24 mm Ø 25 mm Ø 29 mmSpindle seatSpindle stroke 127 mm 127 mm 125 mmSpindle seat MT 3 MT 3 MT4Throat 235 mm 260 mm 285 mmAutomatic spindle sleeve feed - - 0,1 / 0,15 / 0,2 mmSpeedsSpindle speeds, 8 steps 75 - 2'900 min -1 75 - 2'900 min-1 75 - 2'000 min-1Drilling tableWork surface table length x width 380 x 380 mm 376 x 394 mm 400 x 420 mmT-slot size 14 mm 14 mm 14 mmDrilling table turnable 360° 360° 360°Distance spindle - table (max.) 450 mm 875 mm 820 mmDistance spindle - stand (max.) 610 mm 1'200 mm 1'280 mmWorking surface pedestal 350 x 322 mm 350 x 356 mm 420 x 644 mmDimensionsColumn diameter Ø 92 mm Ø 92 mm Ø 115 mmDimensions 570 x 375 x 1'300 mm 640 x 375 x 2'080 mm 725 x 450 x 2'200 mmTotal weight 166 kg 184 kg 295 kgSawingMillTurning DrillingTransportation packaging flat rate - TPFR 1 = € 19.00 plus TPFR 1 = € 19.00 plusDimensions DH 26GTDimensions DH 32GSLampsPolishingGrindingDimensions DH 28GSMeasuringStandard equipment· Adapter MT3-B16 (DH 26GT/28GS)· Adapter MT4-B16 (DH 32GS)CNCAccessories Item No. € plus VATThreading function with foot switchDH 32 GS305 0032 99.00· Switchung from right to left turningIndex„Accessories for drilling <strong>machines</strong>“ on page 4733

B 40E / B 40PTEUniversal column gear drilling <strong>machines</strong> with gearbox and 12 speedsB 40 PTE additionally equipped with automatic feed and slewable drilling tableConvincing arguments: quality, efficiency and price· Heavy, solid cast iron construction· Very smooth running due to ground oil-quenched gear wheels· Large speed range from 95 - 3'200 min -1 due to 12 switchable speeds· Two-stage quality electrical motor· Coupling to switch-over from manual rough feed to manual fine feed·OPTI drill B 40 PTE· Automatic spindle sleeve feed· Drilling table horizontally slewable by 360°OPTI drill DH 32GSAutomatic spindle sleeve feedGearDrill head heightadjustment· via toothed rack· For deep drilling or pocket holedrilling, the coupler of the automaticspindle sleeve feed can beopened or closed at any time byactuating the spindle feed switchSleeve infeed· via handwheelDrilling depth stop· Millimetre scale· adjustableChuck guard· for best possible protectionof the user· Height-adjustable· Micro switchCasting column· Thick-walled· For high power absorptionand stabilityDrilling table· Largely dimensioned· Solid· Precisely worked· Transversally running T-slots· Heavily ribbed at the rear side· Double clampedChip filter· cleans the coolant from roughcomponents· according to the machinedirectiveFig.: OPTI drill B 40EBase plate· Usable as a <strong>working</strong> surface forextra high workpieces due to therotatable drill table· Solid· Precisely machined at the surfaceCoolant equipment· Coolant tank integrated in the baseplateFig: OPTI drill B 40PTE34

Technical data, accessories and dimensionsType B 40E B 40PTEItem No 303 4340 303 4345€ plus VAT 2'690.00 3'090.00DimensionsPrefaceMachine datasElectrical connection400 V / 3 Ph ~50 HzTotal connected value1.1 / 1.5 kWMotor coolant pump40 WDrilling capacityDrilling capacity in steel (S235JR)Ø 32 mmContinuous drilling capacity in steelØ 25 mmSpindle seatSpindle stroke120 mmSpindle sleeve diameter75 mmSpindle seat MT 4Throat285 mmAutom. spindle sleeve feed - 0.1 / 0.18 / 0.26 mm/revDrill head turnable by 360°slewable by 45°SpeedsSpindle speeds 95 - 3'200 min -1Number of steps2 x 6 stepsDrilling tableTable size length x width 425 x 420 mm 400 x 445 mmT-slot size14 mmDrilling table turnable 360°Drilling table slewable - 180°Distance spindle - table (max.)855 mmWorking surface pedestal L x W385 x 385 mmDistance spindle - stand (max.)1'215 mmDimensionsColumn diameterØ 115 mmLength x width x height 700 x 600 x 2'050 mm 720 x 700 x 2'050 mmTotal weight322 kgStandard equipmentOperating toolQuick-action drill chuck (1-16 mm)Transportation packaging flat rateTPFR 1 = € 19.00 plus VATFig: OPTI drill B 40PTEPolishing GrindingSawingMillTurning DrillingAccessories Item No € plus VATQuick-action drill chuck MT4/1-16 mm 305 0574 76.50Reducing bushes MT 4 - MT 3 305 0664 12.30Morse taper MT 4 - B16 305 0661 13.20Twist drill kit coated with titanium 13mm 305 1010 41.00Clamping tool kit SPW 12 335 2017 79.00Tapping chuck M5-M12 335 2042 349.00LampsMeasuringMachine vices Item No € plus VATBSI 140 300 0214 179.00BSI 200 300 0220 229.00Fig: OPTI drill B 40ECNCIndexPlease find further information on „Accessories for drilling <strong>machines</strong>“ on page 4735

B 40GSP / B 40GSMHeavy geared upright drill with coolant system and threading mechanism. OPTI drill B40GSM additionally with automatic spindle sleeve feedConvincing arguments: quality, efficiency and price· Heavy, solid cast iron construction· Automatic toothed wheel lubrication via oil pump· Very smooth running due to ground oil-quenched gear wheels· High true running accuracy due to hardened and ground main spindle· Threading unit· Lockable main switch and motor protection switch· Two-stage driving motorOPTI drill B 40GSP· mechanic, 2-fold adjustable spindle sleeve feedOPTI drill B 40GSM· Automatic spindle sleeve feedDimensions...GearSpindle speed· 9 selectable speeds via gear shiftinglever at the front of the drill head· Two-stage driving motor· 18 speeds 50 - 1'450 min -1 Drilling depth stopControl cabinet· Clearly arranged structure· Generously dimensioned· Easy-to-attain· Adjustable using themillimetre scaleEasy tool changedue to integrated drill drift:· Insert drill drift· Press grip upwards· The taper mandrel ispressed out of thedrilling spindleRight-/left handed rotation· when threadingMachine lamp· Integrated in the drill headCasting column· Thick-walled· High power absorption· Extremely robustDrilling table· Largely dimensioned· Solid· Precisely worked· Transversally running T-slots· Heavily ribbed at the rear side· Rotation of 360° through its ownaxis and about the columnChip filter· cleans the coolant from rough components· according to the machine directiveCoolant equipment· Coolant tank integrated inthe base plate· Tank capacity 5 litres· Delivery volume 2 l/min.Fig.: OPTI drill B 40GSMBase plate· Solid· Parallelly running T-slots· Precisely machinedsurfaceFig.: OPTI drill B 40GSP36

Technical data, accessories and dimensionsTypeB 40GSPItem No 303 4403€ plus VAT 3'950.00DimensionsPrefaceTypeB 40GSMItem No 303 4400€ plus VAT 4'200.00Machine datasElectrical connection400 V / 3 Ph ~50 HzTotal connected value1.5 kWMotor coolant pump40 WDrilling capacityDrilling capacity in steel (S235JR)Ø 35 mmContinuous drilling capacity in steel (S235JR)Ø 35 mmThread cutting in steel (S235JR) M 24Spindle seatSpindle stroke180 mmSpindle seat MT 4Throat350 mmAutom. spindle sleeve feed2 steps, 0.1/0.2 mm/revSpeedsSpindle speeds 50 - 1'450 min -1Number of steps18 stepsDrilling tableWork surface table length x width560 x 560 mmT-slot size18 mmDistance spindle - table (max.)780 mmDrilling table slewable/turnable 360°/360°Load bearing capacity of the table300 kgWork surface stand length x width510 x 500 mmDistance spindle - stand (max.)1'320 mmDimensionsColumn diameterØ 150 mmLength x width x height935 x 560 x 2'280 mmTotal weight500 kgStandard equipmentQuick-action drill chuck 0 - 16 mmMorse taper MT 4Polishing GrindingSawingMillTurning DrillingTransportation packaging flat rateTPFR 1 = € 19.00 plus VATAccessories Item No € plus VATQuick-action drill chuck MT4/1-16 mm 305 0574 76.50Reducing bushes MT 4 - MT 3 305 0664 12.30Morse taper MT 4 - B16 305 0661 13.20Twist drill kit coated with titanium ø 1-13 mm 305 1010 41.00Clamping tool kit SPW 16 335 2019 109.00Tapping chuck M5-M12 335 2042 349.00LampsMeasuringCNCMachine vices Item No € plus VATMSO 125 300 0125 28.90MSO 150 300 0150 33.90BMS 150 300 0015 75.00BMS 200 300 0020 99.00BSI 140 300 0214 179.00BSI 200 300 0220 229.00 Please find further information on „Accessories for drilling <strong>machines</strong>“ on page 47Index37

B 50GSMHeavy gear drilling machine with coolant system and threadingmechanism as well as automatic spindle sleeve feedHeavy, solid cast iron construction950 kgSmooth running and stableConvincing arguments: quality, efficiency and price· Heavy, solid cast iron construction· Very smooth running due to ground oil-quenched gear wheels· High true running accuracy due to hardened and ground work spindle· Two-stage driving motor· Automatic toothed wheel lubrication via oil pump· Threading unit· Lockable main switch and motor protection switch· Machine lamp integrated in the drill headGearDrilling depth stop· Adjustable· Millimetre scaleSpindle sleeve finefeed· Via handwheelIntegrated drill drift· Easy tool change due to ejectionmechanismAutomatic spindle sleeve feed· For deep drilling or pocket hole drilling,the coupler of the automaticspindle sleeve feed can be openedor closed at any time by actuatingthe spindle feed switchChuck guard· Best possible protection ofthe user· Height-adjustable· micro switchDrilling table· Largely dimensioned· Solid· Precisely worked· Transversally running T-slots· Heavily ribbed at the rear side· Rotation of 360° through its own axisand about the columnCasting column· Thick-walled· High smooth running and stability· Column diameter 200 mmTable height adjustment· Motor drivenBase plate· Usable as a <strong>working</strong> surface for extra highworkpieces due to the rotatable drill table· Solid· Parallelly running T-slots· Precisely machined at the surfaceCoolant equipment· Coolant tank integrated inthe base plate· Tank capacity 5 litres· Delivery volume 2 l/min.Chip filter· cleans the coolant fromrough components· according to the machinedirectiveFig.: OPTI drill B 50GSM38

Technical data, accessories and dimensionsTypeB 50GSMItem No 303 4500€ plus VAT 7'690.00DimensionsPrefaceMachine datasElectrical connection400 V / 3 Ph ~50 HzTotal connected value3.0 / 2.4 kWMotor coolant pump40 WDrilling capacityDrilling capacity in steel (S235JR)Ø 50 mmContinuous drilling capacity in steel (S235JR)Ø 45 mmThread cutting in steel (S235JR) M 42Spindle seatSpindle stroke230 mmSpindle seat MT 4Throat375 mmAutom. spindle sleeve feed6 steps, 0.05/0.3 mm/revSpeedsSpindle speeds 54 - 2'090 min -1Number of steps18 stepsDrilling tableWork surface table length x width600 x 600 mmT-slot size18 mmLoad drilling table400 kgDrilling table slewable 360°Drilling table turnable 360°Distance spindle - table (max.)800 mmWork surface stand length x width600 x 520 mmDistance spindle - stand (max.)1'300 mmDimensionsColumn diameterØ 200 mmLength x width x height1'134 x 600 x 2'460 mmTotal weight950 kgStandard equipmentQuick-action drill chuck 0 - 16 mmMorse taper MT 4T-slotsTransportation packaging flat rateTPFR 1 = € 19.00 plus VATPolishing GrindingSawingMillTurning DrillingAccessories Item No € plus VATDirect quick-action drill chuck MT4/1-16 mm 305 0574 76.50LampsReducing bushes MT 4 - MT 3 305 0664 12.30Twist drill HSS incl. Morse taper MT 3 305 1003 139.00Morse taper MT 4 - B16 305 0661 13.20CNCMeasuringClamping tool kit SPW 16 335 2019 109.00Tapping chuck M5-M12 335 2042 349.00Fig.: Drawing without motor-driven tableheight adjustmentIndexPlease find further information on „Accessories for drilling <strong>machines</strong>“ on page 4739

DZ 25 / DZ 35Heavy PREMIUM gear drilling <strong>machines</strong>Convincing arguments: quality, efficiency and price· 3-year <strong>Optimum</strong> warranty*· High smooth running due to hardened andground gearwheels· Thick-walled, largely dimensioned cast columnfor high force absorption and stability· High true running accuracy due to hardenedand ground main spindle made of high qualitysteel· High continuous drilling capacity· Automatic drill drift· Drill chuck protection with micro switchGear· Threading function· Electrical system made by European manufacturers· Safety switching avoidsunsafe start-upDZ 35:· Feed gear· Coolant equipment· MT 4 spindle sleeve· First quality finish· Best quality· High quality materials· High functional safety· Durable and stable valueElectrical system· made by Europeanmanufacturers· Clearly arrangedswitch cabinetSpindle speed· 8 selectable speeds viagear shifting leverAutomatic feedIntegrated drill drift· Easy tool changeMachine lamp· Integrated in the drillheadPREMIUMCasting column· Thick-walled· High power absorption· Extremely robustDrilling table· Largely dimensioned· Solid· Precisely worked· Heavily ribbed at the rearside· 360° turnable round thecolumnCoolant equipment· Coolant tank integrated inthe base plateBase plate· Solid· 2 pcs parallellyrunning T-slots· Precisely machinedsurfaceFig.: OPTI drill DZ 25 Fig.: OPTI drill DZ 3540

Technical data, accessories and dimensionsType DZ 25 DZ 35Item No 304 1030 304 1060€ plus VAT 4'990.00 7'590.00DimensionsPrefaceMachine datasElectrical connection 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 HzMotor power 0.8 / 1.2 kW 0.9 / 1.5 kWMotor coolant pump 60 watts 60 wattsDrilling capacityDrilling capacity in steel (ST60 - E335) Ø 25 mm Ø 35 mmContinuous drilling capacity in steel(ST60 - E335) Ø 25 mm Ø 35 mmThreading in steel (ST60 - E335) M 22 M 28Spindle seatSpindle stroke 120 mm 160 mmSpindle seat MT 3 MT 4Throat 250 mm 300 mmAutomatic spindle sleeve feed - 0.1 / 0.2 / 0.3 mm/revSpeedsSpindle speeds 64 - 3'060 min -1 75 - 2'100 min -1Number of steps 8 steps 8 stepsDrilling tableWork surface table length x width 270 x 300 mm 400 x 420 mmT-slot size / distance / number 14 mm / 2 / 150 mm 16 mm / 3 / 121 mmDistance spindle - table (min/max.) 170 / 680 mm 70 / 885 mmDrilling table turnable 360° 360°Work surface stand length x width - 310 x 288 mmT-slot size / number / distance - 18 mm / 2 / 180 mmDistance spindle - stand (max.) 1,185 mm 1,245 mmDimensionsColumn diameter Ø 100 mm Ø 125 mmWidth x Height 600 x 805 x 2'025 mm 520 x 860 x 2'260 mmTotal weight 260 kg 317 kgFig.: DZ 25GrindingSawingMillTurning DrillingTransport surcharge plus VAT € 120.00 (TPZ600) € 120.00 (TPZ600)Accessories Item No € plus VATDirect quick-action drill chuck MT3 / 1-16 mm 305 0573 76.50Direct quick-action drill chuck MT4 / 1-16 mm 305 0574 76.50PolishingReducing bushes MT 4 - MT 3 305 0664 12.30Reducing bushes MT 3 - MT 2 305 0663 7.70Twist drill HSS incl. Morse taper MT 3 305 1003 139.00Morse taper MT 4 - B16 305 0661 13.20Morse taper MT 3 - B16 305 0660 8.10Clamping tool kit SPW 12 335 2017 79.00Clamping tool kit SPW 14 335 2018 99.00Tapping chuck M5-M12 335 2042 349.00Machine vice BSI 140 300 0214 179.00Machine vice BSI 200 300 0220 229.00Machine vices BSI-Q 140 300 0324 199.00Machine vices BSI-Q 200 300 0240 259.00Fig.: DZ 35LampsMeasuringCNCFig.: BSI 200„Guarantee provisions“ on page 225Please find further information on „Accessoriesfor drilling <strong>machines</strong>“ on page 47Index41

DZ 40 / DZ 50Heavy PREMIUM gear drilling <strong>machines</strong>Convincing arguments: quality, efficiency and price· 3-year <strong>Optimum</strong> warranty*· High smooth running due to hardened and groundgearwheels· Thick-walled, largely dimensioned cast column for highforce absorption and stability· High true running accuracy due to hardened andground main spindle made ofhigh quality steel· High continuous drilling capacity· Automatic drill drift· Drill chuck protection with micro switch· Threading function· Electrical system made by Europeanmanufacturers· Safety switchingavoidsunsafe start-up· First quality finish· Best quality· High quality materials· High functional safety· Durable and stable valueGearSpindle speed· 8 resp. 9 selectable speedsvia gear shifting leverAutomatic feedIntegrated drill drift· Easy tool changeMachine lamp· Integrated in the drillheadPREMIUM42Fig.: OPTI drill DZ 40 Fig.: OPTI drill DZ 50Casting column· Thick-walled· High power absorption· Extremely robustDrilling table· Largely dimensioned· Solid· Precisely worked· Heavily ribbed at the rearside· 90° turnable around theown axis with scale· 360° turnable round thecolumnCoolant equipment· Coolant tank integratedin the base plateBase plate· Solid· 3 pcs parallelly runningT-slots· Precisely machinedsurface

Technical data, accessories and dimensionsType DZ 40 DZ 50Item No 304 1070 304 1090€ plus VAT 9'150.00 12'590.00DimensionsPrefaceMachine datasElectrical connection 400 V / 3 Ph ~50 Hz 400 V / 3 Ph ~50 HzMotor power 1.5 kW 3 kWMotor coolant pump 60 watts 60 wattsDrilling capacityDrilling capacity in steel (ST60 - E335) Ø 40 mm 50 mmContinuous drilling capacity in steel Ø 40 mm 50 mmThreading in steel (ST60 - E335) M 35 M 40Spindle seatSpindle stroke 180 mm 260 mmSpindle seat MT 4 MT 4Throat 350 mm 400 mmAutomatic spindle sleeve feed mm/rev 0.1 / 0.18 / 0.24 0.08/0.16/0.24/0.35SpeedsSpindle speeds 93 - 1'420 min -1 45 - 1'115 min -1Number of steps 8 steps 9 stepsDrilling tableWork surface table length x width 480 x 480 mm 430 x 430 mmT-slot size / number / distance 16 mm / 3/ 125 mm 18 mm / 3/ 160 mmDistance spindle - table (min/max.) 95 / 865 mm 70 / 800 mmDrilling table turnable 360° 360°Work surface stand length x width 356 x 370 mm 500 x 700 mmT-slot size / number / distance 16 / 2 / 220 mm 16 / 3 / 138 mmDistance spindle - stand (max.) 1'201 mm 1'270 mmDimensionsColumn diameter Ø 150 mm Ø 200 mmWidth x Height 820 x 565 x 2'300 mm 1'060 x 615 x 2'590 mmTotal weight 435 kg 850 kgFig.: DZ 40GrindingSawingMillTurning DrillingTransport surcharge plus VAT € 120.00 (TPZ600) € 150.00 (TPZ1000)Accessories Item No € plus VATDirect quick-action drill chuck MT4/1-16 mm 305 0574 76.50PolishingLampsReducing bushes MT 4 - MT 3 305 0664 12.30Twist drill HSS incl. Morse taper MT 3 305 1003 139.00Morse taper MT 4 - B16 305 0661 13.20Clamping tool kit SPW 16 335 2019 109.00Clamping tool kit SPW 14 335 2018 99.00Tapping chuck M5-M12 335 2042 349.00Machine vice BSI 140 300 0214 179.00Machine vice BSI 200 300 0220 229.00Machine vices BSI-Q 140 300 0224 199.00Machine vices BSI-Q 200 300 0240 259.00Fig.: DZ 50MeasuringCNCFig.: BSI 200„Guarantee provisions“ on page 225Please find further information on„Accessories for drilling <strong>machines</strong>“ on page 47Index43

DR4 / DR5 / DR6Precise <strong>working</strong>, solid radial drilling <strong>machines</strong> ideal for versatile use in the single partand series productionConvincing arguments: quality, efficiency and price· Wide range of applications drilling, reaming, threading· Heavy, solid, high quality castings· Powerful quality engine· Working range by horizontally adjustable machine head· Motorized adjustment of spindle head· Clearly arranged control panel· Solid, precise drilling table, dimensioned· With parallel T-slots· Durable, rigid construction of the arm· Height adjustment of the arm is powerful spindle motor drive· Oil bath gearbox of the arm· Hardened gears made of chrome-nickel steel and precision-ground, inquiet and smooth running· Right-/left-hand rotation· coolant equipment in the machine base with coolant tank· Arm guideways hardened and precision ground· Maschine lamp· Thick-walled steel column for and stability· Adjustable depth stop with millimeter scale· Drilling head and column can be clipped together or separately or dissolved· DR4 - All axes are clamped manually· DR5 - Z column is clamped manually, the arm and the drill head can beclamped hydraulically· DR6 - All axles are hydraulically clampedGearDrilling head· travels on hardened and groundguidewaysLifting spindle· Powerful motor drive· Height adjustment of the armHandwheel· centrally disposed· positioned exactlycolumn swivelling· complex worked· optimized clamping· highest stabilityCasting column· Thick-walled· High power admission· SolidCube table· hardened and precisionground· Largely dimensionedCoolant equipment· Coolant tank integratedin the base plateFig.:DR 544