MarVision MS 222

MarVision MS 222

MarVision MS 222

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

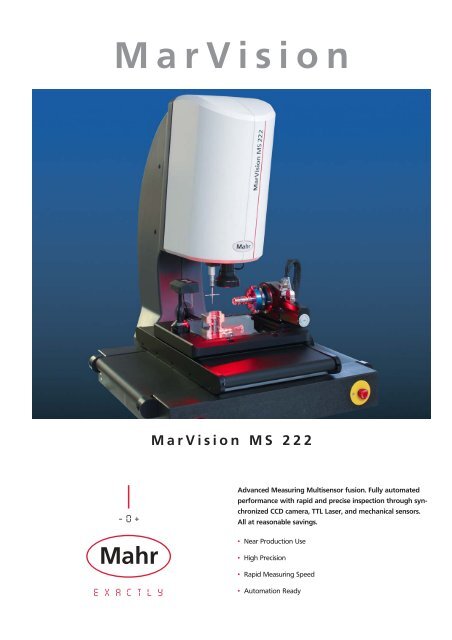

<strong>MarVision</strong><strong>MarVision</strong> <strong>MS</strong> <strong>222</strong>Advanced Measuring Multisensor fusion. Fully automatedperformance with rapid and precise inspection through synchronizedCCD camera, TTL Laser, and mechanical sensors.All at reasonable savings.• Near Production Use• High Precision• Rapid Measuring Speed• Automation Ready

Advanced Measuring Multisensor fusion. Fully automatedperformance with rapid and precise inspection through synchronizedCCD camera, TTL Laser, and mechanical sensors.All at reasonable savings• Near Production Use. Cost savings by production scrapreduction and through immediate results• High Precision. Minimizes measurement uncertainty, whilemaximizing your manufacturing tolerance window• Rapid Measuring Speed. Increases manufacturing confidenceby rapid and repeatable measurements of significantsample lots• Automation Ready. Further reduce overhead cost by virtuallyeliminating system operator dependency<strong>MarVision</strong> <strong>MS</strong> <strong>222</strong>Technical dataMeasuring Range Single Sensor Both SensorApplication in plastic industryX 250 mm (10’’) 200 mm (8’’)Y 200 mm (8’’) 200 mm (8’’)Z 200 mm (8’’) 200 mm (8’’)Lead framesLength Measuring UncertaintyAccording to VDI/VDE 2617 E 1 = (2.2 + L / 150) µmE 2 = (3.2 + L / 125) µmISO 10360-2E 3 = (3.9 + L / 100) µm*(L = Measuring length in mm)* with Option 3D packageApplication in the electronic industry(Test conditions: maximum zoom magnification, ambient temperature 20°C± 1K, acceptance according to Mahr acceptance test procedure)Weight170 kg (375 lbs) Machineweight90 kg electronic cabinet(198 lbs)Max. Load on Glass Plate: 10 kg (22 lbs)Note: Support does not belong to the standard versionSensorsOptionalStandard optical sensorLaser sensor, touch probeand 2-step zoomExamples of typical applications for optical / tactile 3D Mahr instrumentsApplication in fine mechanicsMahr Multisensor GmbHWendelstraße 90, 66787 Wadgassen, Germany,Phone +49 (6834) 9411-0, Fax +49 (6834) 48785,e-mail: info.marvision@mahr.com, www.mahr.com© by Mahr GmbH, GöttingenWe reserve the right to modify our products, particularly with a view totechnical improvement and further development. All illustrations andnumbers etc. are therefore subject to change.3756821-21.11.2003