Valtek MaxFlo 3 Control Valves - Nooneycontrols.com

Valtek MaxFlo 3 Control Valves - Nooneycontrols.com

Valtek MaxFlo 3 Control Valves - Nooneycontrols.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

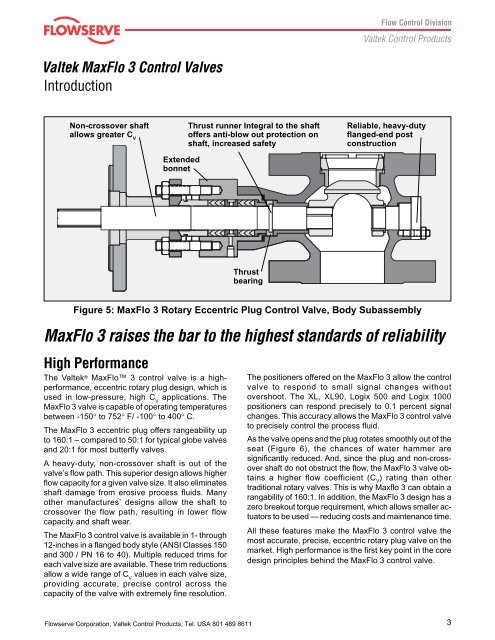

<strong>Valtek</strong> <strong>MaxFlo</strong> 3 <strong>Control</strong> <strong>Valves</strong>IntroductionNon-crossover shaftallows greater C VExtendedbonnetThrust runner Integral to the shaftoffers anti-blow out protection onshaft, increased safetyReliable, heavy-dutyflanged-end postconstructionThrustbearingFigure 5: <strong>MaxFlo</strong> 3 Rotary Eccentric Plug <strong>Control</strong> Valve, Body Subassembly<strong>MaxFlo</strong> 3 raises the bar to the highest standards of reliabilityHigh PerformanceThe <strong>Valtek</strong> ® <strong>MaxFlo</strong> 3 control valve is a highperformance,eccentric rotary plug design, which isused in low-pressure, high C Vapplications. The<strong>MaxFlo</strong> 3 valve is capable of operating temperaturesbetween -150° to 752° F/ -100° to 400° C.The <strong>MaxFlo</strong> 3 eccentric plug offers rangeability upto 160:1 – <strong>com</strong>pared to 50:1 for typical globe valvesand 20:1 for most butterfly valves.A heavy-duty, non-crossover shaft is out of thevalve’s flow path. This superior design allows higherflow capacity for a given valve size. It also eliminatesshaft damage from erosive process fluids. Manyother manufactures’ designs allow the shaft tocrossover the flow path, resulting in lower flowcapacity and shaft wear.The <strong>MaxFlo</strong> 3 control valve is available in 1- through12-inches in a flanged body style (ANSI Classes 150and 300 / PN 16 to 40). Multiple reduced trims foreach valve size are available. These trim reductionsallow a wide range of C Vvalues in each valve size,providing accurate, precise control across thecapacity of the valve with extremely fine resolution.The positioners offered on the <strong>MaxFlo</strong> 3 allow the controlvalve to respond to small signal changes withoutovershoot. The XL, XL90, Logix 500 and Logix 1000positioners can respond precisely to 0.1 percent signalchanges. This accuracy allows the <strong>MaxFlo</strong> 3 control valveto precisely control the process fluid.As the valve opens and the plug rotates smoothly out of theseat (Figure 6), the chances of water hammer aresignificantly reduced. And, since the plug and non-crossovershaft do not obstruct the flow, the <strong>MaxFlo</strong> 3 valve obtainsa higher flow coefficient (C V) rating than othertraditional rotary valves. This is why Maxflo 3 can obtain arangability of 160:1. In addition, the <strong>MaxFlo</strong> 3 design has azero breakout torque requirement, which allows smaller actuatorsto be used — reducing costs and maintenance time.All these features make the <strong>MaxFlo</strong> 3 control valve themost accurate, precise, eccentric rotary plug valve on themarket. High performance is the first key point in the coredesign principles behind the <strong>MaxFlo</strong> 3 control valve.Flowserve Corporation, <strong>Valtek</strong> <strong>Control</strong> Products, Tel. USA 801 489 86113