Dow Corning 3145 RTV MIL-A- 46146 Adhesive ... - C3 Teknoloji

Dow Corning 3145 RTV MIL-A- 46146 Adhesive ... - C3 Teknoloji

Dow Corning 3145 RTV MIL-A- 46146 Adhesive ... - C3 Teknoloji

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

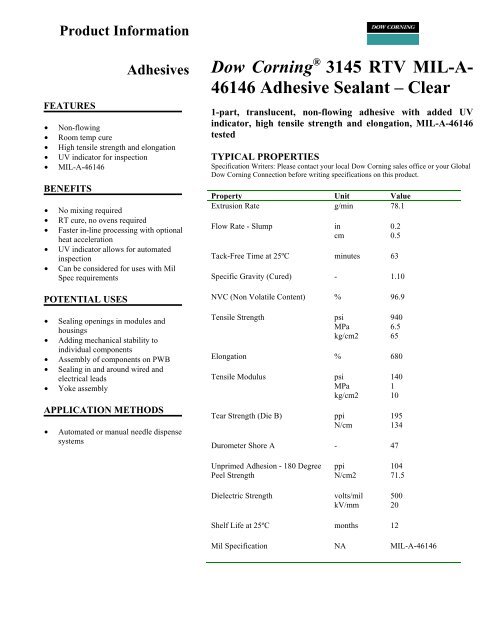

Product InformationFEATURES<strong>Adhesive</strong>s• Non-flowing• Room temp cure• High tensile strength and elongation• UV indicator for inspection• <strong>MIL</strong>-A-<strong>46146</strong>BENEFITS• No mixing required• RT cure, no ovens required• Faster in-line processing with optionalheat acceleration• UV indicator allows for automatedinspection• Can be considered for uses with MilSpec requirementsPOTENTIAL USES• Sealing openings in modules andhousings• Adding mechanical stability toindividual components• Assembly of components on PWB• Sealing in and around wired andelectrical leads• Yoke assemblyAPPLICATION METHODS• Automated or manual needle dispensesystems<strong>Dow</strong> <strong>Corning</strong> ® <strong>3145</strong> <strong>RTV</strong> <strong>MIL</strong>-A-<strong>46146</strong> <strong>Adhesive</strong> Sealant – Clear1-part, translucent, non-flowing adhesive with added UVindicator, high tensile strength and elongation, <strong>MIL</strong>-A-<strong>46146</strong>testedTYPICAL PROPERTIESSpecification Writers: Please contact your local <strong>Dow</strong> <strong>Corning</strong> sales office or your Global<strong>Dow</strong> <strong>Corning</strong> Connection before writing specifications on this product.Property Unit ValueExtrusion Rate g/min 78.1Flow Rate - Slumpincm0.20.5Tack-Free Time at 25ºC minutes 63Specific Gravity (Cured) - 1.10NVC (Non Volatile Content) % 96.9Tensile StrengthpsiMPakg/cm29406.565Elongation % 680Tensile ModulusTear Strength (Die B)psiMPakg/cm2ppiN/cm140110195134Durometer Shore A - 47Unprimed Adhesion - 180 DegreePeel StrengthDielectric StrengthppiN/cm2volts/milkV/mm10471.550020Shelf Life at 25ºC months 12Mil Specification NA <strong>MIL</strong>-A-<strong>46146</strong>

DESCRIPTION<strong>Dow</strong> <strong>Corning</strong> one-part moisture cureadhesives are generally cured at roomtemperature and in an environment of30 to 80 percent relative humidityeliminating the need for curing ovensand the associated costs of energy andcapital. Greater than 90 percent offull physical properties should beattained within 24 to 72 hours andvaries according to product. Fastermanufacturing throughput is achievehowever since the adhesive andcomponent can be handled in muchshorter times of about 10 to 120minutes depending on the adhesiveselected and the amount of applied.These adhesives are not typicallyused in highly confined spaces orwhere a deep section cure is requiredas they generally cure from theexposed surface inward at a rate of0.25 inch per seven days. Cureprogresses from the outer exposedsurface and is dependent on themoisture in the air. Working time isgenerally a few minutes to an hourfor these products until a surface skinbegins to form. Mild heat below 60°C(140°F) may be used to increasethrough-put by accelerating the cure.<strong>Dow</strong> <strong>Corning</strong> silicone adhesivesretain their original physical andelectrical properties over a broadrange of operating conditions whichenhance the reliability of and servicelife of electronic devices. The stablechemistry and versatile processingoptions of these adhesives offerbenefits for a variety of electronicsneeds from increasing componentsafety and reliability, reducing totalcost or increasing the performanceenvelope of devices or modules.PACKAGING<strong>RTV</strong> <strong>Adhesive</strong>s are typicallypackaged in 100 ml syringes and 330ml cartridges, 1 kg tubs and pails (18- 25 kg). In general, <strong>Dow</strong> <strong>Corning</strong>adhesives/sealants are supplied innominal 0.45-, 3.6-, 18- and 200-kg(1-, 8-, 40- and 440-lb) containers,net weight. Not all products may beavailable in all packages and someadditional packages, such as a bladderpacks or tubes, may be available forcertain package sizes.STORAGE AND SHELFLIFEFor best results, <strong>Dow</strong> <strong>Corning</strong> <strong>RTV</strong>adhesives should be stored at orbelow 25°C (77°F). Specialprecautions must be taken to preventmoisture from contacting thesematerials. Containers should be kepttightly closed with head or air spaceminimized. Partially filled containersshould be purged with dry air or othergases, such as nitrogen. Shelf life isindicated by the “Use Before” datefound on the product label.PREPARING SURFACESAll surfaces should be thoroughlycleaned and/or degreased with <strong>Dow</strong><strong>Corning</strong>® brand OS Fluids, naphtha,mineral spirits, methyl ethyl ketone(MEK) or other suitable solvent.Solvents such as acetone or isopropylalcohol (IPA) do not tend to removeoils well, and any oils remaining onthe surface may interfere withadhesion. Light surface abrasion isrecommended whenever possible,because it promotes good cleaningand increases the surface area forbonding. A final surface wipe withacetone or IPA is also useful. Somecleaning techniques may providebetter results than others; usersshould determine the best techniquesfor their particular applications.SUBSTRATE TESTINGDue to the wide variety of substratetypes and differences in substratesurface conditions, general statementson adhesion and bond strength areimpossible. To ensure maximumbond strength on a particularsubstrate, 100 percent cohesivefailure of the adhesive in a lap shearor similar adhesive strength test isdesired. This ensures compatibility ofthe adhesive with the substrate beingconsidered. Also, this test can be usedto determine minimum cure time orcan detect the presence of surfacecontaminants such as mold releaseagents, oils, greases and oxide films.ADHESION<strong>Dow</strong> <strong>Corning</strong> silicone adhesives arespecially formulated to provideunprimed adhesion to many reactivemetals, ceramics and glass, as well asto selected laminates, resins andplastics. However, good adhesioncannot be expected on non-reactivemetal substrates or non-reactiveplastic surfaces such as Teflon®,polyethylene or polypropylene.Special surface treatments such aschemical etching or plasma treatmentcan sometimes provide a reactivesurface and promote adhesion tothese types of substrates. <strong>Dow</strong><strong>Corning</strong>® brand Primers can be usedto increase the chemical activity ondifficult substrates. Poor adhesionmay be experienced on plastic orrubber substrates that are highlyplasticized, because the mobileplasticizers act as release agents.Small-scale laboratory evaluation ofall substrates is recommended beforeproduction trials are made.USEFUL TEMPERATURERANGESFor most uses, silicone elastomersshould be operational over atemperature range of -45 to 200°C (-49 to 392°F) for long periods of time.However, at both the low- and hightemperature ends of the spectrum,behavior of the materials andperformance in particular applicationscan become more complex andrequire additional considerations. Forlow-temperature performance,thermal cycling to conditions such as-55°C (-67°F) may be possible, butperformance should be verified foryour parts or assemblies. Factors thatmay influence performance areconfiguration and stress sensitivity ofcomponents, cooling rates and holdtimes, and prior temperature history.At the high-temperature end, thedurability of the cured siliconeelastomer is time and temperaturedependent. As expected, the higherthe temperature, the shorter the timethe material will remain useable.SOLVENT EXPOSUREWhen liquid or vapor solvent or fuelexposure can occur in an application,the silicone adhesive discussed in thisbrochure is intended only to survive

splash or intermittent exposures. It isnot suited for continuous solvent orfuel exposure. Testing should bedone to confirm performance of theadhesives under these conditions.HEALTH ANDENVIRONMENTALINFORMATIONTo support customers in theirproduct safety needs, <strong>Dow</strong> <strong>Corning</strong>has an extensive Product Stewardshiporganization and a team of ProductSafety and Regulatory Compliance(PS&RC) specialists available in eacharea. For further information, pleasesee our website,www.dowcorning.com, or consultyour local <strong>Dow</strong> <strong>Corning</strong>representative.LIMITATIONSThese products are neither tested norrepresented as suitable for medical orpharmaceutical uses.LIMITED WARRANTYINFORMATION PLEASEREAD CAREFULLYThe information contained herein isoffered in good faith and is believedto be accurate. However, becauseconditions and methods of use of ourproducts are beyond our control, thisinformation should not be used insubstitution for customer’s tests toensure that <strong>Dow</strong> <strong>Corning</strong>’s productsare safe, effective, and fullysatisfactory for the intended end use.Suggestions of use shall not be takenas inducements to infringe any patent.<strong>Dow</strong> <strong>Corning</strong>’s sole warranty is thatthe product will meet the <strong>Dow</strong><strong>Corning</strong> sales specifications in effectat the time of shipment. Yourexclusive remedy for breach of suchwarranty is limited to refund ofpurchase price or replacement of anyproduct shown to be other than aswarranted. DOW CORNINGSPECIFICALLY DISCLAIMS ANYOTHER EXPRESS OR IMPLIEDWARRANTY OF FITNESS FOR APARTICULAR PURPOSE ORMERCHANTABILITY. DOWCORNING DISCLAIMSLIABILITY FOR ANYINCIDENTAL ORCONSEQUENTIAL DAMAGES.SAFE HANDLINGINFORMATIONPRODUCT SAFETYINFORMATION REQUIRED FORSAFE USE IS NOT INCLUDED INTHIS DOCUMENT. BEFOREHANDLING, READ PRODUCTAND MATERIAL SAFETY DATASHEETS AND CONTAINERLABELS FOR SAFE USE,PHYSICAL AND HEALTHHAZARD INFORMATION. THEMATERIAL SAFETY DATASHEET IS AVAILABLE ON THEDOW CORNING WEBSITE ATWWW.DOWCORNING.COM, ORFROM YOUR DOW CORNINGREPRESENTATIVE, ORDISTRIBUTOR, OR BY CALLINGYOUR GLOBAL DOW CORNINGCONNECTION.For More InformationTo learn more about these and otherproducts available from <strong>Dow</strong><strong>Corning</strong>, please visit the <strong>Dow</strong><strong>Corning</strong> Electronics website atwww.dowcorning.com/ electronics.<strong>Dow</strong> <strong>Corning</strong> and Sylgard are registered trademarks of <strong>Dow</strong> <strong>Corning</strong> Corporation.All other trademarks or brand names are the property of their respective owners.©2006 <strong>Dow</strong> <strong>Corning</strong> Corporation. All rights reserved. Printed in USA Form No.11-1181A-01