The SINUMERIK 840D sl family

The SINUMERIK 840D sl family

The SINUMERIK 840D sl family

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Contents<strong>The</strong> <strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> CNC platform 4<strong>SINUMERIK</strong> MDynamics 6<strong>SINUMERIK</strong> Operate 7<strong>SINUMERIK</strong> OP 019 8<strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> modular system 9<strong>SINUMERIK</strong> Integrate 12<strong>SINUMERIK</strong> Ctrl-Energy 13SINAMICS S120 drives 14SIMOTICS motors 15<strong>SINUMERIK</strong> Safety Integrated 16Functions, softkeys and shortcuts 17Performance data 18

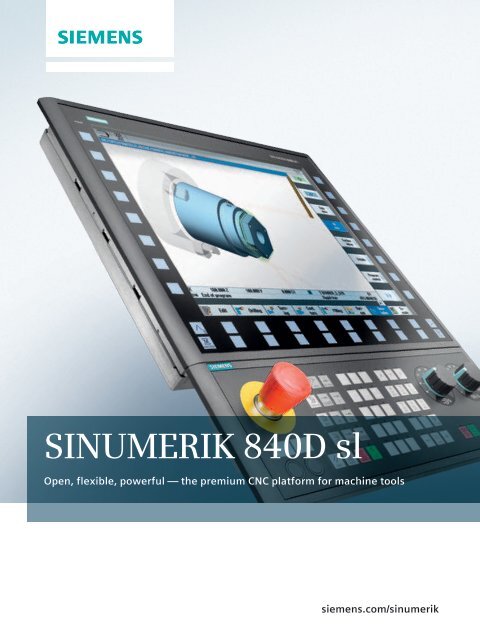

<strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> —powerful system with impressive innovation<strong>The</strong> <strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> CNC is theideal control for every machiningtechnology — no matter if it’smilling, turning, grinding or evenused on multi-tasking machines.MillingTurningSimply innovativeOnce again, the <strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> proves its innovativepower with new, high-performance milling and turningfunctions, the shortest-possible machining times coupledwith excellent surface finish and an ideal integration ofthe turn-milling and mill-turning applications. It is the premiumCNC system for multitasking machines. Several performancevariants provide even more flexibility and opennessso that you can configure your machine as needed.<strong>The</strong> modern <strong>SINUMERIK</strong> Operate graphical user interfacepermits simple and efficient operation on multi-channelmachines and programSYNC allows multi-channel machiningoperations to be synchronized easily and efficiently.Through the use of simulation, the <strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong>makes visualization of multichannel machining easy. Forexample, handling modules or tool changes can be controlled,programmed and visualized in another channel.This provides even more flexibility and economicsthroughout the manufacturing process.Versatile<strong>The</strong> <strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> system platform provides comprehensivemachine tool capabilities and innovative functionalityfor every machining technology. <strong>The</strong> CNC can bedeployed around the world in a variety of machiningapplications, such as milling, turning, drilling, grinding,laser-cutting, nibbling, stamping, as well as in multi-taskingmachines, namely, mill-turning and turn-milling. <strong>The</strong><strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> is the ideal CNC for tool- and moldmaking,high-speed-cutting applications, wood and glassprocessing, composite machining, medical part and powergeneration manufacturing, and not to mention the handlingin transfer lines, rotary indexing machines and shopfloormanufacturing.4

<strong>SINUMERIK</strong> Operate — the innovative graphical userinterface for efficient machine operationDIN and <strong>SINUMERIK</strong>High-level language andprogrammGUIDEShopMill/ShopTurnMachining stepprogrammingprogramSYNCDeveloped formaximum flexibilityand extremely shortmachining timesDeveloped forextremely shortprogramming timesDeveloped forincreased productivityfor multi-channelmachines<strong>The</strong> <strong>SINUMERIK</strong> Operate graphical user interface clearly and intuitively combines every function needed for the operationand programming of a CNC machine. It provides a consistent look-and-feel and offers you the same usability forevery technology — even when a switch is made between different technologies, such as multi-tasking machines.Programming has never been so easy<strong>The</strong> <strong>SINUMERIK</strong> Operate graphical user interface has manynew powerful functions. This permits the combination ofmachining step and high-level language programmingunder a single system user interface — it allows for veryfast, rational and intuitive NC programming and jobpreparation.Flexible and fastG-code programming with cycle support is combined inprogramGUIDE. This ensures maximum flexibility andshort machining times and is ideally suited for mid- tolarge batch sizes. <strong>SINUMERIK</strong> CNC also supports ISO codeprogramming. <strong>The</strong> ShopMill and ShopTurn machining stepprogramming is the tailored programming solution for themanufacture of single part and small batch sizes. Thismakes it perfect for the shopfloor manufacturing.Support for every manufacturing technologyComplex workpieces demand economical manufacturingmethods and innovative CNC solutions. <strong>The</strong> <strong>SINUMERIK</strong><strong>840D</strong> <strong>sl</strong> CNC supports multi-tasking machines for workpiecemanufacturing in a single clamping for which it providesinnovative functionality — or even during thechange between different technologies, such as mill-turningand turn-milling. <strong>The</strong> innovative <strong>SINUMERIK</strong> Operategraphical user interface provides an integrated turningfunctionality for milling applications and an integratedmilling functionality for turning applications, augmentedwith innovative measuring cycles in the Animated Elementdesign. <strong>The</strong> usability and the interface’s look-andfeelare always identical.7

<strong>SINUMERIK</strong> OP 019 — the new operatorpanel for high-end CNC applicationsUser-friendly, powerful, robust, modular and an attractive design — these are the advantages of the new<strong>SINUMERIK</strong> OP 019 operator panel. As a tribute to its functional designs, it was awarded the iF productdesign award 2011.Its excellent design ensures ease-of-useA new, modern <strong>SINUMERIK</strong> operator panel with high-qualitydesign and new command technology sets standardsin modern machine operation. <strong>The</strong> robust <strong>SINUMERIK</strong> OP019 with the new <strong>SINUMERIK</strong> PCU 50.5 was awarded theiF product design award 2011. Thanks to the capacitivesensory system, fast key operation is possible on the large19-inch glass front with IP66 degree of protection — evenif the user wears gloves.<strong>The</strong> proven <strong>SINUMERIK</strong> frame geometry is augmentedwith large-format LEDs that make each key action immediatelyapparent. An integrated key lock protects againstinadvertent, faulty operation. <strong>The</strong> new <strong>SINUMERIK</strong> OP019, based upon the <strong>SINUMERIK</strong> Operate graphical userinterface, can display the machine’s main screen withthree or four channels and up to 13 axes.8

A system that leaves no request unansweredYou can configure the <strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> to meet your requirements. <strong>The</strong> systematic modular CNC conceptallows you to implement innovative and individually tailored machines. Hardware and software can be scaledindependently. Flexible construction is possible for every machine and manufacturing environment —also under harsh operational conditions.Decentralized and flexible designA significant characteristic of the <strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> is itsdecentralized and simplified system construction – fullyintegratedin the design and communications structure ofour SINAMICS S120 drive system. <strong>The</strong> <strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong>unites CNC, HMI, PLC, closed-loop control and communicationstasks on a <strong>SINUMERIK</strong> Numerical Control Unit(NCU). When increased performance is required in theoperating area (HMI), you can use the <strong>SINUMERIK</strong> PCU50.5 industrial PC. NCU Link allows an expansion to amaximum of 93 NC axes.<strong>The</strong> robust CNC system platform provides a high degree offreedom for the placement of the components in themachine, not least thanks to the decentralized componentsfor operation, drive and peripherals. <strong>The</strong> componentscan be positioned as far as 100 m apart. This allowsas many as four decentralized OPs to be deployed concurrentlyon a NCU/PCU. An intelligent displacement mechanismallows even more than four operator panels to beattached. Even the high-performance multiprocessor NCUmodules can be installed separately as far as 100 m fromthe SINAMICS S120.9

<strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> system overviewHMIOP 08TOP 010C OP 012 OP 015A / OP 015AT /TP 015A / TP 015ATOP 019MCPMPPIncreased power for HMI performanceHW HT 2HT 8PCUPCU 50.5-CPCU 50.5-P<strong>840D</strong> <strong>sl</strong>BASIC<strong>840D</strong> <strong>sl</strong>Type 1A<strong>840D</strong> <strong>sl</strong>Type 1BNCUNCU 710.3PNup to 6 axesNCU 710.2NCU 720.2NCU 730.2NCU 710.3PNNCU 720.3PNNCU 730.3PNSINAMICS S120SINAMICS S120DrivesystemCOMBICompactBlocksizeBooksizeChassis1FK71FT71FW6Motors1FN3 1PH8 1FE1 2SP1Matched modular system<strong>The</strong> modular system for the <strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> CNCoffers high flexibility and openness for every machineapplication.In full conformance to the mix-and-match <strong>sl</strong>ogan, thecomponents can be perfectly matched to each other —exactly tailored to the requirements of the machinetool builder and for the subsequent end-user site.11

<strong>SINUMERIK</strong> Integrate – integration of theCNC controller in company processesFrom the development and procurement through to the manufacturing and marketing — the integration of machineand manufacturing data into a company’s manufacturing process is becoming ever more important. <strong>The</strong>integration of the machine tool into the company workflow is a significant requirement for lean and efficientmanufacturing. <strong>SINUMERIK</strong>® Integrate offers a comprehensive product for the integration of machine tools intothe communication, engineering and production processes of your company.<strong>SINUMERIK</strong> IntegrateCreate-it!Integration in the<strong>SINUMERIK</strong>Machine developmentCustomizingKnow-how protection◾◾Creation and customization ofuser interfaces in <strong>SINUMERIK</strong>Operate◾◾Creation of your own compilecycles as part of Open ArchitectureProductionEngineeringLock-it!◾◾Know-how protectionfor <strong>SINUMERIK</strong>Integration in theproductionCommunicationProduction and logisticsService and maintenanceRun-it!◾◾Runtimes for the execution ofindividual screen user interfaceswith <strong>SINUMERIK</strong> as part of OpenArchitecture◾◾Execution of your own compilecycles on the NC kernel and thedrives as well as the virtual NCkernel (VNCK)Analyze-it!Access-it!Manage-it!◾◾Functions forstate-based maintenance◾◾Key data-basedanalysis functions◾◾Programming of interfaces tothe machine tool and to theserver◾◾Remote accesses to the machinefor diagnosis◾ ◾ Organization and managementof NC programs and tools12

<strong>SINUMERIK</strong> Ctrl-Energy —energy savings at the touch of a buttonAs a technology leader in CNC and engineering, weoffer not only technologically-advanced functions, butalso powerful functions to increase the energyefficiency of the machine. In addition to the functionsthat can be called from the graphical user interface,Drive andmotor componentsCNC anddrive functions<strong>SINUMERIK</strong> Ctrl EnergyPCsoftware solutions<strong>SINUMERIK</strong>Manufacturing Excellenceservices<strong>SINUMERIK</strong> Ctrl-Energy provides you with a comprehensiveportfolio of energy-efficient systems, solutionsand services.Ctrl-E Energy AnalysisWith the Energy Analysis function, the CNC acquires notonly the energy consumption of the drive system, but alsothat of the entire machine. <strong>The</strong> machine user can analyzethe energy consumption of each workpiece and, whennecessary, optimize the machining strategy. With theCtrl+E key shortcut, the machine operator can visualizethe energy consumption at the touch of a button.With a wide range of drive and motor components, CNCand drive functions, PC software solutions as well as our<strong>SINUMERIK</strong> Manufacturing Excellence portfolio of services,<strong>SINUMERIK</strong> Ctrl-Energy sets standards for machinetool energy efficiency.Ctrl-E ProfileCtrl-E Efficient standby gives machine tool builders a configurationplatform to control the energy-saving modes ofthe machine. This allows specific energy consumers to beshutdown during machine standstill times. With the Ctrl+Eshortcut, the operator can quickly and easily influence theenergy-saving modes.13

SINAMICS S120 — the flexible, modulardrive system for sophisticated tasks<strong>The</strong> state-of-the-art design of drive components, spindleand feed motors, and switchgear cabinets is thebasis for advanced and energy-efficient machine toolconcepts. <strong>The</strong> SINAMICS S120 drive platform providesthe perfect solution for high-performance applicationsin industrial machinining.Highly productive and modularSINAMICS S120 drive solutions for the coordinated motioncontrol of your machine — high-performance multi-axisconfigurations with modular multi-axis or independentsingle-axis modules. <strong>The</strong> modular system covers the 0.12to 300 kW performance range. Together with <strong>SINUMERIK</strong>CNC, the SINAMICS S120 drive platform creates the perfectbasis for modular plant and machine concepts in thepower range of up to 300 kW. Uniform and integratedengineering tools ensure significantly-reduced engineeringcosts.DRIVE-CLiQ — the digital interface between everydrive componentEvery component of the SINAMICS S120, including motorsand encoders, as well as those from <strong>SINUMERIK</strong>, can beconnected to each other using the common DRIVE-CLiQinterface. <strong>The</strong>y all possess an electronic nameplate thatcontains relevant technical information. Because DRIVE-CLiQ acquires this data automatically from the <strong>SINUMERIK</strong>CNC, such data does not need to be entered during thecommissioning or after replacement. This greatly reducesyour machine’s time for commissioning.Decentralized and flexible designIntegrated communication using DRIVE-CLiQ permits flexibleand decentralized machine concepts. <strong>The</strong> individualcomponents can be installed up to 100 m from eachother. For user solutions that have a larger number ofmoving axes in the machine kinematics, the basic systemunits can be augmented with the <strong>SINUMERIK</strong> NX10/NX15expansion components to increase the computing performancein the drive.<strong>The</strong> new SINAMICS S120 Combi — a unique drive class<strong>The</strong> SINAMICS S120 Combi drive offers the usual SIN-AMICS functionality in an integrated drive concept, tailoredfor compact turning and milling machines. With itsmany technical highlights, the SINAMICS S120 Combi setsnew standards in this drive class.14

Powerful motors to get your machine movingOur comprehensive motor spectrum offers the appropriate type for every drive task in a large performancerange — and always ensures the correct movement.<strong>The</strong> appropriate motor for each feed andauxiliary driveIrrespective of whether high standstill torques, high accuracyor rated powers, high maximum speeds or dynamics,air- or water-cooling, linear or rotary movements — ourcomprehensive motor spectrum offer you the appropriatetype you require for every drive task. This includes synchronousand asynchronous servomotors, as well ashighly-innovative linear and rotary direct drives.◾◾1FK7 servomotors for standard applications◾◾1FT7 servomotors for high-performance applications◾◾1FN3 and 1FN6 linear motors◾◾1FW6 torque motorsSpindle motors for high-performance deployment inmachine toolsIrrespective of whether belt driven, hollow-shaft, built-inor even an integrated motor spindle — the spindles andtools for milling, turning and grinding machines can bedriven in many ways. <strong>The</strong> spindle drive ensures high cuttingperformance, manufacturing precision and availability— all which lead to increased machine productivity.Motor spindles are clearly gaining popularity in this area.<strong>The</strong>ir advantages lie in very high maximum speeds coupledwith minimum vibration susceptibility. <strong>The</strong> result —high productivity and surface finish quality.◾◾1PH8 main spindle motor◾◾1FE1 built-in motors◾◾Motor spindles for milling, turning, grindingand special applications1FT71FK71FN3Weiss hybrid spindle1FE11PH81FW615

More safety — guaranteedWhen safety for personnel and machine is involved, <strong>SINUMERIK</strong> doesn’t make any compromises. <strong>SINUMERIK</strong>Safety Integrated is a comprehensive safety package to protect personnel and machines — extremely efficientand economical, thanks to the complete integration of safety functions in the control and drive.Simply safeThanks to <strong>SINUMERIK</strong> Safety Integrated, your machine canbe operated safely and practicably for all required operatingconditions. For example, in the setup and test operationwhen the protective door is open. Also with regard tothe communication with other safety-relevant components,<strong>SINUMERIK</strong> Safety Integrated is extremely flexible.Flexible, because:◾◾Controllers can communicate safely via PROFIBUS orPROFINET. For example, a <strong>SINUMERIK</strong> <strong>840D</strong> <strong>sl</strong> with aSIMATIC F-CPU.◾◾<strong>The</strong> DP/AS-i F-Link permits safe network transition betweenAS-i Bus and PROFIBUS using ASisafe onPROFIsafe.<strong>The</strong> safety functions satisfy the requirements of category3 as well as PL d in accordance with DIN EN ISO 13849-1and the Safety Integrity Level SIL 2 in accordance with DINEN 61508. This allows the main requirements from the EUmachine regulation to be implemented easily andeconomically.161)This product contains the software developed by the OpenSSL Project for the application in the OpenSSL Toolkit (www.opens<strong>sl</strong>.org)

Functions, softkeys and shortcutsInsert keyControl keyINSERTEdit mode for input fields or selectionmode for comboboxes andtoggle fields. <strong>The</strong>se can be exitedby making a new insert withoutchange.CTRL P Create screenshotCTRL L Toggle between languagesINSERTUndo function provided no input oraccept of the data in the fields hasbeen made.CTRL C CopyCTRL X CutSELECTToggle key<strong>The</strong> Toggle key (Select) also allowstoggle fields to be switched directlywithout opening them. Shift-Toggleswitches them back.Cursor keysOpen/close directory, open/closeprogram, open/close cycleCTRL V InsertCTRLCTRLYZRepeat the input (editorfunctionality)Undo – max. five lines in the editor(editor functionality)CTRL A Select all (editor functionality)VariousCTRLGo to program startSHIFTINSERTComment-out cycles and direct editof programGuide cyclesCTRL END Go to program endCalculator functionHelp functionCTRL ALT SCTRL ALT DSave NCK / PLC / drive/ HMI completearchiveSave the log files on USB or CF cardCTRLSimulation/simultaneous recordingMove: shift cursor up/down androtate in the 3D pictureMove segmentOverride +/– (simulation)VariousCTRL E<strong>SINUMERIK</strong> Ctrl-EnergyCtrl-E Analysis, Ctrl-E ProfileCTRL G Grid model in simulationCTRL M Maximum simulation speedCTRL F Search in all masksCTRL S Single block on/off (simulation)?or*Wildcards can be used in the searchmasks, where “?” represents anycharacter, “*” represents any numberof any characterSHIFTSHIFTALTENDSelect up to the end of the blockSelect up to the beginning of the lineJump to the beginning of the lineALT S Input of Asian charactersENDJump to the end of the line17

Performance dataOptimum, digital complete solution with SINAMICS S120Up to• 10 operating mode groups• 10 channels and• 31 axes/spindlesChannel structure:• Simultaneous, asynchronous processing of part programsAxis functions• Acceleration with jerk limitation• Tracking mode• Separate path feed for fillets and chamfers• Travel to limit stop• Coupled axes (TRAIL)Spindle functions• Various thread cutting functions• Automatic gear ratio selection• Oriented spindle stop• On-the-fly synchronization of the axisInterpolation• Linear-interpolating axes• Circle via center point and end point or via intermediate point• Helical interpolation• NURBS (non-uniform rational B-splines) universal interpolator• Continuous-path mode with programmable rounding clearance• Spline, polynomial and involute interpolationTransformations• Cartesian point-to-point (PTP) travel• Chained transformations• Generic transformationMeasuring functions/cyclesMeasuring level 1:• Two probes (switching) with/without delete distance-to-goMeasuring level 2:• Logging of measurement results• Measuring functions from synchronous actions• Cyclical measurementTechnologies• Stamping and nibbling functions• Oscillation functions• Multiple feeds in the block (e.g. for calipers)• Handwheel superimposition• Electronic transfer• <strong>SINUMERIK</strong> MDynamics three axes• <strong>SINUMERIK</strong> MDynamics five axesMotion synchronous actions• Fast CNC input/outputs• Synchronous actions and fast help function output, includingthree synchronous functions• Positioning of axes and spindles using synchronous actions• Clearance control• Continuous dressing (parallel dressing, online changes of thetool correction)• Asynchronous subroutines• Actions between operating modesOpen Architecture• Integrate configured pictures• Program pictures, operating areas and command interfaces• Integrate OEM-specific solutions in the NC kernelProgrammingCNC programming language:• Powerful programming language(DIN 66025 and high-level language extension), e.g.– configurable user variables– macro technique• Program jumps and branches• Program coordination with WAIT, START, INIT• Control structures IF-ELSE-ENDIF, WHILE, FOR, REPEAT, LOOP• STRING functions• Program creation parallel to the machining• Zero offsets• Look ahead• Program/workpiece managementProgrammer support:• Powerful program editor• Programmer support for geometric inputs andcycles with programGUIDE• Technological cycles for drilling/milling and turning• Programmer and operator support for turning andmilling machines with ShopTurn/ShopMill machining stepprogrammingSimulation/visualization• Up to 10 channels can be simulated sequentially• Quick View for mold making fast view(3D preview for NC programs)• Simultaneous recording, simulation for turning and millingand for multitechnology machinesOperating modes• AUTOMATIC, JOG, TEACH IN, MDA; are supported with Repos(reapproach to the contour)18

Everything you ever wanted to know about <strong>SINUMERIK</strong> CNC:www.siemens.com/sinumerikEverything about shopfloor manufacturing:www.siemens.com/cnc4youEverything about the <strong>SINUMERIK</strong> Manufacturing Excellenceportfolio of services:www.siemens.com/sinumerik/manufacturing-excellenceInformation about CNC training:www.siemens.com/sinumerik/trainingSiemens AGIndustry SectorMotion Control SystemsP.O. Box 31 8091050 ERLANGENGERMANYSubject to change without prior noticeOrder No.: E20001-A1460-P610-X-7600Dispo 06311WÜ/37276 STAN.52.2.02 WS 11113.0Printed in Germany© Siemens AG 2011<strong>The</strong> information provided in this brochure contains merelygeneral descriptions or characteristics of performance whichin case of actual use do not always apply as described or whichmay change as a result of further development of the products.An obligation to provide the respective characteristicsshall only exist if expres<strong>sl</strong>y agreed in the terms of contract.All product designations may be trademarks or product namesof Siemens AG or supplier companies whose use by thirdparties for their own purposes could violate the rights of theowners.