development of column flotation technology at national metallurgical ...

development of column flotation technology at national metallurgical ...

development of column flotation technology at national metallurgical ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

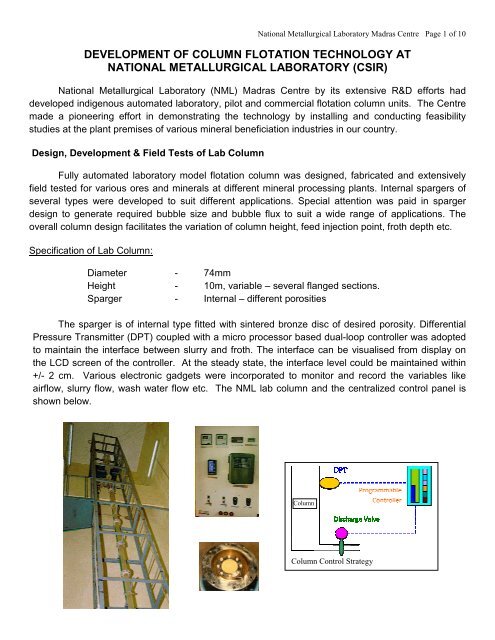

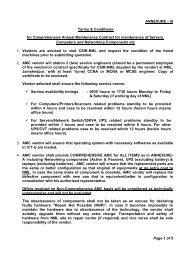

N<strong>at</strong>ional Metallurgical Labor<strong>at</strong>ory Madras Centre Page 1 <strong>of</strong> 10DEVELOPMENT OF COLUMN FLOTATION TECHNOLOGY ATNATIONAL METALLURGICAL LABORATORY (CSIR)N<strong>at</strong>ional Metallurgical Labor<strong>at</strong>ory (NML) Madras Centre by its extensive R&D efforts haddeveloped indigenous autom<strong>at</strong>ed labor<strong>at</strong>ory, pilot and commercial <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> units. The Centremade a pioneering effort in demonstr<strong>at</strong>ing the <strong>technology</strong> by installing and conducting feasibilitystudies <strong>at</strong> the plant premises <strong>of</strong> various mineral benefici<strong>at</strong>ion industries in our country.Design, Development & Field Tests <strong>of</strong> Lab ColumnFully autom<strong>at</strong>ed labor<strong>at</strong>ory model <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> was designed, fabric<strong>at</strong>ed and extensivelyfield tested for various ores and minerals <strong>at</strong> different mineral processing plants. Internal spargers <strong>of</strong>several types were developed to suit different applic<strong>at</strong>ions. Special <strong>at</strong>tention was paid in spargerdesign to gener<strong>at</strong>e required bubble size and bubble flux to suit a wide range <strong>of</strong> applic<strong>at</strong>ions. Theoverall <strong>column</strong> design facilit<strong>at</strong>es the vari<strong>at</strong>ion <strong>of</strong> <strong>column</strong> height, feed injection point, froth depth etc.Specific<strong>at</strong>ion <strong>of</strong> Lab Column:Diameter - 74mmHeight - 10m, variable – several flanged sections.Sparger - Internal – different porositiesThe sparger is <strong>of</strong> internal type fitted with sintered bronze disc <strong>of</strong> desired porosity. DifferentialPressure Transmitter (DPT) coupled with a micro processor based dual-loop controller was adoptedto maintain the interface between slurry and froth. The interface can be visualised from display onthe LCD screen <strong>of</strong> the controller. At the steady st<strong>at</strong>e, the interface level could be maintained within+/- 2 cm. Various electronic gadgets were incorpor<strong>at</strong>ed to monitor and record the variables likeairflow, slurry flow, wash w<strong>at</strong>er flow etc. The NML lab <strong>column</strong> and the centralized control panel isshown below.ColumnColumn Control Str<strong>at</strong>egy

N<strong>at</strong>ional Metallurgical Labor<strong>at</strong>ory Madras Centre Page 2 <strong>of</strong> 10Field Tests: Hindustan Copper Ltd., Malanjkhand (Copper) Kudremukh Iron Ore Co. Ltd., Kudremukh (Iron) Gujar<strong>at</strong> Mineral Development Corpor<strong>at</strong>ion, Ahmedabad (Fluorspar) Gujar<strong>at</strong> Mineral Development Corpor<strong>at</strong>ion, Ahmedabad (Cu-Pb-Zn)) Hindustan Zinc Ltd., Udaipur (Agucha, Lead-Zinc) Hindustan Zinc Ltd., Udaipur (Dariba, Lead-Zinc) Bhar<strong>at</strong> Gold Mines Ltd., KGF, Karn<strong>at</strong>aka (Gold)Chronological Activities <strong>of</strong> the field tests with Labor<strong>at</strong>ory Flot<strong>at</strong>ion ColumnYear Project Title Sponsor Test Site198719881989-911992-93Explor<strong>at</strong>ory project on fine particleprocessing by new techniquesDevelopment <strong>of</strong> 3 types <strong>of</strong> cells –conventional <strong>column</strong>, electro-<strong>column</strong>& combin<strong>at</strong>ion.Design & <strong>development</strong> <strong>of</strong> fullyautom<strong>at</strong>ed <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> with st<strong>at</strong>e<strong>of</strong>-theinstrumentsAmenability studies <strong>at</strong> Malanjkhandcopper project – copper oreMinistry <strong>of</strong> MinesMinistry <strong>of</strong> MinesNML Internal resourcesHindustan Copper LtdNMLMCNMLMCNMLMCMalanjkahand,M.P1993-94Feasibility studies <strong>at</strong> Kudremukh IronOre Company Ltd.Kudremukh Iron Ore Co.Ltd.Kudremukh,Karn<strong>at</strong>aka1994-95Fluorspar benefici<strong>at</strong>ion <strong>at</strong> Gujar<strong>at</strong>Mineral Development Corpn.Gujar<strong>at</strong> MineralDevelopment CorpnKadipani,Gujar<strong>at</strong>1995-96Column <strong>flot<strong>at</strong>ion</strong> <strong>of</strong> Pb-Zn ore <strong>at</strong>Agucha, HZLHindustan Zinc Ltd.Agucha,Rajasthan1996-97Column <strong>flot<strong>at</strong>ion</strong> <strong>of</strong> Pb-Zn ore <strong>at</strong>Dariba, HZLHindustan Zinc Ltd.Dariba,Rajasthan1997-981998-992007-08Benefici<strong>at</strong>ion <strong>of</strong> multi metal ore <strong>at</strong>Ambaji, GMDC – Cu-Pb-Zn oreAmenability studies <strong>at</strong> Bhar<strong>at</strong> GoldMines Ltd. – Gold oreBenefici<strong>at</strong>ion <strong>of</strong> siliceous limestonefrom Jayanthipuram depositGujar<strong>at</strong> MineralDevelopment CorpnBhar<strong>at</strong> Gold Mines Ltd.Madras Cements Ltd.,ChennaiAmbam<strong>at</strong>ha,Gujar<strong>at</strong>Kolar GoldFields,Karn<strong>at</strong>akaNMLMC

Commercializ<strong>at</strong>ion <strong>of</strong> Labor<strong>at</strong>ory Flot<strong>at</strong>ion ColumnN<strong>at</strong>ional Metallurgical Labor<strong>at</strong>ory Madras Centre Page 3 <strong>of</strong> 10After field tests the labor<strong>at</strong>ory <strong>column</strong> was standardized and erected an autom<strong>at</strong>ic systems toNMDC R&D Centre Hyderabad by particip<strong>at</strong>ing in a global tender. The system was installed and isbeing utilized for the benefici<strong>at</strong>ion R&D studies <strong>of</strong> iron ore fines. One more system was installed <strong>at</strong>the Department <strong>of</strong> Mining Engineering, Golden Valley Institute <strong>of</strong> Technology, KGF, Karn<strong>at</strong>aka fortheir curriculum introduced in B.Tec. Course.1999Transfer <strong>of</strong> Fully Autom<strong>at</strong>edLabor<strong>at</strong>ory Column to N M D C R&DCentre, Hyderabad2001Transfer <strong>of</strong> Fully Autom<strong>at</strong>edLabor<strong>at</strong>ory Column to G V I T, KGF,Karn<strong>at</strong>aka

Bhar<strong>at</strong> Gold Mines Ltd., KGF (Gold ore) Gujar<strong>at</strong> Mineral Development Corpor<strong>at</strong>ion Ltd., Kadipani (Fluorspar) Indian Rare Earths Ltd., OSCOM, Ch<strong>at</strong>rapur (Sillimanite) Sociedade de Fomento Industrial Pvt. Ltd, Goa. (Iron ore) Calpro Mineral Technologies Ltd., Salem (Limestone) JSW Ltd., Tornagallu (Iron ore) T<strong>at</strong>a Steel, Joda (Iron ore)N<strong>at</strong>ional Metallurgical Labor<strong>at</strong>ory Madras Centre Page 5 <strong>of</strong> 10Chronological Activities <strong>of</strong> the field tests and Demonstr<strong>at</strong>ions with Pilot Flot<strong>at</strong>ion ColumnYear Project Title Sponsor Test Site19961996-971999-002001-022002-032003-042004-052006-072008-09Design & <strong>development</strong> <strong>of</strong> semicommercial,0.5m dia <strong>column</strong> withautom<strong>at</strong>ic controls.Demo <strong>of</strong> 0.5M dia <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> forgold ore benefici<strong>at</strong>ion <strong>at</strong> BGMLField testing <strong>of</strong> 0.5M dia <strong>column</strong> <strong>at</strong>Kadipani, GMDC, for fluorsparbenefici<strong>at</strong>ionDemo <strong>of</strong> <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> forsillimanite benefici<strong>at</strong>ion <strong>at</strong> OSCOM,OrissaColumn <strong>flot<strong>at</strong>ion</strong> <strong>of</strong> iron ore fines <strong>at</strong>Fomento, GoaDemo <strong>of</strong> 0.5M dia <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> forthe benefici<strong>at</strong>ion <strong>of</strong> Limestone <strong>at</strong>SalemStudies on the Benefici<strong>at</strong>ion <strong>of</strong>GarnetAmenability studies <strong>at</strong> JSW Steel Ltd.0.5M dia semi-commercial <strong>column</strong>Pilot Scale Column Flot<strong>at</strong>ion Studieson the Iron Ore Fines <strong>at</strong> JEIMNML Internal resourcesBhar<strong>at</strong> Gold Mines Ltd.Gujar<strong>at</strong> MineralDevelopment CorpnIndian Rare EarthsLimitedSociedade De FomentoIndustrial Ltd.Calpro MineralTechnologies India Pvt.Ltd.Indian Ocean GarnetSands Co. Pvt. Ltd.Jindal South West SteelsLtd.TATA Steel Ltd.NMLMCKolar GoldFields,Karn<strong>at</strong>akaKadipani,Gujar<strong>at</strong>OSCOM,Ch<strong>at</strong>rapur,OrissaMadgau, GoaSalem,TamilnaduTuticorin,TamilnaduVijayanagar,Ballery,Karn<strong>at</strong>akaJoda, Barbil,OrissaThis exercise cre<strong>at</strong>ed lot <strong>of</strong> interest and confidence in the industrial circles on <strong>column</strong> <strong>flot<strong>at</strong>ion</strong><strong>technology</strong> which lead the industry to adopt this <strong>technology</strong> in their oper<strong>at</strong>ions.

N<strong>at</strong>ional Metallurgical Labor<strong>at</strong>ory Madras Centre Page 6 <strong>of</strong> 10Design, Install<strong>at</strong>ion & Commissioning <strong>of</strong> Commercial Scale Flot<strong>at</strong>ion ColumnsBased on the successful demonstr<strong>at</strong>ion <strong>of</strong> semi-commercial <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> (0.5 m diameter) for thebenefici<strong>at</strong>ion <strong>of</strong> sillimanite and limestone , commercial size <strong>column</strong>s were designed andcommissioned for the following industries.(a). Indian Rare Earths Limited, OSCOM,Ch<strong>at</strong>rapur, Orissa: A commercial size <strong>flot<strong>at</strong>ion</strong><strong>column</strong> <strong>of</strong> 1.3 m dia and 10 m height was designedto tre<strong>at</strong> 7 t/h <strong>of</strong> sillimanite for IREL and installed <strong>at</strong>OSCOM, Ch<strong>at</strong>rapur. The <strong>column</strong> is equipped withst<strong>at</strong>e-<strong>of</strong>-the-art electronic gadgets for the effectivecontrol <strong>of</strong> the slurry/froth interface, slurry feed, airand wash w<strong>at</strong>er flow r<strong>at</strong>es. An indigenouslydeveloped ceramic spargers were incorpor<strong>at</strong>ed towith stand the highly abrasive sillimanite particles.The <strong>column</strong> was successfully commissioned duringNovember 2005. The performance <strong>of</strong> the <strong>flot<strong>at</strong>ion</strong><strong>column</strong> was evalu<strong>at</strong>ed and it was observed th<strong>at</strong> the<strong>column</strong> produced excellent <strong>metallurgical</strong>results for the designed capacity.The sillimamnite concentr<strong>at</strong>e assaying 98% (after magnetic separ<strong>at</strong>ion) with the recovery <strong>of</strong> 90% wasobtained from <strong>flot<strong>at</strong>ion</strong> <strong>column</strong>. With the introduction <strong>of</strong> the <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> in the sillimanite circuit,the production <strong>of</strong> sillimanite has been increased by about 40%.

N<strong>at</strong>ional Metallurgical Labor<strong>at</strong>ory Madras Centre Page 7 <strong>of</strong> 10(b). Calpro Mineral Technologies India Pvt. Ltd.: The Salem district <strong>of</strong> Tamilnadu is bestowed withmany limestone deposits owned by small mine owners. Namakkal <strong>of</strong> Salem district is famous forpoultry industry. Calcium in the form <strong>of</strong> CaCO 3 , is an essential ingredient in the poultry feed and thedemand is about 100 t/d. Since limestone is used to supplement Calcium content, it should be freefrom contamin<strong>at</strong>ion <strong>of</strong> chemicals. Also the silicacontent in limestone should be less than 2%.Hence, reverse <strong>flot<strong>at</strong>ion</strong> where in gangue/silicam<strong>at</strong>erials are flo<strong>at</strong>ed was adopted. Acommercial size <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> <strong>of</strong> 1.2 mdiameter was designed to tre<strong>at</strong> 6 t/h <strong>of</strong> limestoneand installed <strong>at</strong> the mines site <strong>of</strong> M/s CalproMineral Technologies India Pvt. Ltd., Salem.The <strong>column</strong> is completely autom<strong>at</strong>ic andindigenous in all respects.

N<strong>at</strong>ional Metallurgical Labor<strong>at</strong>ory Madras Centre Page 8 <strong>of</strong> 10(c). Indian Rare Earths Limited, Chavara, Kerala:S<strong>at</strong>isfied with the performance and oper<strong>at</strong>ion <strong>of</strong>NML <strong>column</strong> <strong>at</strong> OSCOM, Ch<strong>at</strong>rapur for thebenefici<strong>at</strong>ion <strong>of</strong> sillimanite, M/s IREL decided toinstall another <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> in their mineralsepar<strong>at</strong>ion plant <strong>at</strong> Chavara, Kerala. The <strong>column</strong> issimilar to the <strong>column</strong> <strong>at</strong> OSCOM in design andcapacity which has to tre<strong>at</strong> 6TPH <strong>of</strong> sillimanite. .The plant is commissioned in 2009 and is inoper<strong>at</strong>ion to the designed capacity.

Public<strong>at</strong>ions on Column Flot<strong>at</strong>ion:Peer Reviewed Intern<strong>at</strong>ional Journals : 08Peer Reviewed N<strong>at</strong>ional Journals : 02Intern<strong>at</strong>ional & N<strong>at</strong>ional Conference Proceedings : 19Internal Project Reports : 18N<strong>at</strong>ional Metallurgical Labor<strong>at</strong>ory Madras Centre Page 10 <strong>of</strong> 10Recognitions / Awards:Binani Gold Medal for Best Paper (IIM) - - - - - -- 1994Khare Award for Best Paper (IIME) - - - - - - - - 1998Altekar Award for Best Technology (NML) - - - - - - - - 2002Altekar Award for Best Technology (NML) - - - - - - - -- 2005Mineral Benefici<strong>at</strong>ion Award (IIME) - - - - - - - - - - -- 2006N<strong>at</strong>ional Mineral Award (Min. <strong>of</strong> Mines) - - -- - - - - -2006MOU with McNally Bhar<strong>at</strong> Engineering Co. Ltd., BangaloreLooking <strong>at</strong> the success <strong>of</strong> NML Flot<strong>at</strong>ion <strong>column</strong> in the benefici<strong>at</strong>ion <strong>of</strong> sillimanite andlimestone M/s McNally Bhar<strong>at</strong> Engineering Company Limited, a leading mineral processingequipment manufacturer and marketing organiz<strong>at</strong>ion showed interest in marketing the NML <strong>flot<strong>at</strong>ion</strong><strong>column</strong> <strong>technology</strong>. Both the organiz<strong>at</strong>ions come to an agreement and signed an Memorandum <strong>of</strong>Understanding in 2008. The salient fe<strong>at</strong>ure <strong>of</strong> the agreement is14.5% on the invoice value willbe remitted to NML by McNally Bhar<strong>at</strong> Engineering Co. Ltd. towards premium and royalty oneach supply <strong>of</strong> <strong>flot<strong>at</strong>ion</strong> <strong>column</strong>.Since then the following organiz<strong>at</strong>ions were placed the orders to procure the various <strong>column</strong>s.1. Pilot <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> <strong>of</strong> 0.5m diameter and 14m height with the st<strong>at</strong>e <strong>of</strong> the equipments andfully autom<strong>at</strong>ic controls - M/s RBSSN, Hospet, Karn<strong>at</strong>aka. Cost: Rs.28.00 lakhsSupplied, erected and commissioned.2. Fully autom<strong>at</strong>ic standard 74mm diameter labor<strong>at</strong>ory <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> with advanced controls –NEIST (CSIR), Jorh<strong>at</strong>, Assam. Cost: 18.00 lakhsSuccessfully commissioned and working s<strong>at</strong>isfactorily <strong>at</strong> NEIST Labor<strong>at</strong>ory.3. 70 tph capacity <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> for the benefici<strong>at</strong>ion <strong>of</strong> barites <strong>at</strong> Mangampet, AP – M/sAndhra Barites Corpor<strong>at</strong>ion Ltd., Kadapa, Andhra Pradesh. Cost: 100.00 lakhsWork is in progress.

![Total shortlisted candidates[1].pdf - National Metallurgical Laboratory](https://img.yumpu.com/49458334/1/184x260/total-shortlisted-candidates1pdf-national-metallurgical-laboratory.jpg?quality=85)

![Result _Advt_ 5-2012_[1].pdf - National Metallurgical Laboratory](https://img.yumpu.com/29226263/1/184x260/result-advt-5-2012-1pdf-national-metallurgical-laboratory.jpg?quality=85)