development of column flotation technology at national metallurgical ...

development of column flotation technology at national metallurgical ...

development of column flotation technology at national metallurgical ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

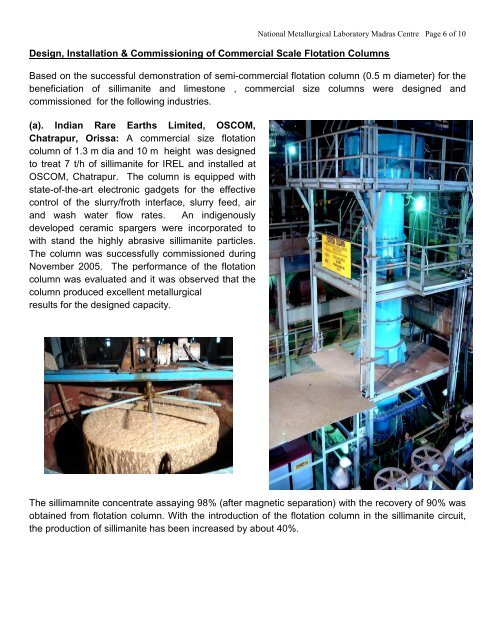

N<strong>at</strong>ional Metallurgical Labor<strong>at</strong>ory Madras Centre Page 6 <strong>of</strong> 10Design, Install<strong>at</strong>ion & Commissioning <strong>of</strong> Commercial Scale Flot<strong>at</strong>ion ColumnsBased on the successful demonstr<strong>at</strong>ion <strong>of</strong> semi-commercial <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> (0.5 m diameter) for thebenefici<strong>at</strong>ion <strong>of</strong> sillimanite and limestone , commercial size <strong>column</strong>s were designed andcommissioned for the following industries.(a). Indian Rare Earths Limited, OSCOM,Ch<strong>at</strong>rapur, Orissa: A commercial size <strong>flot<strong>at</strong>ion</strong><strong>column</strong> <strong>of</strong> 1.3 m dia and 10 m height was designedto tre<strong>at</strong> 7 t/h <strong>of</strong> sillimanite for IREL and installed <strong>at</strong>OSCOM, Ch<strong>at</strong>rapur. The <strong>column</strong> is equipped withst<strong>at</strong>e-<strong>of</strong>-the-art electronic gadgets for the effectivecontrol <strong>of</strong> the slurry/froth interface, slurry feed, airand wash w<strong>at</strong>er flow r<strong>at</strong>es. An indigenouslydeveloped ceramic spargers were incorpor<strong>at</strong>ed towith stand the highly abrasive sillimanite particles.The <strong>column</strong> was successfully commissioned duringNovember 2005. The performance <strong>of</strong> the <strong>flot<strong>at</strong>ion</strong><strong>column</strong> was evalu<strong>at</strong>ed and it was observed th<strong>at</strong> the<strong>column</strong> produced excellent <strong>metallurgical</strong>results for the designed capacity.The sillimamnite concentr<strong>at</strong>e assaying 98% (after magnetic separ<strong>at</strong>ion) with the recovery <strong>of</strong> 90% wasobtained from <strong>flot<strong>at</strong>ion</strong> <strong>column</strong>. With the introduction <strong>of</strong> the <strong>flot<strong>at</strong>ion</strong> <strong>column</strong> in the sillimanite circuit,the production <strong>of</strong> sillimanite has been increased by about 40%.

![Total shortlisted candidates[1].pdf - National Metallurgical Laboratory](https://img.yumpu.com/49458334/1/184x260/total-shortlisted-candidates1pdf-national-metallurgical-laboratory.jpg?quality=85)

![Result _Advt_ 5-2012_[1].pdf - National Metallurgical Laboratory](https://img.yumpu.com/29226263/1/184x260/result-advt-5-2012-1pdf-national-metallurgical-laboratory.jpg?quality=85)