MODERN 130' TURNTABLE - Walthers

MODERN 130' TURNTABLE - Walthers

MODERN 130' TURNTABLE - Walthers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

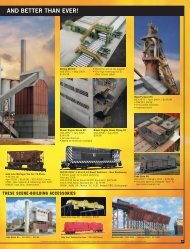

933-2829 I sheet 12/2/04 10:22AM Page 1HO ScaleStructure Built-up933-2829<strong>MODERN</strong> <strong>130'</strong> <strong>TURNTABLE</strong>Thanks for purchasing this CornerstoneSeries ® Built-up.HISTORY OF THE <strong>TURNTABLE</strong>Although we associate turntables withsteam locos, they’re still used in someengine terminals. Requiring less spacethan a wye or loop, they’re an economicalway to reverse locos or cars. Aturntable is basically a large bridgeequipped with rails that can revolve ina full circle. Around the turntable, aseries of radial tracks (other nicknameswere also used) run into roundhousestalls, open-air storage or servicetracks. So that all rails were at thesame height, the turntable was constructedin a large circular opening,called a pit. Early pits were made ofearth or stone, while modern designsused concrete.The basic concept of the turntableevolved before the railroad, whencrude examples were used to reversecoal carts in mines. From the earliestdays, steam locos (as well as specializedequipment like snowplows andobservation cars) were built to operatein one direction, and had to be turnedaround for their return trip. By 1842, adevice we would recognize as a railroadturntable was in regular use inEngland. Over the next century, theturntable became a fixture of railroadingaround the world.In America, three basic types developed.The first was the center-balance,with a central pivot point and wheelsunder each end of the bridge to supportthe weight, but bigger and heavierlocos put too much strain on theseearly turntables. The next was theArticulated Design, with a central verticalhinge, which allowed the table totip in the direction of the greatestweight. The final type (still seen todayand the prototype for this model) wasthe Continuous Girder, which supportsthe weight on a center pivot and onload-bearing wheels under each end.Two styles of turntable bridges becamecommon. These included the DeckStyle, with most of the bridge belowground level (requiring a deep pit) andthe Through Type, where a portion ofthe bridge was above ground.In order to swing the table end for end asource of power was needed. In theearly days, men pushed the tables, andthey came to be called “armstrongs,” asit took strong arms to do the job! Inlater years steam and gasoline engineswere used to drive one set of the loadbearingwheels, but electric motorswere found to be the best choice formost applications. Electricity was suppliedto most tables by an arch over thecenter, connected to overhead powerlines.In most terminals, the turntable androundhouse were in constant use. Foreasier and safer operation, turntableshad a small operator’s cabin at one endof the bridge. This housed controls andplaced the operator in the best positionto align the rails. Many also sported anold engine bell, which was rung to warnthat the table was being turned.As was the case with most engine servicefacilities, new turntables were builtto accommodate the longest engines inservice on a division. For this reason,some large engines were restricted toone or two divisions where turntablesand facilities were big enough for them.Railroads also went to extremes to utilizeexisting turntables. Some orderednew steam locos with short wheelbasesso they would fit, others extendedturntable rails, and some resorted tojacking up the end of the tender!With the coming of diesels, the need forturntables began to decline. Although Funits still had to be turned, the newroadswitchers and Geeps could be runin either direction. Today, the number ofturntables on active duty is declining,but those in use can be found at majorshops and engine terminals. A few arealso in use at railroad museums.ON YOUR LAYOUTThis <strong>130'</strong> table is typical of unitsinstalled by most roads from the 1920son at division point terminals, whereengines were changed and serviced. Itwill easily accommodate large articulatedsteam locos and most diesels up to 18"(45cm) long.As bigger power came into service, biggerroundhouses were also required.This can easily be modeled with theModern Roundhouse (933-2900) whichincludes parts for three complete stalls.It can be expanded up to a full circlewith the Modern Roundhouse Add-OnStalls (933-2901) which includesmatching roof panels, doors and interiortruss work. Your new model will beright at home alongside the MachineShop (933-2902), Modern CoalingTower (933-2903), Sanding Tower(933-3182), Steel Water Tank (933-3043), and Cinder Conveyor and AshPit (933-3181) as well.In many bigger cities, the terminal waspart of the railroad’s shop complex,which can be modeled with theBackshop (933-3039) and Car Shop(933-3040).For more ideas to detail your scene, askyour dealer, visit walthers.com or seethe latest <strong>Walthers</strong> HO Scale ModelRailroad Reference Book.For additional prototype history andinformation on turntables, see “TheLocomotive Merry-Go-Round” byJames Alexander Jr. in the July 1995issue of Trains magazine. Your locallibrary may also have copies of olderRailroad Maintenance Cyclopedias,which provided basic information onturntables and other facilities.©2004 Wm. K. <strong>Walthers</strong>, Inc.Milwaukee WI, 53218

933-2829 I sheet 12/2/04 10:23AM Page 2INSTALLATION ON YOURLAYOUTYour new turntable has been carefullyassembled and tested to provideyears of enjoyable operation.Please take a few minutes to lookover the parts, read these instructionsINSTALLING THE PITYour new turntable automaticallyreverses track polarity whenturned. As a result, the unit has twoelectrically insulated areas wherethe track on the bridge is not powered.These are identified on theunderside of the lip by the “NOTRACK” lettering (also shown onthe mounting template). Workingapproach and fan tracks must beinstalled away from these areas –we suggest placing them at 90° tothe approach tracks. You can, however,add an unpowered displaytrack at these points if desired.The opening in the wall of the pithouses the optical sensor used asthe “zero point.”For the indexing to work properly,INSTALLING THE CONTROLBOXThis unit is used to program andoperate your turntable. As notedabove, we suggest a dedicatedpower pack be used as a powerthis area, along with the small gearteeth and ring rail molded in thebottom of the pit, must be cleanand open at all times. If you planto paint or weather the pit further,mask off these areas before starting.Before installing the pit, coverthe center pivot hole with tape tokeep out dust and debris.supply. Do not attempt to run theturntable at this time.The control box can be used as-is,or flush-mounted on the surface orside of your layout. Simply removethe four screws from the back toand study the drawings beforestarting.Your new turntable drive should bepowered from its own power pack,sold separately. Check the outputof the transformer with a voltmeterbefore making any electrical connections.The drive operates best at15 Volts AC or DC, 500mA; aminimum of 12 Volts is required,but total output must not exceed 19Volts AC (RMS) or DC.For best results your new turntablemust be installed on a flat, levelsurface. Determine the location foryour pit; use the enclosed templateto cut the mounting hole in yourbenchwork. Allow at least 2-1/4"(5.7cm) of clearance below the pit.The zero reader is mounted directlybelow a mounting boss; be sureto provide clearance in your benchworkfor the reader too.If your pit will be mounted on awooden surface, drill out the areasfor the mounting bosses as shownon the template with a 5/16"(8mm) bit. Secure the pit in placeusing the eight screws and washers— if the thickness of your woodsurface is less than 1/2", use additionalwashers (not included) forcorrect spacing — do not overtighten as this could cause the pitto warp.If you are using foam for the surfaceof your layout, open the areasfor the mounting bosses slightlyand push the pit into place.Make sure the pit is level, secureand properly supported beforeproceeding.remove the front panel. Cut amounting hole with the template,place the front panel in the openingand reattach the back.RIGHT/LEFT ARROW: Use to moveand stop the bridge.SET: Use to programthe stopping points.WiringConnection points are markedon the underside as follows:B1 and B2 = connect to railpower supply; powers bridgerails.U & V = connect to AC terminalson power pack; powersdrive mechanism.All wires are secured using thesmall screw terminals.Plug in the large gray cablefrom the indexing unit (locatedbeneath the pit) into the porton the side of the control box.ZERO: Use to locate the zero point.POS: Red LED comes onwhen the turntable is in aprogrammed position.POWER: Red LED stayslit when power is on.

933-2829 I sheet 12/2/04 10:23AM Page 3INSTALLING SERVICETRACKSWith the pit in place, you caninstall service tracks. The indexingcan be programmed for up to 60different stopping positions so youcan add tracks almost anywherearound the pit – but remember,don’t install working tracks in the“NO TRACK” areas.The bridge is equipped with Code83 rail; if you are using anothersize for your service tracks, use<strong>Walthers</strong> Transition Tracks #948-897 for Code 100 or #948-898 forCode 70 (each sold separately).For a smooth transition betweenthe bridge and service tracks,you’ll need to modify your railsby filing the inside ball of the railat a slight angle for about 3/16"(4mm) (see below).remove with a fileAll service tracks must align withthe bridge rails in a straight line.The bridge can be used as a guide,but VACUUM THE PIT ANDTHE SURROUNDING AREABEFORE PUTTING THEBRIDGE IN THE CENTERPIVOT! Follow the instructionsbelow for installing the bridge.For the rails to sit correctly on thelip of the pit, you must remove afew ties from the end of the track.Important Note: Rails must end atthe edge of the pit — leave a gapof about 1/16" (1.5mm) betweenthe end of each service track andthe bridge. Temporarily tape or pinthe service tracks in place so youcan make any adjustments afterprogramming your stopping positions.Wire the service tracks (parts notincluded) for power as desired.BRIDGE INSTALLATIONImportant Note: Before starting,make sure the bridge rails areequally spaced about 1/16"(1.5mm) beyond each end.Before installing the bridge, thoroughlyvacuum the entire pit toremove all debris from the centerpivot point, the ring rail and geartrack. Remove the tape you placedon the center pivot hole. Insert thecenter pivot on the bridge into thisopening. The arch snaps in placeas shown at the middle of thebridge — don’t glue it down, leaveit removable for track cleaning andmaintenance.PROGRAMMING YOUR<strong>TURNTABLE</strong>Initializing the TurntableBegin by plugging in the powerpack. With the power pack turnedoff, press the SET and ZERO buttonsdown at the same time. Now,turn on the power and hold bothbuttons for four to five seconds.When the POWER light stays on,the unit is ready to use. Press theZERO button until the POWERlight flashes, then release. Theturntable will move to the zeropoint.Programming New StoppingPositions1) Move the bridge from the zeropoint to the first track you’d liketo program by pressing and releasingeither ARROW button.Two stop positions are programmedinto the unit for testingat the factory. Don’t remove theseuntil you have programmed two orthree of your own tracks! You canalso use these to test the operationof your unit at this time – simplypress and release either the LEFTor RIGHT ARROW keys. Thebridge will move in the directionselected until it locates a factorysetting. The table will over-run thestop position slightly when turningcounterclockwise — this is normal— then back slowly into position.2) Move the bridge to your firstdesired position and stop the tableabout 1/8" (3mm) from the righthand rail. (If you go too far, pressand release the LEFT ARROW button;touch and release eitherARROW button to stop, then movethe bridge counterclockwise withthe RIGHT ARROW button.)3) Hold the SET button and graduallyinch the bridge rails into a 90°alignment by pushing and releasingthe RIGHT ARROW key asneeded to move the bridge counterclockwise— use the outsideedges of the rails as a guide tocheck that all rails are perfectlyaligned.(If the POS light comes on beforethe track is aligned correctly, clearthe setting by pressing and holdingthe SET key until the POS lightgoes off.)4) When the tracks and bridge arealigned to your satisfaction, pressand hold the SET button until thePOS light comes on to show thestop position is programmed intothe memory.Repeat steps one through five foreach stopping position.Important Note: Although tracksmay be directly across from eachother, you must program a separatestopping position on each endof the bridge.

933-2829 I sheet 12/2/04 10:23AM Page 4FINAL ASSEMBLYOnce you’re satisfied with theoperation of the bridge and how italigns with each track, fasten eachrail securely so its base restsdirectly on the outside lip of theturntable pit. You may wish toglue each rail to the pit surface, orspike the track in place at the firsttie on the benchwork. ImportantNote: Before doing any scenerywork, such as painting or addingballast and ground cover, removethe bridge from the pit and tapeover the center pivot. Before puttingthe bridge back in the centerpivot, carefully and completelyvacuum the pit and the surroundingarea. After reinstalling thebridge, you must find the zeropoint before resuming operation.Just press the ZERO button untilthe POWER light flashes, thenrelease.NORMAL OPERATIONTurn on the power pack; the unit isready to use when the red POWERlight stays on. Use either ARROWbutton to turn the bridge: press andhold the button to pass stoppingpositions. As the bridge approachesthe desired service track,release the ARROW key. Thebridge will overrun the stop positionslightly, then align itself.When the unit stops, the POS indicatorwill light; move your locousing your standard throttle. Fromtime to time, “zero” the turntableto maintain your programmedpositions.MAINTENANCEAs operation can be affected bydust, you may wish to cover yourmodel with a plastic sheet betweenoperating sessions.Zero Point: Make sure this areaand the pit edge is always cleanand free of dust.Use contact cleaner to clean thewipers and slip rings on the bottomof the bridge, should they getdirty.Counting Wheel: If your tablebegins stopping out of alignment,the counting wheel may havebecome plugged with dust. Simplyremove the bridge from the pit andblow any dust clear of the cogwheel.Important Note: Any timethe bridge is removed from the pit,you must find the zero pointbefore resuming operation. Justpress the ZERO button until thePOWER light flashes, thenrelease. The bridge will turnclockwise until it locates the zeropoint and stop. You’re now readyto resume operation using theARROW buttons to move the bridge.Lubrication: In normal use,the drive mechanism shouldonly require servicing aboutonce a year. Use plastic compatiblelubricants made especiallyfor hobby products —NEVER use household oils orlubricants! Remove the arch.Loosen the circuit board,which is held in place withdouble-sided tape. Removethe three screws from the cover.Apply a drop of light oil for electricmotors to the bearing. Applylight gear lubricant to the geartrain. Apply powdered graphite tothe final drive. Reverse these stepsto reassemble — make sure themotor leads are positioned asshown.TROUBLESHOOTINGPOS LIGHT ON CONTROLBOX FLASHES RAPIDLY; Youmay be trying to program a newposition too close to an existingone; it will also flash if youattempt to program more than 60positions.TO FIND THE ZERO POINT;Press the ZERO button until thePOWER light flashes – thenrelease. The bridge will turnclockwise until it locates the zeropoint. NOTE: turn off any otherinfra-red sources in the roomwhen searching for the zero point.TO REMOVE SETTINGS; Movethe bridge to the desired positionand stop — the POS indicator willcome on. Press and hold the SETbutton for a few seconds until thePOS light goes out. (After youhave programmed two or threenew positions, clear the factorytest settings the same way.) Toclear all programmed settings andreset the factory test positions;turn the power pack off. Holddown the SET and ZERO and turnthe power pack back on.IF BRIDGE IS SLIGHTLY OUTOF ALIGNMENT WITHTRACKS (usually all in one direction);Re-zero the turntable byholding down the ZERO buttonuntil the POWER light flashes; theturntable will then re-zero itselfand restore your programmedstopping positions.