Motorized Pulley 220M & 220H, Ã 8.50 in. (216 mm)

Motorized Pulley 220M & 220H, Ã 8.50 in. (216 mm)

Motorized Pulley 220M & 220H, Ã 8.50 in. (216 mm)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

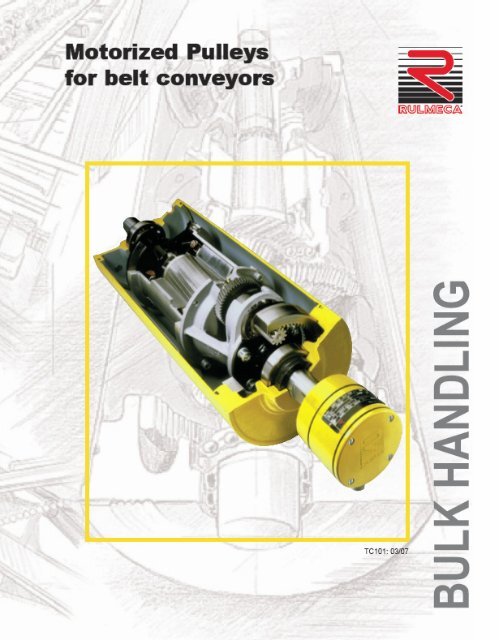

Rulmeca <strong>Motorized</strong> <strong>Pulley</strong>s: a new name with deep rootsThe Rulmeca <strong>Motorized</strong> <strong>Pulley</strong>s presented<strong>in</strong> this catalogue have a long historyto tell. It goes back to the 1950’s, whenthe product was developed <strong>in</strong> Germanyand Denmark.Eventually, through a merg<strong>in</strong>g processthe German Förder und AntriebstechnikAschersleben GmbH and the DanishJohn Kirkegaard Mask<strong>in</strong>fabrik A/Sbecame partners <strong>in</strong> the Interroll Group.From the early 1990’s the manufactur<strong>in</strong>gof all Interroll’s BULK <strong>Motorized</strong> <strong>Pulley</strong>swere centralized <strong>in</strong> Aschersleben, Germany.In July 2003 Rulli Rulmeca S.p.A. purchasedthe production facility <strong>in</strong> Aschersleben,Germany, where <strong>Motorized</strong> <strong>Pulley</strong>shave been developed and producedfor almost half a century, along with theentire BULK Bus<strong>in</strong>ess Unit.Today this plant, renamed RulmecaFAA GmbH, will cont<strong>in</strong>ue the JOKItradition for quality and reliability underthe Rulmeca brand.Thanks to this long history Rulmeca is avery experienced manufacturer of BULK<strong>Motorized</strong> <strong>Pulley</strong>s, offer<strong>in</strong>g the world’slargest product range.www.rulmecacorp.comwww.precismeca.ab.cawww.rulmecacorp.com 2TC101: 03/07

Features and Benefits of Rulmeca <strong>Motorized</strong> <strong>Pulley</strong>sPurpose-built designThe Rulmeca <strong>Motorized</strong> <strong>Pulley</strong> has beenspecifically designed for belt conveyors.Hermetically SealedThe motor, gearbox and bear<strong>in</strong>gs arehermetically sealed <strong>in</strong>side a steel shell.Therefore they are unlikely to fail due toharmful environmental conditions suchas water, dust, grit, chemicals, grease,oil, etc.Space sav<strong>in</strong>g designBecause the drive unit and the bear<strong>in</strong>gsare mounted <strong>in</strong>side the <strong>Motorized</strong> <strong>Pulley</strong>shell, it requires much less room than anexposed drive. No need for costly extraslike cha<strong>in</strong>s, v-belts, coupl<strong>in</strong>gs, bear<strong>in</strong>gs,support structure and special guard<strong>in</strong>g.SafetyThe Rulmeca <strong>Motorized</strong> <strong>Pulley</strong> is one ofthe safest drives available because themotor is completely enclosed and theexternal shafts are always stationary.The only mov<strong>in</strong>g external parts are the<strong>Motorized</strong> <strong>Pulley</strong> shell and bear<strong>in</strong>g hous<strong>in</strong>gs.Low purchas<strong>in</strong>g and <strong>in</strong>stallation costThe Rulmeca <strong>Motorized</strong> <strong>Pulley</strong> is quiteoften less expensive than exposeddrives because it has fewer parts. Thereforeless conveyor design time and partspurchas<strong>in</strong>g costs. It is also much quickerand easier to <strong>in</strong>stall - certa<strong>in</strong>ly less thana quarter of the time taken to fit anexposed system.Low ma<strong>in</strong>tenance costThe end user also benefits from the Rulmeca<strong>Motorized</strong> <strong>Pulley</strong>, because itrequires no ma<strong>in</strong>tenance other than thereco<strong>mm</strong>ended oil change every 10,000operat<strong>in</strong>g hours and oil seal changeevery 30,000 operat<strong>in</strong>g hours. In otherwords, almost 5 years between oilchanges based on an 8-hour/day work<strong>in</strong>gweek. Synthetic oil can be specifiedto extend the oil service life up to 30,000operat<strong>in</strong>g hours.EfficiencyThe Rulmeca <strong>Motorized</strong> <strong>Pulley</strong> usuallyhas a much higher efficiency from electricalmotor to shell (<strong>Pulley</strong> face) thanexposed drives, because it has fewerfrictional losses. Therefore, efficienciesof up to 97% can be achieved.Cleanl<strong>in</strong>essBecause the Rulmeca <strong>Motorized</strong> <strong>Pulley</strong>is hermetically sealed it cannot contam<strong>in</strong>ateany convey<strong>in</strong>g materials such asfood, electrical components, plastics andother materials that must be kept perfectlyclean dur<strong>in</strong>g handl<strong>in</strong>g.Aesthetic appearanceIf <strong>in</strong>stalled correctly the Rulmeca <strong>Motorized</strong><strong>Pulley</strong> always looks good. Due to itscompact size and smooth l<strong>in</strong>es, the<strong>Motorized</strong> <strong>Pulley</strong> is out of sight, because itis hidden with<strong>in</strong> the conveyor frame.Thermal protectionAll three phase Rulmeca <strong>Motorized</strong> <strong>Pulley</strong>sare protected by our thermal protectionswitches. These heat-sensitiveswitches are built <strong>in</strong>to the motor w<strong>in</strong>d<strong>in</strong>gsto protect the motor from overheat<strong>in</strong>g.The thermal protectors must be connectedto a normally closed control circuit<strong>in</strong> order to protect the motor.Weight sav<strong>in</strong>g and distributionThe Rulmeca <strong>Motorized</strong> <strong>Pulley</strong> is oftenlighter than exposed drives. It is possibleto reduce the weight and cost of theconveyor structure, because the conveyordrive weight is evenly distributed with<strong>in</strong>the conveyor frame.Variable frequency driveAll Rulmeca <strong>Motorized</strong> <strong>Pulley</strong>s with 3phase motors are easily controlled byvariable frequency drives work<strong>in</strong>g <strong>in</strong> the12 Hz to 66 Hz frequency range. SeeTechnical Precautions <strong>in</strong> the catalogue.Fewer partsA Rulmeca <strong>Motorized</strong> <strong>Pulley</strong> consists ofthe <strong>Motorized</strong> <strong>Pulley</strong> and two fix<strong>in</strong>gbrackets! Exposed drives can require upto eight or more separate components,most of which have to be purchasedfrom different suppliers or custom manufactured.Low noiseThanks to the totally sealed enclosureand high quality gears the Rulmeca<strong>Motorized</strong> <strong>Pulley</strong> runs almost at a whisper– a very important fact <strong>in</strong> today’smodern factory environments.The Rulmeca <strong>Motorized</strong> <strong>Pulley</strong> – theideal drive unit for conveyors “Fit itand forget it!”www.rulmecacorp.com 3TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong>sDual Drive ConceptBucket Wheel Reclaimer for taconite pelletsLocated <strong>in</strong> “center drive position” beneath a 4,000 TPH bucket wheelreclaimer tail conveyor at Lake Superior taconite ship load<strong>in</strong>g facility, twomodel 800H 120 HP <strong>Motorized</strong> <strong>Pulley</strong>s drive discharge belt at 768 FPM.S<strong>in</strong>ce the 2004 reclaimer upgrade, each <strong>Motorized</strong> <strong>Pulley</strong> is powered by460V/3ph/60 Hz directly by the on-board diesel electric generator. Motorsynchronization was not necessary on either this reclaimer or its two sistermach<strong>in</strong>es at the term<strong>in</strong>al.Technical Precaution: Always mount motorized pulley with “UP” directionoriented accord<strong>in</strong>g to <strong>in</strong>stallation <strong>in</strong>structions.Revers<strong>in</strong>g Shuttle Conveyor for crushed graniteOne of two 31.5” diameter 50 HP <strong>Motorized</strong> <strong>Pulley</strong>s, one on north end andone on south end, driv<strong>in</strong>g revers<strong>in</strong>g shuttle conveyor at Lafarge’s Mountsorrelgranite quarry s<strong>in</strong>ce 1998. Photo shows stone discharg<strong>in</strong>g from 600FPM belt at 2,500 TPH. Chang<strong>in</strong>g from a “s<strong>in</strong>gle drive” to a “dual drive”arrangement can reduce slack-side belt tension (T 2) to 20%. This willreduce maximum belt tension (T 1) and can significantly extend conveyor beltlife because it provides 360 degrees of belt wrap around pulleys (180degrees per <strong>Motorized</strong> <strong>Pulley</strong>), without the use of “dirty side” snub pulleys.Technical Precaution: When us<strong>in</strong>g <strong>Motorized</strong> <strong>Pulley</strong>s <strong>in</strong> revers<strong>in</strong>g application,always br<strong>in</strong>g conveyor to complete stop before start<strong>in</strong>g belt <strong>in</strong> oppositedirection (see page 84-85.)Suspended Construction Conveyor for wet concreteOne of four 150 foot long “dual drive” conveyors suspended from constructioncranes to pour wet concrete dur<strong>in</strong>g Sesam River Dam construction <strong>in</strong>Southeast Asia. Dur<strong>in</strong>g the five year project each conveyor was driven atthe head and tail by a model 800H 50 HP Rulmeca <strong>Motorized</strong> <strong>Pulley</strong>.Overland Conveyor for graniteOne of two 150 HP Rulmeca <strong>Motorized</strong> <strong>Pulley</strong>s on two mile long overlandconveyor at Lafarge’s Mountsorrel Quarry <strong>in</strong> “center drive position.” The two<strong>Motorized</strong> <strong>Pulley</strong>s are driven by synchronized ABB variable frequencydrives (VFDs), transferr<strong>in</strong>g granite on the 48” wide belt at various rates upto 2,000 TPH. The VFDs: (1.) provide a “soft start” feature, (2.) enable thetwo drives to “talk” and keep rotor speeds synchronized, and (3.) conservepower by l<strong>in</strong>k<strong>in</strong>g to load sensors and optimiz<strong>in</strong>g belt speed accord<strong>in</strong>g tomeasured conveyor throughput.Technical Precaution: When us<strong>in</strong>g a VFD always restrict frequencies tobetween 12 Hz to 66 Hz and <strong>in</strong>stall a filter on the VFD output if it is locatedmore than 30 feet from the <strong>Motorized</strong> <strong>Pulley</strong> (see page 86.)www.rulmecacorp.com 6TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 138E, Ø 5.45 <strong>in</strong>. (138 <strong>mm</strong>)<strong>Motorized</strong> <strong>Pulley</strong> with Term<strong>in</strong>al box<strong>Motorized</strong> <strong>Pulley</strong>with cablestraight connectorElbow connector(not for TS7N)Idler <strong>Pulley</strong> 3 TS7N version<strong>Motorized</strong> <strong>Pulley</strong> or idler <strong>Pulley</strong> (UT) Compact term<strong>in</strong>al Straight Elbowbox connector connectorA B C D E F G H K W L M N N1 U V R S TModel <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong>138E 5.45 5.39 0.93 1.18 2.13 0.79 0.20 0.65 0.93 – 1.61 0.95 3.74 0.55 0.14 0.77 0.79 1.89 0.47UT138E 5.45 5.45 0.93 1.18 2.13 0.79 0.53 0.65 – 1.421 A dimension is outer diameter of unlagged pulley shell at pulley centerl<strong>in</strong>e.2 B dimension is outer diameter of unlagged pulley shell at each end of shell.3 Idler pulley shown is non-crowned TS7N version with regreasable seals.Mount<strong>in</strong>g brackets<strong>Motorized</strong><strong>Pulley</strong>sMaterialBracketSizePartNumberDimensionsWeightModel138ECast ironpa<strong>in</strong>tedCast ironNi platedSta<strong>in</strong>lesssteelKL30S2YAKLS2YAKMS3KL33A<strong>in</strong>D<strong>in</strong>F<strong>in</strong>I<strong>in</strong>K<strong>in</strong>S<strong>in</strong>T<strong>in</strong>7.09 1.18 0.79 3.39 2.24 0.43 0.67 0.47 0.95 4.33 1.75 2.83 1.54V<strong>in</strong>W1<strong>in</strong>X<strong>in</strong>Z<strong>in</strong>Z1<strong>in</strong>lbswww.rulmecacorp.com 10TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 138E, Ø 5.45 <strong>in</strong>. (138 <strong>mm</strong>)60 HzPowerHPMotorNo.ofPoles0.13 120.25 80.33 60.50 40.75 21.0No.GearStagesModel3 138ENom<strong>in</strong>al beltspeed 1 atFull Load60 Hzfpm1012142 138E 24303 138E1824302 138E 383 138E2 138E3 138E2 138E3 138E2 138E4 3 138E2 2 138E482430384860763848607696120150486076961201501922403007696120150192240300Actual beltspeed 1 atFull Load60 Hzfpm1014162428202429445125313855658238475885981231505564749311316619624429688104129157207258314BeltPull 2lbs39731826317815238430925417214740432526518215512441233127318515812610441636331024920513911995Max.RadialLoad 3T1 + T2lbsM<strong>in</strong>.RL<strong>in</strong>RL Dimension <strong>in</strong>ches (RL max = 70.87”)Weight <strong>in</strong> lbs 511.81 12.60 13.78 15.75 17.72 19.69 21.65 23.62 25.591,066 11.81 32 33 34 37 40 42 44 46 4978357304244201 12.60 - 34 37 41 43 45 47 49 53152122100longerthan25.59SeeFootnote4TypeofBracketKL30S2YAKLIdler <strong>Pulley</strong> Model UT138E 1,066 11.81 15 16 18 21 23 25 27 29 32SeeFootnote4KL30S2YAKL1 Use “nom<strong>in</strong>al belt speed” to specify pulley. “Actual belt speed” is presented (for pulley lagged with 1/8” thick rubber) to assist with process design calculations.See Technical Precautions page 77. Note that “actual belt speed” decreases when lagg<strong>in</strong>g is not used due to decreased pulley diameter.2 Belt pull value allows for gearbox loss.3 <strong>Pulley</strong> must not be subjected to radial load exceed<strong>in</strong>g “Maximum radial load” def<strong>in</strong>ed above. See “Belt Tension” section <strong>in</strong> Technical Precautions, page 78.4 Additional <strong>Motorized</strong> <strong>Pulley</strong> and Idler <strong>Pulley</strong> weight, specified per Roller Length:25.59”< RL < 39.37” Wt = 1.3 lbs/<strong>in</strong>ch39.37”< RL < 59.06” Wt = 1.5 lbs/<strong>in</strong>ch59.06”< RL < 70.87” Wt = 2.0 lbs/<strong>in</strong>ch5 All weights shown above are for pulleys with 1/8” thick rubber lagg<strong>in</strong>g. To calculate unlagged pulley weight subtract 0.1 lbs/<strong>in</strong> of Roller Length from above.www.rulmecacorp.com 11TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 138E, Ø 5.45 <strong>in</strong>. (138 <strong>mm</strong>)Spare parts list and sectional draw<strong>in</strong>gsPos. Description Pos. Description Pos. Description1 Front shaft3 Rear flange5 Bear<strong>in</strong>g hous<strong>in</strong>g complete withgeared rim7 Bear<strong>in</strong>g hous<strong>in</strong>g complete8 Gearbox10 Term<strong>in</strong>al box – bottom part11 Term<strong>in</strong>al box cover12 Shell16 Rear shaft19 Input wheel20 Output p<strong>in</strong>ion22 Geared rim23 Intermediate p<strong>in</strong>ion shaft24 Intermediate wheel31 Labyr<strong>in</strong>th seal cover53 Nipple (term<strong>in</strong>al box53.1 Cable seal nipple (cable option)55 Spacer bush<strong>in</strong>g56 Spacer bush<strong>in</strong>g63 Ball bear<strong>in</strong>g64 Needle bear<strong>in</strong>g65–70 Ball bear<strong>in</strong>g71 Inner race74 Lock<strong>in</strong>g r<strong>in</strong>g84 Lock<strong>in</strong>g r<strong>in</strong>g86 Lock<strong>in</strong>g r<strong>in</strong>g93 Elbow or straight connector102 Screw103 Screw110 Screw111 Screw113 Screw114 Socket set screw115 Oil plug with magnet126 Key127 Key131 Key132 Key136 O-r<strong>in</strong>g/Rubber seal138 Rubber seal139 Grease nipple140 Deflection seal142 Double lip seal143 O-r<strong>in</strong>g2-stage gearboxwww.rulmecacorp.com 12TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 138E, Ø 5.45 <strong>in</strong>. (138 <strong>mm</strong>)Spare parts list and sectional draw<strong>in</strong>gsPos. Description Pos. Description Pos. Description145 Distance washer146 Washer148 Washer150 Electromagnetic brake150.1 Friction disc156 Rectifier (not shown)160 Oil plug161 O-r<strong>in</strong>g163 O-r<strong>in</strong>g167 Screw200 Rubber seal204 Rotor complete with p<strong>in</strong>ion208 Sta<strong>in</strong>less steel cover – gearend210 Fix<strong>in</strong>g guard223 Cable226 Stator complete240 Distance r<strong>in</strong>gTS7N with cable connectionElbow connectorTS7N with cable connection 3-stage gearbox Electromagnetic brakewww.rulmecacorp.com 13TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 165E, Ø 6.49 <strong>in</strong>. (165 <strong>mm</strong>)<strong>Motorized</strong> <strong>Pulley</strong> 165E, withmach<strong>in</strong>ed helical gearbox, performswith a gearbox efficiency of 95% ofnom<strong>in</strong>al power, <strong>in</strong> a compact diameterof 6.49 <strong>in</strong>ches. With a m<strong>in</strong>imumroller length (RL) of 13.78” and powersrang<strong>in</strong>g from 0.15 to 3.0 HP, this<strong>Motorized</strong> <strong>Pulley</strong> is suitable for mostsmall diameter applications. These<strong>in</strong>clude:• Light agricultural conveyors• Light C & D debris conveyors• Mobile and portable conveyors<strong>Motorized</strong> <strong>Pulley</strong> 165E features astandard enclosure class of IP66/67and is also available <strong>in</strong> sta<strong>in</strong>lesssteel for wash down applications.STANDARD SPECIFICATIONof <strong>Motorized</strong> <strong>Pulley</strong>• Crowned mild steel 6.49” shell treatedwith anti-rust wax• Die cast alum<strong>in</strong>um bear<strong>in</strong>g hous<strong>in</strong>g• Mild steel shaft treated with anti-rustwax• Die cast lightweight alum<strong>in</strong>um gearboxhous<strong>in</strong>g• Seal<strong>in</strong>g system – degree of protectionIP66/67 (EN60034-5.) See page 88.• Compact die cast alum<strong>in</strong>um term<strong>in</strong>albox with WAGO connectors• Voltage: All co<strong>mm</strong>on voltages available.Please specify.• Three phase <strong>in</strong>duction motor• One out of two oil plugs is fitted with amagnet to filter the oil.• Motor w<strong>in</strong>d<strong>in</strong>g <strong>in</strong>sulation class F• Dynamically balanced rotor• Oil change reco<strong>mm</strong>ended every10,000 operational hours• Maximum RL 70.87”• Non standard RL lengths available• S<strong>in</strong>gle phase is available <strong>in</strong> 0.50 and1.50 HP, supplied with a runn<strong>in</strong>g capacitor• To be used <strong>in</strong> the horizontal positiononly.STAINLESS STEELoptionsTS7N• Sta<strong>in</strong>less steel shell – AISI 304 range• Sta<strong>in</strong>less steel shafts – AISI 303 range• Sta<strong>in</strong>less steel covered alum<strong>in</strong>um bear<strong>in</strong>ghous<strong>in</strong>gs – AISI 304 range• Sta<strong>in</strong>less steel oil plugs with magnet –AISI 304 range• Compact sta<strong>in</strong>less steel term<strong>in</strong>al box –AISI 304 range• Alternatively, straight sta<strong>in</strong>less steelconnector – AISI 303 range with powercord.• Regreasable sta<strong>in</strong>less steel seals –AISI 303 range• Degree of protection IP66/67 (EN60034-5.) See page 88.• FDA & USDA food grade grease• Option: FDA & USDA food grade recognizedoil.• Special mount<strong>in</strong>g brackets are available.Please note:• Noise-sensitive Areas: High speed 2-pole motors can cause higher noiselevels and are not reco<strong>mm</strong>ended fornoise-sensitive areas• Technical Precautions for Design,Installation, and Ma<strong>in</strong>tenance: pages76-86• Environmental Considerations: page72• Optional Extras: pg 15 and back cover• Electrical Connection Diagrams:pages 94-96.www.rulmecacorp.com 14TC101: 03/07

OPTIONAL EXTRAS<strong>Motorized</strong> <strong>Pulley</strong> 165ESpecificationAvailabilityTotal sta<strong>in</strong>less steel option AISI 304 range TS7N with regreasable labyr<strong>in</strong>th seals xFood grade oil & grease - FDA & USDA recognizedxDust explosion proof <strong>Motorized</strong> <strong>Pulley</strong>s - ATEX 95 - Zone 22 - for applicationshandl<strong>in</strong>g dusty gra<strong>in</strong> etc. Accord<strong>in</strong>g to European Directive 94/9/EC.xTotal acid resistant sta<strong>in</strong>less steel option - AISI 316xBlack rubber lagg<strong>in</strong>g - Standard specifications (See page 80.)1/8” smooth lagg<strong>in</strong>g - Hardness 60 ±5 Shore A oWhite smooth rubber lagg<strong>in</strong>g (FDA). Oil, fat & grease resistantoSpecial lagg<strong>in</strong>g (e.g. hot vulcanized)oElectromagnetic brake M<strong>in</strong>. RL <strong>in</strong>creases by 1.97” xMechanical backstop M<strong>in</strong>. RL does not <strong>in</strong>crease with backstop option xModified for vertical mount<strong>in</strong>goModified for mount<strong>in</strong>g between 5° and 90° (e.g. for magnetic separators)Insulation class F with standard oil: (Allowable ambient temperature: -13°F/+104°F)Insulation class H with synthetic oil: (Allowable ambient temperature: -13°F/+120°F)Special motors for applications with no belt contactLow noise drives for noise sensitive areasParallel shellThermal protectorStd.IP66/67 Compact unpa<strong>in</strong>ted alum<strong>in</strong>um term<strong>in</strong>al boxStd.IP66/67 Compact sta<strong>in</strong>less steel term<strong>in</strong>al box- AISI 304 or 316 rangexStraight or elbow connector with standard power cordxStraight connector with screened power cord (See page 86 for VFD precautions) xStraight connector with standard power cord (Sta<strong>in</strong>less steel <strong>in</strong> AISI 304 range) xVoltage: s<strong>in</strong>gle voltage (460) stator (Y w<strong>in</strong>d<strong>in</strong>g) wired for 460v/3ph/60 Hz at term<strong>in</strong>al boxStd.s<strong>in</strong>gle voltage (230) stator (YY w<strong>in</strong>d<strong>in</strong>g) wired for 230v/3ph/60 Hz at term<strong>in</strong>al boxx2 speed motors xSpecial voltage motorsxS<strong>in</strong>gle phase motorsCSA approved motorsoStd.xoxxoxx = Optional extra’so = An option with certa<strong>in</strong> limitations. Please refer to Technical precautions pages 76-86!Std. = Fitted as standardwww.rulmecacorp.com 15TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 165E, Ø 6.49 <strong>in</strong>. (165 <strong>mm</strong>)<strong>Motorized</strong> <strong>Pulley</strong> with Term<strong>in</strong>al Box<strong>Motorized</strong> <strong>Pulley</strong>with cablestraight connectorElbow connector(not for TS7N)Idler <strong>Pulley</strong> 3 TS7N version<strong>Motorized</strong> <strong>Pulley</strong> or idler <strong>Pulley</strong> (UT) Compact term<strong>in</strong>al Straight Elbowbox connector connectorA B C D E F G H K W L M N N1 U V R S TModel <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong>165E 6.49 6.44 1.71 1.57 3.15 1.18 0.39 0.85 1.63 – 1.61 0.95 3.74 0.55 0.16 1.06 0.79 1.89 0.47UT165E 6.49 6.49 1.71 1.57 2.95 1.18 0.65 0.85 – 1.811 A dimension is outer diameter of unlagged pulley shell at pulley centerl<strong>in</strong>e.2 B dimension is outer diameter of unlagged pulley shell at each end of shell.3 Idler pulley shown is non-crowned TS7N version with regreasable seals.Mount<strong>in</strong>g brackets<strong>Motorized</strong><strong>Pulley</strong>sMaterialBracketSizePartNumberDimensionsWeightModelSteel pa<strong>in</strong>ted6YA0KA<strong>in</strong>D<strong>in</strong>F<strong>in</strong>I<strong>in</strong>K<strong>in</strong>S<strong>in</strong>T<strong>in</strong>V<strong>in</strong>W1<strong>in</strong>X<strong>in</strong>Z<strong>in</strong>Z1<strong>in</strong>lbs165ESteelNi platedSta<strong>in</strong>lesssteelKL41-HD6YA0W6YA0U7.48 1.57 1.18 3.31 2.44 0.55 0.79 0.87 1.57 4.33 1.97 3.27 4.63www.rulmecacorp.com 16TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 165E, Ø 6.49 <strong>in</strong>. (165 <strong>mm</strong>)60 HzPowerHPMotorNo.ofPolesNo.GearStagesModel0.15 12 3 165E0.5041.00 41.502.00 23.00 2Nom<strong>in</strong>al beltspeed 1 atFull Load60 Hzfpm121418246 3 165E 243038483 165E 6076962 165E3 165E120150192Actual beltspeed 1 atFull Load60 Hzfpm1416202625303748597798123152199BeltPull 2lbsMax.RadialLoad 3T1 + T2lbs240 251 62 195538 38 81048 48 66460 59 53776 77 40996 98 325 2097120 123 2562 165E150 152 207192 199 158240 251 125 19554 3 165E 60 66 73076 81 56996 99 467 20973 165E 120 123 378150 161 288192 203 2282240 257 180 1955300 318 1452 165E3844806003 165E1201501922403002 165E 3844806007683 165E1201501923 165E 2403003842 165E 48060076841652564612316120325731841652565178713<strong>216</strong>1192250302417527648783M<strong>in</strong>.RL<strong>in</strong>15.75RL Dimension <strong>in</strong>ches (RL max = 70.87”)Weight <strong>in</strong> lbs 515.75 17.72 19.69 21.65 23.62 25.59 27.56 29.53 31.5035128866 69 72 76 78 80 83 87 9023317762451268 71 75 78 80 83 86 89 92414 2,09732826520<strong>216</strong>0 64 67 70 73 76 78 81 84 8812610278111887451539331124619815112010588717588466378314227180146121156220971955156220971955156270 74 77 80 82 84 88 91 9475 78 81 84 87 89 92 95 9977 80 83 87 89 91 94 98 10117.72 - 84 87 91 93 95 98 102 105longerthan31.50SeeFootnote4TypeofBracketKL41-HD6YA0KIdler <strong>Pulley</strong> Model UT165E 2,097 15.75 33 35 39 43 45 47 50 54 58SeeFootnote4KL41-HD6YA0K1 Use “nom<strong>in</strong>al belt speed” to specify pulley. “Actual belt speed” is presented (for pulley lagged with 1/8” thick rubber) to assist with process design calculations.See Technical Precautions page 77. Note that “actual belt speed” decreases when lagg<strong>in</strong>g is not used due to decreased pulley diameter.2 Belt pull value allows for gearbox loss.3 <strong>Pulley</strong> must not be subjected to radial load exceed<strong>in</strong>g “Maximum radial load” def<strong>in</strong>ed above. See “Belt Tension” section <strong>in</strong> Technical Precautions, page 78.4 Additional <strong>Motorized</strong> <strong>Pulley</strong> and Idler <strong>Pulley</strong> weight, specified per <strong>in</strong>ch of Roller Length:31.50”< RL < 45.28” Wt = 1.5 lbs/<strong>in</strong>45.28”< RL < 64.96” Wt = 2.1 lbs/<strong>in</strong>64.96”< RL < 70.87” Wt = 2.9 lbs/<strong>in</strong>5 All weights shown above are for pulleys with 1/8” thick rubber lagg<strong>in</strong>g. To calculate unlagged pulley weight subtract 0.1 lbs/<strong>in</strong> of Roller Length from above.www.rulmecacorp.com 17TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 165E, Ø 6.49 <strong>in</strong>. (165 <strong>mm</strong>)Spare parts list and sectional draw<strong>in</strong>gsPos. Description Pos. Description Pos. Description1 Front shaft3 Rear flange5 Bear<strong>in</strong>g hous<strong>in</strong>g complete withgeared rim7 Bear<strong>in</strong>g hous<strong>in</strong>g complete8 Gearbox10 Term<strong>in</strong>al box – bottom part11 Term<strong>in</strong>al box cover12 Shell16 Rear shaft19 Input wheel20 Output p<strong>in</strong>ion22 Geared rim23 Intermediate p<strong>in</strong>ion shaft24 Intermediate wheel31 Labyr<strong>in</strong>th seal cover53 Cable seal nipple (cable option)53.1 Nipple (term<strong>in</strong>al box)55 Spacer bush<strong>in</strong>g56 Spacer bush<strong>in</strong>g63 Ball bear<strong>in</strong>g64 Needle bear<strong>in</strong>g65–70 Ball bear<strong>in</strong>g71 Inner race73 Lock<strong>in</strong>g r<strong>in</strong>g74 Lock<strong>in</strong>g r<strong>in</strong>g74 Lock<strong>in</strong>g r<strong>in</strong>g81 Lock<strong>in</strong>g r<strong>in</strong>g84 Lock<strong>in</strong>g r<strong>in</strong>g85 Lock<strong>in</strong>g r<strong>in</strong>g86 Lock<strong>in</strong>g r<strong>in</strong>g93 Elbow or straight connector102 Screw103 Screw110 Screw111 Screw112 Socket set screw113 Screw114 Socket set screw115 Oil plug with magnet126 Key127 Key131 Key132 Key136 O-r<strong>in</strong>g/Rubber seal138 Rubber seal2-stage gearboxwww.rulmecacorp.com 18TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 165E, Ø 6.49 <strong>in</strong>. (165 <strong>mm</strong>)Spare parts list and sectional draw<strong>in</strong>gsPos. Description Pos. Description Pos. Description139 Grease nipple140 Deflection seal141 Double lip seal142 Double lip seal143 O-r<strong>in</strong>g145 Distance washer146 Washer148 Washer150 Electromagnetic brake150.1 Friction disc156 Rectifier (not shown)160 Oil plug161 O-r<strong>in</strong>g163 O-r<strong>in</strong>g167 Screw200 Rubber seal204 Rotor complete with p<strong>in</strong>ion206 Insulated sleeve for wireprotection208 Sta<strong>in</strong>less steel cover – gearend209 Sta<strong>in</strong>less steel cover – oil plugend210 Fix<strong>in</strong>g guard223 Cable226 Stator complete240 Distance r<strong>in</strong>gTS7NElbow connectorTS7N with cable connection 3-stage gearbox Electromagnetic brakewww.rulmecacorp.com 19TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> <strong>220M</strong> & <strong>220H</strong>, Ø <strong>8.50</strong> <strong>in</strong>. (<strong>216</strong> <strong>mm</strong>)Our <strong>8.50</strong>” diameter <strong>Motorized</strong> <strong>Pulley</strong>range offers two differentperformance levels for BULKapplications:- M for Medium duty- H for Heavy dutyIt is important to note the productdifferences and choose theappropriate pulley based onestimated belt tension (radial load.)See page 78. The actual radial loadmust be less than the maximumallowable radial load shown <strong>in</strong> thiscatalog.Be aware of <strong>in</strong>creased belttensions required to drive multi-plythick heavy belts and/or larger beltwidths.If the <strong>8.50</strong>” diameter model is notstrong enough to resist estimatedbelt tension, then select 12.64”diameter model.M for Medium dutyThe <strong>in</strong>ternal parts of <strong>220M</strong> aredesigned to match irregular work<strong>in</strong>gconditions <strong>in</strong> applications such asmobile crush<strong>in</strong>g & screen<strong>in</strong>g, cement& concrete plants, mobile conveyorsand open stone & gravel pits.H for Heavy dutyA re<strong>in</strong>forced 3-stage-gearboxprovides <strong>220H</strong> with the necessarystrength needed for low speeds andhigh torque. <strong>220H</strong> is popular <strong>in</strong> recycl<strong>in</strong>g(hand sorter conveyors),bunker discharge conveyors andwhere a comb<strong>in</strong>ation of slow speedand high torque is required.STANDARD SPECIFICATIONof <strong>Motorized</strong> <strong>Pulley</strong>• Crowned mild steel <strong>8.50</strong>” diameter steelshell treated with anti-rust wax• Powder coated cast iron bear<strong>in</strong>g hous<strong>in</strong>gs• Mild steel shafts treated with anti-rustwax• Shaft seal<strong>in</strong>g system - degree of protectionIP66/67 (EN60034-5.) Seepage 88.• Powder coated die cast alum<strong>in</strong>um term<strong>in</strong>albox• 3-phase <strong>in</strong>duction motors with thermalprotector• Voltage: All co<strong>mm</strong>on voltages available.Please specify.• Motor w<strong>in</strong>d<strong>in</strong>g <strong>in</strong>sulation Class F• Dynamically balanced rotor• One out of two oil plugs fitted with amagnet to filter the oil• Oil change reco<strong>mm</strong>ended every10,000 operational hours• M<strong>in</strong>imum RL. Please refer to pages23-24• Maximum RL – Please <strong>in</strong>quire• Non standard RL’s available• To be used <strong>in</strong> horizontal positions ± 5degree onlyPlease note:• Noise-sensitive Areas: High speed 2-pole motors can cause higher noiselevels and are not reco<strong>mm</strong>ended fornoise-sensitive areas• Technical Precautions for Design,Installation, and Ma<strong>in</strong>tenance: pages76-86• Environmental Considerations: page72• Optional Extras: pg 21 and back cover• Electrical Connection Diagrams:pages 94-96.STAINLESS STEELoptionsTS9N• Sta<strong>in</strong>less steel shell – AISI 304 range• Sta<strong>in</strong>less steel shafts – AISI 303/4range• Sta<strong>in</strong>less steel covered bear<strong>in</strong>g hous<strong>in</strong>gs– AISI 316 range• Sta<strong>in</strong>less steel oil plugs – AISI 304range – one out of two with magnet• Sta<strong>in</strong>less steel exterior bolts – AISI 304range• Regreasable labyr<strong>in</strong>th seals withgrease nipples <strong>in</strong> sta<strong>in</strong>less steel– AISI 304 range• Shaft seal<strong>in</strong>g system – degree of protectionIP66/67 (EN60034-5).TS10N• As TS9N, but without regreasablelabyr<strong>in</strong>th seals.SEMI-RUST-FREE optionsTS11N• As TS9N, but with crowned mild steelshell treated with anti-rust wax.TS12N• As TS10N, but with crowned mild steelshell treated with anti-rust wax.Other Sta<strong>in</strong>less Options:• FDA & USDA food grade recognizedoil and grease are not <strong>in</strong>cluded <strong>in</strong> TS9Nto TS12N, but available on request• Complete <strong>Motorized</strong> <strong>Pulley</strong>s <strong>in</strong> acidresistant sta<strong>in</strong>less steel – AISI 316range – available on request.• Special mount<strong>in</strong>g brackets are availableElectrical connection options:• Salt water resistant powder coatedalum<strong>in</strong>um term<strong>in</strong>al box with z<strong>in</strong>c platedexterior bolts• Sta<strong>in</strong>less steel term<strong>in</strong>al box – AISI 304range (max. 5.5 HP)• Straight sta<strong>in</strong>less steel connector withfly<strong>in</strong>g lead – AISI 304 range.Please specify required TS-numberwhen order<strong>in</strong>g Sta<strong>in</strong>less Steeloptions.www.rulmecacorp.com 20TC101: 03/07

OPTIONAL EXTRAS<strong>Motorized</strong> <strong>Pulley</strong> <strong>220M</strong> & <strong>220H</strong>SpecificationAvailabilityTotal sta<strong>in</strong>less steel option AISI 304 range TS9N with regreasable labyr<strong>in</strong>th seals xTotal sta<strong>in</strong>less steel option AISI 304 range TS10N with standard seals xSemi-rust free option TS11N with regreasable labyr<strong>in</strong>th seals xSemi-rust free option TS12N with standard seals xRegreasable labyr<strong>in</strong>th sealsxFood grade oil & grease - FDA & USDA recognizedxDust explosion proof <strong>Motorized</strong> <strong>Pulley</strong>s - ATEX 95 - Zone 22 - for applications handl<strong>in</strong>g of dusty gra<strong>in</strong> etc.Accord<strong>in</strong>g to European Directive 94/9/EC.xTotal acid resistant sta<strong>in</strong>less steel option - AISI 316xBlack rubber lagg<strong>in</strong>g - Standard specifications (See page 80.)1/4” smooth lagg<strong>in</strong>g - Hardness 60 ±5 Shore A o1/4” diamond lagg<strong>in</strong>g - Hardness 60 ±5 Shore A oWhite smooth rubber lagg<strong>in</strong>g (FDA). Oil, fat & grease resistantoSpecial lagg<strong>in</strong>g (e.g. hot vulcanized)oElectromagnetic brake M<strong>in</strong>. RL <strong>in</strong>creases by 3.94” xMechanical backstop M<strong>in</strong>. RL does not <strong>in</strong>crease with backstop option xModified for vertical mount<strong>in</strong>goModified for mount<strong>in</strong>g between 5° and 90° (e.g. for magnetic separators)oInsulation class F with standard oil: (Allowable ambient temperature -13°F/+104°F)Std.Insulation class H with synthetic oil: (Allowable ambient temperature -13°F/+120°F)xSpecial motors for applications with no belt contactoLow noise drives for noise sensitive areasxParallel shell (i.e. no crown)xThermal protectorStd.IP66/67 Yellow powder coated alum<strong>in</strong>um term<strong>in</strong>al boxStd.IP66/67 Gray powder coated alum<strong>in</strong>um term<strong>in</strong>al box (food grade approved)xIP66/67 Compact powder coated alum<strong>in</strong>um term<strong>in</strong>al box (food grade approved) < 5.5 HP only oIP66/67 Compact sta<strong>in</strong>less steel term<strong>in</strong>al box - AISI 304 or 316 range < 5.5 HP only oStraight or elbow connector with standard power cord < 5.5 HP only xStraight connector with screened power cord (See page 86 for VFD precautions.) < 5.5 HP only xStraight connector with power cord (Sta<strong>in</strong>less steel <strong>in</strong> AISI 304 range) < 5.5 HP only xVoltage: < 5.5 HP dual voltage (230/460) stator (YY/Y w<strong>in</strong>d<strong>in</strong>g) wired for 460v/3ph/60 Hz at term<strong>in</strong>al boxStd.< 5.5 HP dual voltage (230/460) stator (YY/Y w<strong>in</strong>d<strong>in</strong>g) wired for 230v/3ph/60 Hz at term<strong>in</strong>al box x7.5 HP s<strong>in</strong>gle voltage (460) stator (Y w<strong>in</strong>d<strong>in</strong>g) wired for 460v/3ph/60 Hz at term<strong>in</strong>al box Std7.5 HP s<strong>in</strong>gle voltage (230) stator (YY w<strong>in</strong>d<strong>in</strong>g) wired for 230v/3ph/60 Hz at term<strong>in</strong>al box x2 speed motors xSpecial voltage motorsxS<strong>in</strong>gle phase motorsoCSA approved motorsxx = Optional extraso = An option with certa<strong>in</strong> limitations. Please refer to Technical precautions pages 76-86Std. = Fitted as standardwww.rulmecacorp.com 21TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> <strong>220M</strong> & <strong>220H</strong>, Ø <strong>8.50</strong> <strong>in</strong>. (<strong>216</strong> <strong>mm</strong>)Compactterm<strong>in</strong>al box< 5.5 HPStandardterm<strong>in</strong>al box<strong>Motorized</strong> <strong>Pulley</strong> with term<strong>in</strong>al boxStraightconnectorElbowconnectorIdler <strong>Pulley</strong> 3 UT<strong>220M</strong> / UT<strong>220H</strong><strong>in</strong> TS9N/TS11N<strong>Motorized</strong> <strong>Pulley</strong> or Idler <strong>Pulley</strong> Standard term<strong>in</strong>al Compact term<strong>in</strong>al Straight Elbowbox box < 5.5 HP connector connectorG < 5.5 HP < 5.5 HPA B C D E F G TS9/11 H K W L M N O L M N N1 U V R S TModel <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong><strong>220M</strong> & <strong>220H</strong> <strong>8.50</strong> 8.44 1.71 1.57 3.94 1.18 0.61 0.77 0.85 1.63 – 3.43 1.06 4.21 4.13 1.61 0.95 3.74 0.55 0.16 1.06 0.79 1.89 0.47UT<strong>220M</strong> & UT<strong>220H</strong> <strong>8.50</strong> <strong>8.50</strong> 1.71 1.57 3.94 1.18 0.61 0.77 0.85 – 2.051 A dimension is outer diameter of unlagged pulley shell at pulley centerl<strong>in</strong>e.2 B dimension is outer diameter of unlagged pulley shell at each end of shell.3 Idler pulley shown is non-crowned TS9N/TS11N version with regreasable seals.<strong>Motorized</strong><strong>Pulley</strong>sModelMaterialBracketSizePartNumberDimensionsD<strong>in</strong>F<strong>in</strong>I<strong>in</strong>K<strong>in</strong>S<strong>in</strong>T<strong>in</strong>V<strong>in</strong>Mount<strong>in</strong>g bracketsW1<strong>in</strong>X<strong>in</strong>X1<strong>in</strong>Z<strong>in</strong>Z1<strong>in</strong>WeightlbsSteel pa<strong>in</strong>ted6YA0K<strong>220M</strong> &<strong>220H</strong>SteelNi platedKL41-HD6YA0W1.57 1.18 3.31 2.44 0.55 0.79 0.87 1.57 4.33 7.48 1.97 3.27 4.63Sta<strong>in</strong>less steel6YA0Uwww.rulmecacorp.com 22TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> <strong>220M</strong> & <strong>220H</strong>, Ø <strong>8.50</strong> <strong>in</strong>. (<strong>216</strong> <strong>mm</strong>)60 HzPowerHPMotorNo.ofPolesNo.GearStagesModelNom<strong>in</strong>al beltspeed 1 atFull Load60 Hzfpm3 <strong>220H</strong> 30384860760.50 8962 <strong>220M</strong> 1201501922403003 <strong>220H</strong> 30384860760.75 8962 <strong>220M</strong> 1201501922403003 <strong>220H</strong>24303848601 876962 <strong>220M</strong> 120150192240300303 <strong>220H</strong> 386482 <strong>220M</strong> 6076961.51201501924 2 <strong>220M</strong> 240300384480600Actual beltspeed 1 atFull Load60 Hzfpm344054698410112815920825031934405469841011281592082503192834405469841011281592082503193746547291108137168201256319415501637BeltPull 2lbs458383287227185155122977562496855774303372772311811461129373113792877458346037631424719815212699125110218526415064273372762301801451119373Max.RadialLoad 3T1 + T2lbsM<strong>in</strong>.RL<strong>in</strong>RL Dimension <strong>in</strong>ches (RL>78.74” available on request)Weight <strong>in</strong> lbs 5longer15.75 17.72 19.69 21.65 23.62 25.59 27.56 29.53 31.50 than31.505620 17.72 - 146* 154 160 168 175 182 189 1962585 15.75 111* 117 125 132 139 146 154 160 1685620 19.69 - - 163 169 177 183 191 198 2052585 17.72 - 126 134 140 148 155 162 169 1775620 19.69 - - 163* 169 177 183 191 198 2052585 17.72 - 126* 134 140 148 155 162 169 1775620 19.69 - - 156 163 170 177 184 191 1992585 17.72 - 122* 129 136 144 150 158 165 1722585 15.75 106* 113 121 127 135 141 149 156 163TypeofBracketSeeKL41-HDFootnote6YA0K4Idler <strong>Pulley</strong> Model UT<strong>220M</strong> 2585 15.75 60 65 70 74 80 84 90 94 99 SeeFootnoteKL41-HD6YA0KModel UT<strong>220H</strong> 5620 15.75 64 69 74 79 84 89 94 98 10441 Use “nom<strong>in</strong>al belt speed” to specify pulley. “Actual belt speed” is presented (for pulley lagged with 1/4” thick rubber) to assist with process design calculations.See Technical Precautions page 77. Note that “actual belt speed” decreases when lagg<strong>in</strong>g is not used due to decreased pulley diameter.2 Belt pull value allows for gearbox loss.3 <strong>Pulley</strong> must not be subjected to radial load exceed<strong>in</strong>g “Maximum radial load” def<strong>in</strong>ed above. See “Belt Tension” section <strong>in</strong> Technical Precautions, page 78.4 Additional <strong>Motorized</strong> <strong>Pulley</strong> and Idler <strong>Pulley</strong> weight, specified per Roller Length:31.50”< RL < 59.06” Wt = 3.7 lbs/<strong>in</strong>59.06”< RL < 78.74” Wt = 7.1 lbs/<strong>in</strong>5 All weights shown above are for pulleys with 1/4” thick lagg<strong>in</strong>g. To calculate unlagged pulley weight subtract 0.3 lbs/<strong>in</strong> of Roller Length from *above.Special “Short Roller Length” Optionwww.rulmecacorp.com 23TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> <strong>220M</strong> & <strong>220H</strong>, Ø <strong>8.50</strong> <strong>in</strong>. (<strong>216</strong> <strong>mm</strong>)60 HzPowerHP2MotorNo.ofPolesNo.GearStagesModelNom<strong>in</strong>al beltspeed 1 atFull Load60 HzfpmActual beltspeed 1 atFull Load60 HzfpmBeltPull 2lbsMax.RadialLoad 3T1 + T2lbsM<strong>in</strong>.RL<strong>in</strong>RL Dimension <strong>in</strong>ches (RL>78.74” available on request)Weight <strong>in</strong> lbs 5longer15.75 17.72 19.69 21.65 23.62 25.59 27.56 29.53 31.50 than31.503 <strong>220H</strong> 48 55 1137 5620 19.69 - - 156 163 170 177 184 191 199660 68 9282 <strong>220M</strong> 76 91 690 2585 17.72 - 126* 134 140 148 155 162 169 17796 108 583120 137 460150 168 376192 201 3144 2 <strong>220M</strong> 240 256 247 2585 15.75 110* 117 125 132 139 146 154 160 164300 319 198384 415 152480 501 126600 637 993 <strong>220H</strong> 60 68 1361 5620 19.69 - - 156* 165 172 179 187 193 20176 82 1136961201503 41922 <strong>220M</strong> 2403003844806003 <strong>220H</strong> 961201501924 42402 <strong>220M</strong> 3003844806003 <strong>220H</strong> 1201501925.5 22402 <strong>220M</strong> 3003844806001922407.5 2 3 <strong>220H</strong> 300384480600108137168201256319415501637104129168201256319415501637136163<strong>216</strong>2743364025126362022543144085226258556755514603612912231851451<strong>216</strong>9787516274923963042521971237103377761450141832926411469097355674433702585 17.72 - 126* 134 140 148 155 162 169 1775620 21.65 - - - 169 177 183 191 198 2012585 19.69 - - 138 145 153 159 167 173 1815620 21.65 - - - 169 177 183 191 198 2052585 19.69 - - 138 145 153 159 167 173 1815620 21.65 - - - 169 177 183 191 198 205TypeofBracketSeeKL41-HDFootnote6YA0K4Idler <strong>Pulley</strong> Model UT<strong>220M</strong> 2585 15.75 59 65 70 74 80 84 90 94 99 SeeFootnoteKL41-HD6YA0KModel UT<strong>220H</strong> 5620 15.75 63 69 74 79 84 89 94 98 10441 Use “nom<strong>in</strong>al belt speed” to specify pulley. “Actual belt speed” is presented (for pulley lagged with 1/4” thick rubber) to assist with process design calculations.See Technical Precautions page 77. Note that “actual belt speed” decreases when lagg<strong>in</strong>g is not used due to decreased pulley diameter.2 Belt pull value allows for gearbox loss.3 <strong>Pulley</strong> must not be subjected to radial load exceed<strong>in</strong>g “Maximum radial load” def<strong>in</strong>ed above. See “Belt Tension” section <strong>in</strong> Technical Precautions, page 78.4 Additional <strong>Motorized</strong> <strong>Pulley</strong> and Idler <strong>Pulley</strong> weight, specified per Roller Length:31.50”< RL < 59.06” Wt = 3.7 lbs/<strong>in</strong>59.06”< RL < 78.74” Wt = 7.1 lbs/<strong>in</strong>5 All weights shown above are for pulleys with 1/4” thick lagg<strong>in</strong>g. To calculate unlagged pulley weight subtract 0.3 lbs/<strong>in</strong> of Roller Length from *above.Special “Short Roller Length” Optionwww.rulmecacorp.com 24TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> <strong>220M</strong>, Ø <strong>8.50</strong> <strong>in</strong>. (<strong>216</strong> <strong>mm</strong>)Spare parts list and sectional draw<strong>in</strong>gsPos. Description Pos. Description Pos. Description1 Shell2 End hous<strong>in</strong>g with geared rim3 End hous<strong>in</strong>g8 Geared rim9 Rotor p<strong>in</strong>ion10 Input wheel11 Output p<strong>in</strong>ion12 Gear box13 Front shaft14 Rear shaft15 Stator completeCompact Term<strong>in</strong>al Box15.1 Rotor16 Term<strong>in</strong>al box complete17 Nipple20 Cover20.1 Cover with labyr<strong>in</strong>th groove23 Rear flange23.1 rear flange for backstop23.2 Rear flange for electromagneticBrake24 2 dust lip seals at each side24 Double lip seal at each side forlabyr<strong>in</strong>th option25 O-r<strong>in</strong>g26 Bear<strong>in</strong>g27 Bear<strong>in</strong>g28 Bear<strong>in</strong>g29 Bear<strong>in</strong>g (Backstop solution:One-way-bear<strong>in</strong>g)30 Bear<strong>in</strong>g31 Bear<strong>in</strong>g39 Hexagon socket screw40 Hexagon socket screw41 Hexagon socket screw52 Magnetic oil plug53 Distance washer53.1 Compression nipple59 Countersunk head screw66 Waved spr<strong>in</strong>g washer68 Key70 Toothed washer78 Gasket79 Hold<strong>in</strong>g clip or plastic tie85.1 Intermediate flange for brakeassembly91 Electromagnetic brake93 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g95 Straight connector96 Elbow connector101 Key104 Distance washer120 Labyr<strong>in</strong>th cover121 Set screw122 O-r<strong>in</strong>g123 Grease nipple124 Distance washer143 O-r<strong>in</strong>g146 Special shaped compressionwasher200 Rubber sealwww.rulmecacorp.com 25TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> <strong>220H</strong>, Ø <strong>8.50</strong> <strong>in</strong>. (<strong>216</strong> <strong>mm</strong>)Spare parts list and sectional draw<strong>in</strong>gsPos. Description Pos. Description Pos. Description1 Shell2 End hous<strong>in</strong>g with geared rim3 End hous<strong>in</strong>g8 Geared rim9 Rotor p<strong>in</strong>ion10 Input wheel11 Output p<strong>in</strong>ion12 Gear box13 Front shaft14 Rear shaft15 Stator complete15.1 Rotor16 Term<strong>in</strong>al box complete17 Nipple20 Cover20.1 Cover with labyr<strong>in</strong>th groove23 Rear flange23.1 Rear flange for backstopIntermediate Shaft23.2 Rear flange for electromagneticbrake24 2 Dust lip seals each side24 1 double lip seal at labyr<strong>in</strong>thoption25 O-r<strong>in</strong>g26 Bear<strong>in</strong>g27 Bear<strong>in</strong>g28 Bear<strong>in</strong>g29 Bear<strong>in</strong>g (Backstop solution:One-way-bear<strong>in</strong>g)30 Bear<strong>in</strong>g40 Hexagon socket screw41 Hexagon socket screw52 Magnetic oil plug53 Distance washer53.1 Compression nipple59 Countersunk head screw66 Waved spr<strong>in</strong>g washer68 Key70 Toothed washer78 Gasket79 Hold<strong>in</strong>g clip or plastic tie85.1 Intermediate flange for brakeassembly91 Electromagnetic brake93 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g95 Straight connector96 Elbow connector101 Key104 Distance washer120 Labyr<strong>in</strong>th cover121 Set screw122 O-r<strong>in</strong>g123 Grease nipple124 Distance washer143 O-r<strong>in</strong>g146 Special shaped compressionwasher180 Intermediate p<strong>in</strong>ion181 Intermediate wheel182 Distance washer184 Roller bear<strong>in</strong>g185 Roller bear<strong>in</strong>g186 Key187 Key188 Spr<strong>in</strong>g washer190 Spr<strong>in</strong>g washer191 Spr<strong>in</strong>g washer194 Set crew196 Key197 Spr<strong>in</strong>g washer198 Distance washer200 Rubber sealwww.rulmecacorp.com 26TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> <strong>220M</strong> & <strong>220H</strong>, Ø <strong>8.50</strong> <strong>in</strong>. (<strong>216</strong> <strong>mm</strong>)Sectional draw<strong>in</strong>gsStraight ConnectorElbow ConnectorElectromagnetic Brake OptionMechanical Backstop OptionShort Roller Length OptionLabyr<strong>in</strong>th Option - Mild Steelwww.rulmecacorp.com 27TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> <strong>220M</strong> & <strong>220H</strong>, Ø <strong>8.50</strong> <strong>in</strong>. (<strong>216</strong> <strong>mm</strong>)Sectional draw<strong>in</strong>gs<strong>220M</strong> & <strong>220H</strong>Sta<strong>in</strong>less steel options TS10N & TS12N<strong>220M</strong> & <strong>220H</strong>Sta<strong>in</strong>less steel options TS9N & TS11Nwww.rulmecacorp.com 28TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong>sCompact DrivesTriple Cross BeltsThree 12.64” diameter 5.5 HP motorized pulleys simplify design, <strong>in</strong>stallation,and ma<strong>in</strong>tenance of cross belt drives <strong>in</strong> this mobile double screen plant <strong>in</strong>Spokane, Wash<strong>in</strong>gton. Mobile screen plant designers frequently use motorizedpulleys to drive cross belts because of the severe space restrictions <strong>in</strong>the drive nest.Self-clean<strong>in</strong>g Magnetic SeparatorA 12.64” diameter 4 HP motorized pulley drives cleated belt surround<strong>in</strong>gelectromagnet on portable crush<strong>in</strong>g/screen<strong>in</strong>g system at this Louisiana C &D debris recycl<strong>in</strong>g facility. Also <strong>in</strong> service <strong>in</strong> Europe, this Austrian-designedrig also features motorized pulleys on screen feed, cross belts, and dischargebelts.Technical Precaution: When us<strong>in</strong>g electromagnets near motorized pulleysalways direct magnetic flux away from motorized pulley so that flux fielddoes not <strong>in</strong>terfere with motor. It is NOT necessary to use sta<strong>in</strong>less steel pulleyshells <strong>in</strong> these applications.Double Triple Cross BeltsThis Canadian mobile screen features four 12.64” diameter 5.5 HP and two12.64” diameter 3 HP cross belt drives. Note the absence of separate motorand gearbox mount<strong>in</strong>g platforms and expanded metal guard<strong>in</strong>g—all elim<strong>in</strong>atedthrough the use of motorized pulleys. Photo taken <strong>in</strong> Ontario limestonequarry <strong>in</strong> 1994.Glass Recycl<strong>in</strong>g ConveyorThe 12.64” diameter 5.5 HP motorized pulley used at this cullet conveyortransfer po<strong>in</strong>t m<strong>in</strong>imizes space requirements. It also offers <strong>in</strong>creased drivereliability (due to its hermetic seals) <strong>in</strong> the highly abrasive atmosphere.Photo was taken at the Raleigh, North Carol<strong>in</strong>a glass recycl<strong>in</strong>g center <strong>in</strong>1994.Technical Precaution: When us<strong>in</strong>g optional regreasable seals on motorizedpulleys <strong>in</strong> abrasive applications periodically purge grease through seals toprevent grit-laden grease from caus<strong>in</strong>g premature oil seal wear.www.rulmecacorp.com 29TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 320L, 320M & 320H, Ø 12.64 <strong>in</strong>. (321 <strong>mm</strong>)Our 12.64” diameter <strong>Motorized</strong> <strong>Pulley</strong>range offers three differentperformance levels for BULKapplications:- L for Light duty- M for Medium duty- H for Heavy dutyIt is important to note the productdifferences and choose theappropriate pulley based onestimated belt tension (radial load.)See page 78. The actual radial loadmust be less than the maximumallowable radial load shown <strong>in</strong> thiscatalog.Be aware of <strong>in</strong>creased belttensions required to drive multi-plythick heavy belts and/or larger beltwidths.If the 12.64” diameter model is notstrong enough to resist estimatedbelt tension, then select 15.91”diameter model.L for Light duty320L is designed for regular andcont<strong>in</strong>uous operat<strong>in</strong>g conditions. It isadvisable to rubber lag these pulleysto grip the belt and limit belt tension.Typical applications are portableconveyors and cross belts <strong>in</strong> mobilecrush<strong>in</strong>g and screen<strong>in</strong>g equipment.320L should not be used for lowspeed high torque feeder conveyors.320L uses motor and gearbox from<strong>220M</strong>.M for Medium dutyThe <strong>in</strong>ternal parts of 320M aredesigned for tough and irregularoperat<strong>in</strong>g conditions (e.g. crush<strong>in</strong>g &screen<strong>in</strong>g applications, asphalt,cement, and concrete plants.)H for Heavy dutyA solid 3-stage gearbox, largershafts, and stronger bear<strong>in</strong>gs enablethe 320H to provide low speed athigh torque and handle irregularload<strong>in</strong>gs <strong>in</strong> harsh operat<strong>in</strong>gconditions.STANDARD SPECIFICATIONof <strong>Motorized</strong> <strong>Pulley</strong>• Crowned mild steel 12.64” diametersteel shell treated with anti-rust wax• Powder coated cast iron bear<strong>in</strong>g hous<strong>in</strong>gs• Mild steel shafts treated with anti-rustwax• Shaft seal<strong>in</strong>g system – degree of protectionIP66/67 (EN60034-5.) Seepage 88.• Powder coated die cast alum<strong>in</strong>um term<strong>in</strong>albox• 3-phase <strong>in</strong>duction motors with thermalprotector• Voltage: All co<strong>mm</strong>on voltages available.Please specify.• Motor w<strong>in</strong>d<strong>in</strong>g <strong>in</strong>sulation Class F• Dynamically balanced rotor• One out of two oil plugs fitted with amagnet to filter the oil <strong>in</strong> 320L• Two oil plugs fitted with a magnet tofilter the oil <strong>in</strong> 320M & 320H• Oil change reco<strong>mm</strong>ended every10,000 operational hours• M<strong>in</strong>imum RL. Please refer to pages33-34• Maximum RL – Please <strong>in</strong>quire.• Non standard RL’s available• To be used <strong>in</strong> horizontal positions ± 5degree onlyPlease note:• Noise-sensitive Areas: High speed 2-pole motors can cause higher noiselevels and are not reco<strong>mm</strong>ended fornoise-sensitive areas• Technical Precautions for Design,Installation, and Ma<strong>in</strong>tenance: pages76-86• Environmental Considerations: page72• Optional Extras: page 31 and backcover• Electrical Connection Diagrams:pages 94-96.STAINLESS STEELoptionsTS9N• Sta<strong>in</strong>less steel shell – AISI 304 range• Sta<strong>in</strong>less steel shafts – AISI 303/4 range• Sta<strong>in</strong>less steel covered bear<strong>in</strong>g hous<strong>in</strong>gs– AISI 316 range• Sta<strong>in</strong>less steel oil plugs – AISI 304range – one out of two with magnet• Sta<strong>in</strong>less steel exterior bolts – AISI 304range• Regreasable labyr<strong>in</strong>th seals with greasenipples <strong>in</strong> sta<strong>in</strong>less steel –AISI 304 range• Shaft seal<strong>in</strong>g system – degree of protectionIP66/67 (EN60034-5).TS10N• As TS9N, but without regreasablelabyr<strong>in</strong>th seals.SEMI-RUST-FREE optionsTS11N• As TS9N, but with crowned mild steelshell treated with anti-rust wax.TS12N• As TS10N, but with crowned mild steelshell treated with anti-rust wax.Other Sta<strong>in</strong>less Options:• FDA & USDA food grade recognized oiland grease are not <strong>in</strong>cluded <strong>in</strong> TS9N toTS12N, but available on request• Complete <strong>Motorized</strong> <strong>Pulley</strong>s <strong>in</strong> acidresistant sta<strong>in</strong>less steel – AISI 316range – available on request.• Special mount<strong>in</strong>g brackets are available.Electrical connection options:• Salt water resistant powder coatedalum<strong>in</strong>um term<strong>in</strong>al box with z<strong>in</strong>c platedexterior bolts• Sta<strong>in</strong>less steel term<strong>in</strong>al box – AISI 304range (max. 5.5 HP)• Straight sta<strong>in</strong>less steel connector withfly<strong>in</strong>g lead – AISI 304 range.Please specify required TS-numberwhen order<strong>in</strong>g Sta<strong>in</strong>less Steel options.www.rulmecacorp.com 30TC101: 03/07

OPTIONAL EXTRAS<strong>Motorized</strong> <strong>Pulley</strong> 320L, 320M & 320HSpecificationAvailabilityTotal sta<strong>in</strong>less steel option AISI 304 range TS9N with regreasable labyr<strong>in</strong>th seals xTotal sta<strong>in</strong>less steel option AISI 304 range TS10N with standard seals xSemi-rust free option TS11N with regreasable labyr<strong>in</strong>th seals xSemi-rust free option TS12N with standard seals xRegreasable labyr<strong>in</strong>th sealsxFood grade oil & grease - FDA & USDA recognizedxDust explosion proof <strong>Motorized</strong> <strong>Pulley</strong>s - ATEX 95 - Zone 22 - for applications handl<strong>in</strong>g of dusty gra<strong>in</strong> etc.Accord<strong>in</strong>g to European Directive 94/9/EC.xTotal acid resistant sta<strong>in</strong>less steel option - AISI 316xBlack rubber lagg<strong>in</strong>g - Standard specifications (See page 80.)5/16” diamond lagg<strong>in</strong>g - Hardness 60 ±5 Shore A < 7.5 HP x1/4” diamond lagg<strong>in</strong>g - Hardness 60 ±5 Shore A 10 HP oWhite smooth rubber lagg<strong>in</strong>g (FDA listed) Oil, fat & grease resistantoSpecial lagg<strong>in</strong>g (e.g. hot vulcanized)oElectromagnetic brake M<strong>in</strong> RL <strong>in</strong>creases by 3.94” xMechanical backstop M<strong>in</strong> RL does not <strong>in</strong>crease for 320L, xM<strong>in</strong>. RL <strong>in</strong>creases by 1.97” for 320 M & 320HxModified for vertical mount<strong>in</strong>goModified for mount<strong>in</strong>g between 5° and 90° (e.g. for magnetic separators)oInsulation class F with standard oil: (Allowable ambient temperature -13°F/+104°F)Std.Insulation class H with synthetic oil: (Allowable ambient temperature -13°F/+120°F)xSpecial motors for applications with no belt contactoLow noise drives for noise sensitive areasxParallel shell (i.e. no crown)xThermal protectorStd.IP66/67 Yellow powder coated alum<strong>in</strong>um term<strong>in</strong>al boxStd.IP66/67 Gray powder coated alum<strong>in</strong>um term<strong>in</strong>al box (food grade approved)xIP66/67 Compact powder coated alum<strong>in</strong>um term<strong>in</strong>al box (food grade approved) < 5.5 HP only oIP66/67 Compact sta<strong>in</strong>less steel term<strong>in</strong>al box - AISI 304 or 316 range < 5.5 HP only oStraight or elbow connector with standard power cord < 5.5 HP only xStraight connector with screened power cord (See page 86 for VFD precautions) < 5.5 HP only xStraight connector with power cord (Sta<strong>in</strong>less steel <strong>in</strong> AISI 304 range) < 5.5 HP only xVoltage: < 5.5 HP dual voltage (230/460) stator (YY/Y w<strong>in</strong>d<strong>in</strong>g) wired for 460v/3ph/60 Hz at term<strong>in</strong>al boxStd.< 5.5 HP dual voltage (230/460) stator (YY/Y w<strong>in</strong>d<strong>in</strong>g) wired for 230v/3ph/60 Hz at term<strong>in</strong>al box x> 7.5 HP s<strong>in</strong>gle voltage (460) stator (Y w<strong>in</strong>d<strong>in</strong>g) wired for 460v/3ph/60 Hz at term<strong>in</strong>al box Std> 7.5 HP s<strong>in</strong>gle voltage (230) stator (YY w<strong>in</strong>d<strong>in</strong>g) wired for 230v/3ph/60 Hz at term<strong>in</strong>al box x2 speed motors xSpecial voltage motorsxS<strong>in</strong>gle phase motorsoCSA approved motorsxx = Optional extraso = An option with certa<strong>in</strong> limitations. Please refer to Technical precautions pages 76-86!Std. = Fitted as standardwww.rulmecacorp.com 31TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 320L, 320M & 320H, Ø 12.64 <strong>in</strong>. (321 <strong>mm</strong>)Compactterm<strong>in</strong>albox < 5.5HPStandardterm<strong>in</strong>albox<strong>Motorized</strong> <strong>Pulley</strong> with term<strong>in</strong>al boxStraightconnectorElbowconnectorIdler <strong>Pulley</strong> 3 UT320M / UT320H<strong>in</strong> TS9N/TS11N<strong>Motorized</strong> <strong>Pulley</strong> or idler <strong>Pulley</strong> Standard term<strong>in</strong>al Compact term<strong>in</strong>al Straight Elbowbox box < 5.5 HP connector connectorG < 5.5 HP < 5.5 HPA B C D E F G TS9/11 H K W L M N O L M N N1 U V R S TModel <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong> <strong>in</strong>320L 12.72 12.56 1.97 1.57 3.78 1.18 0.59 0.75 0.98 2.13 – – – – – 1.61 0.95 3.74 0.55 0.16 1.06 0.79 1.89 0.47320M 12.64 12.56 1.97 1.57 4.92 1.18 0.69 0.89 0.98 2.13 – 3.43 1.06 4.21 4.13 1.61 0.95 3.74 0.55 0.16 1.06 0.79 1.89 0.47320H 12.64 12.56 1.97 1.97 5.83 1.57 0.43 0.81 0.98 2.17 – 3.43 1.06 4.21 4.13 1.61 0.95 3.74 0.55 0.16 1.06 0.79 1.89 0.47UT320M 12.64 12.64 1.97 1.57 4.92 1.18 0.57 0.89 0.98 – 2.05UT320H 12.64 12.64 1.97 1.97 5.83 1.57 0.43 0.81 0.98 – 2.051 A dimension is outer diameter of unlagged pulley shell at pulley centerl<strong>in</strong>e.2 B dimension is outer diameter of unlagged pulley shell at each end of shell.3 Idler pulley shown is non-crowned TS9N/TS11N version with regreasable seals.Mount<strong>in</strong>g brackets<strong>Motorized</strong><strong>Pulley</strong>sMaterialBracketSizePartNumberDimensionsWeightModel320L &320MSteel pa<strong>in</strong>tedSteel NiplatedSta<strong>in</strong>less steelKL41-HD6YA0K6YA0W6YA0UD<strong>in</strong>F<strong>in</strong>I<strong>in</strong>K<strong>in</strong>S<strong>in</strong>T<strong>in</strong>V<strong>in</strong>1.57 1.18 3.31 2.44 0.55 0.79 0.87 1.57 4.33 7.48 1.97 3.27 4.63W1<strong>in</strong>X<strong>in</strong>X1<strong>in</strong>Z<strong>in</strong>Z1<strong>in</strong>lbs320HSteel pa<strong>in</strong>tedSteel NiplatedKL426YA0J6YA0S1.97 1.57 4.76 3.54 0.71 1.18 0.98 1.97 5.91 9.84 2.76 4.33 9.92www.rulmecacorp.com 32TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 320L, Ø 12.64 <strong>in</strong>. (321 <strong>mm</strong>)MotorPowerHP<strong>Motorized</strong> <strong>Pulley</strong> 320M & 320H, Ø 12.64 <strong>in</strong>. (321 <strong>mm</strong>)MotorPowerHPNo.ofPolesNo.ofPolesNo.Gear ModelStages1 8 2 320L1.52No.Gear ModelStagesNom<strong>in</strong>al beltspeed 1 atFull Load60 Hzfpm7696120150192240300Nom<strong>in</strong>al beltspeed 1 atFull Load60 Hzfpm3 320H 243038481 12602 320M 7696120150192123 320H 24302 320M 3848601.576968 2 320M 120150192240300Actual beltspeed 1 atFull Load60 Hzfpm78100122146186231300Actual beltspeed 1 atFull Load60 Hzfpm253241546983108135166212253241546181103126162203249319BeltPull 2lbs402317259<strong>216</strong>170137105BeltPull 2lbs1241984774581461377291233190148182114441128851752568450368285228186145Max.RadialLoad 3T1 + T2lbsMax.RadialLoad 3T1 + T2lbsM<strong>in</strong>.RLSpecialm<strong>in</strong>.RL1 Use “nom<strong>in</strong>al belt speed” to specify pulley. “Actual belt speed” is presented (for pulley lagged with 1/4” thick rubber) to assist with process design calculations.See Technical Precautions page 77. Note that “actual belt speed” decreases when lagg<strong>in</strong>g is not used due to decreased pulley diameter.2 Belt pull value allows for gearbox loss.3 <strong>Pulley</strong> must not be subjected to radial load exceed<strong>in</strong>g “Maximum radial load” def<strong>in</strong>ed above. See “Belt Tension” section <strong>in</strong> Technical Precautions, page 78.4 Additional <strong>Motorized</strong> <strong>Pulley</strong> and Idler <strong>Pulley</strong> weight, specified per Roller Length: 31.50”< RL < 62.99” Wt = 6.1 lbs/<strong>in</strong>; 62.99”< RL < 78.74” Wt = 11.7 lbs/<strong>in</strong>5 All weights shown above are for pulleys with 1/4” thick lagg<strong>in</strong>g. To calculate unlagged pulley weight subtract 0.5 lbs/<strong>in</strong> of Roller Length from above.*Special “Short Roller Length” Optionwww.rulmecacorp.com 33TC101: 03/07<strong>in</strong><strong>in</strong>RL Dimension <strong>in</strong>ches (RL>78.74” available on request)Weight <strong>in</strong> lbs 5longer15.75 17.72 19.69 21.65 23.62 25.59 27.56 29.53 31.50 than31.50”2585 17.72 - 180* 190 200 209 219 223 239 2496 2 320L 120 132 349 2585 17.72 - 185 194 204 214 224 234 243 2531501921571992942334 2 320L240300384480600243292371462602190159124100772585 15.75 168* 176 185 195 205 215 225 234 2446 2 320L 120 132 476 2585 17.72 - 189 199 209 218 228 238 248 2581501921571994023174 2 320L240300384480600243292371462602259<strong>216</strong>1701371052585 15.75 172* 180 190 200 209 219 229 239 2493 4 2 320L4 4 2 320L5.5 2 2 320L1501922403003844806002403003844806003003844806001571992432923714626022432923714626023143974875835904663803172492001545184333402732105364233452892585 17.72 - 189* 199 208 218 228 238 248 2582585 19.69 - - 207 217 227 237 247 257 2662585 19.69 - - 207 217 227 237 247 257 266RL Dimension <strong>in</strong>ches (RL>78.74” available on request)Weight <strong>in</strong> lbs 5longer17.72 19.69 21.65 23.62 25.59 27.56 29.53 31.50 33.46 than33.467868 21.65 - - 308* 317 329 341 354 366 3784496 19.69 - 251* 261 271 281 291 301 310 320TypeofBracketKL426YA0JKL41-HD6YA0KSee7868 21.65 - - 308* 317 329 341 354 366 378 FootnoteKL426YA0J4496 19.69 - 251* 261 271 281 291 301 310 32060 HzTypeofBracketSeeKL41-HDFootnote6YA0K460 HzKL41-HD6YA0K

<strong>Motorized</strong> <strong>Pulley</strong> 320M & 320H, Ø 12.64 <strong>in</strong>. (321 <strong>mm</strong>)MotorPowerHPNo.ofPolesNo.Gear ModelStagesNom<strong>in</strong>al beltspeed 1 atFull Load60 HzfpmActual beltspeed 1 atFull Load60 HzfpmBeltPull 2lbsMax.RadialLoad 3T1 + T2lbsM<strong>in</strong>.RL<strong>in</strong>RL Dimension <strong>in</strong>ches (RL>78.74” available on request)Weight <strong>in</strong> lbs 5longer17.72 19.69 21.65 23.62 25.59 27.56 29.53 31.50 33.46 than33.46”60 HzTypeofBracket3 320H 384838481655131260 61 102676 81 7742 896 103 6142 320M 120 126 503150 162 389192 203 311240 248 253300 318 19883 320H 38488748242719252 320M607661811505113696 103 9033120150123163752568192 206 4504 2 320M 240300251324368285384 406 228480 498 186600 637 14563 320H48 51 248360 64 196976 78 16132 320M 96 108 1161120 123 1026415019<strong>216</strong>32067746144 2 320M 240300251324503389384 406 311480 498 253600 637 1985.57.5 410 26 3 320H4 2 320M3 320H2 320M3 320H2 320M7696120150192240300384480600961201501922403003844806001501922403003844806007810112316320625132440649863796117152206251324406498637153192235325411501649215116611368103281967051841433826424061971152311259237135694653632069164013449687686294867868 21.65 - - 308* 317 329 341 354 366 3784496 19.69 - 252* 261 271 281 291 301 310 3207868 21.65 - - 308* 317 329 341 354 369 3784496 19.69 - 252* 261 271 281 291 301 310 3204496 19.69 - 229* 239 249 258 268 278 288 2987868 21.65 - - 308* 317 329 341 354 366 3784496 19.69 - 229* 239 249 258 268 278 288 2987868 21.65 - - 308* 317 329 341 354 366 3784496 19.69 - 252* 261 271 281 291 301 310 3207868 21.65 - - 308* 317 329 341 354 366 3784496 19.69 - 252* 261 271 281 291 301 310 3207868 21.65 - - 308* 317 329 341 354 366 3784496 19.69 - - 261 271 281 291 301 310 320SeeFootnote4KL426YA0JKL41-HD6YA0KKL426YA0JKL41-HD6YA0KKL41-HD6YA0KKL426YA0JKL41-HD6YA0KKL426YA0JKL41-HD6YA0KKL426YA0JKL41-HD6YA0KKL426YA0JKL41-HD6YA0KKL41-HDIdler <strong>Pulley</strong> Model UT320M 4496 17.72 118 128 138 148 158 167 177 187 197 See 6YA0KFootnote4 KL42Model UT320H 7868 17.72 131 143 153 163 173 183 193 202 2126YA0J1 Use “nom<strong>in</strong>al belt speed” to specify pulley. “Actual belt speed” is presented (for pulley lagged with 1/4” thick rubber) to assist with process design calculations.See Technical Precautions page 77. Note that “actual belt speed” decreases when lagg<strong>in</strong>g is not used due to decreased pulley diameter.2 Belt pull value allows for gearbox loss.3 <strong>Pulley</strong> must not be subjected to radial load exceed<strong>in</strong>g “Maximum radial load” def<strong>in</strong>ed above. See “Belt Tension” section <strong>in</strong> Technical Precautions, page 78.4 Additional <strong>Motorized</strong> <strong>Pulley</strong> and Idler <strong>Pulley</strong> weight, specified per Roller Length: 31.50”< RL < 62.99” Wt = 6.1 lbs/<strong>in</strong>; 62.99”< RL < 78.74” Wt = 11.7 lbs/<strong>in</strong>5 All weights shown above are for pulleys with 1/4” thick lagg<strong>in</strong>g. To calculate unlagged pulley weight subtract 0.5 lbs/<strong>in</strong> of Roller Length from above.*Special “Short Roller Length” Optionwww.rulmecacorp.com 34TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 320L, Ø 12.64 <strong>in</strong>. (321 <strong>mm</strong>)Spare parts list and sectional draw<strong>in</strong>gsPos. Description Pos. Description Pos. Description1 Shell2 End hous<strong>in</strong>g with geared rim3 End hous<strong>in</strong>g8 Geared rim9 Rotor p<strong>in</strong>ion10 Input wheel11 Output p<strong>in</strong>ion12 Gear box13 Front shaft14 Rear shaft15 Stator complete15.1 Rotor16 Term<strong>in</strong>al box completeCompact Term<strong>in</strong>al Box17 Nipple20 Cover20.1 Cover with labyr<strong>in</strong>th groove23 Rear flange23.1 Rear flange for backstop23.2 Rear flange for electromagneticbrake24 2 Dust lip seals each side24 1 Double lip seal for labyr<strong>in</strong>thoption25 O-r<strong>in</strong>g26 Bear<strong>in</strong>g27 Bear<strong>in</strong>g28 Bear<strong>in</strong>g29 Bear<strong>in</strong>g (Backstop solution:One-way-bear<strong>in</strong>g)30 Bear<strong>in</strong>g31 Bear<strong>in</strong>g39 Hexagon socket screw40 Hexagon socket screw52 Magnetic oil plug53 Distance washer53.1 Compression nipple59 Countersunk head screw66 Waved spr<strong>in</strong>g washer68 Key70 Toothed washer78 Gasket79 Hold<strong>in</strong>g clip or plastic tie85 Intermediate flange for backstop85.1 Intermediate flange for brakeassembly91 Electromagnetic brake93 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g95 Straight connector96 Elbow connector101 Key104 Distance washer120 Labyr<strong>in</strong>th cover121 Set screw122 O-r<strong>in</strong>g123 Grease nipple143 O-r<strong>in</strong>g146 Special shaped compressionwasher200 Rubber sealwww.rulmecacorp.com 35TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 320M, Ø 12.64 <strong>in</strong>. (321 <strong>mm</strong>)Spare parts list and sectional draw<strong>in</strong>gsPos. Description Pos. Description Pos. Description1 Shell2 End hous<strong>in</strong>g with geared rim3 End hous<strong>in</strong>g8 Geared rim9 Rotor p<strong>in</strong>ion10 Input wheel11 Output p<strong>in</strong>ion12 Gear box13 Front shaft14 Rear shaft15 Stator complete15.1 Rotor16 Term<strong>in</strong>al box complete17 Nipple20 Cover20.1 Cover with labyr<strong>in</strong>th groove23 Rear flange23.1 Rear flange for backstop/Brake24 2 Dust lip seals each side25 O-r<strong>in</strong>g26 Bear<strong>in</strong>g27 Bear<strong>in</strong>g28 Bear<strong>in</strong>g29 Bear<strong>in</strong>g30 Bear<strong>in</strong>g31 Bear<strong>in</strong>g32 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g33 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g35 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g37 Hexagon socket screw43 Hexagon socket screw44 Hexagon socket screw45 Hexagon head screw46 Hexagon head screw49 Washer52 Magnetic oil plug53 Distance washer53.1 Compression nipple60 Parallel p<strong>in</strong>64 Prevail<strong>in</strong>g torque type hexagonnut66 Waved spr<strong>in</strong>g washer67 Waved spr<strong>in</strong>g washer68 Key70 Waved spr<strong>in</strong>g washer75 Gasket78 Gasket79 Hold<strong>in</strong>g clip or plastic tie85 Intermediate flange for backstop85.1 Intermediate flange for brakeassembly91 Electromagnetic brake93 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g94 Hexagon head screw95 Straight connector96 Elbow connector99 Waved spr<strong>in</strong>g washer101 Key104 Distance washer120 Labyr<strong>in</strong>th cover121 Set screw122 O-r<strong>in</strong>g123 Grease nipple143 O-r<strong>in</strong>g146 Special shaped compressionwasher200 Rubber sealwww.rulmecacorp.com 36TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 320H, Ø 12.64 <strong>in</strong>. (321 <strong>mm</strong>)Spare parts list and sectional draw<strong>in</strong>gsPos. Description Pos. Description Pos. Description1 Shell2 End hous<strong>in</strong>g with geared rim3 End hous<strong>in</strong>g8 Geared rim9 Rotor p<strong>in</strong>ion10 Input wheel11 Output p<strong>in</strong>ion12 Gear box13 Front shaft14 Rear shaft15 Stator complete15.1 Rotor16 Term<strong>in</strong>al box complete17 Nipple20 Cover front side20.1 Cover with labyr<strong>in</strong>th groove21 Cover – rear side21.1 Cover with labyr<strong>in</strong>th groove23 Rear flange23.1 Rear flange for brake option24 2 Dust lip seals each side25 O-r<strong>in</strong>g26 Bear<strong>in</strong>g27 Bear<strong>in</strong>g28 Bear<strong>in</strong>g29 Bear<strong>in</strong>g20 Cover front side20.1 Cover with labyr<strong>in</strong>th groove21 Cover – rear side21.1 Cover with labyr<strong>in</strong>th groove23 Rear flange23.1 Rear flange for brake option24 2 Dust lip seals each side25 O-r<strong>in</strong>g26 Bear<strong>in</strong>g27 Bear<strong>in</strong>g28 Bear<strong>in</strong>g29 Bear<strong>in</strong>g30 Bear<strong>in</strong>g31 Bear<strong>in</strong>g32 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g33 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g35 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g37 Hexagon socket screw43 Hexagon head screw44 Hexagon head screw45 Hexagon head screw46 Hexagon head screw49 Washer52 Magnetic oil plug53 Distance washer53.1 Compression nipple60 Parallel p<strong>in</strong>64 Hexagon head nut66 Waved spr<strong>in</strong>g washer67 Waved spr<strong>in</strong>g washer68 Key70 Waved spr<strong>in</strong>g washer73 Set screw75 Gasket78 Gasket79 Hold<strong>in</strong>g clip or plastic tie80 Hexagon head screw84 Rear flange for brake85 Intermediate flange for backstop85.1 Intermediate flange for brakeassembly90 Backstop91 Electromagnetic brake93 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g94 Hexagon head screw95 Straight connector96 Elbow connector99 Waved spr<strong>in</strong>g washer101 Key104 Distance washer120 Labyr<strong>in</strong>th cover121 Set screw122 O-r<strong>in</strong>g123 Grease nipple143 O-r<strong>in</strong>g146 Special shaped compressionwasher180 Intermediate p<strong>in</strong>ion shaft181 Intermediate p<strong>in</strong>ion182 Distance bush<strong>in</strong>g183 Washer184 Roller bear<strong>in</strong>g185 Roller bear<strong>in</strong>g186 Key187 Key188 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g190 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g191 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g192 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g193 Distance washer194 Set screw195 Prevail<strong>in</strong>g torque type hexagonnut196 Key197 Reta<strong>in</strong><strong>in</strong>g r<strong>in</strong>g198 Distance r<strong>in</strong>g200 Rubber sealwww.rulmecacorp.com 37TC101: 03/07

<strong>Motorized</strong> <strong>Pulley</strong> 320L, 320M & 320H, Ø 12.64 <strong>in</strong>. (321 <strong>mm</strong>)Sectional draw<strong>in</strong>gsTS9N & TS11NLabyr<strong>in</strong>th Option(valid for 320M)sealed withseal<strong>in</strong>g compoundthe pos. no. <strong>in</strong> brackets(21 & 21.1) is valid for320H 3-stageRegreasableLabyr<strong>in</strong>th OptionTS10N & TS11Nwithout labyr<strong>in</strong>thSta<strong>in</strong>less Steel Option320L TS9NElbow ConnectorElectromagnetic Brake OptionStraight ConnectorBackstop Optionwww.rulmecacorp.com 38TC101: 03/07