TITAN III POWERFUL PRODUCTIVITY - Messer Cutting Systems

TITAN III POWERFUL PRODUCTIVITY - Messer Cutting Systems

TITAN III POWERFUL PRODUCTIVITY - Messer Cutting Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

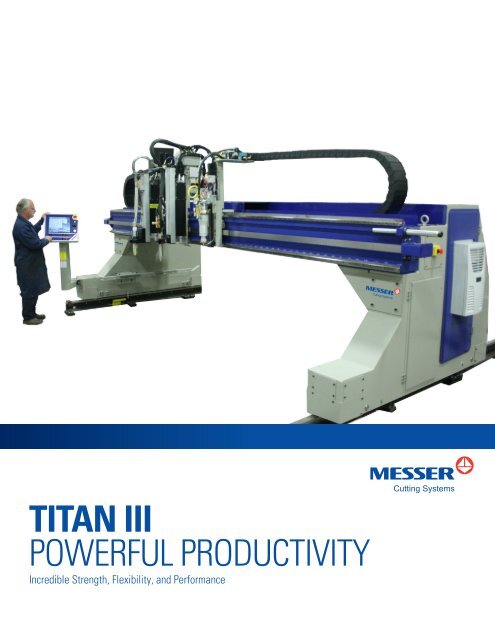

<strong>TITAN</strong> <strong>III</strong><strong>POWERFUL</strong> <strong>PRODUCTIVITY</strong>Incredible Strength, Flexibility, and PerformanceTedkomaben guared 3

THE <strong>TITAN</strong> <strong>III</strong><strong>POWERFUL</strong> <strong>PRODUCTIVITY</strong>HAIEGDF

Tedkomaben guared 6Y-AXIS DRIVELinear ways combined with <strong>Messer</strong>SureTrack pitch line gear engagement toinsure long life and precise motion.ESLAGGER ® CUTTING TABLEThe Slagger ® automates the removalof slag as well as small parts that mayhave fallen into the table, using a pusherblade mechanism. This is achievedin under five minutes for most tableconfigurations. The need to remove slatsto retrieve small parts or clean the tableis also eliminated. (Optional)FGPLASMA AND ALFA TM / OXYFUELTORCHESOxyfuel automation using <strong>Messer</strong>’sALFA TM torch and OmniFlow technology.The ALFA TM torch provides bothinternal ignition and height control.The OmniFlow automates gas andpiercing controls. Precision Plasma up to800 amps. (Optional)H I JVIDEO CAMERAThe on-board video camera featurecan be used by the operator as both analignment tool and to monitor the cuttingprocess. The image is convenientlydisplayed on the 15” TFT color screen ofthe Global Control Plus. (Optional)OMNIFLOW AUTOMATIC GASCONTROLOperators concentrate on cuttingparts not on costly torch setup andadjustments. Internal database makesnovices experts in minutes, not years.Less scrap and setup time, more profit.(Optional)X-AXIS RAIL SYSTEMOver-sized floor mounted rail providesa rigid foundation for smooth, stablemachine motion. Fast, accurateinstallation is assured with the <strong>Messer</strong>exclusive precision leveling andalignment pads.KFIBER LASERFine details such as hole diametersless than material thickness andsharp internal corners previously notachievable with Plasma can now beaccomplished. (Optional)PLASMA TORCH COLLISIONPROTECTIONNo more expensive torch repairs aftera collision. Place torch back in holderfor quick, simple re-alignment. You savedown time and money. (Optional)GLOBAL ROTATOR DELTA eRotation of +/- 460° with results incut part angles of +/- 45°. Completewith bevel programming software andtraining. (Optional)

Tedkomaben guared 2STANDARD ANDOPTIONAL FEATURESSTANDARD FEATURES• <strong>Cutting</strong> widths from 6’ to 14’• Standard cutting lengths up to 150 feet• Machine motion accuracy; +/-.010” accuracy; .010” repeatability(compensated machine motion in 72”)measured with a laser interferometer• Cut material from 26 ga. to 8” thick plate• Cuts mild steel, stainless steel, aluminum• Contouring speeds up to 400 ipm• Positioning speeds up to 1,700 ipm• Reinforced steel weldment constructionwith high rigidity beam (less than 0.001”bend and 0.002 degrees of twist)• Machined mating surfaces and bores(critical tolerances of 0.002” maintained)• Powertrack in both axes is standard• Up to eight torch stations (maximumtwo plasma stations)• Up to three stations will coverfull rated cutting width• Global Control Plus, Windows ® basedwith easy to use operator interface• Right or left hand mounted control consolewith tilt and swivel for operator comfort• Virtual Service remote consultationand diagnostics• Surestop station collision protectionwith easy and accurate reset• Advanced Oxyfuel technology providesconsistent piercing and faster cutting• High productivity Smart Lifters• Designed and manufactured in the USAto machine tool and ISO 230-2 standards• UL availableOPTIONAL FEATURES• Precision Plasma up to 800 amps• Fiber Laser• Delta e Plasma Bevel Unit• TurboFlame ® or ALFA TM Oxyfuel torches• Manual Plasma strippingbevel unit for the X-Axis• Advanced Oxyfuel technologywith Omniflow automatedgas regulation system• Auto torch spacing withprogrammable torch selection• Torch ignitor, and automatic heightcontrol for Oxyfuel systems• High-speed automated Oxyfuel cutting• Rotary rail cleaners with rack air purge• Beveling of weld prep surfaces;straight line and contour, Oxyfuel andPlasma, single torch and multi-torch• Various plate markers: Plasma,Airscribe, Pneumatic Punch, ZincPowder, Ink Jet, and Pin Stamp ®• Video Camera• Laser Pointer• Global Reporter• Programming and nesting software• Electric drilling up to ½”• Operator glare curtain• Zoned exhaust tables, includingself-cleaning Slagger ®• <strong>Messer</strong> dust collection system• Exhaust ducting kits• Material handling systems• Sentry Service preventativemaintenance program<strong>Messer</strong> <strong>Cutting</strong> <strong>Systems</strong> reserves the right to makechanges in equipment or specifications at any timewithout notice. Windows is a registered trademarkof Microsoft Corporation. Slagger is a registeredtrademark of Missouri Valley Steel, a division ofOwen Industries. © 2014 <strong>Messer</strong> <strong>Cutting</strong> <strong>Systems</strong><strong>Messer</strong> <strong>Cutting</strong> <strong>Systems</strong>, Inc.W141 N9427 Fountain BoulevardMenomonee Falls, WI 53051Tel. +1 262-255-5520Fax +1 262-255-5170E-mail: sales@messercutting.comwww.messer-cs.com