Metrology Assisted Assembly & Automated Inspection - Leica ...

Metrology Assisted Assembly & Automated Inspection - Leica ...

Metrology Assisted Assembly & Automated Inspection - Leica ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

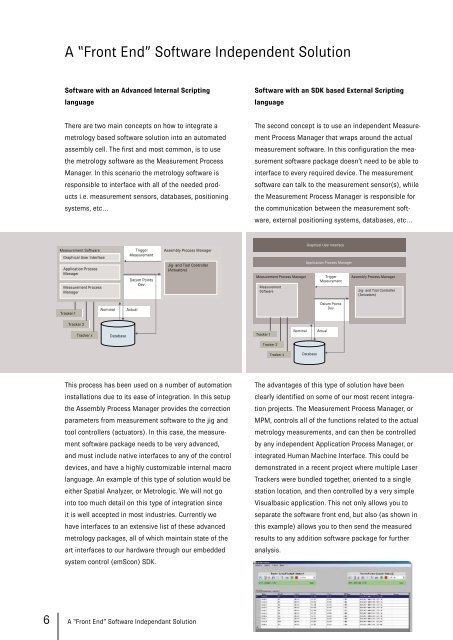

A “Front End” Software Independent SolutionSoftware with an Advanced Internal ScriptinglanguageSoftware with an SDK based External ScriptinglanguageThere are two main concepts on how to integrate ametrology based software solution into an automatedassembly cell. The first and most common, is to usethe metrology software as the Measurement ProcessManager. In this scenario the metrology software isresponsible to interface with all of the needed productsi.e. measurement sensors, databases, positioningsystems, etc…The second concept is to use an independent MeasurementProcess Manager that wraps around the actualmeasurement software. In this configuration the measurementsoftware package doesn’t need to be able tointerface to every required device. The measurementsoftware can talk to the measurement sensor(s), whilethe Measurement Process Manager is responsible forthe communication between the measurement software,external positioning systems, databases, etc…Measurement SoftwareGraphical User InterfaceApplication ProcessManagerMeasurement ProcessManagerTriggerMeasurementDatum PointsDev.<strong>Assembly</strong> Process ManagerJig- and Tool Controller(Actuators)Measurement Process ManagerMeasurementSoftwareGraphical User InterfaceApplication Process ManagerTriggerMeasurement<strong>Assembly</strong> Process ManagerJig- and Tool Controller(Actuators)Tracker 1NominalActualDatum PointsDev.Tracker 2Tracker xDatabaseTracker 1NominalActualTracker 2Tracker xDatabaseThis process has been used on a number of automationinstallations due to its ease of integration. In this setupthe <strong>Assembly</strong> Process Manager provides the correctionparameters from measurement software to the jig andtool controllers (actuators). In this case, the measurementsoftware package needs to be very advanced,and must include native interfaces to any of the controldevices, and have a highly customizable internal macrolanguage. An example of this type of solution would beeither Spatial Analyzer, or Metrologic. We will not gointo too much detail on this type of integration sinceit is well accepted in most industries. Currently wehave interfaces to an extensive list of these advancedmetrology packages, all of which maintain state of theart interfaces to our hardware through our embeddedsystem control (emScon) SDK.The advantages of this type of solution have beenclearly identified on some of our most recent integrationprojects. The Measurement Process Manager, orMPM, controls all of the functions related to the actualmetrology measurements, and can then be controlledby any independent Application Process Manager, orintegrated Human Machine Interface. This could bedemonstrated in a recent project where multiple LaserTrackers were bundled together, oriented to a singlestation location, and then controlled by a very simpleVisualbasic application. This not only allows you toseparate the software front end, but also (as shown inthis example) allows you to then send the measuredresults to any addition software package for furtheranalysis.6 A “Front End” Software Independant Solution