You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>All</strong>-<strong>Ceramic</strong> SystemsCynthia S. Petrie, D.D.S., M.S.

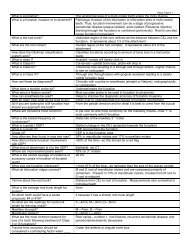

• Chemistry• Classification• Material PropertiesDental Porcelain

• 70-90% Feldspar:Chemistrypotassium aluminum silicate K 2 O·Al 2 O 3·6SiO 2a. potash feldspar orb. sodium feldspar• 10-20% Quartz: high-fusing SiO 2• 1-10% Kaolin: clay• Coloring frits

Potash Feldspar• Crystalline material, becomes glassywhen heated• Translucent after heated• When heated it decomposes to form:a. glass andb. leucite KAlSi 2 O 6• Leucite: provides strength, controls thethermal expansion coefficient

Quartz• Crystals of silicon dioxide SiO 2• Provides stability during heating,acts as a framework for all the otheringredients

Kaolin• Opaque properties• Responsible for the binding of theparticles

Coloring• “Color frits”• Less than 1%• Metallic oxides ground to fine powderand added to the mixture.

Classification• High-fusing: 2,350-2,500 F• Medium-fusing: 2,000-2,300 F• Low-fusing: 1,600-1,950 FThe low- and medium-fusing are made by theprocess of fritting (fusing of the different powdersat high temperature). The frit (mass) is thenreground into ultra-fine powder and metallic oxidesare added.

Material Properties• Very brittle• Low tensile and shear strength• High compressive strength• Good insulator• High hardness – Abrasiveness• Superior esthetics• The lower the fusing temperature the lessabrasive the porcelain

• Vitrification: the fusion of porcelainparticles into a translucent amorphous mass• Devitrification: prolonged heating of theporcelain, to temperatures below glasstransition, results in a more opaquecrystalline mass• Sintered: fusion of porcelain particles byheating above the glass transitiontemperature• Glass transition: the range of temperatureabove which the porcelain will change itsphysical stage

<strong>All</strong>-<strong>Ceramic</strong> Systems• Porcelain Jacket Crowns• In-Ceram• Empress/Empress 2/IPSe.max• Procera• Zirconia-based ceramics

Contemporary <strong>All</strong>-<strong>Ceramic</strong> Systems1. Glass ceramicsClassification2. Alumina reinforced3. Lithium disilicate4. Zirconia-based ceramics

Dental PorcelainLaboratory Techniques• Hand stacking• Infiltration system (In-Ceram)• Heat-pressed ceramic (Empress)• CAD/CAM technology (Procera, Cerec,e.max, In-ceram, Lava)

Porcelain Jacket Crowns• Basically the same porcelain used formetal-ceramic restorations (feldspathic)• High-fusing porcelain• Prone to fracture• Different tooth preparation design inorder to achieve bulk of the material• Not used routinely today

In-CeramComposition:• Aluminum Oxide (In-Ceram)• Magnesium aluminous spinel (In-Ceram Spinell)• Aluminum and Zirconium (In-Ceram Zirconia)

In-Ceram• Alumina crystal: restriction of crackpropagation• Infiltrated glass: reduces the porosity

In-Ceram SPINELLSpinel:natural oxide ofmagnesium and aluminumLess strong than In-Ceram (aluminum oxide)Less opaque core

In-Ceram Zirconia• 33% Zirconia in the aluminum core• Strength sufficient for posterior FPDs

Vita In-Ceram• VITABLOCS: VITA In-Ceram AL (Al 2 O 3 )and YZ (ZrO 2 ) for CEREC system• The VITABLOCS is used to fabricate acoping and layering ceramic is pressed overthe coping

IPS EmpressComposition (mainly):• Silicon oxide• Aluminum oxide• Potassium oxide• Reinforced with leuciteFlexural Strength: 120 MPa

Glass <strong>All</strong>-<strong>Ceramic</strong> SystemsAmorphous glassy feldspathic matrixDevitrification: prolonged heating cyclesSecondary crystalline phase(improvement in the mechanicaland optical properties)

IPS EmpressHow is it made?• Wax pattern• The pattern is sprued and invested• The muffle is heated to 800 C• The ceramic ingot is heat pressed in thephosphate–bonded investment (Empressfurnace).• Leucite reinforced

IPS EmpressRecommended for:• Single crowns: only anterior• Veneers• Inlays – Onlays• Only for non-discolored teeth (requirea stump shade)

IPS Empress(and all glass-ceramics)Preparation design:• At least 1.5 mm axial reduction• 2.0 mm for cuspal or incisal coverage• Rounded internal angles• 1.5 mm wide shoulder finish line (circum.)

Empress 2/IPS e.maxComposition: 2 different glass ceramics• FRAMEWORK (flexural strength 350- High strength- Lithium disilicate (SiO 2 – Li 2 O)50 MPa)• LAYERING GLASS CERAMIC (flexuralstrength 120 20 MPa)- Fluoroapatite crystals

Empress 2/IPS e.maxRecommended:• Crowns: anterior or posterior• 3 unit Fixed Partial Dentures:– Anterior– Posterior as long as the secondpremolar is the most distal abutment

Empress 2/IPS e.maxPreparation Design:• Framework thickness at least 0.8 mm• Preparation design same as Empress• Pontic span should not exceed 11 mm MD anteriorto canine or 9 mm posterior to canine

IPS e.max• In-lab CAD/CAM copings (veneeringceramic is applied manually)• Different materials available via e.max:e.max ZirCAD: zirconia oxidee.max Cad: lithium disilicate

Procera<strong>All</strong> ceramic material• CAD/CAM system• The coping is made of 99.5% pure sinteredaluminum oxide• The veneering material Procera <strong>All</strong>Ceram is 73%less abrasive than typical feldspathic porcelainAvailable materials• Procera Alumina (for short span FPDs)• Procera Zirconia (for long span FPDs)• Procera Laminate Alumina (for veneers)

ProceraThe die is scanned using a calculation of20-40K data points, depending on thesize of the die.

ProceraThe data is transmitted to the lab, linearexpansion adjustments are made, and anexact replica of the die is milled.

Procera• The coping is made to fit the die.• Veneering porcelain is applied on thecoping.

Recommended for:Procera• Single units - Crowns: anterior and posterior• FPDs (Procera Alumina and Zirconia)• Veneers (Procera Laminate)

Preparation design (same for allZr copings, Procera, & In-Ceram)• Axial reduction: 1.2-1.5mm• Occlusal reduction/clearance: 1.5-2.0 mm• Total occlusal convergence: ~ 10 degress• Chamfer finish line: 0.8-1.2 mm wide or• Shoulder finish line: with rounded internalangles

Zirconia-based ceramics• improved strength, biocompatibility, andenhanced esthetics• used as a substructure (coping) for singlecrowns and FPD frameworks• manufactured using CAD/CAM technology

Zirconia-based ceramics• flexural strength 900-1200 MPa• unique material property: transformationtoughening (the material resists crackpropagation)• Grinding or airborne-particle abrasion(sandblasting) → increases the chances ofthe veneering porcelain cracking

CEREC system• Cerec is a technique and not a material• the restorations are milled by a computer in thedental office (optical impressions used)• Single crowns, veneers, inlays, onlays• Blocks (w. limited shade selection) used formilling restorations• Blocks made from different materials (glassceramic, composite-resins, e.max, Zr-based, ...)

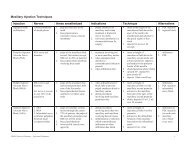

Classification1.Glass ceramics:Empress, OPC, Fortress2.Alumina reinforced-Zirconia reinforcedcombinationof Al & Zi reinforced:In-Ceram, Procera, Lava, e.maxZr3.Li disilicate:Empress 2, e.max

ComparisonsFlexural strength:zirconia-reinforced > alumina-reinforced > lithiumdisilicate > leucite-reinforcedEsthetics:Leucite-reinforced/Glass ceramics better than aluminaor zirconia reinforced because of their translucency.Discolored teeth:Glass ceramics will not “mask” the discoloration.Only alumina or zirconia-reinforced ceramics arerecommended.

Indications• Veneers:Empress, OPC, Fortress, (Procera)• Inlays/Onlays:Empress, OPC, Fortress• Anterior crownsEmpress, Empress 2,Zirconia-based, In-Ceram

• Posterior crownsIndicationsZirconia-based, In-Ceram,In-Ceram Zirconia, Empress 2, Procera• FPDsZirconia-based, In-Ceram Zirconia,e.max, Procera• Discolored teethAlumina or Zirconia reinforced

Cementation• Resin cements (require a moisture-free environment):a. light curedb. dual cured (light activated & chem. polymerized)Required for glass ceramics• Glass Ionomer: should not be used because of waterimbibition with Glass ceramics, can be used withZr copings and High alumina ceramics• Zinc Phosphate: only for Procera, Empress 2, andZr-reinforced ceramics

FailuresThe majority of the failures are due to fracture.(chipping or flaking of the layering ceramic)<strong>All</strong> <strong>Ceramic</strong> FPDs• Limited data from literature thus far• Caution when used and rec. for selected casesMarginal fit• 34-119 µm

Adjusting all-ceramic restorations• <strong>All</strong> ceramics: only after they have been bonded(fine diamonds, silicone cups and points)• Zr-based: careful not to overheat, silicone cupsand points, the undersurface of the zirconiacoping should not be adjusted, instead, theprepared tooth should be altered to completelyseat the restoration

Repair of a PorcelainShoulder MarginBefore Cementation• Etch, rinse, dry porcelain margin on restoration• Application of porcelain mixture onto the openmargin (mixture of Ceramco II Add-On Porcelainwith bonding agent ProBond)• Margin is “light activated” for 2 min• Crown is fired in porcelain oven at 1600º F

Uses of Porcelain Repair Procedures• Repair uncemented porcelain shouldermargins• Improve interproximal contacts areas• Refine occlusal contacts