Latvia University of Agriculture - Latvijas Lauksaimniecības ...

Latvia University of Agriculture - Latvijas Lauksaimniecības ...

Latvia University of Agriculture - Latvijas Lauksaimniecības ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

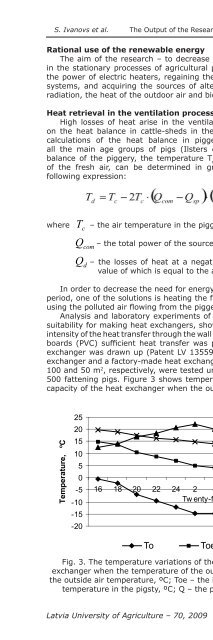

S. Ivanovs et al. The Output <strong>of</strong> the Research Institute <strong>of</strong> Agricultural Machinery since 1990Rational use <strong>of</strong> the renewable energyThe aim <strong>of</strong> the research – to decrease the consumption <strong>of</strong> fossil energy resourcesin the stationary processes <strong>of</strong> agricultural production by using in a more rational waythe power <strong>of</strong> electric heaters, regaining the heat flowing away through the ventilationsystems, and acquiring the sources <strong>of</strong> alternative energy, including the heat <strong>of</strong> solarradiation, the heat <strong>of</strong> the outdoor air and bi<strong>of</strong>uel.Heat retrieval in the ventilation processesHigh losses <strong>of</strong> heat arise in the ventilation process, which has a negative impacton the heat balance in cattle-sheds in the heating season. This is confirmed by thecalculations <strong>of</strong> the heat balance in piggeries at various heat resistances and forall the main age groups <strong>of</strong> pigs (Ilsters et al., 2006). In the analysis <strong>of</strong> the heatbalance <strong>of</strong> the piggery, the temperature T d, at which it is necessary to start heating<strong>of</strong> the fresh air, can be determined in graphic way or calculated according to thefollowing expression:, (1)whereTc – the air temperature in the piggery, ºC;Qcom – the total power <strong>of</strong> the sources <strong>of</strong> heat, W;Qd – the losses <strong>of</strong> heat at a negative outdoor air temperature, the numericalvalue <strong>of</strong> which is equal to the air temperature in the piggery, ºC.In order to decrease the need for energy resources for heating the air in the heatingperiod, one <strong>of</strong> the solutions is heating the fresh cold air by means <strong>of</strong> a heat exchangerusing the polluted air flowing from the piggery as a source <strong>of</strong> heat.Analysis and laboratory experiments <strong>of</strong> various materials in order to clear up theirsuitability for making heat exchangers, showed that at the 60-80% moisture <strong>of</strong> air theintensity <strong>of</strong> the heat transfer through the wall made from hollow structure polyvinylchlorideboards (PVC) sufficient heat transfer was possible. A technical design <strong>of</strong> such a heatexchanger was drawn up (Patent LV 13559 B). An experimental specimen <strong>of</strong> the heatexchanger and a factory-made heat exchanger WVT-120K (Germany) with surface areas100 and 50 m 2 , respectively, were tested under production conditions in a piggery with500 fattening pigs. Figure 3 shows temperature variations <strong>of</strong> the flows <strong>of</strong> air and thecapacity <strong>of</strong> the heat exchanger when the outdoor air temperature falls during the night2516Temperature,o C20151050-5-10-1516 18 20 22 24 2 4 6 8 10 12 14 16Tw enty-four hours1412108642Power, kW-200To Toe Tp QFig. 3. The temperature variations <strong>of</strong> the air flows and the efficiency <strong>of</strong> the heatexchanger when the temperature <strong>of</strong> the outdoor air falls during the night hours: To –the outside air temperature, ºC; Toe – the inflow air ending temperature, ºC; Tp – thetemperature in the pigsty, ºC; Q – the power <strong>of</strong> the recovered heat energy, kW.<strong>Latvia</strong> <strong>University</strong> <strong>of</strong> <strong>Agriculture</strong> – 70, 2009 117