2013 / 1 - Conoship

2013 / 1 - Conoship

2013 / 1 - Conoship

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

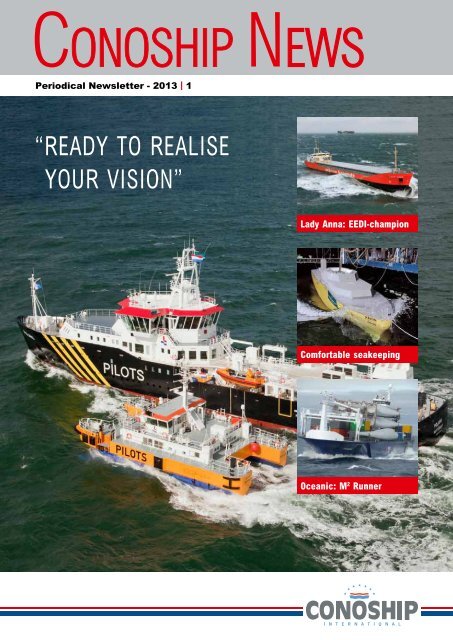

Best wishes and a prosperous <strong>2013</strong> !ConoDuctTailSea River Liner 3700: ‘Energy EfficiThe <strong>Conoship</strong> Design Team is looking forward to <strong>2013</strong> and is ready torealise your visions. In this edition of the <strong>Conoship</strong> Newsletter you will finda selection of recently delivered innovative ships, each originated from avision of one of our creative clients, resulting in a challenging set of designrequirements. We are happy and proud to support them- and you - to find newopportunities for today’s and future markets.READY TO REALISE YOUR VISIONInnovative designsthat realisethe visions ofshipowners onnew opportunitiesin their (niche)markets, are themain theme of this <strong>Conoship</strong> News.The earlier research program foraft ship development led to thenew ConoDuctTail, reducing fuelconsumption and emissions basedon maximum propulsive efficiency, asdescribed in the first article. Applicationof the ConoDuctTail in the new River-Sea-Vessels for Wijnne Barendsresults in an EEDI-Champion thanks tosurprisingly limited fuel consumption.Another innovative concept is the‘Hartman M 2 Runner’, developed inclose cooperation with the HartmanMarine Group, supporting their creativevision on transport logistics of projectcargo for the wind farm industry. Thefirst vessel of the series, MV Oceanic isvery successful in her niche market.The first Pilot Station Vessel, thePolaris was successfully deliveredby Barkmeijer Shipyards, turning thevisions of a large number of wellexperiencedPilots into reality. Themotional behavior of the <strong>Conoship</strong> hulldesign proved to be very good. Thisexperience provides a good basis forall kinds of new designs for offshoresupport operations.In the field of dredging, the variousdredging specialists have their ownvision on the optimal design of a TrailingSuction Hopper Dredger (TSHD).<strong>Conoship</strong> supported amongst othersthe following parties to realise theirvision:- The 2125 m 3 TSHD Contender wasdelivered to ABEKO last year, a veryversatile dredger, being a conversionof a former <strong>Conoship</strong> general cargovessel;- After the good performance of the4500 m 3 TSHD Shoalway , Boskalisordered three more sister vesselsfurther optimized in close cooperationwith D.W. den Herder Maritiem BV;- For Bijlsma Shipyard we developedthe SmartDredge3500 in closecooperation with DredgeVision:a modular dredging equipmentpackage, with hull lines for whichexisting steel hulls can be applied,reducing building time to less thana year.We hope that the presented visions anddesigns may inspire you to find newopportunities in your existing or newmarkets, both for new designs or theconversion of existing vessels.We are looking forward to meet you andwish you good luck in the new year.Guus van der BlesConoDuctTail for maximum propulsive efficiencyOptimal wake-field of ConoDuctTail

ent Champion’ of Short Sea ShippingDesign description: 3700 TDW Sea River LinerVessels names: MV ‘Lady Anna’/ ‘Lady Anneke’/ ‘Lady Alexandra’ / ‘Lady Amalia’Owner:Wijnne Barends, Delfzijl, The NetherlandsBuilder:Groningen Shipyard BV, Waterhuizen, The NetherlandsMV Lady Amalia with ConoDuctTail : EEDIchampionin her DWT-class with an “AttainedEnergy Efficiency Design Index” of 11.3, only62% of the maximum allowable value ! Inpractice a daily fuel consumption of less than3 ton/24h is reported, carrying 3000 – 3500ton cargo at a service speed of abt. 10 kn.<strong>Conoship</strong> developed the ConoDuctTail to improve the energy efficiency ofShort Sea Ships. The propulsive efficiency of the ConoDuctTail is maximizedfor actual (rather low) speeds of abt. 10 to 12 kn, by optimizing an aft shipshape with a duct, a nozzle and a propeller with a large diameter. Applicationin the MV Lady Anna of 3700 tdw shows a fuel consumption at 10 kn of abt.3 ton per day: a reduction of up to 50% on emissions and fuel consumptioncompared to older existing vessels of same size!Last few years, numerous innovativebow forms emerged which claim tosubstantially improve the efficiencyand reduce the fuel consumption.They show characteristic hull shapesabove the waterline that at leastfunction as marketing tools for thedesigns and have positive effects inheavy seaway. At <strong>Conoship</strong> however,we were convinced that the largestenergy efficiency gains could be foundin a vessel’s aft ship, so we startedan extensive research program incooperation with MARIN, SasTech andDelft University of Technology.The analysis also included numerousdiscussions with ship-owners andcaptain-owners regarding the meritsand disadvantages of various aft shiphull shapes.Development of theConoDuctTail-conceptWith the use of extensive CFDcalculations, performed in closecooperation with specialists SasTechand Van Oossanen, an aft ship hullformwas developed which incorporates anintegrated nozzle and a ducted-tunnelshape in order to maximize the propellerdiameter. Numerous CFD iterationssupported an integral optimization oftunnel lines, nozzle design, resultingwakefield and propeller design,leading to the optimal combination oflow resistance and best propulsiveefficiency: the ConoDuctTail.The optimized ducted-tunnel designreached 17% less resistance comparedto a conventional tunnel aft ship hullshape. The tunnel design provides anoptimal wakefield and the possibilityto incorporate a nozzle and a largerpropeller diameter (up to 25% larger).This results in quite an increase inpropulsive efficiency and a considerablereduction of fuel consumption andemissions.Practical Application of ConoDuctTail:MV Lady Anna + sister vesselsThe performance of the first practicalapplication of the ConoDuctTail in aseries of 3700 dwt Sea/River vesselsis very successful according to theowner Wijnne Barends. While themain dimensions of these vessels(Lpp=84.98 m, B=13.35 m, D=7.05 m)are comparable to those of other Sea/River liners, the 748 kW installed poweris often 20 to 50% lower! On the designdraft of 4.30 m, these vessels carry3000 tdw and reach a trial speed of10.8 kn at 748 kW MCR. In practicethey sail at an average service speed ofabt. 10 kn in regular weather, with lessthan 3,0 ton fuel per day, carrying 3000to 3500 ton cargo. Consumption figuresof around 2.7 ton per day (!) have beenreported by Wijnne Barends, by carefulconsideration of the actual requiredspeed/power at each part of the trip.Also in adverse weather conditions theConoDuctTail fulfils the expectationsof Wijnne Barends: the combinationof nozzle and tunnel enables goodsustaining propeller thrust in heavyseaway.Four vessels of this successful serieswere built at Groningen Shipyardand the design was elaborated incollaboration with Groot Ship Designwho optimized steelweight and generalarrangement while <strong>Conoship</strong> focussedon optimization of hull lines and speed/power.<strong>Conoship</strong>’s mission: improvingeCONOlogyThe ConoDuctTail enables optimizationof both ‘economy’ and ‘ecology’ ,considered by us as the best wayto improve the ‘eCONOlogy’ of ourdesigns. Application in the Lady Annaseries leads to the EEDI-Champion inthis DWT-class!New ‘eCONOlogic’ designs are underdevelopment, combining ConoDuctTaildesign with new ConoSeaBowdevelopments,incorporating an LNGinstallation for propulsion fuel, enabling<strong>Conoship</strong>s’ drive for continuousimprovement of the ‘energy efficiency’ ofthe Short Sea Shipping sector.

Any automotive-type ignition system may be used. Rev limits may be changed or removed.Suspension- Dampers (shocks) and springs may be replaced, but must utilize original mounting points.Sway bars (anti-roll bars) may be added, removed, or replaced. Ride height must be a minimum of three (3)inches (measured to the bottom of the frame rail) as raced, with driver.Any tire may be used. Wheels may be replaced with those that have a diameter and effective width that is thesame as stock.Solo Classes (Car Requirements per Solo Rules, Safety per TTR)Street Modified (SM, SSM)Street Prepared (ASP,BSP,CSP,DSP,ESP,FSP)Street Modified Front Wheel Drive (SMF)Supplemental Classes (as defined below)Vintage (V1,V2,V3) Historic (H1,H2,H3,H4) RallySolo V (SV) ITE Special (S1,S2,S3)VINTAGE/HISTORIC: Cars Prepared shall be prepared to and in possession of the SCCA Vintage Rules. A vintage orhistoric car will not be able to compete at full competition speed unless it conforms to the current safety/roll bar rules specificin the current GCR, TTR. If a car does not conform to these specifications, it may be allowed to take exhibition runs at theposted road speed limit with no time posted. No exhibition runs will be allowed at track events. In Historic 1, 2 and 4carburetors and intake manifolds, valve rockers and brakes are free. Transmissions are free as long as they have the samenumber of forward gears. Rear tube shocks can replace lever shocks. Fender flares composed of steel, fiberglass oraluminum are allowed. No racing slicks are allowed in any of these classes.Vintage 1 (V1) – 1950-1962 Sports Cars and Sedans 2000cc and underVintage 2 (V2) – 1950-1962 Sports Cars and Sedans Over 2000ccVintage 3 (V3) – 1950-Pre 1967 Sports Racing and Formula CarsHistoric 1 (H1) – 1963-Pre 1973 Sports Cars and Sedans 1301cc to 2000ccHistoric 2 (H2) – 1963-Pre 1973 Sports Cars and Sedans Over 2000ccHistoric 3 (H3) – 1967-Pre 1973 Sports Racing, FIA, Can-Am and 1967-Pre1973 Formula Car, All Formula 5000Historic 4 (H4) – 1963-Pre 1973 Sports Cars and Sedans 1300cc and underRALLY: All cars must meet Rally America's classing and safety requirements and posses a current rule book from thatseries.SOLO V (SOLO MODIFIED CLASS F): Car preparation must meet the Solo V specifications set forth in the SCCA Soloregulations. Both car and driver must meet the safety requirements outlined in the TTR.ITE: The purpose of the ITE class is to allow vehicles from other race series, Showroom Stock (those not otherwise eligiblefor IT or SS) and equivalent marque club classes ( ie NASA, PCA) to compete. No guarantee of competitiveness or equalityis expressed or implied. Excluded from this class are cars of former Professional Race Series such as World Challenge,IMSA, Trans Am, Can Am or any car prepared to levels that can be included in Super Touring. To that end, the ITE rulesand guidelines are that ALL VEHICLES MUST:a) Meet or exceed the current GCR-listed safety standards for the IT category and run on DOT tires.b) ALL ENTRANTS MUST have in their possession the “Series Rulebooks and specification sheets” and an officialmanufacturer’s shop manual(s) to authenticate the vehicle in its state/condition of preparation.c) It is recommended that a potential competitor submit details of the car and series for approval to the PHA before theevent.SPECIAL CLASSES: Automobiles that are of a design and construction not covered in the TIME TRIALS RULES or thesesupplementals may be placed in one of three classes based on engine displacement. All cars competing in this categoryshall conform to the following specifications:a) Meet the safety requirements as outlined in the TTR.b) Have operating suspension on all wheels.c) The chassis must be equally distributed along the centerline of the car.d) The body style may be open or closed wheel.Class by engine displacement (multiplication factor of 1.5 shall be used for forced induction)S1 – 0 to 1650ccS2 – 1651 to 3500ccS3 – 3501cc to 500 cubic inNOVICE REGULATIONS: A novice is defined as any driver currently competing under a TT Novice Permit or SCCA NoviceCompetition License OR any driver that has not competed at that site in the past 5 years. ALL novices are required to meetthe following expectations in order to obtain a SATisfactory rating:a. Novices must present themselves and their car at registration on Friday evening.4

M 2 Runner OceanicProject Cargo vision turned into realityDesign description: 3500 TDW Hartman M 2 RunnerVessel name: MV ‘Oceanic’Owner:Global Seatrade BV, Urk, The NetherlandsBuilder:Hartman Marine BV, Urk, The NetherlandsFlexibility, (fuel) efficiency and a maximization of the deck area were theleading aspects to be taken into account in the design of the Hartman M 2runners. Recently the MV ‘Oceanic’ - the first of this series - has beendelivered to her owner Global Seatrade.In close cooperation with HartmanMarine BV, <strong>Conoship</strong> International BVdeveloped the Hartman M 2 Runner,a flexible and spacious project cargovessel for the short sea project market.With a total hold volume of 219,000 cuftand a free deck area of more than1300 m 2 , the vessel is ‘oversized’compared to conventional 3500 tdwvessels. In fact, the hold capacity anddeck area of the M 2 Runners are almostcomparable to the capacities of a6000 dwt general cargoes vessel.With the M 2 Runner, Hartman Marineand Global Seatrade meet the changingneeds of the project cargo market. Moreand more offshore plants and offshorewindmill parks are constructed indeeper waters, remote areas and harshenvironments, requiring larger transportvolumes and a need for more flexiblevessels, capable of transporting largerparts or components in one-piece.Even more than in the past, shippingof project cargos will be dominated byavailable deck area and hold volume.Open topAfter extensive tank testing at MARIN,the M 2 Runner received permissionfrom the Authorities to sail “open top”.This enables worldwide operationswithout hatchcovers closing the holdand provides the possibility to transportvery large and high parts. “Open-top”operations are usually not feasible withvessels of this size, but only permittedwith vessels much larger than theHartman M 2 Runner.The Hartman M 2 Runner is alsoan environmentally friendly vessel.Featuring an integrated nozzle and arelatively large propeller, the HartmanM2 Runner is a very fuel efficientvessel. With an installed power of1200 kW, a service speed of about12 knots is reached.PRINCIPAL PARTICULARSLength over allLength between p.p.Breadth mouldedBreadth max.DepthDraught (summer)DeadweightGross tonnageMain engineSpeed (service)92.90 m84.99 m14.00 m15.00 m10.00 m5.00 m3500 ton2979 GT1200 kW12.0 knCARGO CAPACITIESHold dimensions:Lower 53.90 x 12.00 x 3.20/3.90 mUpper 69.30 x 12.50 x 4.60/3.90 mTank top area 635 m 2Tweendeck area 830 m 2Deck length x breadth 90 x 15 mDeck area 1300 m 2Cargo hold capacity 219200 cb.ft.Container cap. 105 hold - 199 deck TEU

TSHD ‘Contender’: MV Sirocco convertedto 2125 m 2 multi-purpose Trailing Suction Hopper DredgerDesign description: 2100 m 3 Trailing Suction Hopper DredgerVessel name: TSHD ‘Contender’Owner:ABEKO Marine BV, Beverwijk, The NetherlandsBuilder:Neptune Marine Services BV,Hardinxveld-Giesendam, The NetherlandsThe successful ‘extreme make-over’ of the <strong>Conoship</strong> designed 3200 tdwGeneral Cargo vessel Sirocco to a multi-purpose Trailing Suction HopperDredger resulted in the versatile 2125 m 3 TSHD Contender for ABEKO Marine.The dredger was handed over in April when she directly started her first job inWilhelmshaven and proved to be very efficient.The design challenge for <strong>Conoship</strong> wasto integrate the wide variety of requireddredging equipment. One of the keyissues for ABEKO is the possibility tofit an excavator on top of the hopper,conveyor belts alongside the hopperand a rotatable shore-conveyor on theforecastle. This system is fully integratedin the design and can be installed forspecific jobs in which dry delivery ofsand or gravel to quay is required. Formaintenance or construction jobs, thecargo can be discharged through thebottom doors or through the rainbowingnozzle or bow-coupling to a floatingpipeline.This modular design approach,elaborated together with DredgeVision,leads to a very flexible ‘dredging-tool’that can be adapted to any specificjob. The design of the hopper and hullmodifications enables the installationof this extra dredging equipment.Pumprooms were fitted in the aft- andforward part of the original cargohold,the forecastle was raised and twosponsoons were fitted to enlargethe breadth from 12.50 m to 16 m toincrease deadweight and stability.At the foreship the sponsoons werefaired into the existing hull lines,resulting in a good speed/powerperformance. The project managementof this conversion was done byDredgeVision. This successful “makeover” shows one of the opportunities tocreate a “new life” for good second handGeneral Cargo vessels that are widelyavailable these days.IMSV ‘Sanaborg’:Multipurpose support vessel for extreme iceDesign description: 3900 kW Ice Breaking Support VesselVessel name: IMSV ‘Sanaborg’Owner:Wagenborg Offshore, Delfzijl, The NetherlandsBuilder:Royal Niestern Sander, Delfzijl, The NetherlandsRecently Royal Niestern Sander in Delfzijl delivered the “Sanaborg” andthe “Serkeborg” to Wagenborg Offshore. These Ice Breaking MultipurposeSupport Vessels (IMSV) have been jointly developed, by the shipyard,Wagenborg and <strong>Conoship</strong>, for offshore services in shallow water and underarctic conditions.Sanaborg and Serkeborg are moreefficient than the existing vesselsbecause of the new hull form,which was developed by <strong>Conoship</strong>International. Design target was toreach a minimum speed of 4.0 knotsin unbroken first year ice of 0.60 mthickness. Model tests were conductedto verify the icebreaking performancein deep and shallow waters, as wellas “washing and breaking the ice” topenetrate grounded ridges travellingstern first. Equipped with two WärtsiläIcepod ® thrusters the vessels reacha bollard pull of 36.3 mT and haveexcellent ice management capabilities.PRINCIPAL PARTICULARSLength between p.p. 63.45 mBreadth moulded 14.00 mDepth 5.10 mDraught (design) 2.50 mDeadweight (design) 444 tonDraught (summer freeboard) 3.15 mDeadweight (summer) 1005 tonGross tonnage 1520 GTMain propulsion 2 x 1950 kWTank capacities:Potable water 329 m 3Gasoil 790 m 3Treated water 260 m 3Ballastwater 605 m 3

New DesignTSHD ‘SmartDredge 3500’Design description: 3500 m 3 Trailing SuctionHopper DredgerBuilder:Veka Bijlsma, Lemmer,The NetherlandsProfitable dredger shaped out of existing hull modulesPRINCIPAL PARTICULARSLength over all 90.50 mLength between p.p. 84.41 mBreadth moulded 15.80 mDepth 6.90 mDraught (summer) 5.23 mDeadweight (summer) 4200 tonDraught (dredging) 6.35 mDeadweight (dredging) 5700 tonGross tonnage 2999 GTSpeed (service) 13 knMain generators 3 x 1400 kWDREDGING PARTICULARSDiameter of drag arm 800 mmMax. dredge depth 25-38 mSand pump output 1400 kWJet pump output 2 x 360 kWHopper capacity 3500 m 3Densitiy of hopper load 1.0-2.2 t/m 3Under ConstructionTSHD ‘Causeway’Boskalis’ triple repeat order aftersuccessful 4500 m 3 TSHD ‘Shoalway’Design description: 4500 m 3 Trailing Hopper Suction DredgerVessel name: TSHD ‘Causeway’Owner:Royal Boskalis, Papendrecht, The NetherlandsBuilder:D.W. den Herder Maritiem BV, Sliedrecht, The NetherlandsPRINCIPAL PARTICULARSLength over all 92.10 mLength between p.p. 84.88 mBreadth moulded 19.00 mDepth 7.25 mDraught (summer) 6.16 mDeadweight (summer) 5950 tonDraught (dredging) 6.82 mDeadweight (dredging) 6980 tonGross tonnage abt. 4300 GTSpeed (service) 11 knMain engines 2x1500 kWDREDGING PARTICULARSDiameter of drag arm 900 mmMax. dredge depth 30 mSand pump output 2x1825 kWJet pump output 2x750 kWHopper capacity 4520 m 3Densitiy of hopper load 1.0-2.2 t/m 3Recent DeliveryMV ‘FIORANO’Efficient trader for niche marketDesign description: Bijlsma Confeeder 350Vessel name: MV ‘FIORANO’Owner:Fiorano CV, Werkendam, The NetherlandsBuilder:Veka Bijlsma, Lemmer, The NetherlandsPRINCIPAL PARTICULARSLength over all 99.97 mLength between p.p. 84.99 mBreadth moulded 15.85 mDepth 8.85 mDraught 5.65 mDeadweight 4533 tonGross tonnage 3871 GTSpeed (service) 15 knMain engine 3280 kWCAPACITIESHold dimensionsHold 1 24.20 x 13.20 x 8.85 mHold 2 27.27 x 13.20 x 8.85 mCargo hold capacity 212360 cb.ft.Container capacity354/124 hold- 230 deck TEUHFO 319 m 3Ballast water 2615 m 3

<strong>Conoship</strong> International:the innovative designer of Short Sea vesselsDesign and Engineering<strong>Conoship</strong> International providesdesign, engineering and consultancyservices for the maritime industry. Since1952 <strong>Conoship</strong> designs are renownthroughout the world. More than 2.000<strong>Conoship</strong> designs are sailing theseven seas. Each design is customizedbased on the client’s demand in orderto achieve an optimum technical andeconomical solution, enabled by themost innovative ship design tools.Our wide range of services forshipowners, brokers and shipyards,includes:• Conceptual ship design• Basic ship design• Class approval design• Conversion design• Market and marketing studies• Ship design and shipbuilding projectmanagement• Feasibility studies• Research and developmentPlease contact us to find out moreabout our services, to discuss yourideas and to see whether we can be ofany assistance to you.Upcoming topicsin next issues:• EEDI news• New concepts• LNG for propulsion• ConoSeaBow• Wind propulsion• New DredgersCheck www.conoship.comEnergy Efficiency DesignIndexOn the 1st of January <strong>2013</strong> the newIMO-regulations on ‘energy efficiencyfor ships’ enters into force, includingthe mandatory Energy EfficiencyDesign Index. The regulations aimto reduce the CO2-emissions ofshipping, prescribing a maximumallowable EEDI-value for newdesigns. <strong>Conoship</strong> performed astudy together with MARIN for theDutch Shipbuilding Associationon correction factors in the EEDIcalculation for small GeneralCargo ships. <strong>Conoship</strong> presentedthe results in the IMO-meeting inLondon in October last year andthe proposed correction factors areadopted in the Guidelines. For moreinfo see www.conoship.comMember shipyards:Barkmeijer Shipyards, The NetherlandsRoyal Bodewes Shipyards, The NetherlandsRoyal Niestern Sander, The NetherlandsRecent selection of yardsbuilding our designs:Bijlsma Shipyard, The NetherlandsHartman Marine, The NetherlandsGroningen Shipyard, The NetherlandsChowgule Shipyards, IndiaGelibolu Shipyard, TurkeyShipkits Shipbuilders, PolandDaesun Shipbuilding, KoreaWuxue Kaiyangxing, ChinaBusiness Partners:Dredge Vision Engineering, The NetherlandsSasTech, The NetherlandsIndia Futuristic Marine, IndiaSEDS Engineering, IndiaGTRC Algoship, Bahama’sRecent selection of shipownerssailing our designs:Dutch Pilot Association, The NetherlandsRoyal Boskalis, The NetherlandsDTM Dredging, FranceABEKO Marine, The NetherlandsUK Dredging, United KingdomWagenborg, The NetherlandsArklow Shipping, IrelandGlobal Seatrade, The NetherlandsWijnne Barends, The NetherlandsUnion Transport, United KingdomAmasus Shipping, The NetherlandsAlbros Shipping, RussiaNavigia Group, The NetherlandsDanser van Gent Shipping, The NetherlandsFehn Shipping, GermanyLEONARD SPRINGERLAAN 9, GRONINGEN, THE NETHERLANDSP.O. BOX 6029, 9702 HA GRONINGEN, THE NETHERLANDSTELEPHONE + 31 50 526 88 22, TELEFAX + 31 50 525 22 23,E-mail conoship@conoship.com, website www.conoship.com