Filter Systems - HYDAC USA

Filter Systems - HYDAC USA

Filter Systems - HYDAC USA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

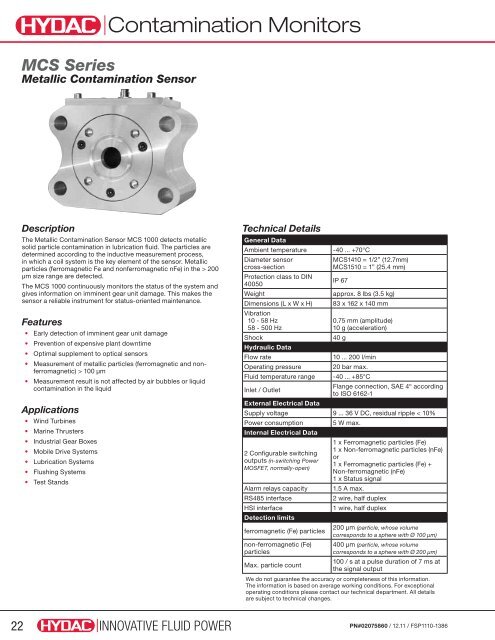

Contamination MonitorsMCS SeriesMetallic Contamination SensorDescriptionThe Metallic Contamination Sensor MCS 1000 detects metallicsolid particle contamination in lubrication fluid. The particles aredetermined according to the inductive measurement process,in which a coil system is the key element of the sensor. Metallicparticles (ferromagnetic Fe and nonferromagnetic nFe) in the > 200µm size range are detected.The MCS 1000 continuously monitors the status of the system andgives information on imminent gear unit damage. This makes thesensor a reliable instrument for status-oriented maintenance.Features• Early detection of imminent gear unit damage• Prevention of expensive plant downtime• Optimal supplement to optical sensors• Measurement of metallic particles (ferromagnetic and nonferromagnetic)> 100 µm• Measurement result is not affected by air bubbles or liquidcontamination in the liquidApplications• Wind Turbines• Marine Thrusters• Industrial Gear Boxes• Mobile Drive <strong>Systems</strong>• Lubrication <strong>Systems</strong>• Flushing <strong>Systems</strong>• Test StandsTechnical DetailsGeneral DataAmbient temperature -40 ... +70°CDiameter sensorcross-sectionMCS1410 = 1/2” (12.7mm)MCS1510 = 1” (25.4 mm)Protection class to DIN40050IP 67Weightapprox. 8 lbs (3.5 kg)Dimensions (L x W x H) 83 x 162 x 140 mmVibration10 - 58 Hz58 - 500 Hz0.75 mm (amplitude)10 g (acceleration)Shock40 gHydraulic DataFlow rate10 ... 200 l/minOperating pressure 20 bar max.Fluid temperature range -40 ... +85°CInlet / OutletFlange connection, SAE 4“ accordingto ISO 6162-1External Electrical DataSupply voltage 9 ... 36 V DC, residual ripple < 10%Power consumption 5 W max.Internal Electrical Data2 Configurable switchingoutputs (n-switching PowerMOSFET, normally-open)Alarm relays capacityRS485 interfaceHSI interfaceDetection limitsferromagnetic (Fe) particlesnon-ferromagnetic (Fe)particlesMax. particle count1 x Ferromagnetic particles (Fe)1 x Non-ferromagnetic particles (nFe)or1 x Ferromagnetic particles (Fe) +Non-ferromagnetic (nFe)1 x Status signal1.5 A max.2 wire, half duplex1 wire, half duplex200 µm (particle, whose volumecorresponds to a sphere with Ø 100 μm)400 µm (particle, whose volumecorresponds to a sphere with Ø 200 μm)100 / s at a pulse duration of 7 ms atthe signal outputWe do not guarantee the accuracy or completeness of this information.The information is based on average working conditions. For exceptionaloperating conditions please contact our technical department. All detailsare subject to technical changes.22 INNOVATIVE FLUID POWERPN#02075860 / 12.11 / FSP1110-1386