Examination Items - Fibreboard - Engineered Wood Products ...

Examination Items - Fibreboard - Engineered Wood Products ...

Examination Items - Fibreboard - Engineered Wood Products ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

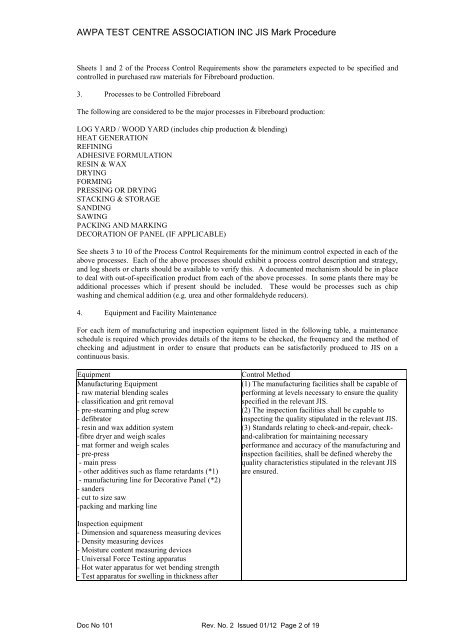

AWPA TEST CENTRE ASSOCIATION INC JIS Mark ProcedureSheets 1 and 2 of the Process Control Requirements show the parameters expected to be specified andcontrolled in purchased raw materials for <strong>Fibreboard</strong> production.3. Processes to be Controlled <strong>Fibreboard</strong>The following are considered to be the major processes in <strong>Fibreboard</strong> production:LOG YARD / WOOD YARD (includes chip production & blending)HEAT GENERATIONREFININGADHESIVE FORMULATIONRESIN & WAXDRYINGFORMINGPRESSING OR DRYINGSTACKING & STORAGESANDINGSAWINGPACKING AND MARKINGDECORATION OF PANEL (IF APPLICABLE)See sheets 3 to 10 of the Process Control Requirements for the minimum control expected in each of theabove processes. Each of the above processes should exhibit a process control description and strategy,and log sheets or charts should be available to verify this. A documented mechanism should be in placeto deal with out-of-specification product from each of the above processes. In some plants there may beadditional processes which if present should be included. These would be processes such as chipwashing and chemical addition (e.g. urea and other formaldehyde reducers).4. Equipment and Facility MaintenanceFor each item of manufacturing and inspection equipment listed in the following table, a maintenanceschedule is required which provides details of the items to be checked, the frequency and the method ofchecking and adjustment in order to ensure that products can be satisfactorily produced to JIS on acontinuous basis.EquipmentManufacturing Equipment- raw material blending scales- classification and grit removal- pre-steaming and plug screw- defibrator- resin and wax addition system-fibre dryer and weigh scales- mat former and weigh scales- pre-press- main press- other additives such as flame retardants (*1)- manufacturing line for Decorative Panel (*2)- sanders- cut to size saw-packing and marking lineControl Method(1) The manufacturing facilities shall be capable ofperforming at levels necessary to ensure the qualityspecified in the relevant JIS.(2) The inspection facilities shall be capable toinspecting the quality stipulated in the relevant JIS.(3) Standards relating to check-and-repair, checkand-calibrationfor maintaining necessaryperformance and accuracy of the manufacturing andinspection facilities, shall be defined whereby thequality characteristics stipulated in the relevant JISare ensured.Inspection equipment- Dimension and squareness measuring devices- Density measuring devices- Moisture content measuring devices- Universal Force Testing apparatus- Hot water apparatus for wet bending strength- Test apparatus for swelling in thickness afterDoc No 101 Rev. No. 2 Issued 01/12 Page 2 of 19