The MC 15 Mini Casting Machine: Casting in studios

The MC 15 Mini Casting Machine: Casting in studios

The MC 15 Mini Casting Machine: Casting in studios

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

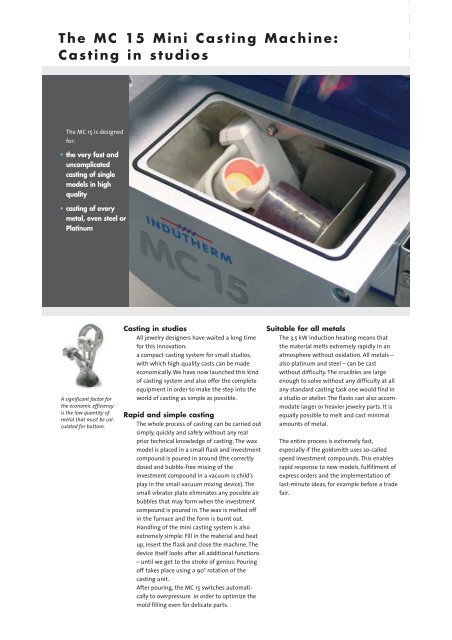

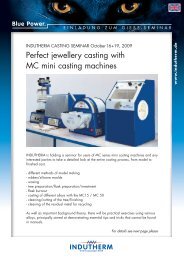

<strong>The</strong> <strong>MC</strong> <strong>15</strong> <strong>M<strong>in</strong>i</strong> <strong>Cast<strong>in</strong>g</strong> <strong>Mach<strong>in</strong>e</strong>:<strong>Cast<strong>in</strong>g</strong> <strong>in</strong> <strong>studios</strong><strong>The</strong> <strong>MC</strong> <strong>15</strong> is designedfor:• the very fast anduncomplicatedcast<strong>in</strong>g of s<strong>in</strong>glemodels <strong>in</strong> highquality• cast<strong>in</strong>g of everymetal, even steel orPlat<strong>in</strong>umA significant factor forthe economic efficiencyis the low quantity ofmetal that must be calculatedfor buttom.<strong>Cast<strong>in</strong>g</strong> <strong>in</strong> <strong>studios</strong>All jewelry designers have waited a long timefor this <strong>in</strong>novation:a compact cast<strong>in</strong>g system for small <strong>studios</strong>,with which high-quality casts can be madeeconomically. We have now launched this k<strong>in</strong>dof cast<strong>in</strong>g system and also offer the completeequipment <strong>in</strong> order to make the step <strong>in</strong>to theworld of cast<strong>in</strong>g as simple as possible.Rapid and simple cast<strong>in</strong>g<strong>The</strong> whole process of cast<strong>in</strong>g can be carried outsimply, quickly and safely without any realprior technical knowledge of cast<strong>in</strong>g. <strong>The</strong> waxmodel is placed <strong>in</strong> a small flask and <strong>in</strong>vestmentcompound is poured <strong>in</strong> around (the correctlydosed and bubble-free mix<strong>in</strong>g of the<strong>in</strong>vestment compound <strong>in</strong> a vacuum is child’splay <strong>in</strong> the small vacuum mix<strong>in</strong>g device). <strong>The</strong>small vibrator plate elim<strong>in</strong>ates any possible airbubbles that may form when the <strong>in</strong>vestmentcompound is poured <strong>in</strong>. <strong>The</strong> wax is melted off<strong>in</strong> the furnace and the form is burnt out.Handl<strong>in</strong>g of the m<strong>in</strong>i cast<strong>in</strong>g system is alsoextremely simple: Fill <strong>in</strong> the material and heatup, <strong>in</strong>sert the flask and close the mach<strong>in</strong>e. <strong>The</strong>device itself looks after all additional functions– until we get to the stroke of genius: Pour<strong>in</strong>goff takes place us<strong>in</strong>g a 90° rotation of thecast<strong>in</strong>g unit.After pour<strong>in</strong>g, the <strong>MC</strong> <strong>15</strong> switches automaticallyto overpressure <strong>in</strong> order to optimize themold fill<strong>in</strong>g even for delicate parts.Suitable for all metals<strong>The</strong> 3.5 kW <strong>in</strong>duction heat<strong>in</strong>g means thatthe material melts extremely rapidly <strong>in</strong> anatmosphere without oxidation. All metals –also plat<strong>in</strong>um and steel – can be castwithout difficulty. <strong>The</strong> crucibles are largeenough to solve without any difficulty at allany standard cast<strong>in</strong>g task one would f<strong>in</strong>d <strong>in</strong>a studio or atelier. <strong>The</strong> flasks can also accommodatelarger or heavier jewelry parts. It isequally possible to melt and cast m<strong>in</strong>imalamounts of metal.<strong>The</strong> entire process is extremely fast,especially if the goldsmith uses so-calledspeed <strong>in</strong>vestment compounds. This enablesrapid response to new models, fulfillment ofexpress orders and the implementation oflast-m<strong>in</strong>ute ideas, for example before a tradefair.

Blue Power.<strong>MC</strong> <strong>15</strong>■ THE FOUNDRY FOR STUDIOS – <strong>MC</strong> <strong>15</strong>performancepower max. / electrical connectiontemperature max.3.5 kW 230V s<strong>in</strong>gle phase2000˚ Ccapacitycast<strong>in</strong>g volumefor use of flasks up to<strong>15</strong>0 g Au 18 ct*110 g steel/250 g Ptø 30/50/65/80 mm x 55 mm hA complete cast<strong>in</strong>g equipment cover<strong>in</strong>g just a few square feet(on the table on the left): Vacuum mixer for bubble-free mix<strong>in</strong>gof the <strong>in</strong>vestment compound. <strong>The</strong> vibrator plate elim<strong>in</strong>ates airpockets.<strong>The</strong> 1100°C furnace for melt<strong>in</strong>g out the wax and burnoutthe form. <strong>M<strong>in</strong>i</strong> cast<strong>in</strong>g system <strong>MC</strong> <strong>15</strong>. Sand blast<strong>in</strong>g cab<strong>in</strong>etfor easy removal of plaster.handl<strong>in</strong>g+controlautomatic vacuum functionautomatic overpressure functionfunction wash<strong>in</strong>g by <strong>in</strong>ert gassupply: 230 V s<strong>in</strong>gle phase, cool<strong>in</strong>g water,<strong>in</strong>ert gas argon or nitrogen■■■■1|1| <strong>The</strong> metal is filled <strong>in</strong>tothe crucible. <strong>The</strong> startbutton is pressed and theheat<strong>in</strong>g beg<strong>in</strong>s.accessoriesvacuum mixer for the <strong>in</strong>vestment compoundvibrator plateoo2|2| <strong>The</strong> flask with the moldis removed from thefurnace after a burn-outtime of between one andthree hours and placed <strong>in</strong>the cast<strong>in</strong>g chamber (largepicture left side above).furnace, 1100°Csand blast<strong>in</strong>g cab<strong>in</strong>etvacuum pumpooo3|3| Shut the lid, press thestart button aga<strong>in</strong> and thevacuum starts; just one ortwo m<strong>in</strong>utes later thematerial has melted and ispoured <strong>in</strong>to the mold by a90° rotation of the entirecast<strong>in</strong>g unit.*Liquid metal up to top level of the crucible■ = standard equipment o = optional