DUFLEX BALSA - ATL Composites

DUFLEX BALSA - ATL Composites

DUFLEX BALSA - ATL Composites

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

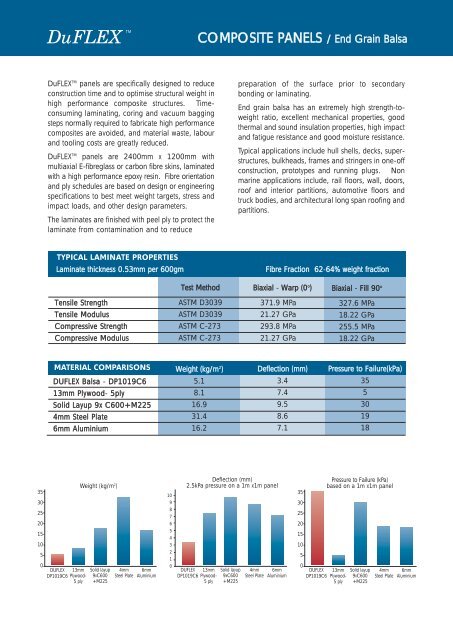

DuFLEXTMCOMPOSITE PANELS / End Grain BalsaDuFLEX TM panels are specifically designed to reduceconstruction time and to optimise structural weight inhigh performance composite structures. Timeconsuminglaminating, coring and vacuum baggingsteps normally required to fabricate high performancecomposites are avoided, and material waste, labourand tooling costs are greatly reduced.DuFLEX TM panels are 2400mm x 1200mm withmultiaxial E-fibreglass or carbon fibre skins, laminatedwith a high performance epoxy resin. Fibre orientationand ply schedules are based on design or engineeringspecifications to best meet weight targets, stress andimpact loads, and other design parameters.The laminates are finished with peel ply to protect thelaminate from contamination and to reducepreparation of the surface prior to secondarybonding or laminating.End grain balsa has an extremely high strength-toweightratio, excellent mechanical properties, goodthermal and sound insulation properties, high impactand fatigue resistance and good moisture resistance.Typical applications include hull shells, decks, superstructures,bulkheads, frames and stringers in one-offconstruction, prototypes and running plugs. Nonmarine applications include, rail floors, wall, doors,roof and interior partitions, automotive floors andtruck bodies, and architectural long span roofing andpartitions.TYPICAL LAMINATE PROPERTIESLaminate thickness 0.53mm per 600gmFibre Fraction 62-64% weight fractionTest MethodBiaxial - Warp (0 o )Biaxial - Fill 90 oTensile StrengthTensile ModulusCompressive StrengthCompressive ModulusASTM D3039ASTM D3039ASTM C-273ASTM C-273371.9 MPa21.27 GPa293.8 MPa21.27 GPa327.6 MPa18.22 GPa255.5 MPa18.22 GPaMATERIAL COMPARISONS<strong>DUFLEX</strong> Balsa - DP1019C613mm Plywood- 5plySolid Layup 9x C600+M2254mm Steel Plate6mm AluminiumWeight (kg/m 2 )5.18.116.931.416.2Deflection (mm)3.47.49.58.67.1Pressure to Failure(kPa)35530191835302520151050<strong>DUFLEX</strong>DP1019C613mmPlywood-5 plyWeight (kg/m 2 )Solid layup9xC600+M2254mmSteel Plate6mmAluminium109876543210Deflection (mm)2.5kPa pressure on a 1m x1m panel<strong>DUFLEX</strong> 13mmDP1019C6 Plywood-5 plySolid layup9xC600+M2254mmSteel Plate6mmAluminium35302520151050<strong>DUFLEX</strong>DP1019C6Pressure to Failure (kPa)based on a 1m x1m panel13mmPlywood-5 plySolid layup9xC600+M2254mmSteel Plate6mmAluminium

DuFLEXTMCOMPOSITE PANELS / End Grain BalsaRIGID END-GRAIN SHEET PROPERTIESNominal Density(ASTM C-271)Tensile Strength perpendicular to the plane (ASTM C-297)Tensile Modulus perpendicular to the plane (ASTM C-297)Compressive Strength perpendicular to the plane (ASTM C-365)Compressive Modulus perpendicular to the plane (ASTM C-365)Shear Strength(ASTM C-273)Shear Modulus(ASTM C-273)Thermal Conductivity @ 24 o C(75 o F)(ASTM C-177)Linear Coefficient of Thermal Expansion -Tangential-Radial-Longitudinal150 kg/m 313.0 MPa3.52 GPa12.67 MPa3.92 GPa2.94 MPa159 MPa0.066 W/m. o K18.9 x 10 -6 m/m/ o C12.6 x 10 -6 m/m/ o C3.06 x 10 -6 m/m/ o C9.4 lb/ft 31886 psi510 ksi1837ksi568 ksi427 psi22.8 ksi0.453 Btu.in/hr.ft 2 . o F10.5 x 10 -6 in/in/ o F7.0 x 10 -6 in/in/ o F1.7 x 10 -6 in/in/ o FJOINING & BONDINGTo offset the individual size of the panel, DuFLEX canbe supplied with both long edges pre-machined tofacilitate joining. The Z-Joint is structurally effectiveand achieves a smooth and fair surface profile. Ahigh density epoxy adhesive is specified for joiningDuFLEX Z-joints. Contact <strong>ATL</strong> <strong>Composites</strong> forsuitable adhesives.Manual joining of the panels is also possible,Contact <strong>ATL</strong> <strong>Composites</strong> for specific details.CUTTINGDiamond-coated fiberglass tooling is recommendedfor best tool life. The best edge finish is achieved withcircular saws running aluminium cutting blades,however blade life is greatly reduced.KITS<strong>ATL</strong> <strong>Composites</strong> offers in-house CAD and CNCcutting services, and can produce pre-fabricatedDuFLEX kits from electronic design files.STANDARD STOCK DuFLEX WITH BALTEK ® <strong>BALSA</strong> CORE 150 kg/m 3Order Code*DescriptionCore ThicknessNominal Weight kg/m 2DP1010C61 x 600gm biaxial E-glass on either side10 mm3.8DP1013C61 x 600gm biaxial E-glass on either side13 mm4.2DP1016C61 x 600gm biaxial E-glass on either side16 mm4.7DP1019C61 x 600gm biaxial E-glass on either side19 mm5.1DP1025C61 x 600gm biaxial E-glass on either side25 mm6.0DP2010C62 x 600gm biaxial E-glass on either side10 mm6.0DP2013C62 x 600gm biaxial E-glass on either side13 mm6.5DP2016C62 x 600gm biaxial E-glass on either side16 mm6.9DP2019C62 x 600gm biaxial E-glass on either side19 mm7.2DP2025C62 x 600gm biaxial E-glass on either side25 mm8.3* Example - order code for a 13mm panel with 1 layer of 600 gm biaxial is DP1013C6 - Alternative skin laminates available on requestSheet size - 1200mm x 2400mmSTORAGEDuFLEX TM panels should be stored flat, out of direct sunlight, and kept dry and clean. Panels supplied with fibreglass skins havepeel-ply on the surface, which should be left in place as long as possible, to protect them from surface contamination.All timber used in the manufacture of DuFLEX Composite Panels is plantation grown. <strong>ATL</strong> <strong>Composites</strong> reserves the right to alterspecifications without prior notice. Weight may vary due to variations in core density.NOTE Our products are intended for sale to industrial and commercial customers. Werequest that customers inspect and test our products before use and satisfy themselves asto contents and suitability. Nothing herein shall constitute a warranty, express or implied,including any warranty or merchantability or fitness, nor is protection from law or patentto be inferred. All patent rights are reserved. The exclusive remedy for all proven claimsis replacement of our materials and in no event shall we be liable for special orconsequential damages. 22/10/09<strong>ATL</strong> composites<strong>ATL</strong> composites Pty LtdTel (+61) 7 5563 1222Fax (+61) 7 5563 1585info@atlcomposites.comwww.atlcomposites.com