Lifting Hazards and Some Ideas on How to Reduce Your Risk of ...

Lifting Hazards and Some Ideas on How to Reduce Your Risk of ...

Lifting Hazards and Some Ideas on How to Reduce Your Risk of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<str<strong>on</strong>g>Lifting</str<strong>on</strong>g> <str<strong>on</strong>g>Hazards</str<strong>on</strong>g> <str<strong>on</strong>g>and</str<strong>on</strong>g> <str<strong>on</strong>g>Some</str<strong>on</strong>g> <str<strong>on</strong>g>Ideas</str<strong>on</strong>g> <strong>on</strong><strong>How</strong> <strong>to</strong> <strong>Reduce</strong> <strong>Your</strong> <strong>Risk</strong> <strong>of</strong> <str<strong>on</strong>g>Lifting</str<strong>on</strong>g>InjuryLotsapounds

By the end <strong>of</strong> this less<strong>on</strong> you will beable <strong>to</strong>:• Identify the types <strong>of</strong> lifting that maycause injuries• Identify the erg<strong>on</strong>omics principles used inreducing lifting hazards <str<strong>on</strong>g>and</str<strong>on</strong>g> preventinginjuries

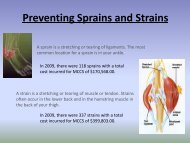

<str<strong>on</strong>g>Lifting</str<strong>on</strong>g> Injuries Aren’t Just Back Injuries<str<strong>on</strong>g>Lifting</str<strong>on</strong>g> results in:30% <strong>of</strong>ShoulderWMSDs43% <strong>of</strong>BackWMSDs22% <strong>of</strong>ElbowWMSDs13% <strong>of</strong>H<str<strong>on</strong>g>and</str<strong>on</strong>g>/WristWMSDsWMSD = Work Related Muscular Skeletal Disorder

<str<strong>on</strong>g>Lifting</str<strong>on</strong>g> Injuries Aren’t Just Due <strong>to</strong> Aging“Overexerti<strong>on</strong> in lifting a heavy objectis the most frequent single type <strong>of</strong>injury for those under 18 resulting inlost work-time.”Source: American Society <strong>of</strong> SafetyEngineers (ASSE,)

Pay special attenti<strong>on</strong> <strong>to</strong>…Heavy liftingFrequent liftingAwkward lifting

Heavy <str<strong>on</strong>g>Lifting</str<strong>on</strong>g>This job is adding bags <strong>of</strong> dry ingredients <strong>to</strong> a hopper in a manufacturing plant.

Frequent <str<strong>on</strong>g>Lifting</str<strong>on</strong>g>This job is palletizing bins <strong>of</strong> small parts in a warehouse.

Awkward <str<strong>on</strong>g>Lifting</str<strong>on</strong>g>• Above the shoulders• Below the knees• At arms’ lengthThis job is lifting 50-pound bags in amanufacturing plant

Calcula<strong>to</strong>r for analyzing liftingoperati<strong>on</strong>sThe use <strong>of</strong> the following 6 steps will assist you indetermining a safe working weight .We will use fac<strong>to</strong>rs based <strong>on</strong>, starting positi<strong>on</strong>, repetiti<strong>on</strong>, <str<strong>on</strong>g>and</str<strong>on</strong>g>durati<strong>on</strong> <strong>of</strong> the task <strong>to</strong> calculate the maximum weight that may be liftedsafely. The purpose <strong>of</strong> this calcula<strong>to</strong>r is <strong>to</strong> identify the lifting limit <str<strong>on</strong>g>and</str<strong>on</strong>g>ensure your starting weight does not exceed the lifting limit.Step 1Enter the weight <strong>of</strong> the object lifted. ___________lbs.(We will use the starting weight in step 1 <strong>to</strong> compare with our answer in step 5)Example – 45 lbs.The above informati<strong>on</strong> can be gotten from the following web site -http://ebookbrowse.com/calcula<strong>to</strong>r-for-analyzing-lifting-operati<strong>on</strong>s-pdf-d314819091

Calcula<strong>to</strong>r for analyzing liftingoperati<strong>on</strong>sStep 2Select from the chart <strong>on</strong> the left,the weight that represents thepositi<strong>on</strong> your h<str<strong>on</strong>g>and</str<strong>on</strong>g>s will be in whenyou begin <strong>to</strong> lift or lower theobjects, i.e. above your head,below your knees , close/awayfrom your body etc.Example - 50

Calcula<strong>to</strong>r for analyzing liftingoperati<strong>on</strong>sStep 3Select the number that corresp<strong>on</strong>ds <strong>to</strong> the times the pers<strong>on</strong>lifts per minute <str<strong>on</strong>g>and</str<strong>on</strong>g> the <strong>to</strong>tal number <strong>of</strong> hours per day spentlifting.<strong>How</strong> many hours per day<strong>How</strong> many lifts per minuteUnder 1 hour 1 hr <strong>to</strong> 2 hrs 2 hrs or more1 lift every 2-5 min 1 0.95 0.851 lift every min 0.95 0.9 0.752-3 lifts every min 0.9 0.85 0.654-5 lifts every min 0.85 0.7 0.456-7 lifts every min 0.75 0.5 0.258-9 lifts every min 0.6 0.35 0.1510+ lifts every min 0.3 0.2 0Example – 2-3 lifts every min for 1-2 hours = .85

Calcula<strong>to</strong>r for analyzing liftingoperati<strong>on</strong>sStep 4If your job involves twisting 45 degrees ormore Select 0.85. Otherwise select 1.0Example – Our job involves twisting 45 degreesor more = .85

Calcula<strong>to</strong>r for analyzing liftingoperati<strong>on</strong>sStep 5Using the numbers in the exampleswe get, 50 x .85 x .85 = 36lbs.

Calcula<strong>to</strong>r for analyzing liftingoperati<strong>on</strong>sStep 6In our example, we started out with a weight <strong>of</strong>45 lbs. <strong>How</strong>ever, our calculati<strong>on</strong>s indicated that36 lbs. was the maximum safe lifting limit weshould use. <str<strong>on</strong>g>Lifting</str<strong>on</strong>g> the initial 45 lbs. could resultin an WMSD (Work Related Muscular Skeletal Disorder.)

Principles for reducing heavy lifting• <strong>Reduce</strong> the weight• Use mechanical assistance• Slide instead <strong>of</strong> lift• Team lifting

Reducing heavy lifting<strong>Reduce</strong> the weight <strong>of</strong> the load(plastic pallets)This example shows usinglightweight plastic pallets, whichweigh anywhere from 13 <strong>to</strong> 30pounds for a st<str<strong>on</strong>g>and</str<strong>on</strong>g>ard 40” x 48”unit (the <strong>on</strong>e in the picture isabout 20 pounds).The traditi<strong>on</strong>al wooden 40” x 48”pallets weigh approximately 60pounds.

Reducing heavy liftingSlide instead <strong>of</strong> liftThis example ismoving heavy dutybatteries from <strong>on</strong>epallet <strong>to</strong> another .Large batteries can weigh up <strong>to</strong> 110pounds (this <strong>on</strong>e weighs about 75pounds). By taking the time <strong>to</strong> set anotherpallet at the same height as the shelf orbattery <strong>to</strong> be moved, it can be slid ratherthan lifted.

Reducing heavy liftingTeam liftingTeam lifting works better <strong>on</strong> larger objects, suchas the wallboard shown here.

Principles for reducing frequent lifting• Use mechanical assistance• Avoid unnecessary lifting• Use mobile s<strong>to</strong>rage

Reducing frequent liftingUse mobile s<strong>to</strong>rageThe example above is a mobile rack that can hold heavy boxes which require movementfrom <strong>on</strong>e place <strong>to</strong> another

Principles for reducing durati<strong>on</strong> <strong>of</strong> lifting• Rotate <strong>to</strong> other jobs• Use mechanical assistance

Reducing durati<strong>on</strong> <strong>of</strong> liftingRotate job tasks, i.e. lifting <strong>to</strong> n<strong>on</strong>liftingtasks

Principles for reducing awkward lifting-reaching -• Remove obstacles• Slide items closer• <strong>Reduce</strong> shelf depth• <strong>Reduce</strong> package size• Use mechanical assistance• Team liftingAl<strong>on</strong>g with object weight, lifting frequency <str<strong>on</strong>g>and</str<strong>on</strong>g> durati<strong>on</strong>, the distance between the h<str<strong>on</strong>g>and</str<strong>on</strong>g>s<str<strong>on</strong>g>and</str<strong>on</strong>g> the low back when lifting is <strong>on</strong>e <strong>of</strong> the main fac<strong>to</strong>rs in determining whether a lift is ahazard or not. The l<strong>on</strong>ger the reach <strong>of</strong> a required lift an object, the more <strong>of</strong> a load itplaces <strong>on</strong> the low back <str<strong>on</strong>g>and</str<strong>on</strong>g> the greater the risk <strong>of</strong> injury.

Reducing awkward lifting-reaching -Remove obstaclesThis shows lifting in <str<strong>on</strong>g>and</str<strong>on</strong>g> out <strong>of</strong> a bin with the side flipped down. Bins with flip-downsides can reduce the reach in many cases, although there may still be some awkwardlifting.

Reducing awkward lifting-reaching -Slide objects closerThis example shows an employee, using an inexpensive, metal hook, made in-house, <strong>to</strong>pull a box close <strong>to</strong> the edge <strong>of</strong> the shelf before lifting it. This works well for lighter items.Heavier items would need <strong>to</strong> be s<strong>to</strong>red lower <str<strong>on</strong>g>and</str<strong>on</strong>g> slid closer using both h<str<strong>on</strong>g>and</str<strong>on</strong>g>s.

Reducing awkward lifting-reaching -<strong>Reduce</strong> package sizeThe drawings show the difference between lifting a large box with many items in itversus lifting a smaller box with fewer items in it. Not <strong>on</strong>ly will this reduce theweight, but it will also reduce the reach necessary <strong>to</strong> pick up the box.

Reducing awkward lifting-reaching -Team liftingTeam lifting can help <strong>to</strong> reduce the effort required <strong>to</strong> pick up a large object. Remember,it’s not as effective as a piece <strong>of</strong> lifting equipment.

Principles for reducing awkward lifting-bending -• Use mechanical assistance <strong>to</strong> raise the load• Add h<str<strong>on</strong>g>and</str<strong>on</strong>g>les• Arrange s<strong>to</strong>rage• Avoid unnecessary lifting

Reducing awkward lifting-bending -Use mechanical assistance <strong>to</strong> raise the loadWorkers can bring objects up <strong>to</strong> abetter height for lifting. The best useis <strong>to</strong> place the cart at the sameheight as the shelf or table in whichthe object is being transferred <strong>to</strong> orfrom, <str<strong>on</strong>g>and</str<strong>on</strong>g> then slide it over ratherthan lifting. Carts with rollers orroller balls also help make the slidingtransfer easier.

Reducing awkward lifting-bending -Add h<str<strong>on</strong>g>and</str<strong>on</strong>g>lesThis shows the difference in lifting posturebetween picking up a box from the bot<strong>to</strong>m, <str<strong>on</strong>g>and</str<strong>on</strong>g>picking it up using h<str<strong>on</strong>g>and</str<strong>on</strong>g>les near the <strong>to</strong>p <strong>of</strong> thebox. In this case, this product is shipped in abox with pre-cut h<str<strong>on</strong>g>and</str<strong>on</strong>g>les. There’s still somebending, but the box is now lifted from abovethe knees, rather than below them.There are a couple <strong>of</strong> other good ideas in thispho<strong>to</strong> as well. The box has been stacked <strong>on</strong> anempty pallet <strong>to</strong> raise it up a little (sometimeseven raising something just 6” can make adifference in posture).

Reducing awkward lifting-bending -Rearrange s<strong>to</strong>rageThe example shown is where they <strong>to</strong>ok a stack <strong>of</strong> heavy items<str<strong>on</strong>g>and</str<strong>on</strong>g> rearranged them <strong>to</strong> be placed <strong>on</strong> shelves between knee <str<strong>on</strong>g>and</str<strong>on</strong>g>shoulder level.

Reducing awkward lifting-bending -Avoid unnecessary liftingThis is an example <strong>of</strong> a commercial product designed <strong>to</strong> allow mechanics <strong>to</strong> hangwheels <strong>of</strong>f the sides <strong>of</strong> the lift when working <strong>on</strong> brakes, hubs, etc. This places the wheelsat a better height for lifting, instead <strong>of</strong> dropping the wheels <strong>to</strong> the ground. The hangerfolds flat against the lift when not in use.

Principles for reducing awkward lifting– reaching above shoulders -• Arrange s<strong>to</strong>rage• Use mechanical assistance• Use a rolling stair or“safety ladder”

Reducing awkward lifting– reaching above shoulders -Arrange s<strong>to</strong>rageThis shows arranging s<strong>to</strong>rage so that larger, heavier <str<strong>on</strong>g>and</str<strong>on</strong>g> more frequently used boxesare between knee <str<strong>on</strong>g>and</str<strong>on</strong>g> shoulder height. In this case, the height <strong>of</strong> the shelf for heavyboxes is just above the height <strong>of</strong> the cart, so they can be slid instead <strong>of</strong> lifted.

Reducing awkward lifting– reaching above shoulders -Use mechanical assistanceThe device shown is a stacker, which is like a h<str<strong>on</strong>g>and</str<strong>on</strong>g> truck with a h<str<strong>on</strong>g>and</str<strong>on</strong>g>-cranked winch <strong>to</strong>move the platform up <str<strong>on</strong>g>and</str<strong>on</strong>g> down so that loads can be mechanically raised <strong>to</strong> the heightthey are shelved or removed from shelves. Stackers are available with lift heights up <strong>to</strong>12 feet.

Reducing awkward lifting– reaching above shoulders -Use mechanical assistanceThis example shows using a forklift <strong>to</strong> combine a stack <strong>of</strong> bins,rather than manually stacking the bins over shoulder height.

Reducing awkward lifting– reaching above shoulders -Use a rolling stairThis example is a cart with a stair attached (or a stair with a cartattached). The advantage is that the steps are always there, so n<strong>on</strong>eed <strong>to</strong> find a ladder, <str<strong>on</strong>g>and</str<strong>on</strong>g> they can set the load down as they goup <str<strong>on</strong>g>and</str<strong>on</strong>g> down the stairs.

Principles for reducing awkward lifting–twisting -• Use c<strong>on</strong>veyors• Provide more space• Arrange s<strong>to</strong>rage

Reducing awkward lifting–twisting -Use c<strong>on</strong>veyorsC<strong>on</strong>veyors are especially useful when changing directi<strong>on</strong>s, <strong>to</strong> help avoidtwisting. This picture shows a gravity c<strong>on</strong>veyor used <strong>to</strong> unload trucks in ashipping department. It allows the receiver <strong>to</strong> bring the boxes over <strong>to</strong> thecomputer <strong>to</strong> scan in the informati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g> inven<strong>to</strong>ry the c<strong>on</strong>tents. The boxes canthen be slid directly <strong>on</strong><strong>to</strong> carts <strong>to</strong> be put away. <str<strong>on</strong>g>Lifting</str<strong>on</strong>g> <strong>on</strong>ly needs <strong>to</strong> occur twice,<strong>on</strong>ce <strong>to</strong> take the box from the truck <str<strong>on</strong>g>and</str<strong>on</strong>g> place it <strong>on</strong> the c<strong>on</strong>veyor, <str<strong>on</strong>g>and</str<strong>on</strong>g> <strong>on</strong>ce <strong>to</strong>put the box away.

Reducing awkward lifting–twisting -Re-arrange s<strong>to</strong>rageThis example shows raising the height <strong>of</strong> the racks <strong>to</strong>provide more room <strong>to</strong> get at products <strong>on</strong> the lower racks.

<str<strong>on</strong>g>Lifting</str<strong>on</strong>g> techniques trainingTeaching lifting techniques <strong>to</strong>employees– Giving training al<strong>on</strong>e isnot effective– Making changes <strong>to</strong> jobs<str<strong>on</strong>g>and</str<strong>on</strong>g> equipment is better– Making changes al<strong>on</strong>gwith training is mosteffectiveTraining all by itself, withoutmaking changes <strong>to</strong> theworkplace, is <strong>of</strong>ten not effectivein preventing injuries. Oftenemployees are taught “properlifting techniques” <str<strong>on</strong>g>and</str<strong>on</strong>g> then sen<strong>to</strong>ut <strong>to</strong> work under c<strong>on</strong>diti<strong>on</strong>s thatd<strong>on</strong>’t allow them <strong>to</strong> use thesetechniques. Training is animportant part <strong>of</strong> implementingchanges. Showing employeeshow <strong>to</strong> use new equipment <str<strong>on</strong>g>and</str<strong>on</strong>g>explaining why it’s important <strong>to</strong>use them helps reduce thepossibility <strong>of</strong> WMSD’s

<str<strong>on</strong>g>Lifting</str<strong>on</strong>g> techniques training• Job-specific, <strong>on</strong>-site, h<str<strong>on</strong>g>and</str<strong>on</strong>g>s<strong>on</strong>training is more effectivethan classroom• Have employees dem<strong>on</strong>strateproper lifting techniquesbefore “graduating”Being trained where they work, using the objects they typically lift<str<strong>on</strong>g>and</str<strong>on</strong>g> the equipment they use <strong>on</strong> the job helps employees <strong>to</strong> relate<strong>to</strong> what they’re being taught, rather than showing them a genericlifting video. Make sure that employees have learned what you’retrying <strong>to</strong> teach them by having each <strong>on</strong>e <strong>of</strong> them dem<strong>on</strong>strate thelifting techniques properly. Follow-up with them <strong>to</strong> make sure theyare able <strong>to</strong> use the techniques <strong>on</strong> the job.

QUIZ1. Using the lifting calcula<strong>to</strong>r… can you safely lift an itemweighing 45 pounds, at waist <strong>to</strong> shoulder height (out 7”)for 4 <strong>to</strong> 5 lifts each minute for 1 <strong>to</strong> 2 hours in durati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g>your not twisting more then 45 degrees?a. Yesb. No2. Job-specific, <strong>on</strong>-site, h<str<strong>on</strong>g>and</str<strong>on</strong>g>s-<strong>on</strong> training is more effectivethan classroom.a. Trueb. False3. Name <strong>on</strong>e <strong>of</strong> the three principles for reducing frequentlifting.____________________

Summary• You have identified the types <strong>of</strong> lifting that may causeinjuries such as; Heavy lifting, Frequent lifting <str<strong>on</strong>g>and</str<strong>on</strong>g>Awkward lifting. You also learnt some erg<strong>on</strong>omicsprinciples used in reducing lifting hazards <str<strong>on</strong>g>and</str<strong>on</strong>g> preventinginjuries such as; Reducing the weight you lift <strong>to</strong> increasingthe weight so that no <strong>on</strong>e will attempt <strong>to</strong> lift the weight.You also learnt that the use <strong>of</strong> mechanical assistance cangreatly reduce injuries <str<strong>on</strong>g>and</str<strong>on</strong>g> the use <strong>of</strong> team lifting worksbetter <strong>on</strong> larger items.• With the proper use <strong>of</strong> the lifting techniques you just learntyou can expect <strong>to</strong> have a productive <str<strong>on</strong>g>and</str<strong>on</strong>g> safe workingenvir<strong>on</strong>ment.• Remember, proper lifting not <strong>on</strong>ly affects you but thoseworking around you.

QUIZ ANSWERS1. Using the lifting calcula<strong>to</strong>r… can you safely lift an itemweighing 45 pounds, at waist <strong>to</strong> shoulder height (out 7”)for 4 <strong>to</strong> 5 lifts each minute for 1 <strong>to</strong> 2 hours in durati<strong>on</strong> <str<strong>on</strong>g>and</str<strong>on</strong>g>your not twisting more then 45 degrees?b. No…The safe weight limit would be 35 lbs.1. Job-specific, <strong>on</strong>-site, h<str<strong>on</strong>g>and</str<strong>on</strong>g>s-<strong>on</strong> training is more effectivethan classroom.a. True3. Name <strong>on</strong>e <strong>of</strong> the three principles for reducing frequentlifting.1. Use mechanical assistance2. Avoid unnecessary lifting3. Use mobile s<strong>to</strong>rage