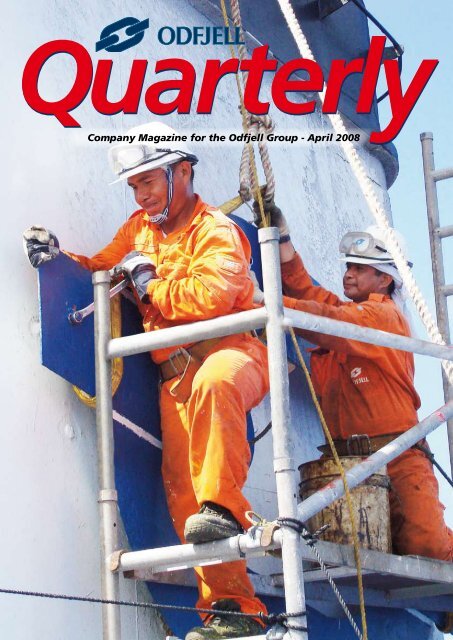

Company Magazine for the Odfjell Group - April 2008

Company Magazine for the Odfjell Group - April 2008

Company Magazine for the Odfjell Group - April 2008

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

already built eight 3,800 Dwt stainlesssteel chemical tankers <strong>for</strong> Sinochemand Nanjing Tanker <strong>Company</strong>, and lastyear it secured orders <strong>for</strong> four 9,000Dwt stainless steel tankers, controlledby Sinochem and Euroceanica UK, andfour stainless steel tankers of 5,500 Dwtfrom IMC.Chuan Dong’s initial design of <strong>the</strong> ships(IMO II) was in principal satisfactory,but <strong>Odfjell</strong> has made some technicalimprovements. We have increased <strong>the</strong>number of tanks from 12 to 14 to improvemarket trade flexibility. In additionwe have increased <strong>the</strong> cargo volumecapacity by 800 m 3 to 10,500 m 3 ,making it possible to fill <strong>the</strong> ship ondeadweight with typical low specificgravity chemicals.Tore Jakobsen, Terje Storeng and Atle Knutsen visiting <strong>the</strong> shipyardThe main engine will be a mediumspeed engine designed by MAN andbuilt on license by a Chinese producer.The ships will have a reduction gearwith a CP propeller, including an amplesized shaft generator. All cargo tankswill be arranged <strong>for</strong> carrying PropyleneOxide, and <strong>the</strong> ship will also be fittedwith a large N 2 generator.The specification has been commentedand improved on a very detailed level,and changes have been included asan amendment to <strong>the</strong> specification.Lengthy discussions were held about<strong>the</strong> Maker’s List. The extent of Chinesemakers have now been reduced, andcritical equipment will be supplied bywell known suppliers providing worldwideservice, which is a crucial issue <strong>for</strong>ships in international service.The six fixed newbuildings will be deliveredto <strong>Odfjell</strong> Asia II Pte Ltd, Singaporebetween <strong>the</strong> fourth quarter of 2010and <strong>the</strong> first quarter of 2012, at a totalprice of US$ 180 million. All units haveDnV class. The ships will operate in ourregional trades in Asia and Europe, andwill replace smaller vessels currentlytrading in <strong>the</strong>se areas.9,000 Dwt particularsLength over all Abt. 118.90 mLength between perpendiculars 111.00 mBreadth, moulded 18.60 mDepth, moulded 10.40 mDraught design 7.80 mDraught scantling 7.80 mService speed Abt. 13.1 knotsNumber of cargo tanks 14Deadweight at design draft Abt. 9,200 M.T.Cargo tank volume (100%) 10,540 Cbm.Unloading capacity Max. 1,320 Cbm. per hour<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 5

Trainees in BahrainBy Gunvor Simonsen Meyer and Hilde BølstadIn January <strong>2008</strong>, <strong>Odfjell</strong> and Det norskeVeritas (DnV) started a trainee exchangeprogramme in which trainees from<strong>the</strong>se two companies spend a period ofsix to eight weeks at <strong>the</strong> o<strong>the</strong>r party’soffices. The first trainee “on exchange”has been Surveyor Trainee Hilde Bølstadof DnV, who as from January has beenwith <strong>Odfjell</strong> to learn more about shipmanagement. After a few weeks workingin <strong>the</strong> Bergen office and sailing withBow Flower, Hilde and SuperintendentTrainee Gunvor S. Meyer went withSuperintendent Oddvin Ertesvåg toBahrain to take part in <strong>the</strong> dry-dockingof Bow Clipper at <strong>the</strong> Arab Shipbuildingand Repair Yard (ASRY).After some days in Bahrain, getting familiarizedwith <strong>the</strong> yard, <strong>the</strong> vessel finallyarrived. There were two excited traineesstanding at <strong>the</strong> dockside, waiting<strong>for</strong> <strong>the</strong> ship to moor. Immediately afterarrival, masses of yard workers rambledon board and various ship parts starteddisappearing in different directionsashore. So what is it like to be a traineeon dry-docking <strong>for</strong> <strong>the</strong> first time? In oneword: chaotic! So many things happenat <strong>the</strong> same time, and <strong>the</strong>re are a lot ofimpressions that need to be absorbed.Fortunately, we were both taken verygood care of. Oddvin, as well as JanBjerkan and Ingvald Larsen from <strong>the</strong>Hilde Bølstad entering a tankTechnical department, have shown animpressing patience and willingness toshare <strong>the</strong>ir knowledge through an unknownamount of cargo tanks and cofferdams,and countless rounds through<strong>the</strong> workshops of ASRY.The two trainees in Bahrain send our bigthanks to all that have accommodated<strong>for</strong> our training: <strong>the</strong> superintendent,officers and crew on Bow Clipper, paintand steel surveyors and <strong>the</strong> people atASRY, and last but not least to <strong>the</strong> DnVand <strong>Odfjell</strong> offices <strong>for</strong> giving us this opportunity!Hilde’s impressions of <strong>the</strong> traineeprogramme:Working at DnV, <strong>the</strong> trainee exchangeprogramme with <strong>Odfjell</strong> is a great opportunity<strong>for</strong> me to see <strong>the</strong> shippingbusiness from <strong>the</strong> Owner’s point ofview. It has been really interesting tofollow <strong>the</strong> steps of “Mr Oddvin” andGunvor during <strong>the</strong>se past few weeksand at <strong>the</strong> same time to learn from <strong>the</strong>irskills and experience. I have learned alot about <strong>the</strong> process of a dry-dockingand <strong>the</strong> working life of <strong>the</strong> “Super”.Participating at a dry-docking also provides<strong>the</strong> opportunity to get familiarwith a specific type of ship on a deeperlevel and thus, gaining more technicalexperience.Superintendent Trainee Gunvor Simonsen Meyer and Surveyor Trainee HildeBølstad during dry-dockingTo see a shipping company from <strong>the</strong>inside, with <strong>the</strong>ir daily challenges andlong-term perspectives on <strong>the</strong> business,is a unique and valuable experience <strong>for</strong>a surveyor trainee. I would like to thank<strong>Odfjell</strong> <strong>for</strong> opening <strong>the</strong>ir doors to meand <strong>for</strong> offering such a warm welcome.As <strong>the</strong> first trainee to this exchange programme,I dare rule this project a success.I wish all <strong>the</strong> best <strong>for</strong> <strong>the</strong> futuretrainees, and hope <strong>the</strong>y will enjoy <strong>the</strong>irstay with DnV as much as I have enjoyedmy time with <strong>Odfjell</strong>.<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 7

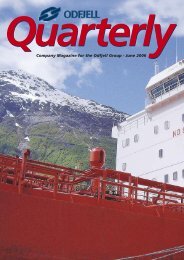

The last of <strong>the</strong> twelveNaming and launching of Bow CapeBy Frode J. StornesOn a chilly but sunny mid winter day inNagasaki, building no. N-2017 was madeready <strong>for</strong> naming and launching. Afternaming <strong>the</strong> ship Bow Cape, Mrs. Lillian H.Stornes cut <strong>the</strong> ribbon, <strong>the</strong> champagnebottle broke to <strong>the</strong> hull and <strong>the</strong> ship sliddown <strong>the</strong> dock into her right element.The ship is yet to be completed, andwill not be delivered until second half of<strong>April</strong>. Following Bow Santos in 2004 andBow Lima last year, Bow Cape is <strong>the</strong> thirdnewbuilding be delivered to its Japaneseowner, Santoku Senpaku Co Ltd, to goon a long-term time-charter to <strong>Odfjell</strong>. Afourth ship is yet to come later this year.The three ships are built by FukuokaShipbuilding; Bow Santos in Fukuokaand Bow Lima and Bow Cape at <strong>the</strong>yard in Nagasaki. Bow Cape is in fact <strong>the</strong>last ship in a series of twelve 19,000 Dwtchemical tankers with stainless steelcargo tanks, built at various Japaneseyards to various Japanese owners andall delivered on long-term time-charterto <strong>Odfjell</strong>. A pool of twelve ships allowsmore flexibility in successful tradingthan operating individually in <strong>the</strong> market,which should provide a win-winsituation <strong>for</strong> all parties involved.The launching ceremonies arrangedby Fukuoka Shipbuilding was a distinguishedand well carried out arrangement.The Lady Sponsor and guests weresolemnly guided through <strong>the</strong> yard areato <strong>the</strong> decorated ceremony plat<strong>for</strong>m.The Norwegian and Japanese nationalan<strong>the</strong>ms were played and flags hoisted.With precise punctuality workers at <strong>the</strong>yard prepared and signalled readiness<strong>for</strong> launching. A school class was present;surely a memorable day <strong>for</strong> <strong>the</strong>pupils and also a charming and evocativeelement in <strong>the</strong> ceremony. Then followed<strong>the</strong> naming, <strong>the</strong> ribbon cutting,<strong>the</strong> champagne bottle breaking to <strong>the</strong>hull, and <strong>the</strong> ship sliding into <strong>the</strong> sea –with an enormous amount of balloonsand colourful paper streamers addingfestivity to <strong>the</strong> arrangement.A special thanks to <strong>the</strong> owner Santoku<strong>for</strong> inviting <strong>Odfjell</strong> to <strong>the</strong> naming ceremonyof <strong>the</strong>ir ship. Fukuoka Shipbuildingper<strong>for</strong>med a grand and well preparedceremony. Also our very specialand personal thanks to Akemi Yamamotofrom <strong>the</strong> yard; in addition to beingceremony master she was also our dedicatedguide and host during our stay inNagasaki.We now look <strong>for</strong>ward to receiving <strong>the</strong>ship in our fleet.Mrs. Lillian H. Stornes cutting <strong>the</strong>ribbonLillian and Frode Stornes with “<strong>the</strong>ir”shipSignalling ready to launchProminent ceremony attendantsM/T Bow Cape8 <strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong>Safely afloat

Distinguished guests at OTRPresident of Mozambique visits <strong>the</strong> Rotterdam TerminalBy Theo KruithofOn February 29th, HisExcellency ArmandoEmílio Gubuza, Presidentof <strong>the</strong> Republicof Mozambique, hisspouse and o<strong>the</strong>r VIP’svisited our terminal inRotterdam. The Presidentwas on an officialthree-day statevisit in The Ne<strong>the</strong>rlands and was stayingwith our Queen Beatrix in The Hague. Inview of this official visit, Queen Beatrixhosted an official state banquet at herpalace in The Hague, where OTR CEO Mr.Zeger van Asch van Wijck attended.Part of <strong>the</strong> state visit was a boat tripthrough <strong>the</strong> Rotterdam port, in collaborationwith <strong>the</strong> Rotterdam Port Authority.The group moored at <strong>the</strong> Geulhaven,just around <strong>the</strong> corner of OTR,to visit our terminal. Mr. Zeger van Aschvan Wijck welcomed <strong>the</strong> President andhis wife at <strong>the</strong> Geulhaven jetty, where acoach was ready to take <strong>the</strong> party to <strong>the</strong>terminal. Escorted by five police motorcyclistsand three dark armour-platedluxury limousines, <strong>the</strong> group of about50 people headed <strong>for</strong> OTR.At <strong>the</strong> office, Mr. Laurence <strong>Odfjell</strong> welcomed<strong>the</strong> President and his wife in fluentPortuguese, Mozambique’s officialMr. Laurence <strong>Odfjell</strong> welcomes His Excellency <strong>the</strong> President at <strong>the</strong> Rotterdamoffice. In <strong>the</strong> middle OTR CEO Zeger van Asch van Wijcklanguage. For <strong>the</strong> occasion, OTR’s canteenwas transferred into a large meetingroom where Mr. Van Asch van Wijckgave a general presentation of <strong>Odfjell</strong>and explained <strong>Odfjell</strong> Terminal’s interestsin Sou<strong>the</strong>rn Africa and Mozambiquein particular.Next on <strong>the</strong> agenda was a bus-tour on <strong>the</strong>terminal, hosted by Mr. Theo Kruithof.Security-man Mr. Bert Streefkerk guided<strong>the</strong> procession in his car, followedby <strong>the</strong> police motorcyclists. Next in rowwas <strong>the</strong> VIP-coach with <strong>the</strong> President,followed by two mini-vans with membersof <strong>the</strong> Mozambique press. Fortunately<strong>the</strong> fog had lifted, since earlierthat day visibility was not even 50 metres.The tour lasted around 20 minutesand we explained to <strong>the</strong> distinguishedparty <strong>the</strong> ins and outs of our Rotterdamterminal. After <strong>the</strong> terminal tour, <strong>the</strong>bus drove back to <strong>the</strong> Geulhaven, wherewe passed by and introduced our newOTM-site. At <strong>the</strong> Geulhaven jetty finally,Mr. Van Asch van Wijck bid farewell to<strong>the</strong> President and his wife.After careful preparation of this visitin close collaboration and discussionwith <strong>the</strong> Project Officers of <strong>the</strong> ProtocolDepartment of <strong>the</strong> Dutch Ministryof Foreign Affairs, <strong>the</strong>ir counterpartsfrom Mozambique and (Inter-)nationalSecurity Officers, we can look back on asuccessful and unique event.Mr. S. Namburete, Mozambique’s Minister of Energy, raises a question after <strong>the</strong>presentation. From left President Guebuza, Laurence <strong>Odfjell</strong> and Mrs. Guebuza<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 9

<strong>Odfjell</strong> Terminals Head OfficeEngineering Best PracticesCommitteeBy Jerry ShreterThe <strong>Odfjell</strong> Terminal<strong>Group</strong> has developedterminalsover <strong>the</strong> past 40years in differentways, <strong>for</strong> differentrequirements, marketsand partners.The initial <strong>Odfjell</strong>terminals were developedin South America in <strong>the</strong> late1960s. The terminal in Houston (OTH)was developed in 1983, based on <strong>the</strong>experience gained in South America,and <strong>the</strong>n <strong>the</strong> experience in Houstonwas used as <strong>the</strong> basis <strong>for</strong> <strong>the</strong> Daliandesign in China. Recent developmentsin Dalian and Jiangyin were based on<strong>the</strong> initial Dalian design. O<strong>the</strong>r terminalsacquired through purchase or jointventures were engineered based on <strong>the</strong>experience of our partners or <strong>the</strong> previousowners.The method of expanding by using <strong>the</strong>experience of previous projects workedwell, and as <strong>the</strong> number of terminalsunder construction increased, and newpeople joined <strong>the</strong> organization, wecould benefit by <strong>for</strong>malizing <strong>the</strong> processwith an Engineering Best Practices Committee.The committee will review <strong>the</strong>practices of different <strong>Odfjell</strong> terminalsThe terminal in HoustonThe terminal in Houstonand select <strong>the</strong> best practices that willbecome a standard or a procedure to beused in new and existing terminals. Thepurpose of <strong>the</strong> Committee is to gain synergiessuch as lower construction costs,increased ease and safety of operations,efficient incorporation of environmentalrequirements and acceleration ofconstruction schedules. In additionwe aim at speeding up <strong>the</strong> transfer ofknow-how, identify project risks, andprovide a uni<strong>for</strong>m management system<strong>for</strong> <strong>the</strong> construction of new facilities.A challenge <strong>for</strong> <strong>the</strong> Committee is todevelop standards that can be used incountries with different regulatory requirements,construction practices andoperational experiences. The best designin <strong>the</strong> US may not be <strong>the</strong> best designin China. The designs will have tobe broken down into <strong>the</strong>ir basic buildingblocks, in order to determine whydifferent strategies should be used, anddetermine <strong>the</strong> pros and cons of one optionversus ano<strong>the</strong>r. Ano<strong>the</strong>r challengeis that many designs are in a continuousstate of evolution, even at <strong>the</strong> sameterminal. We may discover potential improvementsthat lead to a fur<strong>the</strong>r evolutionof an existing design. Thus, aftera standard is defined, it will have to beupdated periodically.The <strong>Odfjell</strong> group has a large pool ofqualified engineers and operationssupervisors who are familiar with differenttypes of facilities, and <strong>the</strong> followingpersons have been selected to10 <strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong>

<strong>for</strong>m <strong>the</strong> Best Practices Committee. RobertoFranck has worked with <strong>the</strong> SouthAmerican terminals since <strong>the</strong> 1960s, andhas been instrumental in <strong>the</strong> buildingand operation of terminals in Argentina,Brazil, Chile, and Peru. MartinRuinaard and Hans Vermeulen have operatedand built several terminal facilitiesin Europe, and OT Rotterdam since<strong>the</strong> 1980s. Clayton Sharver and JerryShreter have operated and built in OTHouston since <strong>the</strong> 1980s. Shaolin Wanghas built facilities in OT Dalian and OTJiangyin since <strong>the</strong> mid 1990s.The committee will first concentrate on<strong>the</strong> big ticket topic in a terminal, whichis <strong>the</strong> tank design. The cost of <strong>the</strong> tanksis 40% of <strong>the</strong> total cost of a bay facility,reflecting <strong>the</strong> large amount of labourand material that <strong>the</strong>y incorporate, and<strong>the</strong>re<strong>for</strong>e <strong>the</strong>y offer <strong>the</strong> largest opportunity<strong>for</strong> improvement. The constructionof <strong>the</strong> tanks has many risks thatneed to be addressed and minimized,such as safety of construction personnel,fire and exposure hazards, risk of engineeringand construction errors during<strong>the</strong> concrete work, <strong>the</strong> tank welding,and <strong>the</strong> hydro-testing of <strong>the</strong> tank.Proper operation of <strong>the</strong> tanks in regardsto storage, cleaning, circulation, filling,emptying and monitoring are issuesthat exist <strong>for</strong> <strong>the</strong> tank’s life of 50 yearsor more. Corrosion minimization anddetection are also major cost factors in<strong>the</strong> life of a tank. The tanks come in avariety of diameters, heights, materialof construction, foundations, pressurerating, equipment and instrumentation.Most of our tanks are designedto minimize <strong>the</strong> emission of vapours bybeing pressurized, similar to <strong>the</strong> ships,and to allow flaring and vapour balancing.The standardization will look at allof <strong>the</strong>se areas. Future topics that will bestandardized include <strong>the</strong> tank bays, <strong>the</strong>pump areas, <strong>the</strong> jetty line systems, <strong>the</strong>dock systems and <strong>the</strong> utilities.The Tagsa Campana terminalThe Rotterdam terminalThe standardization of tank outfitting<strong>for</strong> different chemicals will be ano<strong>the</strong>rmajor topic <strong>for</strong> <strong>the</strong> committee. Due to<strong>the</strong> nature of <strong>Odfjell</strong>’s business, we arefrequently asked to store chemicals thatrequire special outfitting. The cost of <strong>the</strong>outfitting is estimated prior to <strong>the</strong> leaseagreement with our customer, and <strong>the</strong>outfitting is installed after <strong>the</strong> agreementis made. The costs <strong>for</strong> estimating,engineering and <strong>the</strong> cost of engineeringerrors can be reduced if <strong>the</strong> outfittingmethods are standardized. The schedule<strong>for</strong> estimating and construction can alsobe shortened through standardization,and this is often a critical concern inour service industry. The outfitting thatwe usually see in <strong>the</strong> terminals consistsof circulation, insulation, heat tracing,heating, chilling, low oxygen, filtering,metering, special pumping and blendingsystems. These systems come inmultiple variations as a function of <strong>the</strong>characteristics of <strong>the</strong> chemical that isbeing stored and <strong>the</strong> experience of <strong>the</strong>terminal. Project management practiceswill also be reviewed and standardizedto assist in communication and cost andschedule control of projects.The aim of <strong>the</strong> committee is to assembleseveral times per year to review andmake recommendation on one or moretopics. This will result in <strong>the</strong> issuance of<strong>the</strong> standard <strong>for</strong> <strong>the</strong> topic that was covered.The writing and publishing of <strong>the</strong>standards will be done by <strong>the</strong> staff of OTHead Office. We are looking <strong>for</strong>ward to<strong>the</strong> first meeting of <strong>the</strong> Best PracticesCommittee in March, in <strong>the</strong> new HeadOffice in Rotterdam.<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 11

Joint shipping and storagesession in JiangyinBy Atle Knutsen<strong>Odfjell</strong> Terminals(Jiangyin) (OTJ) isnow operationaland has started toreceive <strong>the</strong> firstcargoes <strong>for</strong> customers.On SaturdayJanuary 26th, CEOChang Li invited keypeople from <strong>Odfjell</strong>Seachem in Asia to visit <strong>the</strong> brand newterminal and to participate in a marketingsession.From <strong>the</strong> shipping side, Y.K. Ha, KenKurihara, Zhu Guohe and Thomas Haalandparticipated and from <strong>the</strong> terminalside we had Li Xiao Guang from OT Dalian,Mr. Wang Jian from our partnersin Jiangyin, <strong>the</strong> Garson <strong>Group</strong>, as wellas <strong>the</strong> marketing people from <strong>the</strong> Jiangyinterminal. The objectives <strong>for</strong> <strong>the</strong>session, in addition to present <strong>the</strong> terminal,were to share in<strong>for</strong>mation about<strong>the</strong> terminal and shipping activities inAsia in order to rein<strong>for</strong>ce our shippingand terminal network. This was also agood occasion to discuss new businessopportunities <strong>for</strong> existing terminals inAsia as well as joint storage and shippingprojects.The close cooperation between shippingand storage is fruitful, and over <strong>the</strong>years we have developed and achievedmany joint projects. The benefits aremutual, and <strong>the</strong> terminal side in Chinahas many potential customers <strong>for</strong> <strong>the</strong>shipping side. We also believe that <strong>the</strong>close cooperation between shippingand storage could greatly contributeto expanding <strong>the</strong> logistics chain <strong>for</strong> ourcustomers and also include <strong>Odfjell</strong>’s participationin <strong>the</strong> Chinese coastal shippingbusiness.Our terminal in Jiangyin represents <strong>the</strong>most advanced marine facilities in <strong>the</strong>whole of China, and it offers <strong>the</strong> mostflexible logistics facilities <strong>for</strong> transhipments.Expansion plans are already beingdiscussed. The active cross-selling ofshipping and storage services is productiveand offers many business opportunities.Equally fruitful are <strong>the</strong> requirementsthat are produced through <strong>the</strong>global terminal network.As we are working more closely on <strong>the</strong>commercial side, we have also started tonetwork with <strong>Odfjell</strong> Ship Managementto share experiences on technical andmaintenance issues. Moving <strong>for</strong>ward,our capability to work across companyand departmental lines will be one ofour competitive advantages. Throughan active interaction, we find that <strong>the</strong><strong>Odfjell</strong> organization is rich on experiencesand have many well qualified employeeswho stand ready to assist andsupport whenever help is required.Part of <strong>the</strong> marine facilities at OTJ<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 13

New O-ships to <strong>the</strong> <strong>Odfjell</strong> fleetDelivery of Bow Omaria and Bow OreliaBy Frode J. Stornes<strong>Odfjell</strong> recentlyreceived <strong>the</strong> twonewbuildings BowOmaria and BowOrelia on pool arrangementsfromour business partnerAhrenkiel.Both ships were delivered to us straightfrom <strong>the</strong> Japanese shipbuilding yard,Bow Omaria in November and Bow Oreliain January. On <strong>the</strong>ir maiden voyages,both loaded a full cargo of sulphuricacid to Chile. The trading of <strong>the</strong>se shipsso far has given officers and crew ampletime to get well organised and settledwith everything on board. CDI and customershave already visited <strong>for</strong> inspections,and things seem to be in goodorder.The two new ships are on time-chartersfrom <strong>the</strong> Japanese owner Nisshin ShippingCo Ltd. to Ahrenkiel, who in turnhave time-chartered <strong>the</strong> ships to <strong>the</strong><strong>Odfjell</strong> Seachem pool. The ships are <strong>the</strong>last two in a series of six sisters, <strong>the</strong> fourfirst being Bow Orania, Bow Ophelia, BowOctavia and Bow Olivia, all built by UsukiShipyard Co. Ltd. They are all ships withstainless steel cargo tanks. The shipshave good fresh-water facilities andseparate fresh- and sea-water cleaninglines on deck. They are also equippedwith fixed tank cleaning equipment andfixed nitrogen generators. In additionto <strong>the</strong> six ‘O-ships’, <strong>Odfjell</strong> contributeswith six similar ships on direct timechartersfrom o<strong>the</strong>r Japanese owners.By <strong>April</strong> <strong>2008</strong> <strong>the</strong>re will be a completepool of twelve 19,000-tonners.M/T Bow OmariaCaptain D. Moltefonkais in charge of BowOmaria and Captain G.Labuguen commandsBow Orelia. CaptainLabuguen has had <strong>the</strong>privilege of taking outtwo previous ships in<strong>the</strong> series. We wish <strong>the</strong>two captains and <strong>the</strong>ircompliments welcometo <strong>the</strong> <strong>Odfjell</strong> Seachemfleet.Fast facts Bow Omaria/Orelia:Dwt 19,972LOA / Beam / Draft: 145.6 / 23.7 / 9.7 mTanks: 20Tank lining:Stainless SteelShip type:IMO IIOfficers and crew: PhilippinoBuilt:Usuki Shipyard, JapanClass:Bureau VeritasFlag:PhilippineOwner:Nisshin Shipping Co, TokyoManager:Victoria Ship Management, TokyoM/T Bow Orelia<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 15

OTK on <strong>the</strong> moveBy Rob Meijboom2007 was an importantyear <strong>for</strong> <strong>Odfjell</strong>Terminals (Korea). InMarch we achieved<strong>the</strong> CDI-T attestation,and on December1st we reachedour target of 1,520days without losttimeinjuries. Wehave also almost completed our massiveexpansion programme, increasingour capacity with 61,470 cubic metreson 25 tanks of which some are made ofstainless steel.Safety is a joint ef<strong>for</strong>tSafety of course is essential at OTK, as inany o<strong>the</strong>r <strong>Odfjell</strong> unit. It may seem easyto understand, but reality is sometimesnot so straight<strong>for</strong>ward despite all qualityprocedures. In fact, safety starts witha safe working environment, includingsuitable equipment, proper communication,cleanness, training and awareness,discipline and a dedicated responsibilitytowards colleagues and family. Hence,it’s all about behaviour and attitude.On <strong>the</strong> o<strong>the</strong>r hand, safety is not alwaysdepending on factors that are fully underyour own control. In our industry,much complexity and risk exposure stemfrom third party service providers, suchas operators of trucks and ships, constructioncontractors, etc. An accidentrarely come with a <strong>for</strong>ewarning, and<strong>the</strong>re<strong>for</strong>e to always wear <strong>the</strong> requiredpersonal protection equipment (PPE)can safe you from injuries, even if an accidentshould occur.At OTK we are proud of our safety andquality track record. The milestone of1,520 days without lost-time injuries (LTI)that we reached in December equals fourtimes <strong>the</strong> target of 380 days that is <strong>the</strong> industrystandard in Korea <strong>for</strong> our size andtype of business. As a result, Korean authoritiesnominated OTK <strong>for</strong> <strong>the</strong> “NationalKorean Safety Award”, which we receivedin November last year. However, since <strong>the</strong>nun<strong>for</strong>tunately we have had one minoraccident where one of our technicians injuredhis ankle and was hospitalised <strong>for</strong> aweek. Thus, our final score until February18th stays as 1,598 days without LTI.Rob Meijboom receives <strong>the</strong> NationalKorean Safety Award on behalf ofOTKArea photo showing OTK’s 25 new tanks on <strong>the</strong> right hand side and <strong>the</strong>Bow Sirius at <strong>the</strong> finger pierThe Korean Safety Award 200716 <strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong>

The stainless steel tanksOTK’s jetty with <strong>the</strong> new top deck changing station, seenfrom <strong>the</strong> bridge of Bow SiriusExpansion at <strong>Odfjell</strong> Terminals (Korea)In <strong>the</strong> “Bamboo rising to <strong>the</strong> sky” articlein <strong>the</strong> 2007Q3 issue of <strong>Odfjell</strong> Quarterly,we showed some pictures of <strong>the</strong> newE-2 project at OTK. At <strong>the</strong> time of writingthis project is almost completed and<strong>the</strong> tanks are already fully occupied.The commissioning is practically done.What remains are some cosmetic detailsThe 61,470 cubic metre (cbm)extension distributes as follows:No of Unit Categorytanks capacity(cbm)3 3,300 Carbon steel3 2,200 Carbon steel1 1,660 Carbon steel6 1,660 Stainless steel2 1,250 Stainless steel2 1,250 Carbon steel1 550 Stainless steel2 150 Slop – Carbon steeland some outstanding items, all whichwill be finished around end March <strong>2008</strong>.With this OTK reaches a total capacityof 171,000 cubic metres on 64 tanks, ofwhich 11 units are stainless steel.The project also includes a number ofquality-enhancing features such as vapourcontrol systems, leak detectionsand fixed sampling equipment. Wehave built a new ten-metre diameterintegrated carrousel-pump-place where<strong>the</strong> flexibility of <strong>the</strong> pipeline transfer isassured by changing station plat<strong>for</strong>ms,one beside <strong>the</strong> central manifold andone on <strong>the</strong> new jetty top deck. In additionwe have built new offices and aworkshop, and made o<strong>the</strong>r upgrades ofexisting equipment.The project has been carried out byDaewoo Engineering <strong>Company</strong>, andwithout any LTI <strong>for</strong> <strong>the</strong>ir 220 workersduring <strong>the</strong> 362 days. On March 4th thisyear a safety ceremony was held to honourthis remarkable safety record.Some of <strong>the</strong> new tanksNight view of <strong>the</strong> carrousel and Tank-pit 6 with eight stainless steel tanksThe new workshop<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 17

ICT systems renewal programmeBy Tor JürgensenOver <strong>the</strong> last twodecades <strong>the</strong> numberof businesscritical ICT solutionsin <strong>Odfjell</strong> hasincreased substantially,and we useICT to continuouslyimprove ourcustomer service,internal and external communication,productivity, quality of work, assetutilization, and reporting and control.The business units have matured significantlyregarding efficient use of ICTtools, and requirements <strong>for</strong> new andimproved functionality <strong>for</strong> our ICT solutionshave been a top priority <strong>for</strong> <strong>the</strong>company. To fulfil <strong>the</strong>se requirementsand to benefit from <strong>the</strong> rapid developmentin in<strong>for</strong>mation technology, <strong>Odfjell</strong>top management has initiated a programmeto renew most of our businesscritical ICT solutions.Screen image from <strong>the</strong> Terminal Management SystemThe renewal programme will take placeover several years, founded on a common<strong>Odfjell</strong> ICT Strategy. Important elementsof this strategy are:• When possible implement standardbusiness systems. “SAP BusinessSuite” is <strong>Odfjell</strong>’s preferredapplication plat<strong>for</strong>m.• All business critical systems shall behosted at <strong>Odfjell</strong>’s Corporate DataCentre, with 24-hour availability.Users shall connect to <strong>the</strong> systemsthrough <strong>Odfjell</strong>’s Global Network.• Strong focus on ICT Security andcontingency preparedness solutions.• Business units to be alwaysresponsible <strong>for</strong> project ownershipwhen developing or implementingnew ICT solutions.Our purpose is to achieve reduced ICTcosts, increased efficiency by sharingexperience and knowledge, standardizationon work procedures, improvedconsistency and visibility of in<strong>for</strong>mationwithin <strong>the</strong> various systems, and stableand secure ICT systems that are availableto <strong>the</strong> users at all time.To make sure we address all importantrequirements, and to have a structuredand manageable process when implementingnew or replacing existing solutions,we apply a five step developmentmethod.During <strong>the</strong> Envisioning phase we defineproject goals, analyse work processesand determine project requirements.Choice of technology means decidingon which system plat<strong>for</strong>m to implement<strong>the</strong> new solution. The Business Blueprintphase involves specifying how <strong>the</strong> chosensystem/technology has to be set upin order to fulfil <strong>Odfjell</strong>’s requirements.In <strong>the</strong> Construction phase we build <strong>the</strong>system and test it according to our specifications.Finally we go live, i.e. set <strong>the</strong>system into production, train <strong>the</strong> users,define all system routines, and migratenecessary date from any old systems.Terminal Management SystemThe Terminal Management System (TMS)will replace several old and somewhatoutdated operational and administrativemanagement systems at our terminalswith one global system supportingsales (contract management and orderintake), planning and scheduling, orderexecution, stock administration, invoicing,and customs administration. Thesystem will also offer a customer in<strong>for</strong>mationportal, including facilitating e-capabilities <strong>for</strong> <strong>the</strong> customers.The TMS project is now at <strong>the</strong> end of<strong>the</strong> construction phase, and we will golive in Houston in July <strong>2008</strong>. Start-up atour terminal in Rotterdam will be thisautumn, and later on <strong>the</strong> system will18 <strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong>

currently in its envisioning phase, wherewe are analysing business processes anddefine functional requirements. We estimatethis phase to be finished late autumn<strong>2008</strong>. The next step <strong>the</strong>n will be tomake an evaluation of technology.Einar Øye is managing <strong>the</strong> project, andSigmund Larsen, Morten Nystad and JanA. Hammer are its business owners.Tom Hagesæ<strong>the</strong>rTrond Ove Jacobsenbe implemented at all <strong>Odfjell</strong> managedterminals. Project manager <strong>for</strong> <strong>the</strong> TMSproject is Tom Hagesæ<strong>the</strong>r, and <strong>Odfjell</strong>Terminals representatives Marcel vanden Nieuwendijk and Dave Ellis are TMSproject owners.New systems <strong>for</strong> <strong>Odfjell</strong> TankersThe system portfolio <strong>for</strong> <strong>Odfjell</strong> Tankerswas developed in-house from 1996to 2003. Due to long and complex developmentcycles, parts of <strong>the</strong> systemsare based on different system softwareversions. This complicates maintenanceand fur<strong>the</strong>r development. Autumn2007 we initiated a project to replace<strong>the</strong> <strong>Odfjell</strong> Tankers systems, with a newsolution based on a standard EnterpriseResource Planning (ERP) plat<strong>for</strong>m. Ourvision is to develop a tool that ensurehigh quality and efficient work per<strong>for</strong>mance,and at <strong>the</strong> same time giveeasy access to accurate and relevantin<strong>for</strong>mation. We also want customers,agents, and o<strong>the</strong>r stakeholders to beable to interact efficiently with relevant<strong>Odfjell</strong> processes.The first version of <strong>the</strong> new system willincorporate processes such as contractand sales, voyage planning and execution,voyage closure and follow-up, andreporting and analysis. The project isEinar ØyeNew Human Resources SystemCurrently <strong>Odfjell</strong> has two separate mainHR systems, one <strong>for</strong> <strong>the</strong> seafarers andone <strong>for</strong> shore personnel, in addition toseveral minor supporting systems. Wehave now initiated a project to replace<strong>the</strong>se systems with one common solution,<strong>the</strong> HR SAP system. The system willhandle all personnel administration,including salary, absence registration,competence development, recruitmentand travel administration. HR SAP willoffer self-service capabilities <strong>for</strong> employeesand management.The project is currently in <strong>the</strong> initiationof <strong>the</strong> envisioning phase. According to<strong>the</strong> project plan <strong>the</strong> new system will beimplemented at <strong>Odfjell</strong>’s main officeduring 2009 and be operational from<strong>the</strong> beginning of 2010. After successfulimplementation at <strong>the</strong> main office <strong>the</strong>system will be rolled out to all businessunits. Trond Ove Jacobsen is managerof <strong>the</strong> project and Brit A. Bennett is itsbusiness owner.New Intranet and Internet solutionIn 2001 we introduced <strong>Odfjell</strong>’s currentIntranet/Internet solution, with <strong>the</strong> purposeto unite our global organisationunder one common computer system,and to distribute in<strong>for</strong>mation simultaneouslyto all business units regardlessof geographical location. However, <strong>the</strong>technology behind our Intranet/Internetsolution has not followed <strong>the</strong> generaldevelopment of WEB technology,and consequently we now see that <strong>the</strong>functionality is restricted.To bring our systems up to date a projectwill start up in second quarter <strong>2008</strong>,with <strong>the</strong> purpose of acquiring a newplat<strong>for</strong>m <strong>for</strong> intranet and internet.<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 19

Safety BulletinBy Toralf SørenesOur HSE programmeHealth, Safety and Environment (HSE)has been a focus area in our company<strong>for</strong> many years. Gradually HSE has been<strong>for</strong>malized into procedures and becomemore visible, almost like a slogan. Assuch it has become somewhat of an easyto use catchword to almost everyone onall levels, but we must not <strong>for</strong>get thatit represents something that is very realand a key to success.To get a systematic and long-term approachtowards improving ourselves inthis area, we have established a HSEprogramme. The programme covers, as<strong>the</strong> name indicates, three main components.In this bulletin we will only address<strong>the</strong> safety element. The onboardoperation of chemical tankers is morecomplex and challenging than mosto<strong>the</strong>r areas of seaborne transportation.In addition, it is a trade that exposesour crew to many risks. To keep <strong>the</strong>serisks at a reasonable and acceptable level,we need a robust HSE programme.The programme must be well designedwith regards to scope and capability,understood by ship and shore basedpersonnel, and well implemented in<strong>the</strong> organisation. Although we apply anumber of different factors to monitor<strong>the</strong> success of <strong>the</strong> programme, <strong>the</strong> mostpredominant ones are personal injuriesand near misses.We selected three areas to focus on lastyear: eye injuries, <strong>the</strong>rmal and chemicalburns, and rotating equipment. Theseare areas where we have recorded injuriesand near misses. Fur<strong>the</strong>r, <strong>the</strong> potential<strong>for</strong> a worst case outcome is quitehigh, and we may achieve improvementsthrough relatively simple means. Themain challenge is, as with many o<strong>the</strong>rissues, to change attitudes. For <strong>the</strong>rmaland chemical burns we have recently developeda training course that aims at;1 – give a better understanding of <strong>the</strong>risks involved, 2 – show <strong>the</strong> importanceof Personal Protection Equipment (PPE)and <strong>the</strong> “protection is better than cure”doctrine, and 3 – apply quick and correctfirst aid if something should happen.The course shall be used on boardour ships and at <strong>the</strong> <strong>Odfjell</strong> Academy inSubic Bay. We are also working on similarcourses in o<strong>the</strong>r areas, but want totake one step at <strong>the</strong> time, i.e. make surethat one course is well implemented be<strong>for</strong>ewe introduce a new one.Ano<strong>the</strong>r important element to increaseawareness and change attitude is reportingof near accidents. Terms like nearaccidents, near misses and non con<strong>for</strong>mitiesdo not have a long and historicaltradition within shipping. Seafarers areused to attend to things that happen,and not those that do not happen butcould have. Shipping is a fairly conservativeenvironment of individualists, andimplementation of new ways of doingthings takes time. It is <strong>the</strong>re<strong>for</strong>e positiveto note that reporting of near misseshas gradually increased. One thing thatis particular encouraging is to note thatcrew not wearing PPE or making shortcuts are stopped by colleagues, whichis a very good sign showing that ouref<strong>for</strong>ts are starting to pay off. A goodindication of a living system is that itis working from <strong>the</strong> bottom level andupwards. We are confident that <strong>the</strong>near miss approach will give a positiveeffect over time. All scientific researchsupports this assumption. However, thisis a process that takes time, with repetitionsand patience as key words. Setbacksmay and will come, but we mustnot let <strong>the</strong>se disturb our focus on <strong>the</strong>main structure and elements of our HSEprogramme.It is important that all personnel onboard and ashore, from <strong>the</strong> very top to<strong>the</strong> lowest levels of our organisation,support our HSE programme. We canonly get improvements if we work toge<strong>the</strong>ras a team and <strong>the</strong>reby adopt acommon safety attitude that becomesembedded in us all.20 <strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong>

It happened to me - don’t letit happen to you!By AB Roy AlpangheThe early morning of January 14th thisyear, M/T Bow Century was at berthin Fray Ventos, Uruguay, to unload acargo of caustic soda solution. AB RoyAlpanghe, a 27-year-old who had sailedwith <strong>Odfjell</strong> since 2001, reported <strong>for</strong>duty and was instructed to check andmake sure that all connections weretight and ready <strong>for</strong> discharging cargo.Everything seemed to be in good orderwhile he was connecting <strong>the</strong> air hose to<strong>the</strong> manifold <strong>for</strong> pressure test, a task hehad done several times and thus, hadbecome a regular routine <strong>for</strong> him. Afterpressure testing and in <strong>the</strong> processof disconnecting <strong>the</strong> air hose, <strong>the</strong> hosesuddenly erupted and caustic soda wassprayed over his face and eyes, whichmade him temporarily blind. The unthinkablehad happened. It was AB Alpanghe’snightmare and first encounterwith an accident related to his job.The Chief Officer, who was on deck,immediately brought him to an emergencyshower and tried easing his discom<strong>for</strong>tby flushing his face and eyeswith running water. The Master advised<strong>the</strong> Agent, who called <strong>for</strong> an ambulanceso that <strong>the</strong> injured Alpanghe could bebrought to <strong>the</strong> nearest hospital rightaway. While waiting <strong>for</strong> <strong>the</strong> ambulanceto arrive, AB Alpanghe was brought to<strong>the</strong> ship’s hospital where <strong>the</strong>y administereda continuous application of eyewash.During this, all kinds of thoughts wereoccurring in Alpanghe’s mind. Whatif he was injured permanently? WhatBow Century, archive photoabout his family? What had he donewrong and what caused that suddeneruption of <strong>the</strong> hose? He was trying toreplay <strong>the</strong> steps and <strong>the</strong> procedures hehad undertaken prior to <strong>the</strong> accident,but had no clear recollection of whathad happened.When <strong>the</strong> ambulance arrived, Alpanghewas immediately brought to <strong>the</strong> nearesthospital where <strong>the</strong> attending physicianreported that, as a result of <strong>the</strong> accident,<strong>the</strong> un<strong>for</strong>tunate mariner sustained bilateraleye burn, conjunctivitis, cornealedema and corneal ulcer in both hiseyes. He was declared “unfit <strong>for</strong> duty,but fit <strong>for</strong> travel”. AB Alpanghe wassigned off January 19, <strong>2008</strong>, and uponarrival in Manila he was immediatelybrought to hospital <strong>for</strong> fur<strong>the</strong>r checkup and medication.After <strong>the</strong> accident, a thorough investigationwas carried out and facts wereestablished. At <strong>the</strong> time of <strong>the</strong> accidentAB Alpanghe was wearing all safetyequipments as required, i.e. chemicalsuits, rubber gloves, helmet with faceshield and safety shoes. His training recordsshowed that he had gone throughall <strong>Odfjell</strong> mandated safety trainings.However, what became apparent wasthat while disconnecting <strong>the</strong> air hose, hehad lifted his face shield, thus exposinghimself to imminent danger of havinghis eyes and face exposed to whateversubstance remaining in <strong>the</strong> manifold,in this case caustic soda. Hence, he hadignored one very important aspect ofhis training: <strong>the</strong> strict implementationEmergency shower and eye wash, thisone on Bow Plataand compliance of safety procedures onboard at all times.AB Alpanghe admitted his mistake andlack of better judgment, and pointed atoverconfidence as <strong>the</strong> main reason <strong>for</strong>this accident. This just shows that carelessnesseven <strong>for</strong> a short moment canhave a serious impact. Consequently, removingany personal protection equipment(PPE) or safety gear be<strong>for</strong>e <strong>the</strong> jobis done can expose you to danger. Beingtoo confident just because one is familiarwith a certain task does not relieveanybody from strictly adhering to safetyprocedures. One can not be too complacentwith any task on board, no matterhow familiar you are with <strong>the</strong> task orhow simple it may seem.Luckily AB Alpanghe is recovering well,and he looks <strong>for</strong>ward to join <strong>Odfjell</strong> vesselsagain soon. He insists that <strong>the</strong> accidentwas a lesson learned that he willnever <strong>for</strong>get: “During my recovery periodat home, I was thinking what couldhave happened to me, my family, mycareer and my future if I had damagedor lost my eyesight. It would have beena total disaster <strong>for</strong> us. So please take myadvice: never be complacent nor relaxon following procedures and using <strong>the</strong>PPE/safety equipments”!<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 21

Laurence <strong>Odfjell</strong> as new President of <strong>Odfjell</strong> TerminalsJust scratching <strong>the</strong> surfaceBy Anne-Kristine Øen and Klaus WalderhaugAs from January 1st this year LaurenceWard <strong>Odfjell</strong> took up <strong>the</strong> position asnew president of <strong>Odfjell</strong> Terminals.Laurence is obviously no newcomer to<strong>the</strong> company, having followed it virtuallyall his life. He served as a memberof <strong>the</strong> <strong>Odfjell</strong> board in <strong>the</strong> period2004-2007, and in recent years he hasbeen stationed in Singapore. However,as <strong>the</strong>re are probably still quite a numberof colleagues who haven’t had <strong>the</strong>pleasure of making his acquaintance,we decided to have an interview withhim.At <strong>the</strong> vineyard in Chile22 <strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong>The <strong>Odfjell</strong> winery office buildingThe architectAlready at <strong>the</strong> age of 18, straight outof Norwegian high school, Laurence<strong>Odfjell</strong> went to <strong>the</strong> US to start architecturalstudies at Yale University, as <strong>the</strong>only Norwegian of his year. Having alwaysbeen drawing a lot, this seemed alikely career path. “Yale is an excellentgeneral plat<strong>for</strong>m <strong>for</strong> a number of professions”,he says still feeling very <strong>for</strong>tunatewith his choice of place and study.But he quickly learnt that <strong>the</strong> somewhatlax attitude of Norwegian schools hadto be replaced by hard work and a strictwork discipline, which taught him whatis now one of his main principles: to get<strong>the</strong> job done, whatever it takes. This hasmade him very concerned of deadlinesand to deliver on time. “At times I couldpush it a bit too hard”, he remembers,but he discovered how <strong>the</strong> adrenalinkick of a fast game of squash could compensate<strong>for</strong> lack of sleep. After sevenyears at Yale, only interrupted by hismilitary service in Norway, he graduatedwith a master degree and was readyto start his professional life.The winery-builderThe idea of a winery in Chile had beenborn already in 1991, and since 1993Laurence had been doing some preparatorywork, including visiting wineriesin several countries and making detailednotes of what he saw. Followinghis graduation he also worked <strong>for</strong> architecturalfirms to get a better grip of <strong>the</strong>constructional aspects of architecture.All this enabled him to set things intosystem and know what to look <strong>for</strong>.In 1995 his fa<strong>the</strong>r assigned him <strong>the</strong> taskof drawing <strong>the</strong> new <strong>Odfjell</strong> winery, andhe moved from <strong>the</strong> US down to Chile.Although he was given a full year oncompleting <strong>the</strong> drawings, “a rare luxurytoday to have so much time” he adds,he found that he had to learn everythingfrom scratch, including how <strong>the</strong>contractor market in Chile was functioning,who supplied quality buildingmaterial, etc. He worked closely withhis fa<strong>the</strong>r on <strong>the</strong> project, and <strong>the</strong> resultwas something completely new in Chile;a boutique winery with distinct designelements, where <strong>the</strong> wine was movedthrough <strong>the</strong> production process bygravity and not by traditional pumping.The process showed him <strong>the</strong> importanceof making <strong>the</strong> concepts practicable, andhow essential it is to communicate andcreate enthusiasm <strong>for</strong> <strong>the</strong> end goalamong <strong>the</strong> ones doing <strong>the</strong> actual work.Based on his building experiences he hasdeveloped a system <strong>for</strong> following up onall outstanding issues. “I never delete amessage or a document on a case untilit is completely closed”, he insists.The success of <strong>the</strong> <strong>Odfjell</strong> winery ledto a lot of enquiries <strong>for</strong> his services inbuilding o<strong>the</strong>r wineries. Toge<strong>the</strong>r witha Chilean architect Laurence established‘Arquitectos Anónimos’, and <strong>the</strong>y immediatelytook on several winery projects,both in Chile and in Argentina. Although<strong>the</strong> projects were delivered ontime, it turned out to be far too muchwork, with very short deadlines andsometimes conflicting instructions from<strong>the</strong> customers’ local offices and <strong>the</strong>irinternational headquarters. “The stresstook away <strong>the</strong> joy of it”, he admits andat <strong>the</strong> end he felt burned out. The cooperationwith his associate wasn’t allpainless ei<strong>the</strong>r, which was ano<strong>the</strong>r lessonlearnt: “choose your partners withcare”.

Laurence <strong>the</strong> “cadet”, on Bow LeopardJanuary 2006The terminal manAt <strong>the</strong> end of <strong>the</strong> millennium <strong>the</strong> wineryboom in Chile was more or less over, andfew new projects appeared. In 2000 hewas asked to take up a position at <strong>the</strong>private family-owned Terquim terminalin Chile, first on <strong>the</strong> commercial sideand later as general manager. “It was agood place to start”, he remarks, “andI experienced <strong>the</strong> benefits of an efficientship/terminal combination”. Threeyears later, in 2003, he was requestedto move to Brazil, to start working at<strong>the</strong> private terminal headquarters inSao Paulo. However, at <strong>the</strong> same timehe had received a new commission tobuild a winery. This opportunity to endhis architect career “on a positive note”was too tempting, and he accepted <strong>the</strong>terminal job in Brazil on <strong>the</strong> conditionthat he could in parallel do this very lastwinery project. He stayed in Sao Paulo<strong>for</strong> three years, in various staff functions.In 2004 he was offered a seat on<strong>the</strong> <strong>Odfjell</strong> ASA board of directors. “Ithas been incredible to be part of suchan important team”, he says. Not leastdid he find it interesting and useful tosee <strong>the</strong> decision basis “from both sides”,with his experiences in <strong>the</strong> organizationin mind.A brief spell in shippingIn 2006 Laurence was sent to Singaporeto learn shipping basics, first in shipmanagement and later on in charteringand operations. Already <strong>the</strong> firstweek, be<strong>for</strong>e <strong>the</strong> jetlag from his flightfrom Brazil had worn off, he was senton board Bow Leopard to experiencefirst-hand what life at sea is all about(see also <strong>Odfjell</strong> Quarterly 2006Q2).“Despite my family background in shippingand my military service in <strong>the</strong> Norwegiannavy, I had never be<strong>for</strong>e sailedon a ship”, he admits. He returned oneweek later with lots of impressions anda much better understanding. “It is essentialthat ship/shore understand andrespect each o<strong>the</strong>r’s realities, issues andrequirements”, he says and adds that hehopes to be able to sail with an <strong>Odfjell</strong>vessel again at least once a year. In additionto his shipping-related task andhis duties as a Board member, Laurencealso became involved in a number ofnew terminal projects in Asia. Becauseof all <strong>the</strong> travelling this required, hefound it difficult to handle his day-todaytasks, but all in all he looks back onhis period in Singapore as both interestingand educational.The <strong>Odfjell</strong> Terminals PresidentThe autumn of 2007 it was time againto pack his bags and very few personalbelongings, this time heading <strong>for</strong> Rotterdamto <strong>the</strong> newly relocated head officeof <strong>Odfjell</strong> Terminals to take up <strong>the</strong>position as president. “I have movedaround so much, every time making <strong>the</strong>sacrifice of leaving behind friends andgood colleagues”, he laments. The lastmonths of <strong>the</strong> year he worked closelywith Jan A. Hammer, who was <strong>the</strong>n ultimatelyin charge of our terminals, tostart to get to know <strong>the</strong> division, to beintroduced to our terminal partners,and to develop <strong>the</strong> fur<strong>the</strong>r strategies.“A very tidy process”, he summarises.As to his immediate plans <strong>for</strong> <strong>the</strong> terminals,it is still early days. “We have avery good and professional organisation,so luckily we are not starting fromscratch”, he says. “Personally I have alot to learn in this job, and so far I feelthat I’m barely scratching <strong>the</strong> surface ofit all”. One of his first initiatives as presidentis to establish a Best Practices Committee,to develop a mutually agreedset of technical solutions on terminallayouts, equipment, product handlingand operational standards. He also aimsat building sufficient technical capacityat headquarters in Rotterdam to beable to take on more terminal projectsall over <strong>the</strong> world. “In this context it isessential that we fur<strong>the</strong>r leverage <strong>the</strong>general competence within <strong>the</strong> organisation”,he concludes.And how about his private life? Squashis still his favourite way of keeping fitand to blow off some steam. “In additionI like to follow from a distance <strong>the</strong>vineyard in Chile, which still is kind ofmy baby”, he admits. With this he wrapsup <strong>the</strong> interview and rushes off to ano<strong>the</strong>rmeeting, leaving us realising thatwe have, as <strong>the</strong> title rightly indicates,just scratched <strong>the</strong> surface.The new <strong>Odfjell</strong> Terminals President visiting OTK<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 23

Watch Olympics in Beijing, go sightseeing inDalianBy Xu Tao, <strong>Odfjell</strong> Terminals (Dalian)<strong>2008</strong> is a magnificentyear <strong>for</strong> Chinesepeople allover <strong>the</strong> world, becauseof <strong>the</strong> gamesof <strong>the</strong> 29th SummerOlympics takingplace in Beijingin August. Dalian,a bright pearl in<strong>the</strong> north of China, is looking <strong>for</strong>wardto show our great hospitality to touristsfrom all over <strong>the</strong> world.Dalian is an important coastal city inChina, located on <strong>the</strong> south-eastern tipof <strong>the</strong> Liaodong peninsula in Manchuria,around 800 kilometres east of Beijing.With <strong>the</strong> Yellow Sea on <strong>the</strong> eastand <strong>the</strong> Bohai Sea on <strong>the</strong> west, <strong>the</strong> portcity is a natural and ice free entry pointto nor<strong>the</strong>ast China, with direct highwayand railway connections to all industrialareas of this vast country. Daliancovers about 12,574 square kilometres,including <strong>the</strong> naval port of Lushun andthree counties in <strong>the</strong> north, amongwhich about one fifth is <strong>the</strong> city itself.The Dalian area abounds with beautifulmountains and hills, but with littleplains and lowlands. The terrain, highand broad on <strong>the</strong> north, low and narrowon <strong>the</strong> south, tilts to <strong>the</strong> Yellow Seaon <strong>the</strong> sou<strong>the</strong>ast and towards <strong>the</strong> BohaiSea on <strong>the</strong> northwest.Dalian is a most beautiful beachsidecity, well known <strong>for</strong> clear skies andblue sea. The four seasons are distinct,with nei<strong>the</strong>r extremely cold wintersnor extremely hot summers. AverageCity view of Dalianyear temperature is about 10°C, <strong>the</strong>annual rainfall is 550-950 millimetres,and we have around 2,500-2,800 hoursof sunshine per year. From city downtown<strong>the</strong>re is a very beautiful coastalroad winding up and down <strong>the</strong> greenhills south of <strong>the</strong> city, which should bepart of your tour itinerary when visitingDalian, particularly during summer. Ano<strong>the</strong>rpiece of ‘have to do’ sightseeingis <strong>the</strong> Golden Pebble Beach, about fiftykilometres north of <strong>the</strong> city. If you wantto see a polar bear, <strong>the</strong>n you have to goto <strong>the</strong> Ocean Park at Tiger Beach.The history of Dalian, as a city, goes backa little more than one hundred years.Back <strong>the</strong>n it was just a small fishing villagecalled Qing Niwa. In <strong>the</strong> late Qingdynasty, <strong>the</strong> government constructedloading bridges and <strong>for</strong>tifications withbuilt-in cannons and set up mine campsin <strong>the</strong> nor<strong>the</strong>rn coast of Dalian Bay, thusturning it into a small town. During <strong>the</strong>1st and 2nd Opium Wars, Dalian was invadedand harassed by <strong>the</strong> British army.The Sino-Japanese War and Japanese-Russian War broke out in 1894 and 1904respectively, and as a main battlefield<strong>the</strong> town suffered greatly. After <strong>the</strong> invasionand occupation of Russia, in 1899<strong>the</strong> city was renamed Dalian. Later onDalian came under Japanese colonialrule <strong>for</strong> 40 years. August 1945 <strong>the</strong> SovietRed Army liberated Dalian in <strong>the</strong>anti-fascist war, thus ending half a centuryof colonial rule over <strong>the</strong> city. From1966 to 1976, Dalian experienced <strong>the</strong>Cultural Revolution. In 1984, through<strong>the</strong> Chinese government’s ‘open-doorto <strong>the</strong> world’ policy, Dalian was designatedone of <strong>the</strong> open cities. Under thispolicy, <strong>Odfjell</strong> Terminals (Dalian) Ltd, ajoint venture between <strong>Odfjell</strong> and PDAThe ‘Swallow Nest’, a symbol of <strong>the</strong> old Chinese heritageThe Shell Museum24 <strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong>

The World Trade TowerAn impression of Dalian, with an old church now converted into a fast-foodoutlet contrasting to modern housing projectsA symbol of Dalian’s naval history(Port of Dalian Authority) Corporation,was established in 1995. After morethan ten years of operation, OTD is nowfacing new challenges.Like many o<strong>the</strong>r cities around <strong>the</strong> worldwith a similar colonial rule history, differentculture elements live on such as<strong>the</strong> languages, <strong>the</strong> dialect, <strong>the</strong> foodsand <strong>the</strong> traditions. Especially <strong>the</strong> ChineseShandong, Russian and Japaneseinfluences are infiltrated in <strong>the</strong> life ofolder generations of local people. Youcan still find different architecturestyles coexisting at some corner whenyou walk on <strong>the</strong> street. About 65% of<strong>the</strong> six million inhabitants of <strong>the</strong> Dalianarea are descendents of people comingfrom <strong>the</strong> Shandong peninsula in <strong>the</strong>early 20th Century. Recently <strong>the</strong>re wasa popular TV series named ‘Rush to <strong>the</strong>Nor<strong>the</strong>ast China’ showing on CCTV, justtelling <strong>the</strong> stories of that time.If <strong>the</strong> local inhabitants may have beenlooked upon as ra<strong>the</strong>r traditional andconservative, living of <strong>the</strong> relativelyabundant fishery resources, things arenow really changing. Under <strong>the</strong> slogan‘strive not to be <strong>the</strong> biggest, but<strong>the</strong> best’, Dalian has developed rapidlyover <strong>the</strong> past decade. Roads are gettingwider and <strong>the</strong> city is becomingbrighter. Modern skyscrapers shoot uplike bamboo after a spring rain. In <strong>the</strong>summer of 2007, <strong>the</strong> global inauguralannual meeting of World Economic Forumwas held in Dalian. Nearly 2,000domestic and <strong>for</strong>eign officials, specialistsand business people ga<strong>the</strong>red in<strong>the</strong> World Expo Centre to discuss <strong>the</strong>current economic topics. They could allfeel China’s determination to achievesustainable development <strong>the</strong> moment<strong>the</strong>y arrived in Dalian, with <strong>the</strong> shuttlebuses powered by hybrid engines and<strong>the</strong> 140,000 square metres World ExpoCentre cooled by sea water.Dalian is quite a football city, not onlyas <strong>the</strong> home of Dalian Shide, <strong>the</strong> mostsuccessful club in Chinese professionalsoccer, but also because of <strong>the</strong> footballculture in people’s daily life. Dalian hasseveral primary schools that specializein teaching kids to play football in<strong>the</strong>ir physical education classes. Thereare also many football fans among <strong>the</strong>local residents, and if you want to talkfootball with people, young or old, youcan easily spend hours of your pastime,drinking beer and discussing <strong>the</strong> game.No wonder <strong>the</strong> annual InternationalBeer Festival since 2002 has moved fromBeijing to Dalian. Speaking of festivals,we also have to mention <strong>the</strong> Dalian InternationalFashion Festival, hosted everyautumn <strong>for</strong> <strong>the</strong> last 19 years, whichhas become a showcase of <strong>the</strong> latest developmentof world fashion.Dalian may not be an old cultural citywith a long history, but people livinghere is endeavouring to build and improvea new city culture. Already sevenyears ago at <strong>the</strong> IOC session in Moscow,when <strong>the</strong> IOC announced that Beijingwas elected <strong>the</strong> host city <strong>for</strong> <strong>the</strong> <strong>2008</strong>games, people of Dalian started to getready to welcome friends from all over<strong>the</strong> world to watch <strong>the</strong> Olympics inBeijing and go sightseeing in Dalian.Old and new architectureThe World Trade Expo Centre<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 25

What <strong>the</strong>y actually doShip BrokerBy Hans Christian Rabben and Karl Henrik BergeWorking as ship brokers with <strong>Odfjell</strong>is both challenging and interesting, involvingmany different tasks and issues.Our job is to sell transportation servicesin <strong>the</strong> shape of cargo space on <strong>the</strong> ships,and <strong>the</strong>reby to ensure that we maximise<strong>the</strong> earnings of our shipping activities.Without going into too much detail wewill here describe some of our responsibilities.At <strong>Odfjell</strong> we have organised <strong>the</strong> salesactivities, or chartering of <strong>the</strong> ships aswe call it, by tradelanes. Focusing on ageographical area helps us keeping upto date with what is happening in <strong>the</strong>freight market in our particular allocatedarea. Staying in close contact with<strong>the</strong> market is one of <strong>the</strong> key elementsenabling <strong>the</strong> brokers to per<strong>for</strong>m <strong>the</strong>job to <strong>the</strong> required standard. In orderto make sure we obtain necessary marketin<strong>for</strong>mation and knowledge we arein continual contact with external shipbrokers, customers or charterers as <strong>the</strong>yare usually called, and our overseas offices.Studying market reports and o<strong>the</strong>rperiodicals is also necessary when youwant to keep up with <strong>the</strong> market.To optimise <strong>the</strong> earnings <strong>for</strong> <strong>the</strong> shipsin a trade, <strong>the</strong> brokers set up cargoprogrammes. There are huge variationsto <strong>the</strong> approach on any voyage,but in <strong>the</strong> parcel tanker industry weusually build programmes consisting ofmultiple grades of cargoes. Often wehave a sound base of contract cargoesto be loaded and discharged at some of<strong>the</strong> main ports that we frequently call.Combining this base with spot cargoesshould <strong>the</strong>n ideally end up in a voyagegenerating a best possible timecharterresult <strong>for</strong> <strong>the</strong> ship. However,be<strong>for</strong>e reaching <strong>the</strong> optimal cargo andport combination, we have to considerand calculate <strong>the</strong> earnings potential ofmany different possibilities.There is a long process from <strong>the</strong> initialplanning of a voyage until everythinghas been finalised and <strong>the</strong> books canbe closed. At <strong>the</strong> early stages of a voyage,often as much as 45 days be<strong>for</strong>earriving to load, we nominate <strong>the</strong> vesselto contract customers. Many customerswith whom we have contractsof affreightment (CoA) are producersand have obligations <strong>for</strong> deliveries ofproduct to <strong>the</strong>ir customers. O<strong>the</strong>rs aretraders, making <strong>the</strong>ir profit through arbitrageopportunities of product pricedifferences between ports. Enteringinto CoAs can be a good strategy <strong>for</strong> <strong>the</strong>customers, as it helps <strong>the</strong>m plan <strong>the</strong>irlogistics/shipping requirements at fixedcosts <strong>for</strong> a certain period. CoAs are alsobeneficial to us as ship-owners, securingstable employment and freight income.Contract volumes <strong>for</strong>m <strong>the</strong> backbone ofour service along many tradelanes.During <strong>the</strong> nomination processes wealso start looking <strong>for</strong> possible spot car-From <strong>the</strong> <strong>Odfjell</strong> Chartering department in Bergen26 <strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong>

goes to fill up <strong>the</strong> ship. The point is tofind <strong>the</strong> optimal balance between CoAand spot business, under <strong>the</strong> prevailingmarket conditions. Some of <strong>the</strong> keyquestions in this respect are whe<strong>the</strong>r<strong>the</strong> spot market is on a rise or a fall, andif <strong>the</strong>re are sufficient cargoes available.What about competition – are <strong>the</strong>remany o<strong>the</strong>r vessels with open spacewithin <strong>the</strong> same time frame as our ship?And are we able to book cargoes toand from scheduled ports and berths tominimise expenses and time spent? It isalso essential to learn as much as possibleabout <strong>the</strong> timing and urgency of<strong>the</strong> charterers’ requirements.The negotiation and fixing of a cargonormally start by us sending a proposalto <strong>the</strong> charterers, direct or via a brokeringcompany. Ei<strong>the</strong>r we give a firm bid<strong>for</strong> <strong>the</strong> business, or we indicate at whatterms and conditions we are willing toper<strong>for</strong>m <strong>the</strong> transportation. When makingan offer we always put a time limiton it to make sure we are free to bid <strong>for</strong>o<strong>the</strong>r business in case this one shouldfail. Time is usually of essence, and itis important to both charterers and usto know exactly where we stand in <strong>the</strong>process at any time. Normally <strong>the</strong> negotiationprocess involves several bids andcounter-bids be<strong>for</strong>e eventually endingup in a fixture. An initial fixture is oftendone on “subjects”, i.e. certain conditionsthat have to be met be<strong>for</strong>e <strong>the</strong>deal is final. We <strong>the</strong>n keep cargo spacereserved <strong>for</strong> <strong>the</strong> charterers <strong>for</strong> a setamount of time until <strong>the</strong>y have sortedout <strong>the</strong> details and <strong>the</strong> subjects can belifted. In case <strong>the</strong>y are not able to conclude<strong>the</strong> business <strong>the</strong> fixture fails and<strong>the</strong>y release <strong>the</strong> space.Our success in fixing cargoes dependson support from several o<strong>the</strong>r importantfunctions at <strong>Odfjell</strong>. The overallallocation of <strong>the</strong> fleet to <strong>the</strong> variousgeographical areas is done by ourscheduling officer. In close cooperationwith <strong>the</strong> tradelane managers he distributesvessels to <strong>the</strong> different trades andmaintains a global view of <strong>the</strong> fleet and<strong>the</strong> demand <strong>for</strong> tonnage in <strong>the</strong> differentareas. This is an ever ongoing processwhere things change frequently.Be<strong>for</strong>e loading a cargo, <strong>the</strong> vessel needsto be approved by all parties involved in<strong>the</strong> shipment, such as shippers, receiversand charterers. Usually our tonnage isWhat it is all about; filling <strong>the</strong> vessels to maximise voyage earningsacceptable straight away, but sometimeswe need to provide fur<strong>the</strong>r in<strong>for</strong>mationbe<strong>for</strong>e <strong>the</strong> ship is admitted. For our owntonnage we get this service from ourShip Management department, who isin contact with <strong>the</strong> vetting departmentsof our customers and classification societies.For chartered in tonnage we needassistance from our Operations department,who gets in touch with <strong>the</strong> ownersor any third-party ship manager of<strong>the</strong> ship.Throughout <strong>the</strong> entire sales and fixingprocess we need accurate and reliablein<strong>for</strong>mation on operational aspects andthus, close teamwork between <strong>the</strong> Operationsand Chartering departments isvery important. Be<strong>for</strong>e we can confirman agreement we need to know whe<strong>the</strong>rour ship is able to carry and stow <strong>the</strong>cargoes, by taking into considerationfactors such as cargo compatibility, cargotemperatures, certificate of fitness,etc. When in doubt our Marine Supportpeople provide guidance on whe<strong>the</strong>r ornot we can carry a certain product, howmuch time we are going to need <strong>for</strong>tank cleaning, and o<strong>the</strong>r related issues.Ano<strong>the</strong>r crucial aspect is <strong>the</strong> berths’physical restrictions as to vessel length,width and draft. If such limitations applywe may need assistance to have<strong>the</strong> product barged, a task that is alsocovered by our operators. After havingfixed <strong>the</strong> cargo, <strong>the</strong> operators keep ourcustomers posted on estimated arrivaltimes, port times and o<strong>the</strong>r relevantin<strong>for</strong>mation. A good and close cooperationwith <strong>the</strong> operator is essentialto achieve efficient operations with aslittle time in port as possible.We are also in close dialogue with ourDemurrage group, who administer ourclaims <strong>for</strong> having spent too much timein port on any cargo. Their assistance isparticularly valuable <strong>for</strong> claims wherewe disagree with <strong>the</strong> charterers on howto count <strong>the</strong> time spent. The better jobwe do at <strong>the</strong> chartering desk when negotiatingterms, <strong>the</strong> more manageable<strong>the</strong> job will be <strong>for</strong> <strong>the</strong> demurrage analysts.Every now and <strong>the</strong>n we get generalinput from <strong>the</strong> Demurrage group,providing support and advise when weare discussing specific terms and conditionsduring <strong>the</strong> negotiations with charterers.Our Insurance and Legal sectionalso lend us a hand whenever we arein need of knowing which legal consequencesany terms and wordings couldhave if push comes to shove.There is an excellent working environmen<strong>the</strong>re with well-in<strong>for</strong>med and supportivecolleagues. Having all this expertisein <strong>the</strong> organisation is a necessitythat helps us keeping <strong>the</strong> ships safelyemployed – at <strong>the</strong> best possible earnings.<strong>Odfjell</strong> Quarterly <strong>April</strong> <strong>2008</strong> 27