Specifying Architectural Woodwork - Woodwork Institute

Specifying Architectural Woodwork - Woodwork Institute

Specifying Architectural Woodwork - Woodwork Institute

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

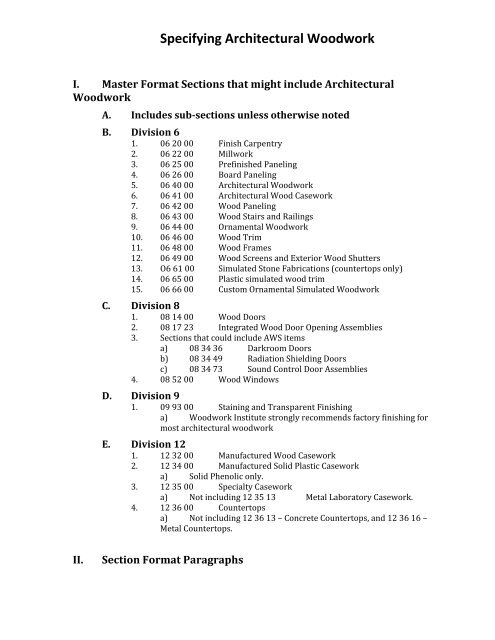

<strong>Specifying</strong> <strong>Architectural</strong> <strong>Woodwork</strong>I. Master Format Sections that might include <strong>Architectural</strong><strong>Woodwork</strong>A. Includes sub-sections unless otherwise notedB. Division 61. 06 20 00 Finish Carpentry2. 06 22 00 Millwork3. 06 25 00 Prefinished Paneling4. 06 26 00 Board Paneling5. 06 40 00 <strong>Architectural</strong> <strong>Woodwork</strong>6. 06 41 00 <strong>Architectural</strong> Wood Casework7. 06 42 00 Wood Paneling8. 06 43 00 Wood Stairs and Railings9. 06 44 00 Ornamental <strong>Woodwork</strong>10. 06 46 00 Wood Trim11. 06 48 00 Wood Frames12. 06 49 00 Wood Screens and Exterior Wood Shutters13. O6 61 00 Simulated Stone Fabrications (countertops only)14. 06 65 00 Plastic simulated wood trim15. 06 66 00 Custom Ornamental Simulated <strong>Woodwork</strong>C. Division 81. 08 14 00 Wood Doors2. 08 17 23 Integrated Wood Door Opening Assemblies3. Sections that could include AWS itemsa) 08 34 36 Darkroom Doorsb) 08 34 49 Radiation Shielding Doorsc) 08 34 73 Sound Control Door Assemblies4. 08 52 00 Wood WindowsD. Division 91. 09 93 00 Staining and Transparent Finishinga) <strong>Woodwork</strong> <strong>Institute</strong> strongly recommends factory finishing formost architectural woodworkE. Division 121. 12 32 00 Manufactured Wood Casework2. 12 34 00 Manufactured Solid Plastic Caseworka) Solid Phenolic only.3. 12 35 00 Specialty Caseworka) Not including 12 35 13 Metal Laboratory Casework.4. 12 36 00 Countertopsa) Not including 12 36 13 – Concrete Countertops, and 12 36 16 –Metal Countertops.II.Section Format Paragraphs

<strong>Specifying</strong> <strong>Architectural</strong> <strong>Woodwork</strong>A. Section Includes1. Typical Inclusions and exclusions for each AWS Section are found at thebeginning of the Product part of each section; typically item 2.2.a) Your project will not include all of the listed items.B. Related Sections1. Framing: blocking, grounds, etc. included inside walls or above ceilings2. For casework & tops: plumbing & electrical fixtures installed incasework or countertops.3. For doors: metal frames4. Finishing, unless factory finishing is specified. Factory Finishing isstrongly recommended!C. References1. “AWS - <strong>Architectural</strong> <strong>Woodwork</strong> Standards, latest edition, publishedjointly by the <strong>Woodwork</strong> <strong>Institute</strong>, <strong>Architectural</strong> <strong>Woodwork</strong> <strong>Institute</strong>, and the<strong>Architectural</strong> <strong>Woodwork</strong> Manufacturer’s Association of Canada.”2. For Finish Carpentry reference NFPA 80 if door frames are included.3. For Doors reference ANSI/WDMA I.S. 1A (Latest Edition) and NFPA 804. For Laboratory Casework reference SEFA5. All the other referenced you might need are included in the AWS.D. Submittals1. “Shop Drawings: Shop drawings are to comply with the standards of theAWS.”2. “Provide a <strong>Woodwork</strong> <strong>Institute</strong> Certified Compliance Label on the firstpage of the shop drawings.”3. Finish samples, veneer samples, hardware samples as desired.4. Before delivery to the job site provide documentation of specialcharacteristics including but not limited to:a) No Added Formaldehyde panel productsb) LEED requirementsc) FSC Certified productsd) Chemical Resistant FinishesE. Quality Assurance1. “Work of this section is to meet the requirements of the AWS for thegrade specified2. Choose <strong>Woodwork</strong> <strong>Institute</strong> Certified Compliance or MonitoredCompliance. Use Monitored Compliance if you want inspection by WI Staff.Certified Compliance projects are inspected only on request or if the shop is nota WI Licensee.

<strong>Specifying</strong> <strong>Architectural</strong> <strong>Woodwork</strong>__________________________________________________Either:“[Certified ComplianceThe Certified Compliance Program provides an additional level of assurance that thework will comply with the requirements of the AWS and the specifications. <strong>Woodwork</strong><strong>Institute</strong> Licensees have been tested, and their work has been inspected by the<strong>Institute</strong>. <strong>Woodwork</strong> <strong>Institute</strong> inspectors will re-inspect Certified Compliance projectsat no charge if there are any questions as to compliance.1. Before delivery to the jobsite the woodwork supplier shall provide a<strong>Woodwork</strong> <strong>Institute</strong> Certified Compliance Certificate indicating themillwork products being supplied and Certifying that these products fullymeet the requirements of the Grade or Grades specified.2. Each elevation of casework, each laminated plastic top, and each solidsurface top shall bear a <strong>Woodwork</strong> <strong>Institute</strong> Certified Compliance Label.3. At completion of installation the woodwork installer shall provide a<strong>Woodwork</strong> <strong>Institute</strong> Certified Compliance Certificate indicating theproducts installed, and Certifying that the installation of these productsfully meets the requirements of the Grade or Grades specified.4. All fees charged by the <strong>Woodwork</strong> <strong>Institute</strong> for their Certified Complianceprogram are the responsibility of the millwork manufacturer and/orinstaller and shall be included in their bid.]”OR:___________________________________________________“[Monitored ComplianceThe Monitored Compliance Program requires that work be inspected by <strong>Woodwork</strong><strong>Institute</strong> inspectors at each phase of manufacturing and installation. Reports are issuedafter each inspection itemizing any non compliant findings.1 All millwork and the installation thereof for this project shall bemonitored for compliance to the contract documents by a <strong>Woodwork</strong><strong>Institute</strong> Director of <strong>Architectural</strong> Services.a. Full particulars of the <strong>Woodwork</strong> <strong>Institute</strong> Monitored ComplianceProgram may be found at the <strong>Institute</strong> web site atwww.woodworkinstitute.com or by calling the administrative office at(916) 372-9943.2 Millwork and/or installation found to be non compliant (and notcorrected) will be rejected.a. Issuance of a Monitored Compliance Certificate is a prerequisite ofacceptance.3 All fees charged by the <strong>Woodwork</strong> <strong>Institute</strong> for their Certified Complianceprogram are the responsibility of the millwork manufacturer and/or installer andshall be included in their bid.]”

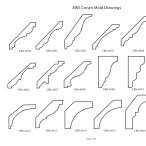

<strong>Specifying</strong> <strong>Architectural</strong> <strong>Woodwork</strong>3. If a list of acceptable manufacturers is required, make sure it is up todate.a) Generally we are not in favor of an acceptable manufacturer’slist. Your clients recycle these specs for decades.F. Delivery Storage and Handling:1. Require compliance with AWS requirements.G. Site Conditions1. Require compliance with AWS requirements.III.Part 2 – ProductA. Components: specify as applicable1. All products to meet the requirements of the AWS includinga) Lumberb) Veneerc) High Pressure Laminated) Cabinet liner or melamine (select one or the other)e) Backing sheetf) Core for veneered or HPL covered panels(1) M-2 or M-3 Particle Board or MDF(2) Special Characteristic such as:(a) No Added Formaldehyde, FSC Certified, FireRetardant, Moisture resistant(3) The AWS requires moisture resistant core at sink tops.(4) Require moisture resistant material at bases and othercomponents within 3” of the floor for Laboratory Casework.g) Edge Band(1) PVC or HPL for Laminate Plastic Products(2) Wood veneer or solid wood (1/8” to ¼”) for wood veneerproductsh) Veneer core plywood(1) Not recommended for core.(2) Possible uses: drawer boxes, cabinet bases, anchor strips.(a) If specified for drawer boxes, use 7 or 9 plyhardwood plywood with no internal voids.i) Hardware(1) Pulls, Hinges, Drawer guides, shelf supports, elbowcatches, magnetic catches, clothes hooks, locks, sliding doorhardware(2) Special Considerations(a) Sliding door hardware, especially for glass doors.If doors are more than 1 ½ times as tall as they are wide,top hung hardware is recommended.

<strong>Specifying</strong> <strong>Architectural</strong> <strong>Woodwork</strong>a) A factory finish is almost always superior to a job site finish.It is very difficult to do a decent job under job site conditions. A shopwith the proper equipment will control dust, temperature and humidity.They will also use environmentally acceptable materials and properlydispose of or recycle the waste.IV.ExecutionA. Installation shall meet the requirements of the AWS.B. Installation shall meet the requirements of the grade specified for the productbeing installed.