Power Buster

Power Buster

Power Buster

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

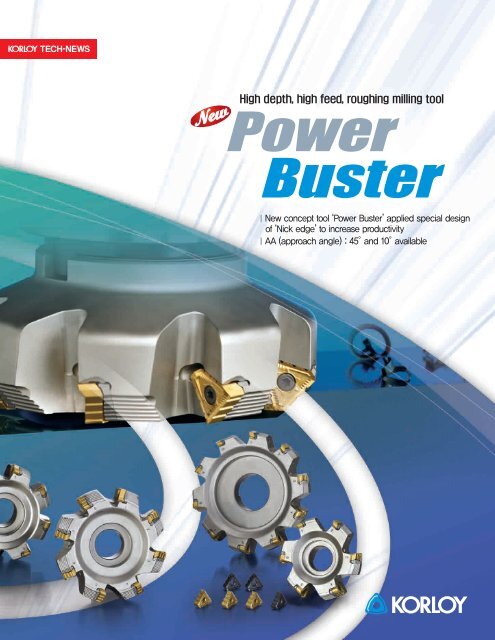

High depth, high feed, roughing milling tool<strong>Power</strong><strong>Buster</strong>I New concept tool ‘<strong>Power</strong> <strong>Buster</strong>’ applied special designof ‘Nick edge’ to increase productivityI AA (approach angle) : 45°and 10°available

KORLOY TECH-NEWS<strong>Power</strong> <strong>Buster</strong>1 Features•New generation, new concept tool <strong>Power</strong> <strong>Buster</strong> applied special design of‘Nick edge’to reduce cutting loadand increase productivity•Double-sided 6 corner insert geometry ensures high rigidity, long tool life and low cost•Nick edge divides chips into small pieces and also make good chip control. It reduces interference of cutter andguarantees good duration of the cutter•AA (approach angle) : 45°and 10°available (same insert used)•Application : High depth of cut and high feed rate (Steel, Cast iron)1)Features of Insert➊ Major cutting edge (Nick edge)•Low cutting load•Ideal chip control and divided small pieces of chip evacuation.Double sided 6 corner insert•Ideal edge design for Steel and Cast iron rough milling▼➊➌➜ Comparison of chip control and cutting force•Work piece : 24CrMo4•Cutting condition : vc=695sfm, ap=0.31inch, ae=3.54inch, fz=0.012ipt➋▼➍<strong>Power</strong> <strong>Buster</strong>ISO milling➎75%Cutting force 5100N100%Cutting force 6500N➋ Thick insert•Thick insert guarantees high rigidity•Balanced insert design for stable mountingTop➌ NM Chip breaker•High rake angle for low cutting force•Good chip flow at various feed and depth of cut•Protecting insert seat area for precise mounting•Low friction and good heat evacuation at high depth cut0.4inch▼▼0.27inch▼▼BottomHigh rake angleInsert seat protectionHollows forlower friction2➍ Minor cutting edge•High rake angle to avoid interference with chip•Calculated minor cutting edge angel for bothAA 45°& 10°cutter1st minor cutting edge for AA 45˚2nd minor cutting edge for AA 10˚<strong>Power</strong> <strong>Buster</strong>➎ Mirror system•Cutting edge on the bothside of insert covers alloverlapped cutting areaTop+Bottom=Perfected cutting edge byusing 2 different side ofcutting edge

2)Features of Cutter➊ Screw➊ Screw on clamping system•Simple and strong screw on clamping systemInsert➋ Better rigidity & Stable Assembly system•Shim protect cutter from insert damage•High accuracy shim ensures tighter clampingShim ScrewThe upper sideand the down sidegrinding➌➋ Shim➌ Foolproof system•Geometry of‘A’and‘B’introduce right position to prevent wrong location of insert and nickB➜ ATop➜ BBottomA➍ Multi-application system•Same insert for multi use (45˚and 10˚)➜ AA 45˚The nicks are effective with a depth ofcut larger than 0.04inch▼▼45˚0.47inch▼▼(MAX.)0.04 inch(Nick 1)0.12 inch(Nick 2)▼▼▼ ▼➜ AA 10˚The nicks are effective with a depth ofcut larger than 0.12inch3▼80˚▼0.71inch▼▼(MAX.)0.12 inch(Nick 1)▼0.24 inch(Nick 2)▼▼ ▼KORLOY TECH-NEWS

20101101TN02-EI-01